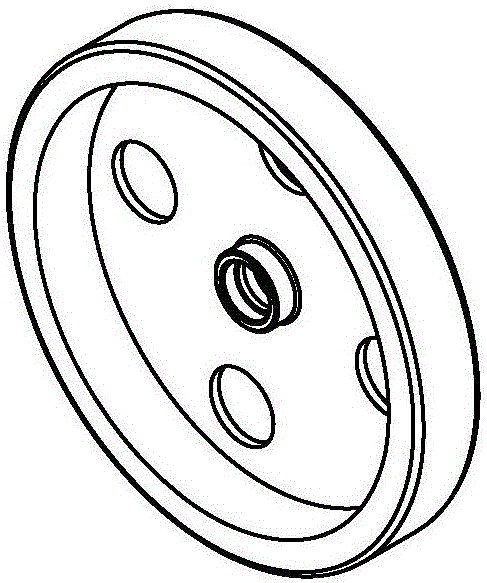

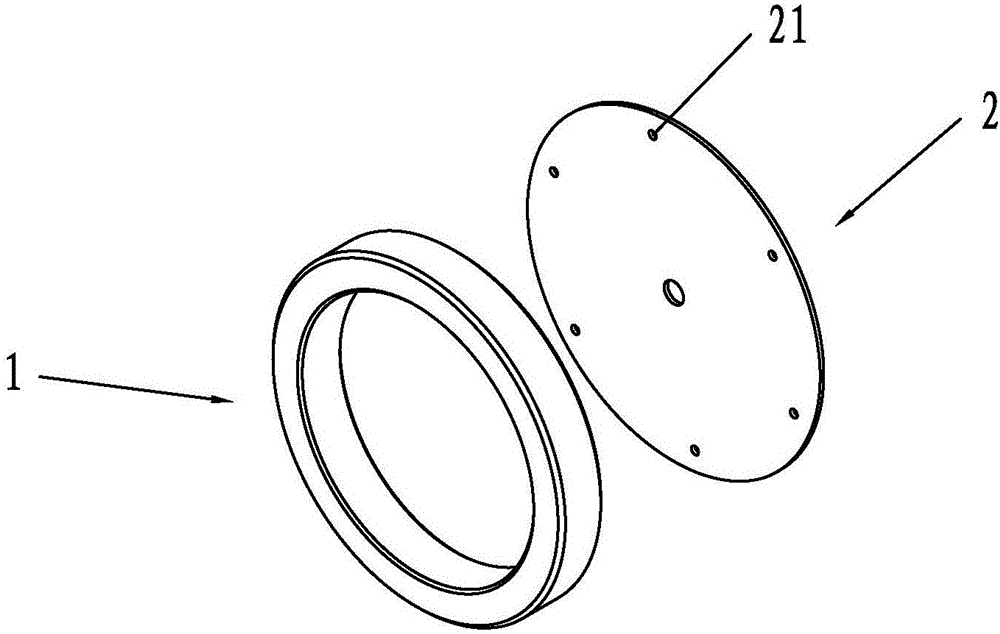

Magnetic counterweight ring, magnetic control wheel and preparation method thereof

The technology of a counterweight ring and magnetic conductivity is applied in sports accessories, training equipment for adjusting the cardiovascular system, training equipment for adjusting coordination, etc. To achieve the effect of reducing production costs and environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] 1) In the 30-80 mesh iron powder, add the manganese sulfide of 5% iron powder weight and the sodium silicate of 5% iron powder weight and the graphite powder of 8% iron powder weight, stir evenly,

[0030] 2) Iron powder rings are pressed by a 300-ton hydraulic press;

[0031] 3) Then use 600 degrees in the front part of the electric furnace for 10 minutes, and use 1100 degrees in the back part for 10 minutes;

[0032] 4) Then go through 300-600 tons of hydraulic secondary pressing to form. Cool naturally after being baked.

Embodiment 2

[0034] 1) In the 30-80 mesh iron powder, add the manganese sulfide of 3% iron powder weight and the sodium silicate of 8% iron powder weight and the graphite powder of 6% iron powder weight, stir evenly,

[0035] 2) Iron powder rings are pressed by a 300-ton hydraulic press,

[0036] 3) Then use 600 degrees in the front part of the electric furnace for 10 minutes, and use 1100 degrees in the back part for 10 minutes;

[0037] 4) Then go through 300-600 tons of hydraulic secondary pressing to form. Cool naturally after being baked.

Embodiment 3

[0039] 1) In the 30-80 mesh iron powder, add the manganese sulfide of 8% iron powder weight and the sodium silicate of 3% iron powder weight and the graphite powder of 12% iron powder weight, stir evenly,

[0040] 2) Iron powder rings are pressed by a 300-ton hydraulic press,

[0041] 3) Then use 600 degrees in the front part of the electric furnace for 10 minutes, and use 1100 degrees in the back part for 10 minutes;

[0042] 4) Then go through 300-600 tons of hydraulic secondary pressing to form. Cool naturally after being baked.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com