a co 2 Method for displacing high-salt brine in deep formation

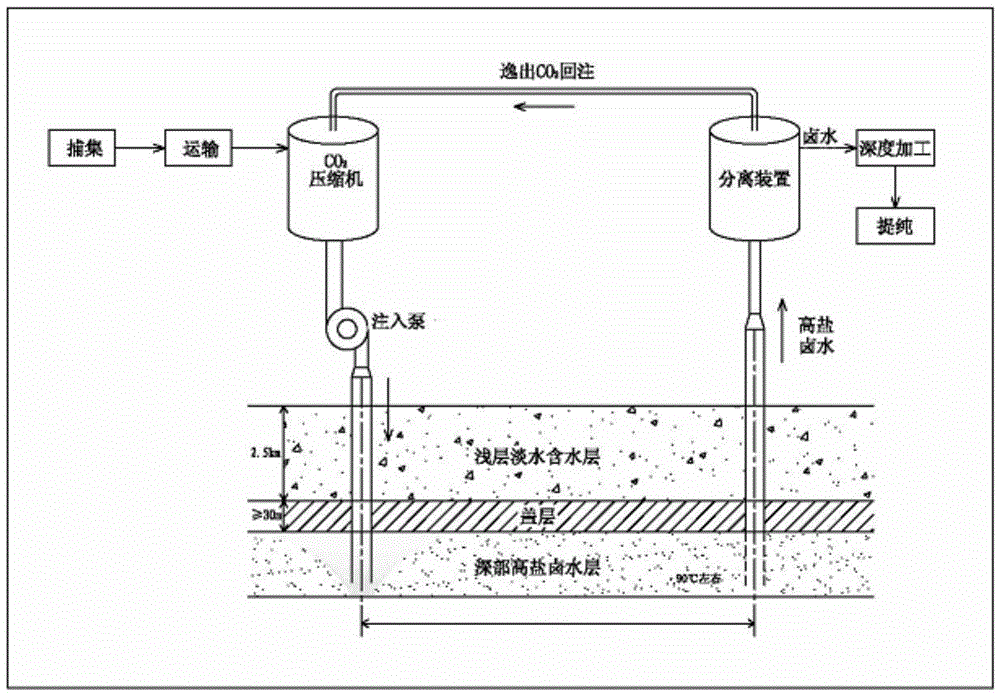

A CO2, high-salt technology, used in wellbore/well components, production fluids, earth-moving drilling, etc., can solve problems such as affecting the normal pumping of injection wells, reducing dissolved and mineral capture, and unfavorable continuous injection. Achieve the best economic and environmental benefits, mitigate global climate change, and maximize utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments, but the protection scope of the present invention is not limited to the following embodiments.

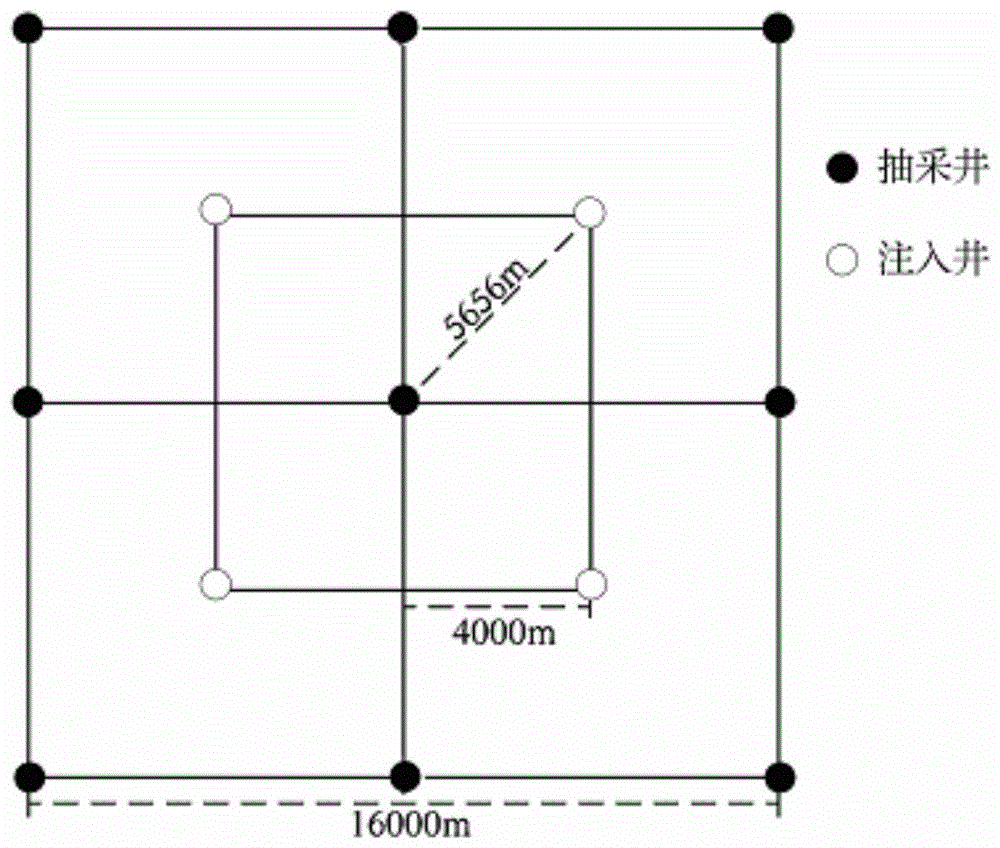

[0018] Wells should be drilled before mining, and corresponding extraction wells and injection wells should be drilled respectively. In this embodiment, the distribution of extraction wells and injection wells is as follows: figure 1 As shown, the extraction well is equipped with N 2 , N≥2, N=3 in the present embodiment, therefore be provided with 9 extraction wells, described extraction wells are distributed in a square array, the distance between any two adjacent extraction wells in the axial direction It is 7.5-8.5 kilometers, and the distance is 8 kilometers in the present embodiment. Four extraction wells adjacent to each other form a square together, such as figure 1 As shown, there is an injection well at the center of each square, and there are M i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com