Liquid material addition synchronous display system for resin sand continuous sand mill

A synchronous display and sand mixer technology, which is applied in metal processing equipment, cleaning/processing machinery of casting mold materials, casting molding equipment, etc., can solve the problem that the liquid material addition ratio of resin sand continuous sand mixer cannot be obtained intuitively and in real time, etc. problems, to avoid errors and measure accurately

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

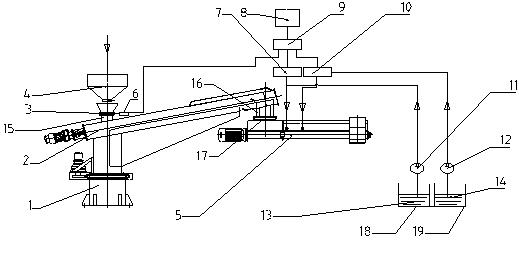

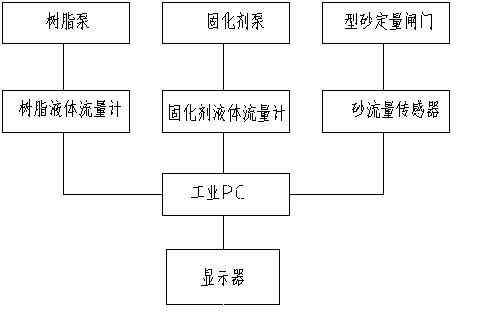

[0013] Depend on figure 1 and figure 2 The liquid material of the resin 13 sand continuous sand mixer shown is added to the synchronous display system. First, the resin sand continuous sand mixer is set. The resin sand continuous sand mixer includes a base 1. The upper side of the cage 2 is provided with a molding sand storage hopper 4, and the bottom of the molding sand storage hopper 4 is provided with a molding sand quantitative gate 3, and the molding sand storage hopper 4 communicates with the feed port 15 of the sand mixing cage 2 through the molding sand quantitative gate 3. The discharge port 16 of the sand sending mixing cage 2 is connected with the feeding port 17 of the mixing mixing cage 5, and the mixing mixing cage 5 is respectively connected with the resin pump 11 and the curing agent pump 12 through pipelines. A sand flow sensor 6 is provided on the molding sand quantitative gate 3, and a resin liquid flow meter 7 and a curing agent are respectively arranged ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com