Forming process of large conic roller blank

A tapered roller, large-scale technology, applied in the field of forming and processing, can solve the problems of production equipment, labor, low utilization rate of steel, low production efficiency, etc., to improve processing efficiency and accuracy, avoid easy cracking, and improve organization. The effect of compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

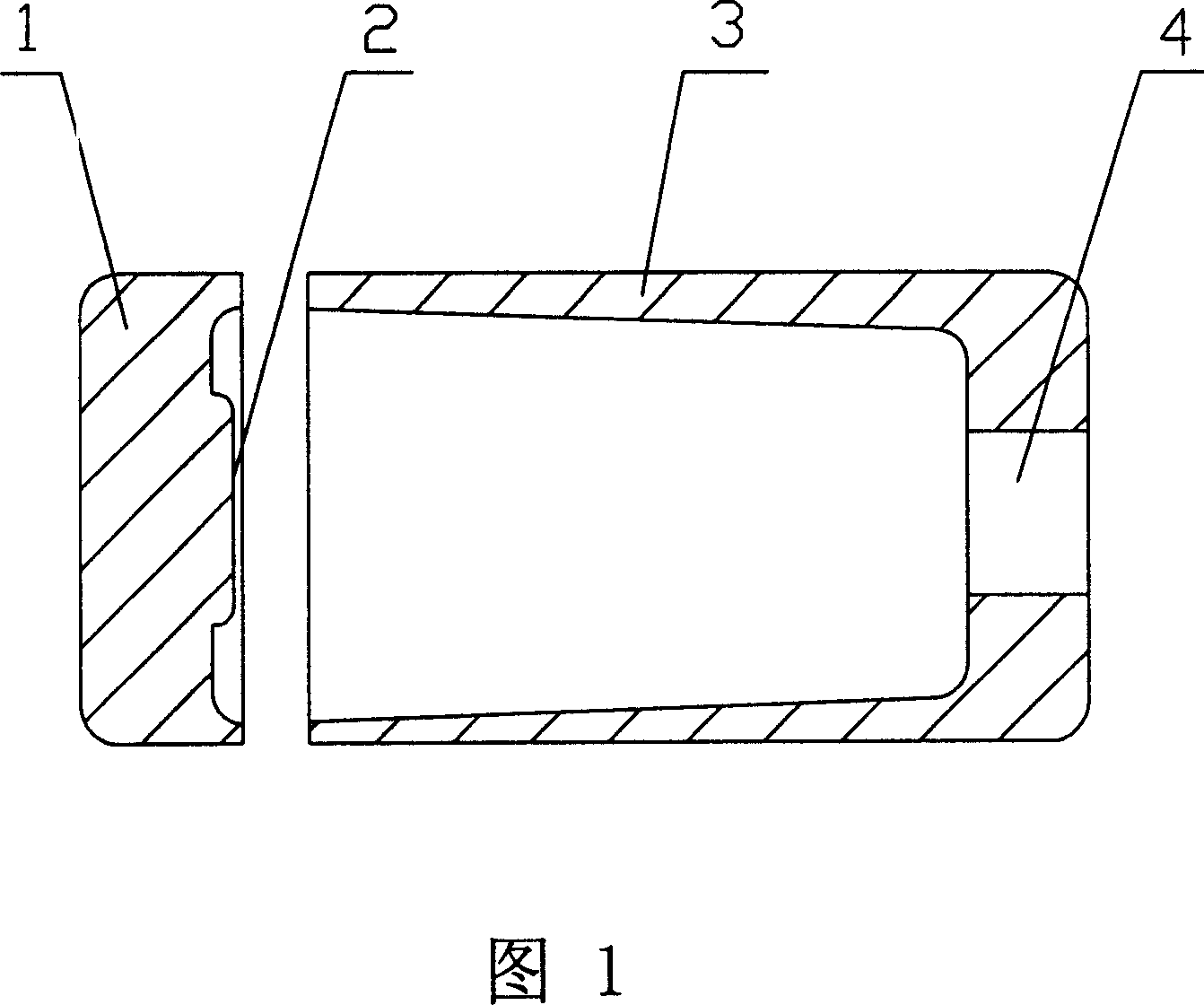

Image

Examples

Embodiment Construction

[0017] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

[0018] The invention is a cold extrusion forming process. The material section is slowly deformed by extrusion at room temperature, and the outer diameter Φ25-50mm, GCr15I hot-rolled annealed round steel is made into a tapered roller blank with an included angle between the outer diameter busbar and the axis of 2°. , the required deformation pressure is 2000-5000KN, and YJ61-315X hydraulic press is used. Since blank forming requires a short stroke, it can process 10-15 pieces per minute, which is 2-4 minutes for one piece compared with traditional turning, and the production efficiency is improved. About 20 times.

[0019] Concrete process steps are:

[0020] a) Cutting the metal bar into sections of required specifications;

[0021] b) Grinding and smoothing the outer circle of the material section to the required outer diameter;

[0022] c) Put the above...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com