Foamed type TPU (thermoplastic polyurethane elastomer) material and preparation method thereof

A technology of thermoplastic polyurethane and elastomer materials, which is applied in the field of foam materials, can solve problems such as inability to monitor and adjust product quality in the middle, difficulty in ensuring product quality stability between batches, and affecting the physical properties of foam materials. Achieve the effect of avoiding unstable product performance, high degree of automation and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

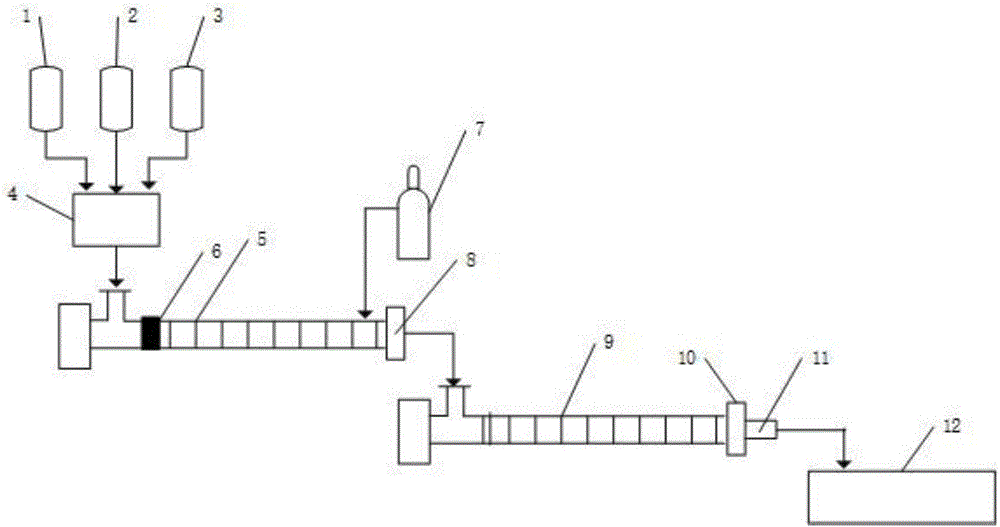

[0042] (1) Pass 100 parts by weight of polytetrahydrofuran polyol, 50 parts by weight of diphenylmethane-4,4'diisocyanate and 10 parts by weight of 1,4-butanediol through the pouring machine in a mass ratio of 100:50:10 Add it into the first reaction extruder, the aspect ratio of the first reaction extruder used is 18, the compression ratio is 2, and the temperature of the first reaction extruder screw is controlled to be 120-150°C, so that the above raw material mixture Polymerization for 10 seconds to obtain a TPU polymer melt, wherein a check valve is installed at the feeding port of the first reaction extruder;

[0043] (2) Inject 20 parts by weight of butane at the end of the first reaction extruder screw, and the TPU polymer melt is preliminarily mixed with butane;

[0044] (3) Add the initially mixed TPU polymer melt and butane into the second reaction extruder, and control the screw temperature of the second reaction extruder to be 150-120° C., and the screw speed is 1...

Embodiment 2

[0053] (1) 100 parts by weight of polybutylene adipate diol, 50 parts by weight of diphenylmethane-4,4' diisocyanate and 15 parts by weight of 1,4-butanediol in a mass ratio of 100 : The ratio of 50:15 is added in the first reaction extruder by pouring machine, and the aspect ratio of the first reaction extruder used is 40, and compression ratio is 5, and controls the first reaction extruder screw temperature to be 130-200°C; polymerize the above raw material mixture for 100 seconds to obtain a TPU polymer melt, wherein a check valve is installed at the feeding port of the first reaction extruder;

[0054] (2) Inject 25 parts by weight of carbon dioxide at the end of the first reaction extruder screw, and the TPU polymer melt and carbon dioxide are initially mixed;

[0055] (3) Add the initially mixed TPU polymer melt and carbon dioxide into the second reaction extruder, and control the screw temperature to be 150-125° C., and the screw speed to be 500 rpm, so that the carbon ...

Embodiment 3

[0062] (1) 100 parts by weight of bio-based poly-1,3-propylene glycol, 45 parts by weight of diphenylmethane-4,4'diisocyanate and 30 parts by weight of 1,4-butanediol in a mass ratio of 100:45 The ratio of :30 is added in the first reaction extruder by pouring machine, and the aspect ratio of the first reaction extruder used is 25, and compression ratio is 2.5, and the first reaction extruder screw temperature of control is 90- 220 ° C, the above-mentioned raw material mixture is polymerized for 150 seconds to obtain a TPU polymer melt, wherein a check valve is installed at the feeding port of the first reaction extruder;

[0063] (2) Inject 25 parts by weight of nitrogen at the end of the first reaction extruder screw, and the TPU polymer melt is initially mixed with nitrogen;

[0064] (3) Add the preliminarily mixed TPU polymer melt and nitrogen into the second reaction extruder, and control the screw temperature to 150-120°C, and the screw speed to 150rpm, so that the nitro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| molar mass | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com