Harmless treatment method and harmless treatment system for metal lithium waste residue

A technology of harmless treatment and treatment system, which is applied in the harmless treatment of metal lithium waste residues, and in the field of rapid and effective harmless treatment of metal lithium waste residues, can solve the problem of unavoidable lithium slag ignition, etc., to ensure the reaction rate. , the effect of improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

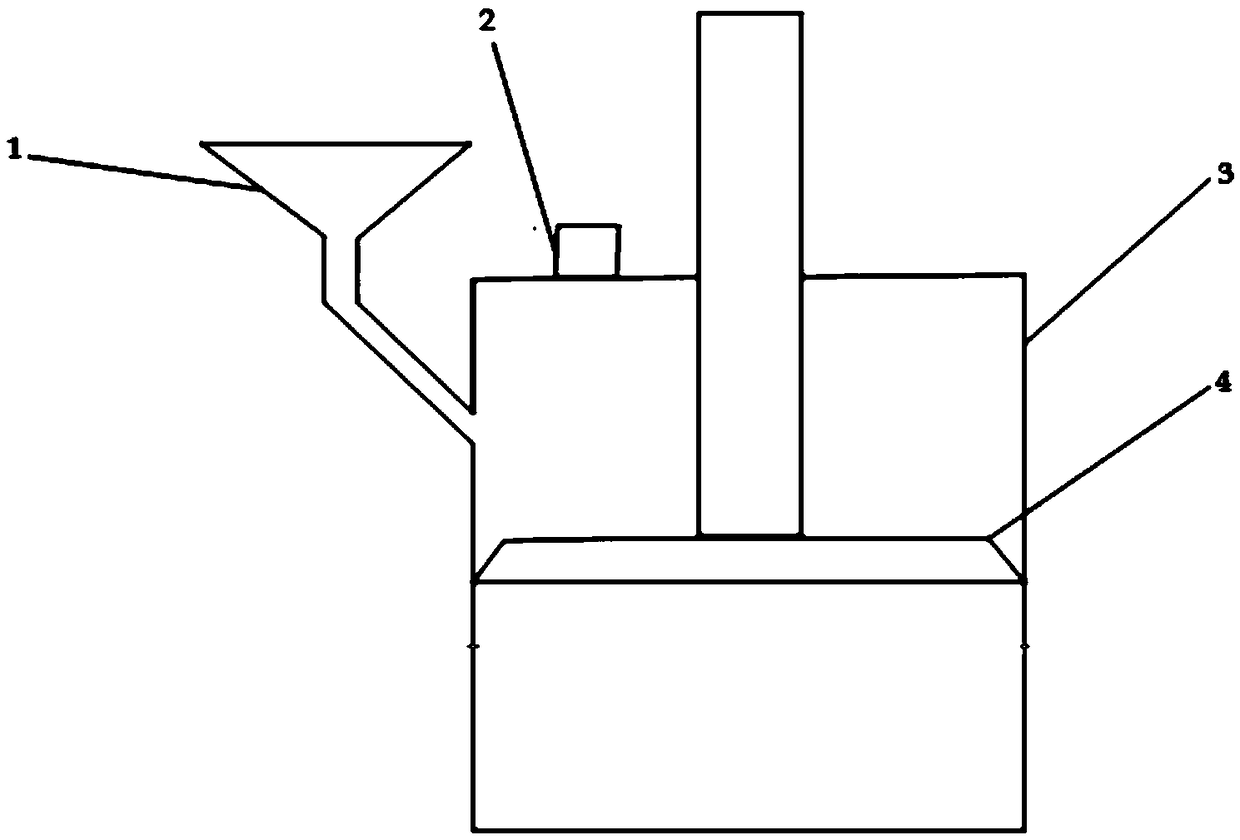

Image

Examples

Embodiment 1

[0074] The harmless treatment method of metal lithium waste residue in the present embodiment specifically comprises the following steps:

[0075] 1. Add white oil and water into the closed reaction vessel, turn on the vacuum pump to maintain a negative pressure of about 0.09MPa in the vessel, and turn on the circulating cooling device on the outer wall of the closed reaction vessel.

[0076] 2. Add metal lithium waste slag from the side of the closed reaction vessel, the metal lithium waste slag will fall on the surface of the white oil first, and will not react immediately.

[0077] 3. Turn on the screen controller, let the screen move down, and sink the lithium metal waste floating on the surface of the white oil to the bottom of the water.

[0078] 4. After the lithium metal waste slag sinks into the bottom of the water, it reacts with water, and the hydrogen gas produced is pumped out by the vacuum pump and discharged into the hydrogen gas treatment system.

[0079] 5. A...

Embodiment 2

[0082] 1. Add white oil and water into the closed reaction vessel, turn on the vacuum pump to maintain a negative pressure of about 0.08MPa in the vessel, and turn on the circulating cooling device on the outer wall of the closed reaction vessel.

[0083] 2. Add metal lithium waste slag from the side of the closed reaction vessel, the metal lithium waste slag will fall on the surface of the white oil first, and will not react immediately.

[0084] 3. Turn on the screen controller, let the screen move down, and sink the lithium metal waste floating on the surface of the white oil to the bottom of the water.

[0085] 4. After the metal lithium waste slag sinks to the bottom of the water, it reacts with water, and the hydrogen gas produced is pumped out by the vacuum pump and discharged into the hydrogen gas treatment system.

[0086] 5. After the negative pressure in the airtight reaction vessel is re-stabilized to a negative pressure of 0.08MPa, repeat the above operation. Aft...

Embodiment 3

[0089] 1. Add white oil and water into the closed reaction vessel, turn on the vacuum pump to maintain a negative pressure of about 0.085MPa in the vessel, and turn on the circulating cooling device on the outer wall of the closed reaction vessel.

[0090] 2. Add metal lithium waste slag from the side of the closed reaction vessel, the metal lithium waste slag will fall on the surface of the white oil first, and will not react immediately.

[0091] 3. Turn on the screen controller, let the screen move down, and sink the lithium metal waste floating on the surface of the white oil to the bottom of the water.

[0092] 4. After the metal lithium waste slag sinks to the bottom of the water, it reacts with water, and the hydrogen gas produced is pumped out by the vacuum pump and discharged into the hydrogen gas treatment system.

[0093] 5. After the negative pressure in the closed reaction vessel is stabilized to a negative pressure of 0.085MPa, repeat the above operation. After ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com