Composite cold iron for iron castings and production method thereof

A production method and technology of iron castings, applied in the field of composite cold iron for iron castings and its production, can solve the problems of insufficient heat capacity, low recycling rate, unfavorable compactness, etc., to reduce the probability of casting defects, manufacture and use The effect of low cost and simplified on-site quality control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

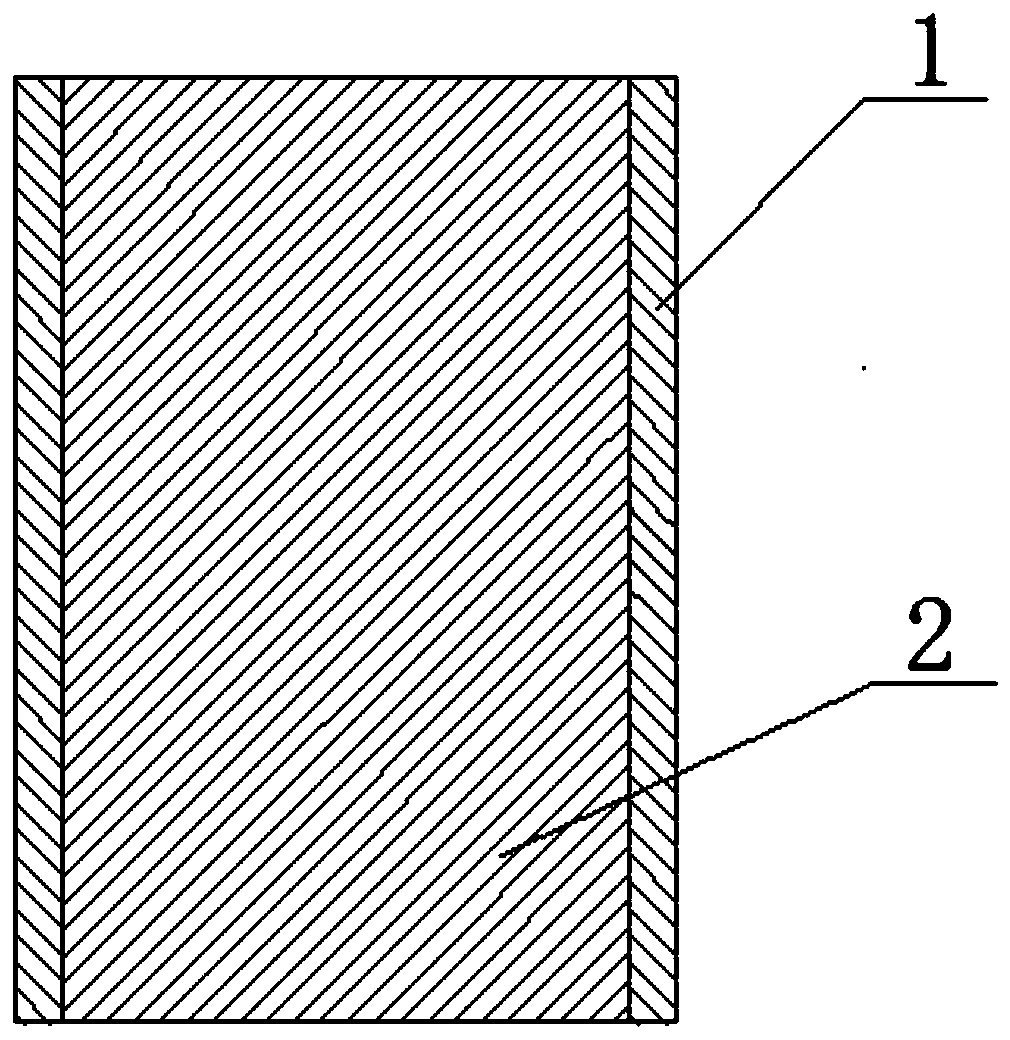

[0039] A kind of composite cold iron for cast iron parts, please refer to the attached figure 1 As shown, the composite cold iron includes a main body, and the main body includes a cladding layer (1) and a gray iron layer (2); the cladding layer (1) is made of ordinary carbon steel; the gray iron layer ( 2) It is made of gray iron; the composite cold iron material has a lower manufacturing cost than steel cold iron.

[0040] Further, the cladding layer (1) is made of ordinary carbon steel, which has better surface hardness and overall toughness.

[0041] Further, the gray iron layer (2) is formed of gray iron material with high carbon equivalent, which can ensure that the material in the middle part has high specific heat capacity and thermal conductivity, and strengthen the cooling effect of cold iron, and the chilling effect is obvious. Under the condition of the same chilling effect, the composite chill reduces the volume and weight of the chill compared with the tradition...

Embodiment 2

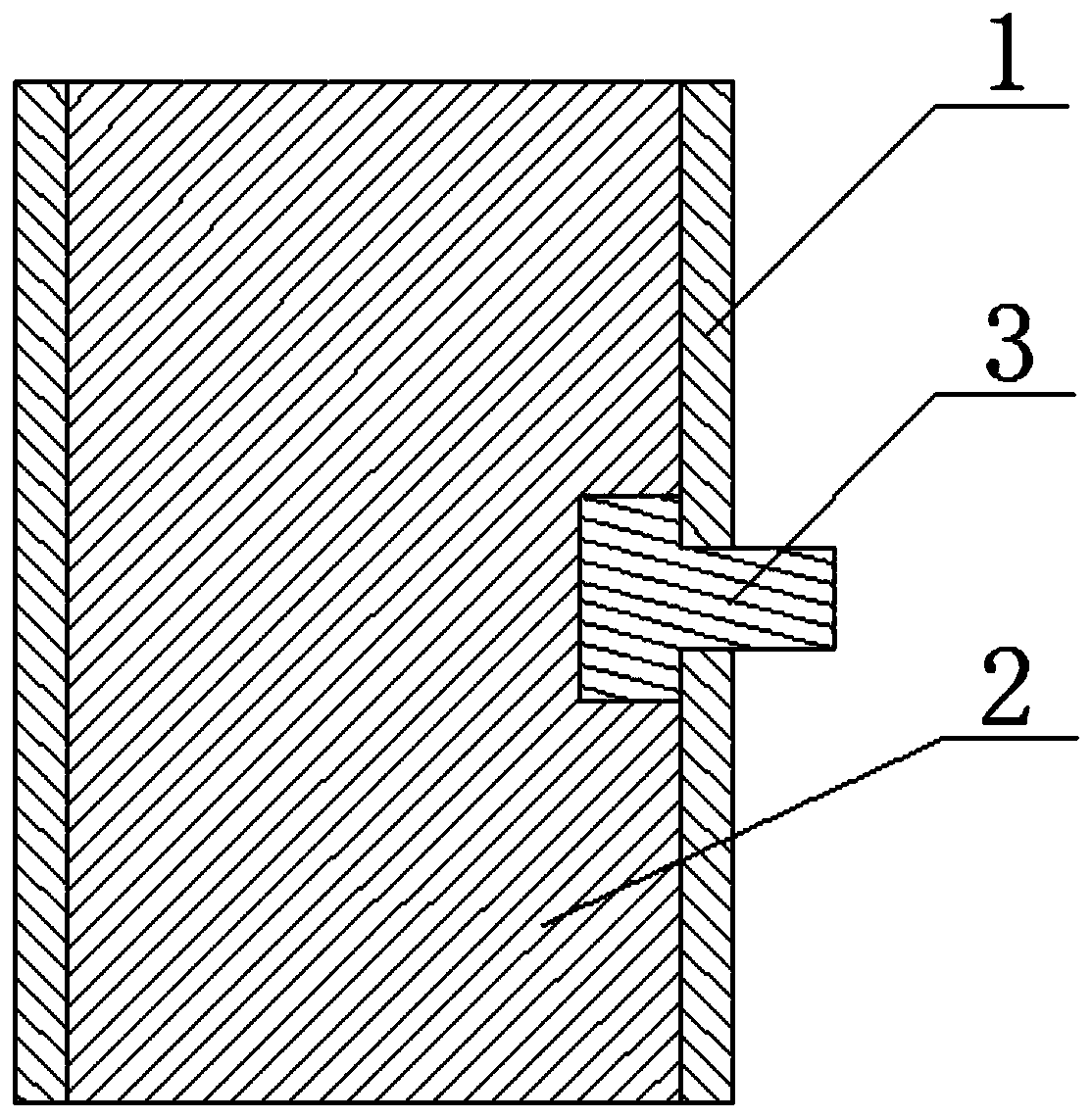

[0048] A kind of composite cold iron for cast iron parts, please refer to the attached figure 2 As shown, the composite cold iron includes a main body, and the main body includes a cladding layer (1), a gray iron layer (2) and a boss (3); the cladding layer (1) is made of ordinary carbon steel; The gray iron layer (2) is made of gray iron; the boss (3) is used to prevent slipping; and the composite cold iron material has a lower manufacturing cost than steel cold iron.

[0049] Further, the outer layer of the cladding layer (1) is made of steel, which has better surface hardness and overall toughness.

[0050]Further, the gray iron layer (2) is formed of gray iron material with high carbon equivalent, which can ensure that the material in the middle part has high specific heat capacity and thermal conductivity, and strengthen the cooling effect of cold iron, and the chilling effect is obvious.

[0051] Further, the cladding layer (1) has a cavity structure; the gray iron lay...

Embodiment 3

[0064] A kind of composite cold iron for cast iron parts, please refer to the attached figure 2 As shown, the composite cold iron includes a main body, and the main body includes a cladding layer (1), a gray iron layer (2) and a boss (3); the cladding layer (1) is made of ordinary carbon steel; The gray iron layer (2) is made of gray iron; the boss (3) is used to prevent slipping.

[0065] Further, the cladding layer (1) has a cavity structure; the gray iron layer (2) cooperates with the cladding layer (1).

[0066] Further, the gray iron layer (2) is poured into the cavity of the cladding layer (1).

[0067] Further, the side wall of the cladding layer (1) is provided with boss positioning holes.

[0068] Further, the shape and size of the positioning hole of the boss match with the protruding part of the boss (3).

[0069] Further, the boss (3) is made of Φ10 round steel.

[0070] Further, the boss (3) exposes 10 mm from the surface of the cladding layer (1).

[0071] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com