Oxidation reaction system for preparing 3-amino-4-methoxybenzanilide and control method of oxidation reaction system

An oxidation reaction, red-based technology, applied in chemical instruments and methods, chemical/physical/physical-chemical stationary reactors, separation methods, etc. High integration, reduce the complexity of heating and cooling equipment, and avoid the effect of gas temperature reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The technical solutions of the present invention will be further described below in conjunction with specific embodiments. It should be pointed out that the specific technical solutions described in the embodiments of the present invention are not intended to limit the claims of the present invention.

[0022] Example.

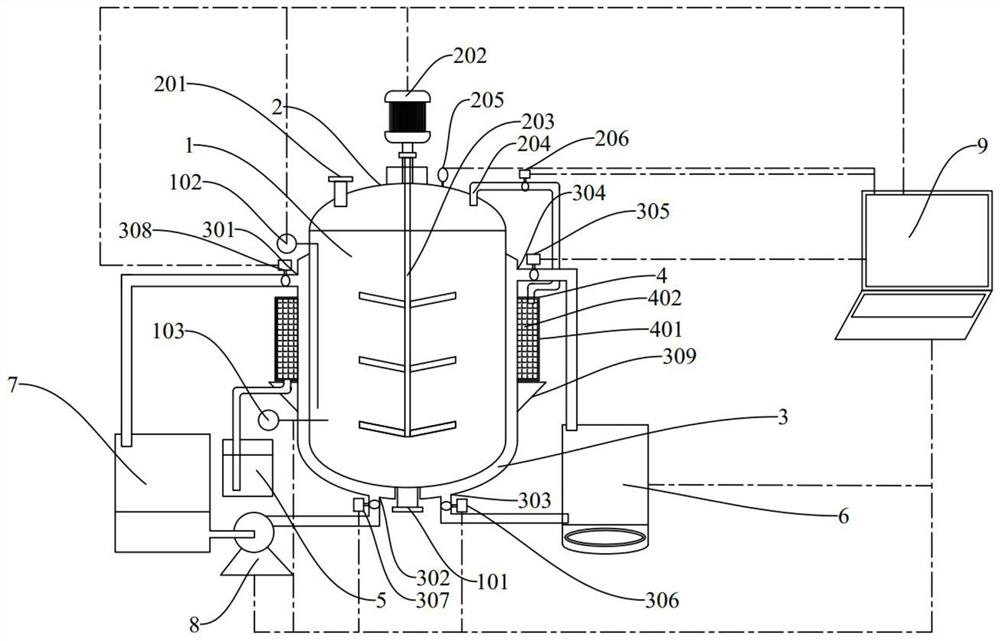

[0023] Such as figure 1 The red-based KD preparation oxidation reaction system shown includes a reaction kettle, nitrogen oxide treatment equipment 4, lye absorption tank 5, steam circulation device 6, condensation circulation device 7, and circulation pump 8;

[0024] The reaction kettle includes a kettle body 1, a kettle cover 2, and a jacket 3. The bottom of the kettle body 1 is provided with a discharge port 101, and the kettle body 1 is provided with a liquid level gauge 102 and a temperature sensor 103;

[0025] The kettle cover 2 is provided with a feed inlet 201 and a stirring device, the stirring device includes a power unit 202 and a stirring...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com