a steam generator

A technology of steam generator and steam-water separator, which is applied in steam generation method using heat carrier, chemical instrument and method, liquid degassing, etc., can solve the problems of poor management, large water capacity, waste of steam, etc. The effect of high coefficient, small water capacity and fast steam production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

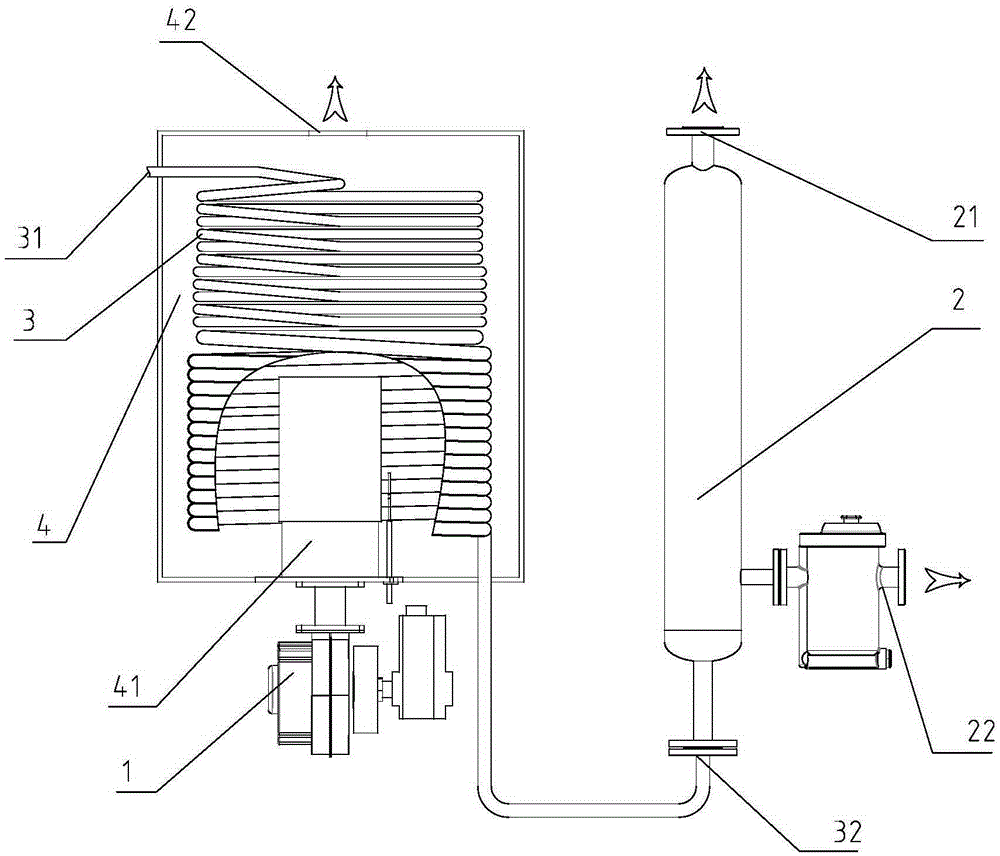

[0021] refer to figure 1 , the steam generator shown includes a coil 3, a burner 1, a steam-water separator 2 and a water supply source, the coil 3 is connected between the steam-water separator 2 and the water supply source, the burner 1 is provided with a furnace 4, and the disk The pipe 3 is arranged in the furnace 4 , and the furnace 4 is provided with a smoke inlet pipe 41 extending into the coil 3 . After the flue gas exchanges heat with the burner 1, it enters the furnace 4 through the smoke inlet pipe 41 to exchange heat with the coil 3, and the deoxygenated water from the water supply source enters the coil 3 through the water pump, and the deoxygenated water flows in the coil 3 During the process, it is heated by the flue gas to form a mixture of steam and water. The steam-water separator 2 separates the two, and the steam is sent from the steam outlet 21 at the upper end of the steam-water separator 2 to the steam-consuming equipment, and the high-temperature water ...

Embodiment 2

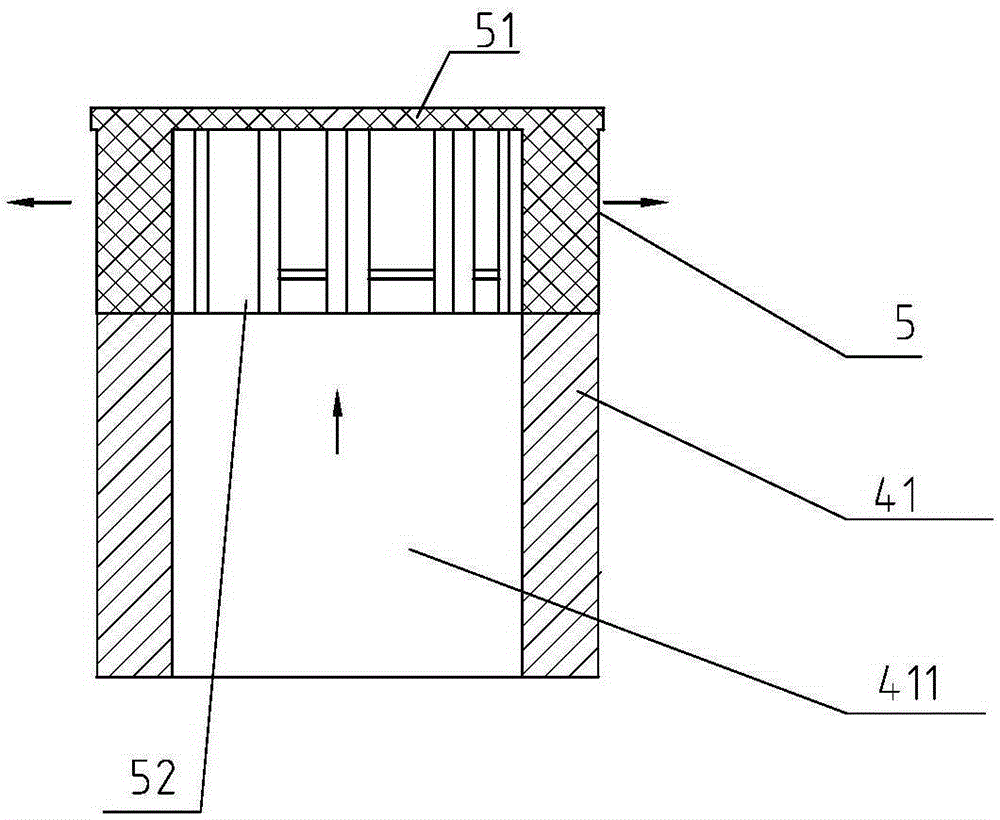

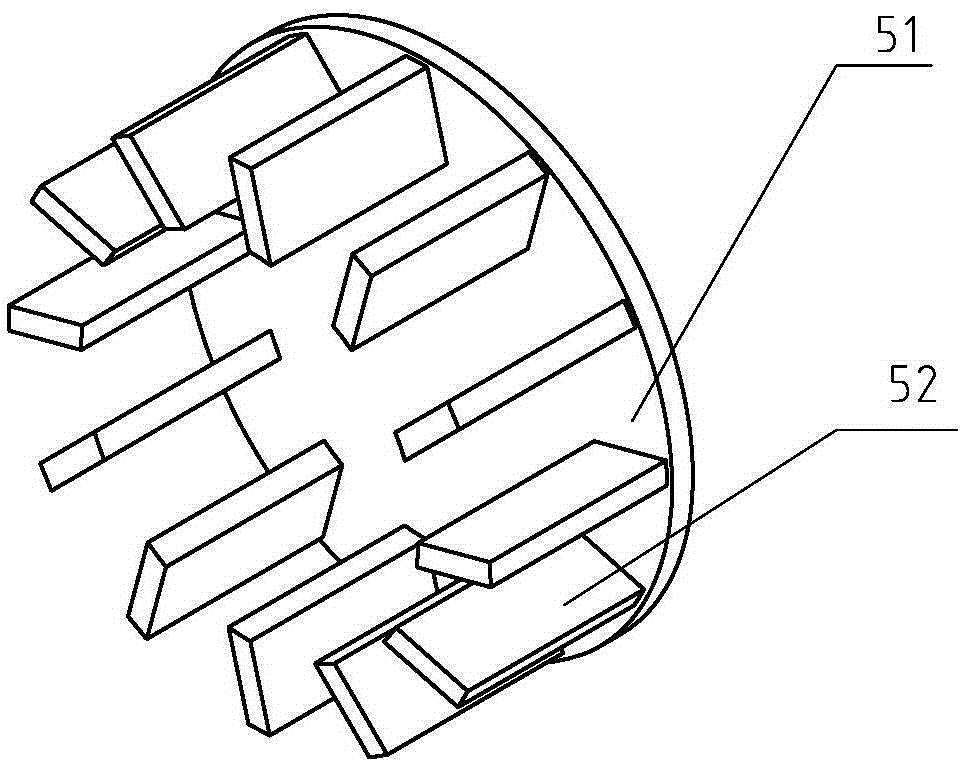

[0025] refer to figure 1 , figure 2 and image 3 , on the basis of Embodiment 1, a spoiler 5 is provided in the furnace 4, and the spoiler 5 is opposite to the smoke inlet 411 of the smoke inlet pipe 41. After the high-temperature flue gas enters the furnace 4, the flow of the flue gas tends to the upper end The direction of the smoke outlet 42 leads to poor utilization of the heat energy of the smoke. The smoke inlet 411 of the smoke inlet pipe is blocked by the spoiler 5. The blocking effect of the spoiler 5 can slow down the speed of the smoke and make the smoke The gas is discharged from the surroundings to ensure that the flue gas is in full contact with the coil 3 and improve the utilization rate of heat energy.

[0026] The spoiler 5 in this embodiment includes a smoke baffle 51 arranged above the smoke inlet pipe 41, and the surface of the smoke baffle 51 opposite to the smoke inlet 411 is surrounded by a disturbance flow sheet 52, and the flow baffle 52 passes thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com