Ordered large-mesoporous copper gallate gas-sensitive material with high specific surface area and preparation method of ordered large-mesoporous copper gallate gas-sensitive material

A high specific surface area, gas-sensing material technology, applied in the field of high specific surface area ordered large mesoporous copper gallate gas-sensing materials and its preparation, can solve the problems of high cost and large volume, and achieve high sensitivity, low detection limit, The effect of increasing the sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

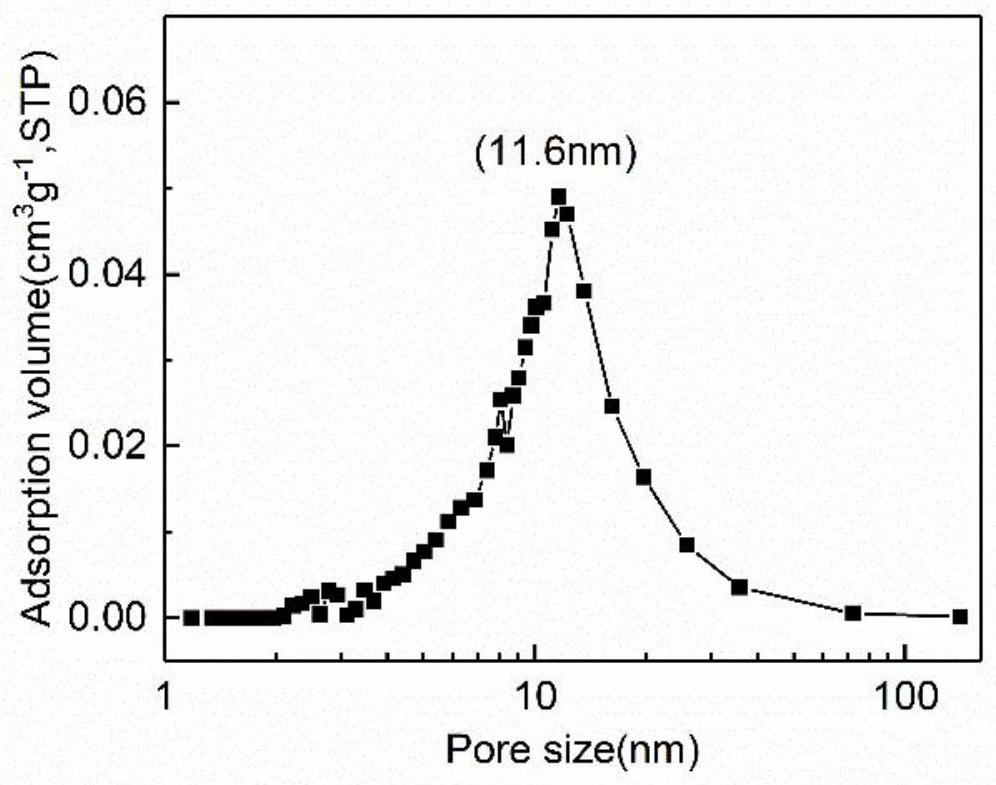

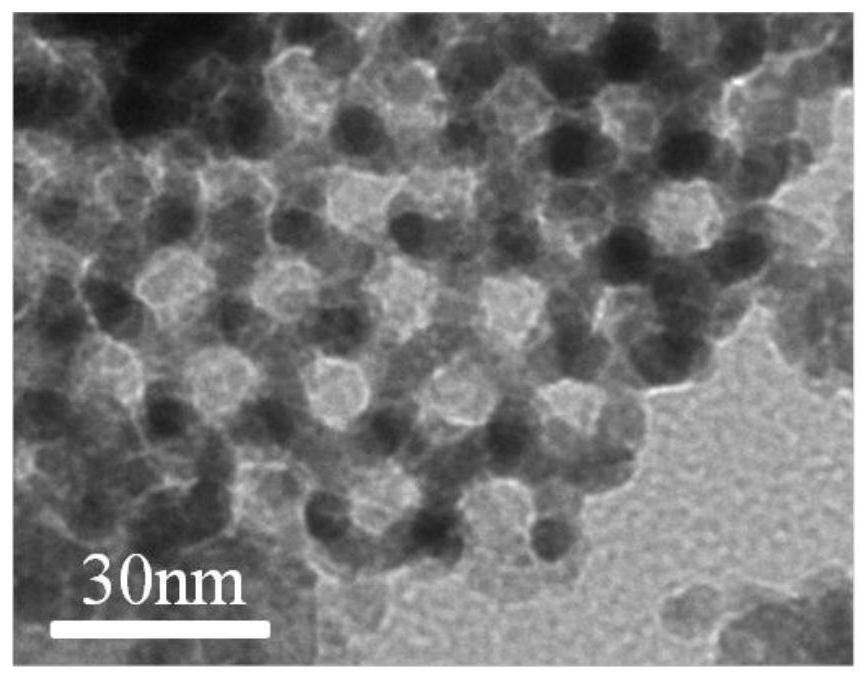

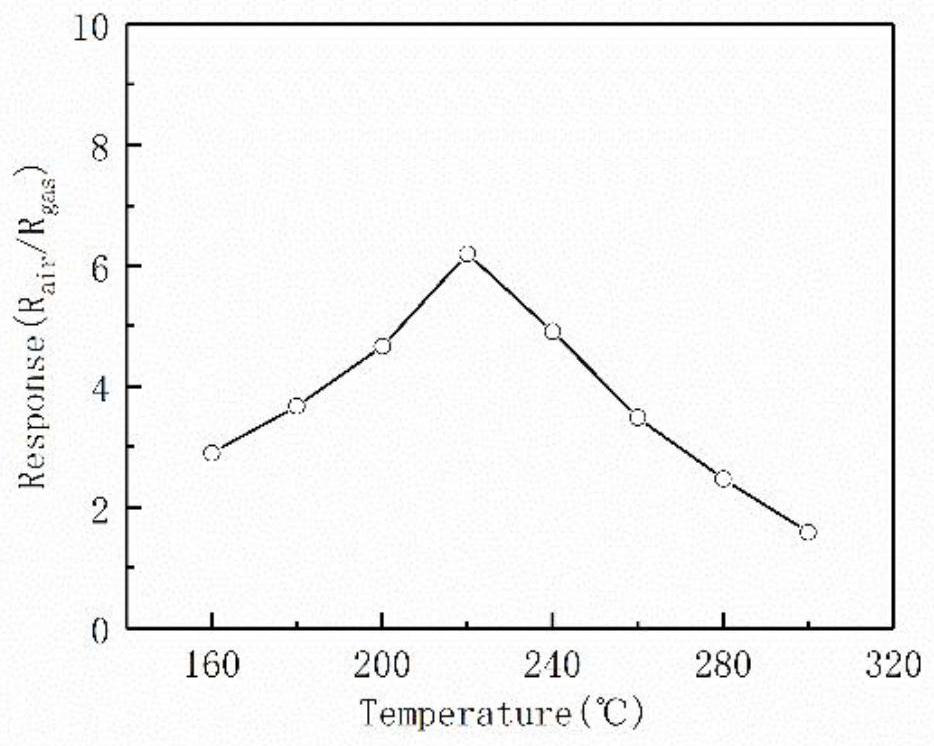

[0028] The invention relates to an ordered and large mesoporous copper gallate acetone gas-sensing material with high specific surface area and a preparation method thereof. The preparation process is as follows: firstly, mesoporous silica is prepared by soft template method at 35°C or 40°C; then copper nitrate and gallium nitrate precursors are melted at a certain temperature and fully oscillated with mesoporous silica to grind uniformly; Then it is calcined in an air atmosphere; the silica template is removed with a certain concentration of sodium hydroxide solution to obtain the required high specific surface area ordered large mesoporous copper gallate material, which is characterized in that the material is made of copper gallate spiral The nanowires are periodically arranged in cubic form. The diameter of the nanowires is about 5nm. 2 / g. The invention has the following effects: the high specific surface area ordered large mesoporous copper gallate gas sensing material ...

Embodiment 1

[0040] Mix 72g of surfactant P123, 2.6L of deionized water and 120ml of hydrochloric acid with a concentration of 37wt%, and stir for 12h at a constant temperature of 35°C in a water bath until the surfactant is completely dissolved and dispersed evenly, then add 72g of n-butanol and stir for 2 Hours later, 154.8 g of tetraethyl orthosilicate (TEOS) was added, and after stirring at a constant temperature of 35 °C in a water bath for 24 hours, it was transferred to a polytetrafluoroethylene bottle, and then hydrothermally reacted in a 40 °C blast drying oven for 24 hours. After natural cooling, it was filtered by suction, washed with deionized water until neutral, and transferred to a blast drying oven at 70°C for drying for 12 hours to obtain mesoporous silica containing surfactant; then the obtained mesoporous silica (sample) was The surfactant P123 was calcined in air at 550°C for 6 hours, and after removing P123, a white powder was obtained, which was mesoporous silica witho...

Embodiment 2

[0045] Mix 72g of surfactant P123, 2.6L of deionized water and 120ml of hydrochloric acid with a concentration of 37wt%, and stir for 12h at a constant temperature of 35°C in a water bath until the surfactant is completely dissolved and dispersed evenly, then add 72g of n-butanol and stir for 2 After 1 hour, 154.8 g of tetraethyl orthosilicate (TEOS) was added, and after stirring at a constant temperature of 35 °C in a water bath for 24 hours, it was transferred to a polytetrafluoroethylene bottle, and then hydrothermally reacted in a blast drying oven at 80 °C for 24 hours. After natural cooling, it was filtered by suction, washed with deionized water until neutral, and transferred to a blast drying oven at 70°C for drying for 12 hours to obtain mesoporous silica containing surfactant; After calcining at 550℃ for 6h to remove P123, white powder was obtained, that is, mesoporous silica without surfactant;

[0046] Mix and disperse 0.2424g copper nitrate and 0.8424g gallium nit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com