Device and method for synthesizing carbonyl fluoride

A technology for synthesizing carbon and carbonyl fluoride, which is applied in the fields of fluorine chemical industry and electronic industrial gas, can solve the problems of difficult industrialization and separation, and achieve the effects of mild reaction process, increased yield and purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

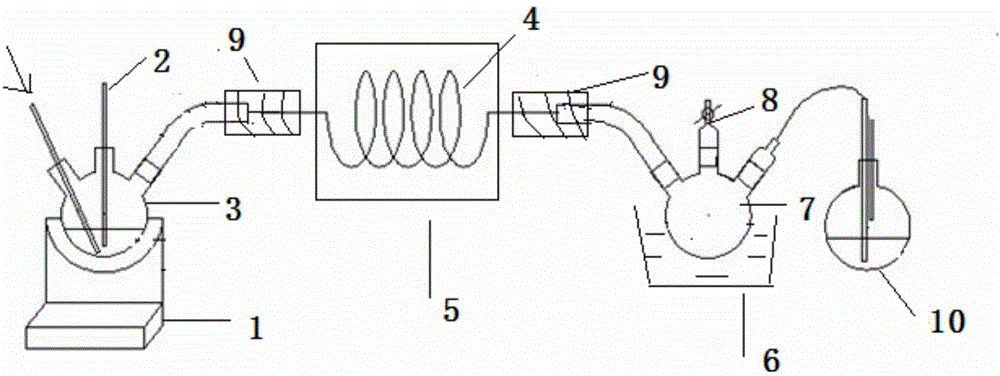

[0032] Example 1, with 60g perfluoroalkyl iodide mixture (TI-n), 75% is TI-10 (perfluorodecyl iodide), 16% is TI-12 (perfluorododecyl iodide), and the rest For TI-8 (perfluorooctyl iodide), TI-14 and (perfluorotetradecyl iodide) other trace impurities, add it to a 100ml three-necked reaction flask, and one of the ports of the reaction flask is used to communicate with the air inlet Bottle (in this embodiment is oxygen cylinder) connection, the port in the middle is used for placing thermometer, and another port is used for connecting with heating reaction tube 4, and heating reaction tube is the stainless steel ring that is 5m in length and 6mm in inner diameter in this embodiment. Spiral tube, wherein, the helical part of the spiral tube is placed in the tube furnace 5, and the straight tube part is wound with a heating belt 9 for heating to prevent perfluoroalkyl iodide condensation from blocking the pipeline.

[0033] Heat the TI-n to 150°C to make it gasify, then blow in O...

Embodiment 2

[0034] Example 2, 60g of perfluorododecyl iodide is heated to 150°C to vaporize it, then high-purity oxygen is blown in at a gas velocity of 300ml / min, the temperature of the tube furnace is 350°C, and the reaction is until the inlet pipe touches Less than TI-n liquid level. Infrared testing of a sample taken from the opening of the product collection bottle showed COF 2 The characteristic peak, the liquid in the tail gas treatment bottle is analyzed by gas chromatography to show that dimethyl carbonate is generated, which further proves that there is COF 2 Generated with a yield of 92% and a purity of 99%.

Embodiment 3

[0035] Embodiment 3, 60g perfluorooctyl iodide is heated to 150 ℃ to make it vaporize, then be the O2 / N2 mixed gas of 60% oxygen concentration with the gas velocity of 300ml / min blowing in afterwards, the temperature of tube furnace is 550 °C, react until the inlet pipe does not touch the TI-n liquid level. Infrared test shows that there is a characteristic peak of COF2, and a characteristic peak of C=C in addition, indicating that the reaction temperature is too high to produce tetrafluoroethylene, and the liquid in the tail gas treatment bottle is analyzed by gas chromatography to show that dimethyl carbonate is generated, which further proves that there is COF2 was generated with a yield of 55% and a purity of 62%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com