Sorting process for high-ash and difficult-separation coal slime

A sorting and difficult-to-separation technology, applied in flotation, solid separation, etc., can solve the difficult problems of high ash and fine mud entrainment and the influence of associated minerals, low product recovery rate and production efficiency, and achieve significant economic benefits , low operating costs, and the effect of improving clean coal quality and recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Implementation of the present invention will be further described below in conjunction with accompanying drawing:

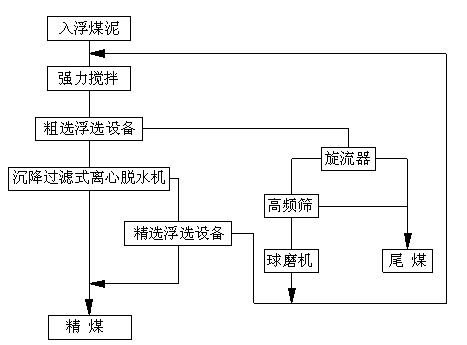

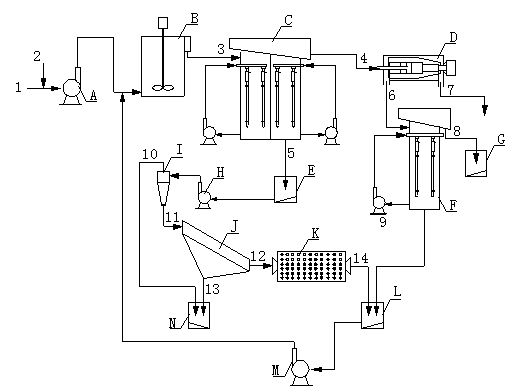

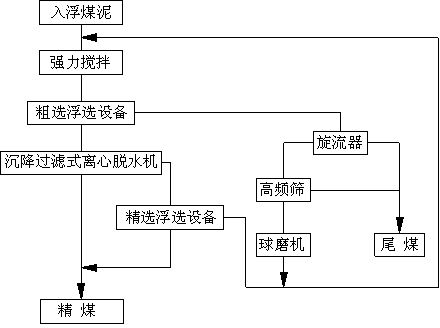

[0015] Such as figure 1 As shown, the incoming floating coal slime and flotation agent are sent into the mixing tank by the feeding pump, and after being evenly stirred by the impeller in the mixing tank, a slurry with a mass percentage concentration of 80 g / L-120 g / L is made, so that The prepared ore pulp is fed into the roughing flotation equipment by gravity through the channel, and the roughing flotation equipment adopts a two-stage flotation bed. After roughing in the two-stage flotation bed, the separated coarsely-selected clean coal flows into the sedimentation filter centrifugal dehydrator for clean coal dehydration, and the filtrate and coarse-clean coal dry matter are obtained, and the filtrate enters the fine-tuning flotation equipment For the selection operation, the selected flotation equipment adopts flotation columns or flotation machines. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com