Carbon nitride high-load dispersed NiS photocatalytic degradation material and preparation method thereof

A degradable material and high-load technology, applied in the direction of catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve problems such as low efficiency and poor response to visible light, and achieve the promotion of photocatalytic degradation reactions, photocatalytic Performance improvement, effect of high specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

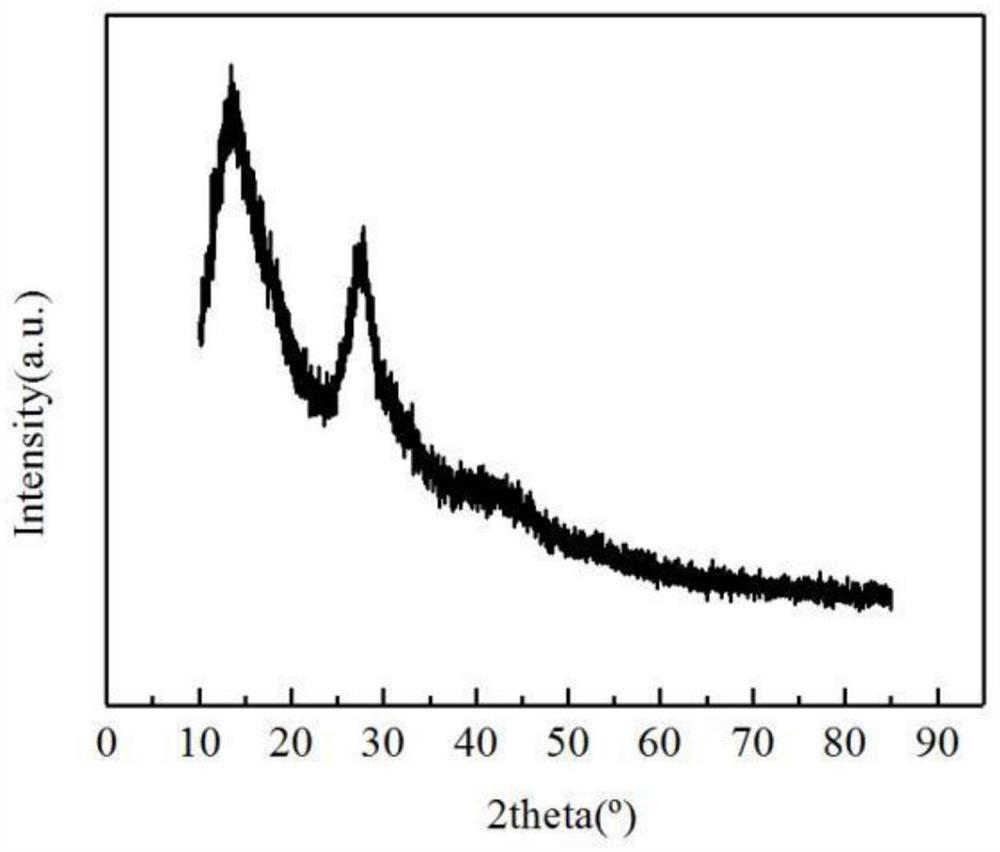

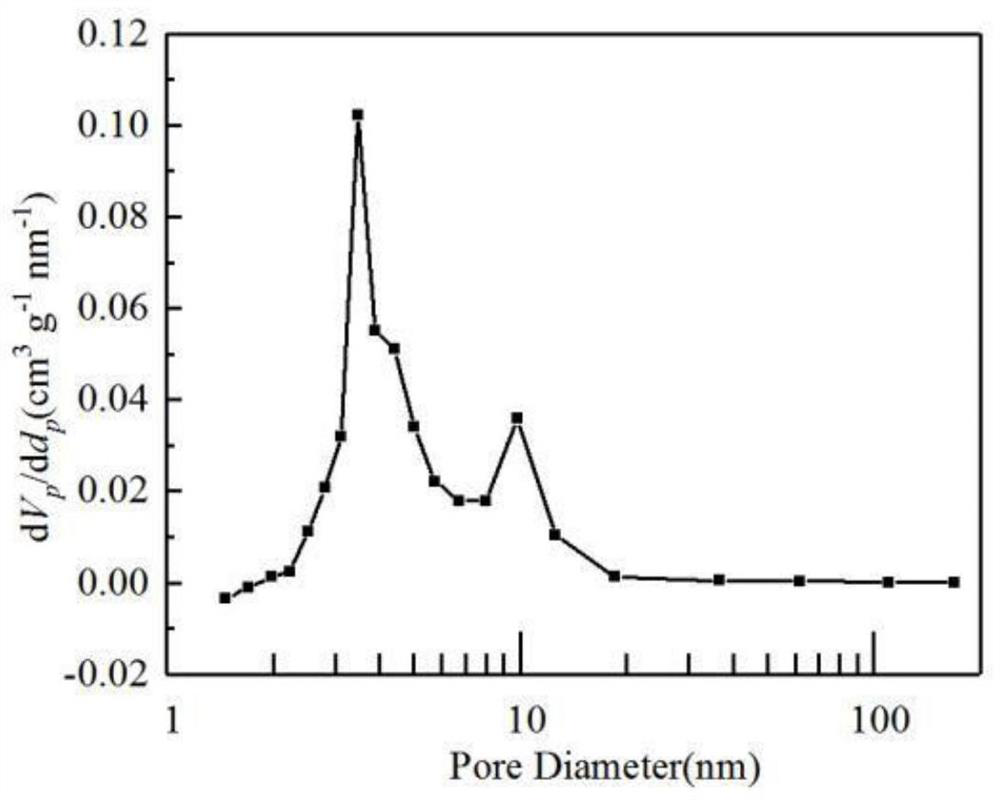

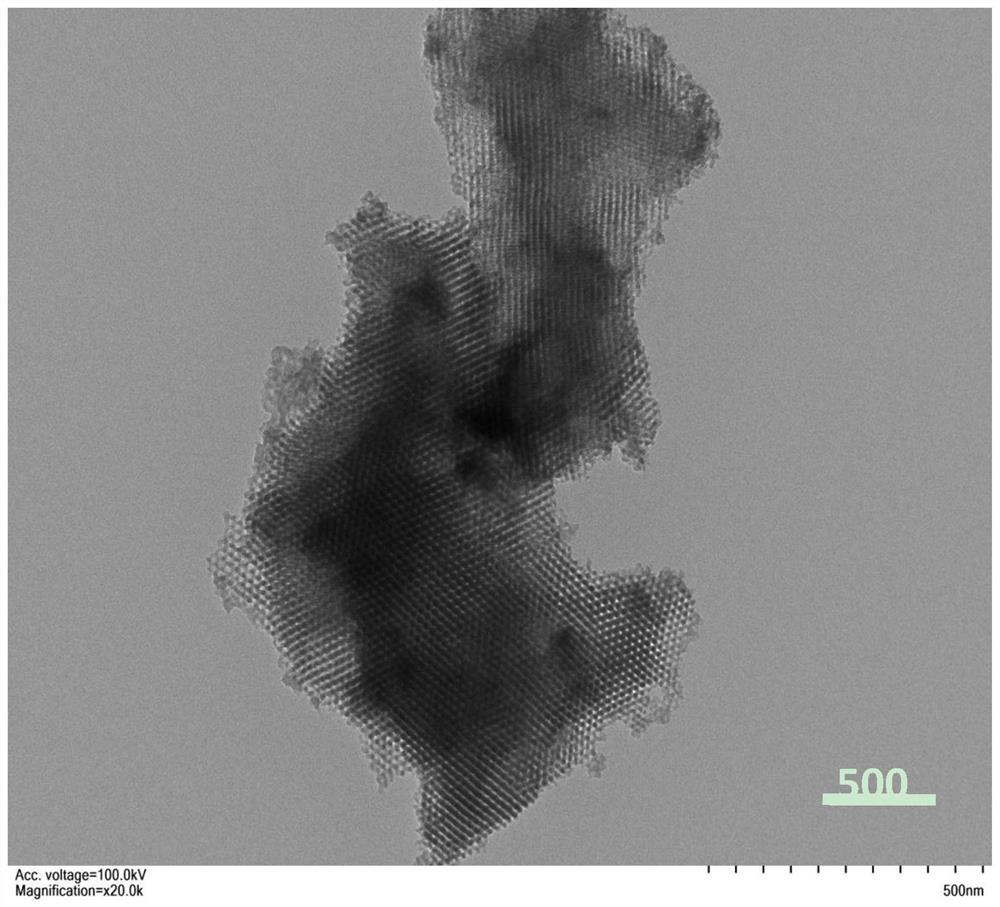

[0028] The invention relates to a method for preparing a large specific surface S-doped carbon nitride high-load dispersed NiS photocatalytic degradation material. The preparation process uses mesoporous silicon dioxide as a template, and first prepares mesoporous materials by using a soft template method at 40°C. Silica template; then cyanamide aqueous solution (50%) and thiourea precursor and mesoporous silica are fully stirred evenly at a certain temperature; secondly, they are calcined in air atmosphere; Silica template to obtain the desired ordered mesoporous carbon nitride. After that, on the photocatalytic degradation performance evaluation device, by adding sodium sulfide nonahydrate and nickel chloride hexahydrate, photodeposition synthesized photocatalytic degradation materials with large specific surface S-doped carbon nitride and high load dispersion NiS.

[0029] The invention provides a large specific surface S-doped carbon nitride high-load dispersed NiS photoca...

Embodiment 1

[0041] Take 7.2g of surfactant P123, 260mL of water and 1.2mL of concentrated hydrochloric acid (37%), mix at 35°C, stir for 12h until the surfactant P123 is completely dissolved and dispersed evenly, then add 7.2g of n-butanol, and stir for 2h , add 15.48g tetraethyl orthosilicate TEOS, stir for 24 hours, then transfer to a polytetrafluoroethylene bottle after suction filtration, react with water in an oven at 40°C for 24 hours, after natural cooling, suction filtration and wash with deionized water until neutral . Dry overnight at 70°C to obtain surfactant-containing mesoporous silica; place it in a muffle furnace for calcination at 550°C for 6 hours to remove surfactant P123 to obtain white powder, which is the mesoporous silica template.

[0042] Take 2.3794g of cyanamide aqueous solution (50%) and 1.3085g of thiourea in the polytetrafluoroethylene lining, add 4g of the aforementioned mesoporous silica as a hard template, and add 40mL of absolute ethanol, and stir at 40°C ...

Embodiment 2

[0045] Take 7.2g of surfactant P123, 260mL of water and 1.2mL of concentrated hydrochloric acid (37%), mix at 35°C, stir for 12h until the surfactant is completely dissolved and dispersed evenly, then add 7.2g of n-butanol, and stir for 2h, Add 15.48g tetraethyl orthosilicate TEOS, stir for 24 hours, then transfer to a polytetrafluoroethylene bottle after suction filtration, hydrothermally react in an oven at 40°C for 24 hours, naturally cool, suction filter and wash with deionized water until neutral. Dry overnight at 70°C to obtain surfactant-containing mesoporous silica; place it in a muffle furnace for calcination at 550°C for 6 hours to remove surfactant P123 to obtain white powder, which is the mesoporous silica template.

[0046] Take 2.3794g of cyanamide aqueous solution (50%) and 1.3085g of thiourea in the polytetrafluoroethylene lining, add 4g of the aforementioned mesoporous silica as a hard template, and add 40mL of absolute ethanol, and stir at 40°C until Dry, cov...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com