Heat pipe type steam generator

A steam generator and heat pipe technology, applied in the field of heat pipe steam generators, can solve the problems of large volume, high flue gas content, and difficult water level control of heat pipe steam generators, achieving no explosion risk, reducing NOx content, The effect of reducing the water volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

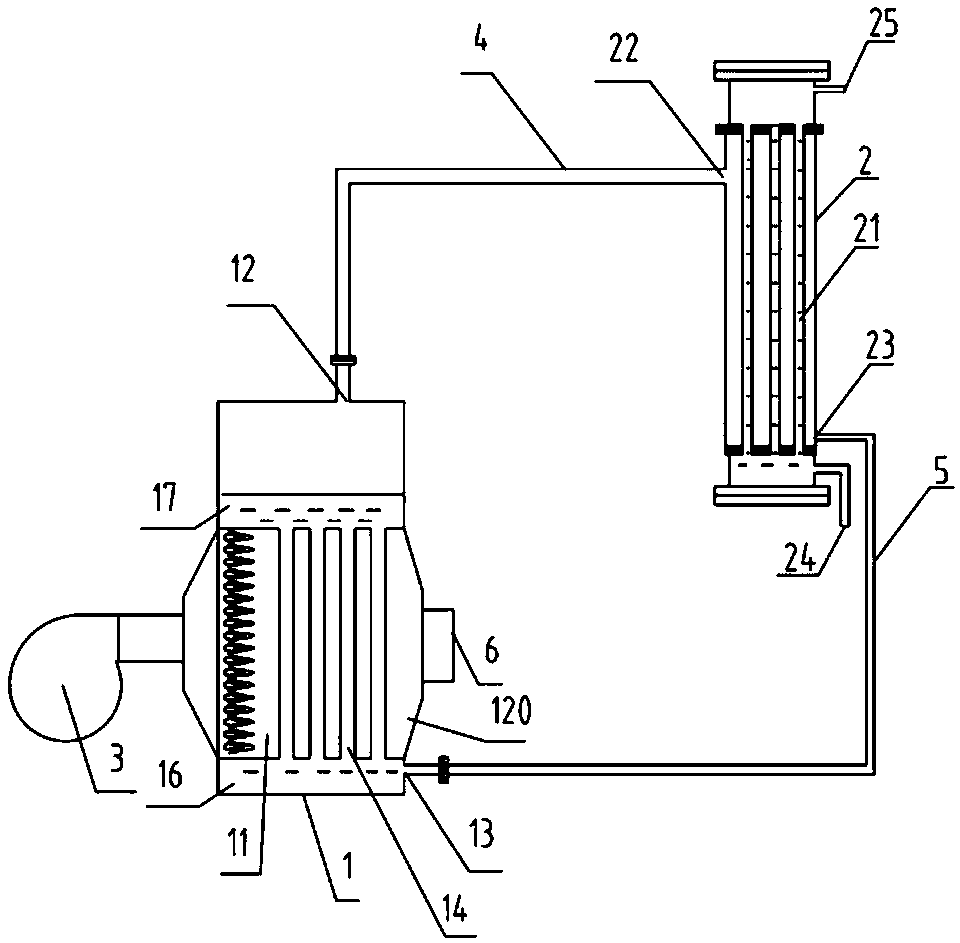

[0030] This embodiment provides a heat pipe type steam generator, such as figure 1 As shown, it includes a boiler 1, a generator 2, and a burner 3. The combustion end of the burner 3 extends into the furnace 11 of the boiler 1. The boiler 1 is connected to the generator 2. The generator 2 is provided with a heat pipe 21. A primary side channel is formed, and a secondary side channel is formed in the heat pipe 21 , and the medium in the primary side channel exchanges heat with the medium in the secondary side channel. The boiler 1 is connected to the primary side channel of the generator 2 to form a primary side circulation loop, and the primary side circulation loop is vacuum-tight. The minimum liquid level of the primary side channel is higher than the maximum liquid level of the boiler 1 .

[0031] The height difference between the liquid level in the primary channel and the boiler 1 is used to ensure that in the primary side circulation loop, the aqueous solution in the ge...

Embodiment 2

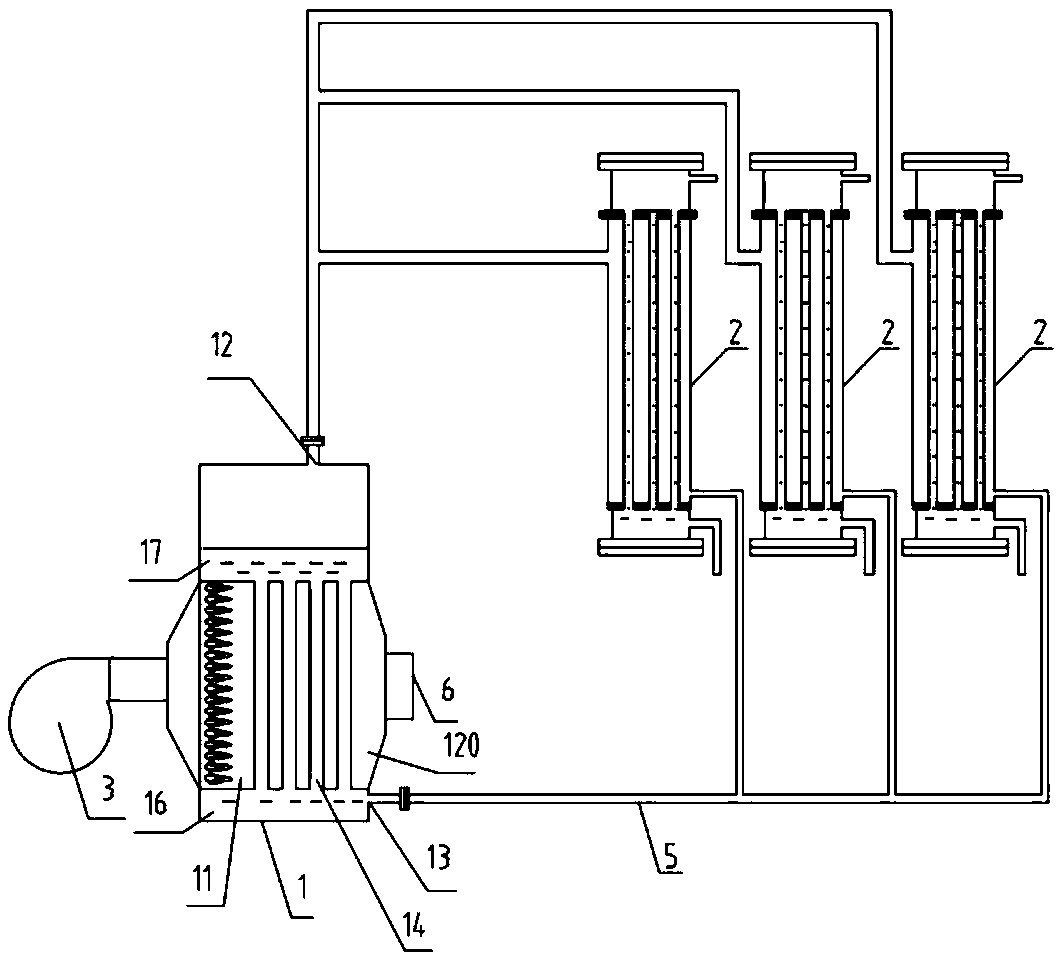

[0043] This embodiment provides a heat pipe type steam generator, such as Figure 4 , Figure 5 shown. The difference between this embodiment and the first embodiment is that the furnace body 120 is provided with a heat exchange sleeve 153 and the boiler 1 is provided with a smoke collection chamber.

[0044] The heat exchange sleeve 153 is composed of an inner tube 154 and an outer tube 155 . The inner pipe 154 is a flue gas waste heat passage, and the water flow passage is between the inner pipe 154 and the outer pipe 155 , and the flue gas waste heat passage communicates with the tail of the furnace body 120 . The high-temperature flue gas in the furnace body 120 and the flue gas in the flue gas waste heat channel jointly heat the water in the water flow channel, and make full use of the waste heat in the flue gas to ensure the evaporation of the aqueous solution in the boiler 1 .

[0045] The lower end of the outer tube 155 is the first water collecting chamber 16 , and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com