A high specific surface area ordered large mesoporous nickel acetone oxide gas sensitive material and preparation method thereof

A high specific surface area, acetone gas-sensing technology, applied in the direction of analytical materials, instruments, measuring devices, etc., to achieve the effect of enhancing thermal stability, accelerating response recovery speed, and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

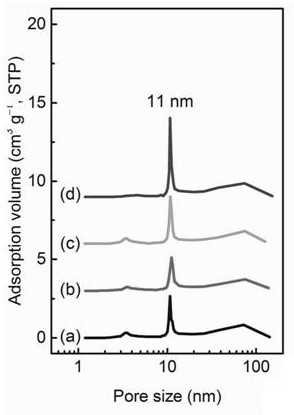

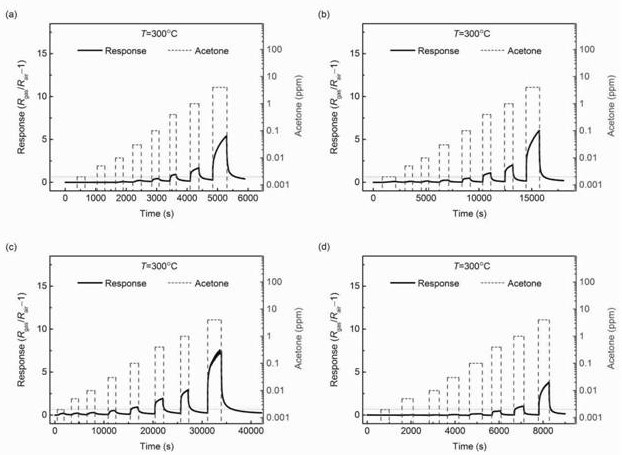

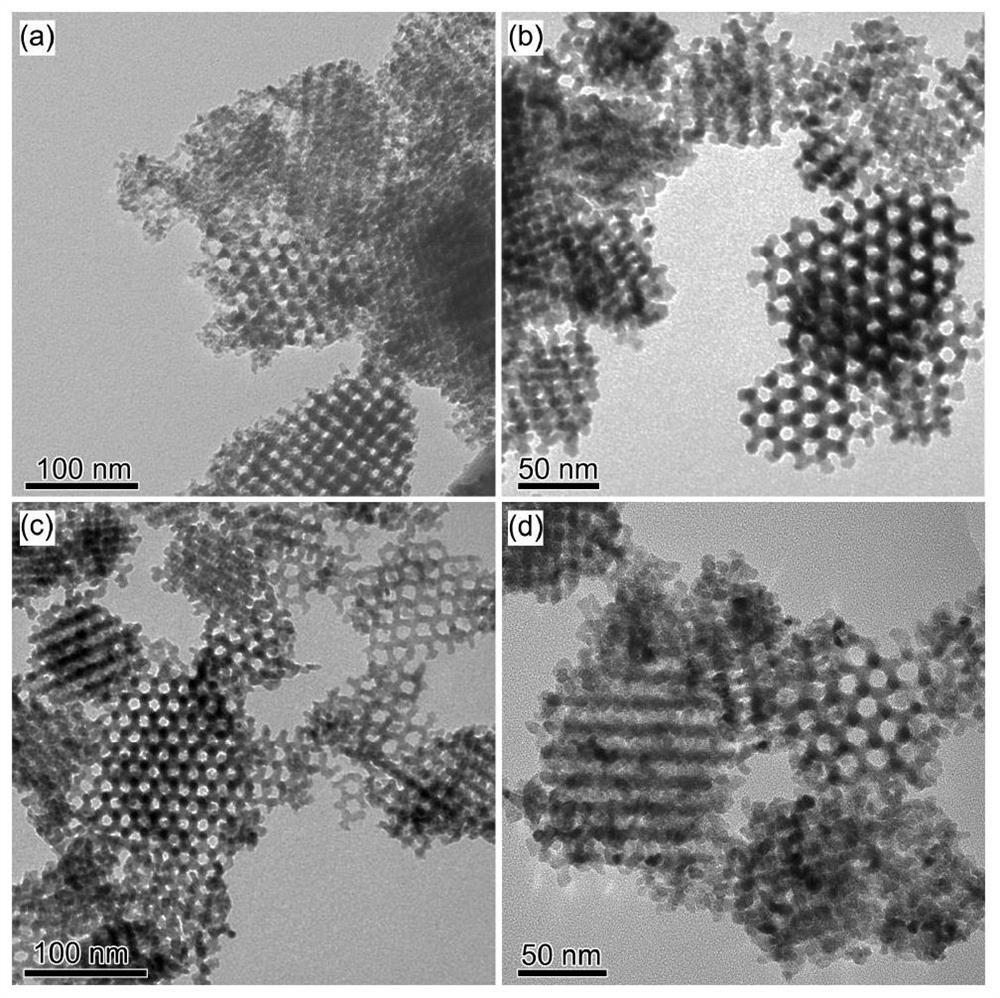

[0025] Mix 6.0g of surfactant P123, 216g of water and 11.8g of concentrated hydrochloric acid at 35°C, stir for 12 hours until the surfactant is completely dissolved and dispersed evenly, then add 6g of n-butanol, stir for 2 hours, then add 12.9g of silicon Ethyl acetate TEOS, stirred for 24 hours, transferred to a polytetrafluoroethylene bottle, followed by hydrothermal reaction at 40 degrees for 1 day, natural cooling, suction filtration, washing, and natural drying at room temperature, that is, the mesoporous surface containing surfactant silicon oxide. The sample surfactant P123 obtained above was removed by calcining at 550°C in air for 6 hours to obtain a white powder. The obtained ordered mesoporous silica has a specific surface area of 586m 2 / g, pore volume 0.67cm 3 / g, the pore size is about 3.8nm.

[0026] Disperse 2.194g of nickel nitrate into a 25mL centrifuge tube, heat it in a blast drying oven at 75°C, add 2g of mesoporous silica treated in step b as a har...

Embodiment 2

[0029] Mix 6.0g of surfactant P123, 216g of water and 11.8g of concentrated hydrochloric acid at 35°C, stir for 12 hours until the surfactant is completely dissolved and dispersed evenly, then add 6g of n-butanol, stir for 2 hours, then add 12.9g of silicon Ethyl acetate TEOS, stirred for 24 hours, transferred to a polytetrafluoroethylene bottle, followed by hydrothermal reaction at 40 degrees for 1 day, natural cooling, suction filtration, washing, and natural drying at room temperature, that is, the mesoporous surface containing surfactant silicon oxide. The sample surfactant P123 obtained above was removed by calcining at 550°C in air for 6 hours to obtain a white powder. The obtained ordered mesoporous silica has a specific surface area of 586m 2 / g, pore volume 0.67cm 3 / g, the pore size is about 3.8nm.

[0030] Disperse 2.194g of nickel nitrate into a 25mL centrifuge tube, heat it in a blast drying oven at 75°C, add 2g of mesoporous silica treated in step b as a hard ...

Embodiment 3

[0033] Mix 6.0g of surfactant P123, 216g of water and 11.8g of concentrated hydrochloric acid at 35°C, stir for 12 hours until the surfactant is completely dissolved and dispersed evenly, then add 6g of n-butanol, stir for 2 hours, then add 12.9g of silicon Ethyl acetate TEOS, stirred for 24 hours, transferred to a polytetrafluoroethylene bottle, followed by hydrothermal reaction at 40 degrees for 1 day, natural cooling, suction filtration, washing, and natural drying at room temperature, that is, the mesoporous surface containing surfactant silicon oxide. The sample surfactant P123 obtained above was removed by calcining at 550°C in air for 6 hours to obtain a white powder. The obtained ordered mesoporous silica has a specific surface area of 586m 2 / g, pore volume 0.67cm 3 / g, the pore size is about 3.8nm.

[0034] Disperse 2.194g of nickel nitrate into a 25mL centrifuge tube, heat it in a blast drying oven at 75°C, add 2g of mesoporous silica treated in step b as a har...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com