Turbo-guiding type cooling apparatus

a cooling apparatus and guiding technology, applied in lighting, heating apparatus, instruments, etc., can solve the problems of reducing the volume of heat removal and saving precious, and achieve the effect of smooth air delivery, enhancing heat removal efficiency, and smooth removal of heat energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

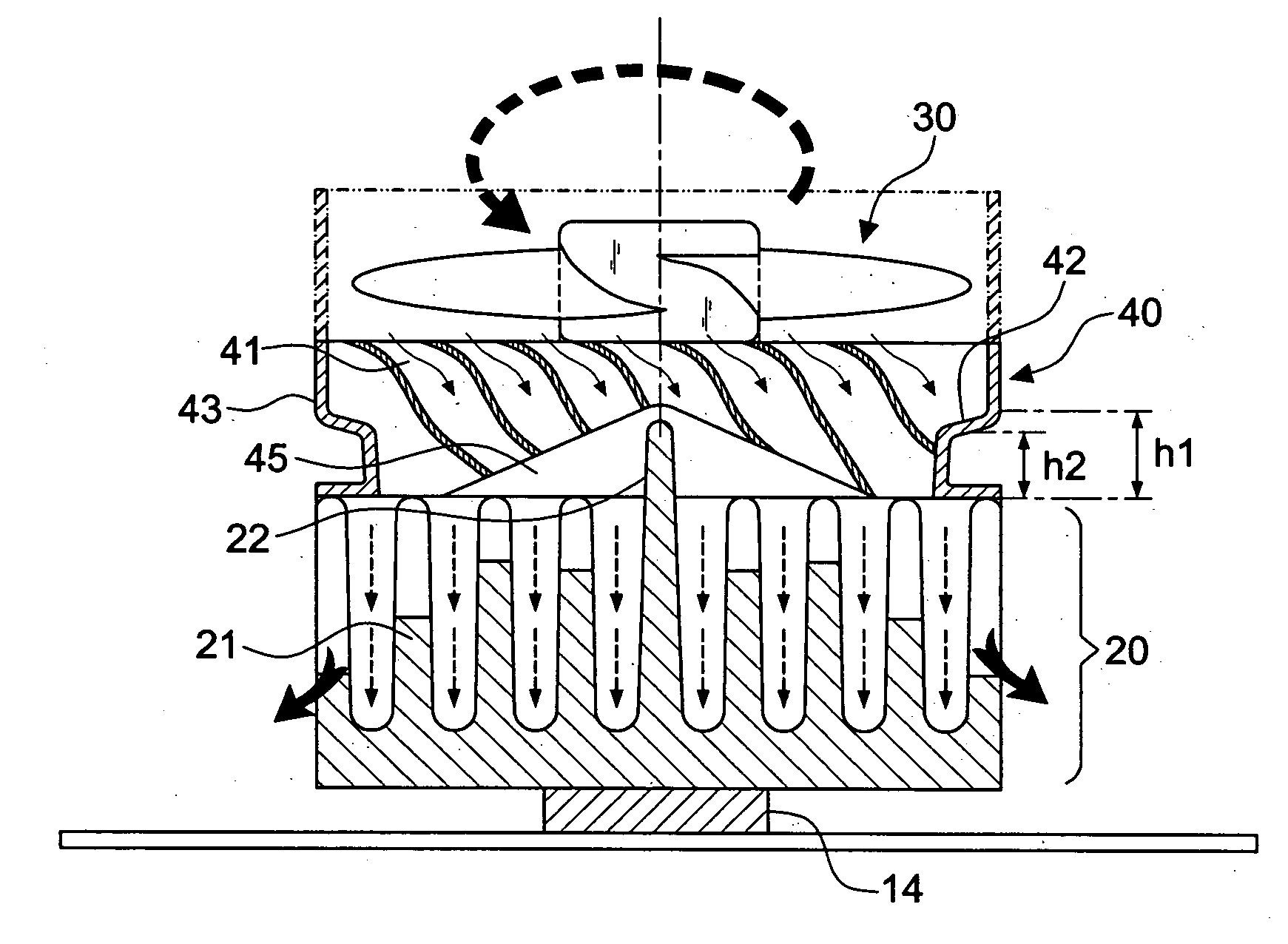

[0048]First of all, referring to FIGS. 6 and 7, a turbo-guiding type cooling apparatus in accordance with the invention includes a heat sink 20, and a fan 30.

[0049]The heat sink 20 includes a plurality of horizontal type cooling fins 21. According to the embodiment, the heat sink 20 belongs to a horizontal type heat sink. It should not be restricted thereto. The configuration of the invention can be also applied to the vertical type heat sink or heat-conducting module. These will be described in detail hereinafter. The heat sink 20 is not the object of the invention so that no further descriptions thereto are given hereinafter.

[0050]The fan 30 is disposed at the top of the heat sink 20. According to the invention, the fan 30 is an axial-flow fan so that the heat exchange takes place by delivering cool air downward to the heat sink 20.

[0051]The invention features a reverse fixed blade unit 40 interposed between the wind exit surface of the fan 30 and the heat sink 20. The rotation di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com