A kind of direct cooling cold iron for casting gray iron castings and ductile iron castings

A technology of direct cooling chilled iron and gray cast iron, which is applied in casting molding equipment, casting molds, casting mold components, etc., can solve problems such as failure to overcome, and achieve rapid decline in heat storage and thermal conductivity, long service life, and elimination of risk cost losses. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

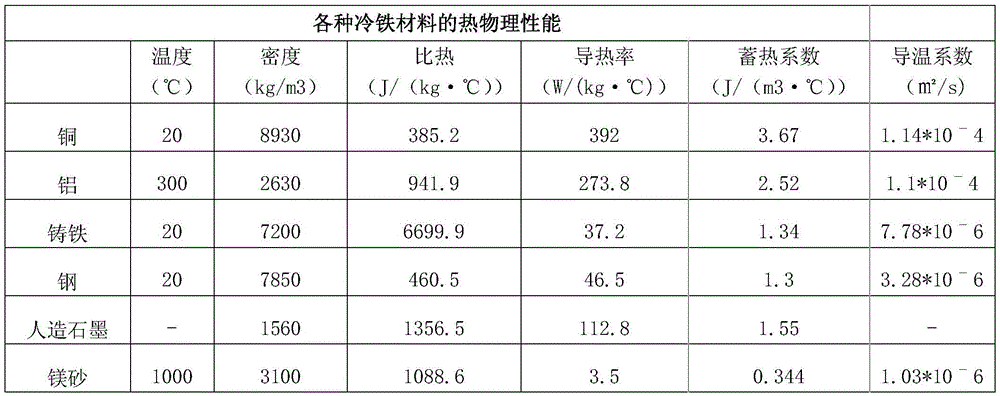

Method used

Image

Examples

Embodiment Construction

[0021] A direct-cooled chiller for casting gray iron castings and ductile iron castings, the material of which is ordinary carbon steel;

[0022] The outer surface of the direct cooling cold iron has an anti-drop groove structure, and its two ends are used as working surfaces, and a groove with a width of 15mm and an angle of 120° is opened in the middle of the cold iron;

[0023] The cross-section of the direct-cooled cold iron is circular, square or rectangular.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com