Coating agent, preparation method thereof, packaging box adopting coating agent and manufacturing method of packaging box

A production method and technology of coating agent, which can be used in coatings, paper coatings, wax coatings, etc., can solve problems such as secondary pollution, unstable air permeability, and inability to truly achieve exhaust effects, and achieve extended shelf life and safety. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

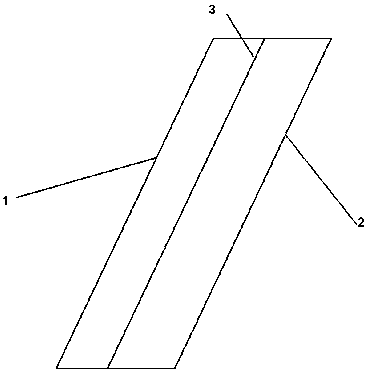

Image

Examples

Embodiment 1

[0040] S1, weigh 55g food-grade paraffin, 16g food-grade microcrystalline wax, 15g ethylene-vinyl acetate copolymer, 7g polyethylene and 7g styrene-isoprene-styrene block copolymer;

[0041] S2, put food-grade paraffin and food-grade microcrystalline wax into the reaction kettle, heat to 120°C, and stir for 15 minutes after the food-grade paraffin and food-grade microcrystalline wax are completely melted;

[0042] S3, add ethylene-vinyl acetate copolymer, polyethylene and styrene-isoprene-styrene block copolymer to S2 in turn, stir for 30 minutes after complete melting.

Embodiment 2

[0044] S1, weigh 60g food-grade paraffin, 20g food-grade microcrystalline wax, 10g ethylene-vinyl acetate copolymer, 5g polyethylene and 5g styrene-isoprene-styrene block copolymer;

[0045] S2, put food-grade paraffin and food-grade microcrystalline wax into the reaction kettle, heat to 120°C, and stir for 15 minutes after the food-grade paraffin and food-grade microcrystalline wax are completely melted;

[0046] S3, add ethylene-vinyl acetate copolymer, polyethylene and styrene-isoprene-styrene block copolymer to S2 in turn, stir for 30 minutes after complete melting.

Embodiment 3

[0048] S1, weigh 65g food-grade paraffin, 24g food-grade microcrystalline wax, 5g ethylene-vinyl acetate copolymer, 3g polyethylene and 3g styrene-isoprene-styrene block copolymer;

[0049] S2, put food-grade paraffin and food-grade microcrystalline wax into the reaction kettle, heat to 120°C, and stir for 15 minutes after the food-grade paraffin and food-grade microcrystalline wax are completely melted;

[0050] S3, add ethylene-vinyl acetate copolymer, polyethylene and styrene-isoprene-styrene block copolymer to S2 in turn, stir for 30 minutes after complete melting.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com