Heat treatment device for semi-closed tubular aluminum profiles

A technology for heat treatment devices and aluminum profiles, applied in heat treatment furnaces, heat treatment equipment, furnace types, etc., can solve the problems of physical properties or internal structure influence, temperature can not meet better heat treatment, large stability difference, etc., to improve internal structure stability High performance, good power saving effect and high heating rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

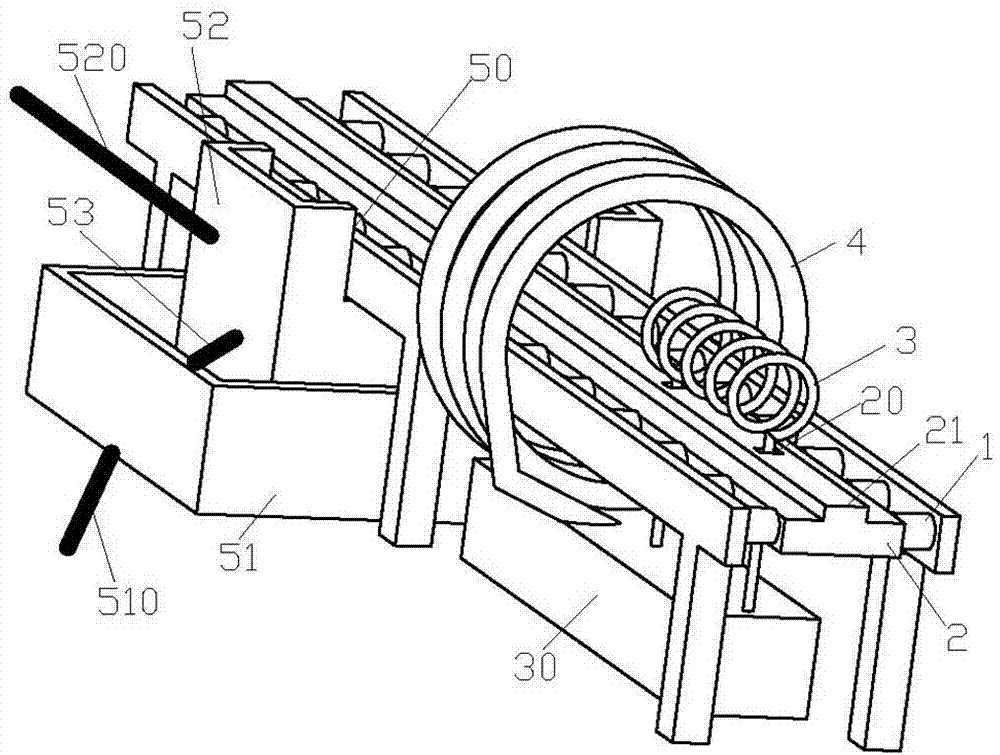

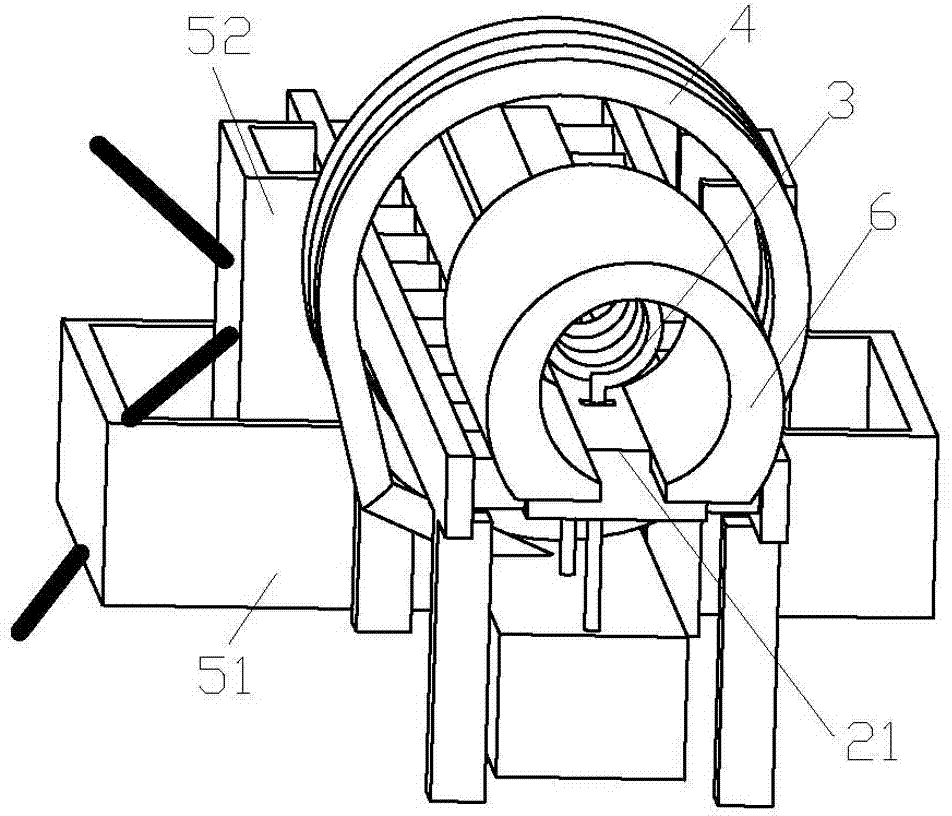

[0021] Example 1, such as figure 1 , figure 2 As shown, a semi-enclosed tubular aluminum profile heat treatment device includes an aluminum profile conveying path 1, and the aluminum profile conveying path 1 is fixed with a positioning track 2 parallel to the conveying direction near the middle position, and in the conveying direction of the aluminum profile conveying path 1, a The side is equipped with an internal heating device for aluminum profiles, an external heating device for aluminum profiles, and a cooling device. The aluminum profile internal heating device includes an internal heating coil 3 and an electromagnetic induction device 30 connected to the internal heating coil 3. The aluminum profile external heating device includes an external heating coil 4, and the external heating coil 4 is also connected to the electromagnetic induction device 30. The internal heating coil 3 Both the outer heating coil 4 and the outer heating coil 4 have a heating section exte...

Embodiment 2

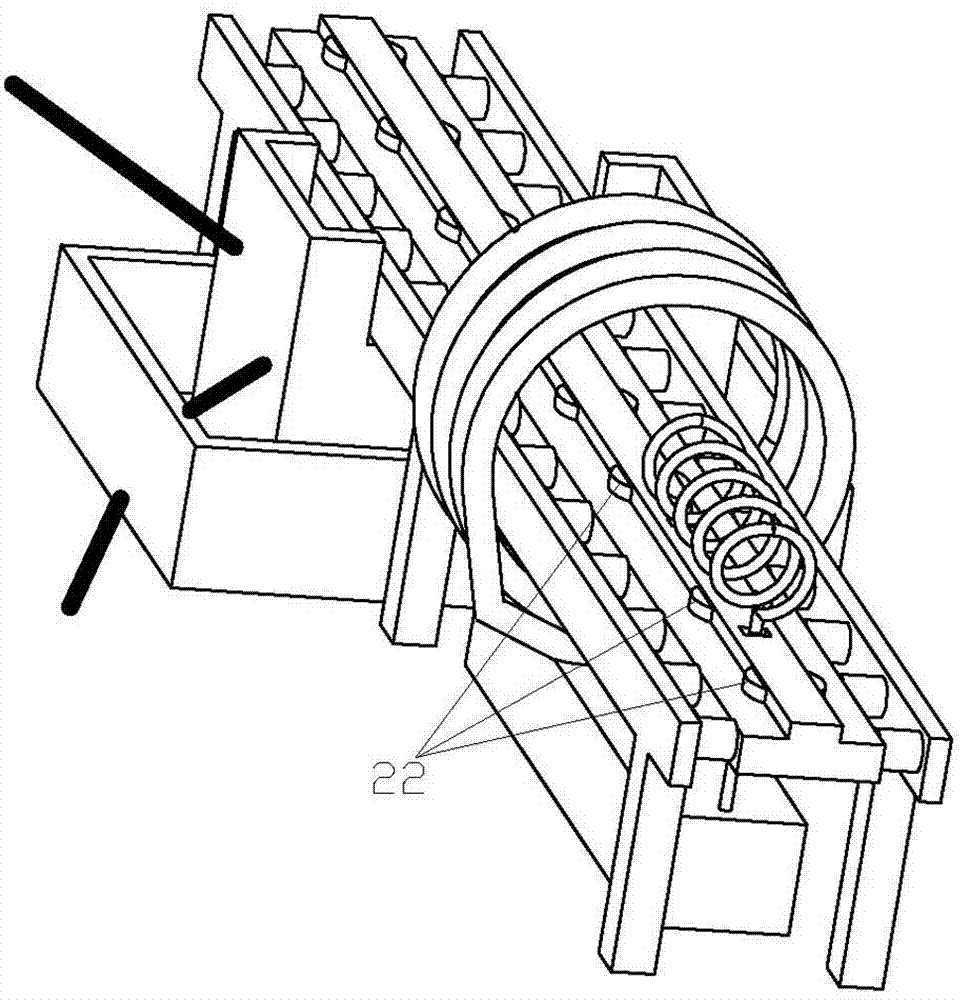

[0022] Example 2, such as image 3 As shown, the difference between it and Embodiment 1 is that: the positioning track 2 is provided with a guide wheel 22 that acts on the aluminum profile 6 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com