A kind of benzene-free environmental protection woven bag drool composite special ink and preparation method thereof

A woven bag and ink technology, which is applied in ink, applications, household appliances, etc., can solve the problems of substandard tensile load of woven bags, large impact on human body and environment, and high comprehensive cost, so as to reduce production cost and comprehensive use cost, The effect of stable quality and strong adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

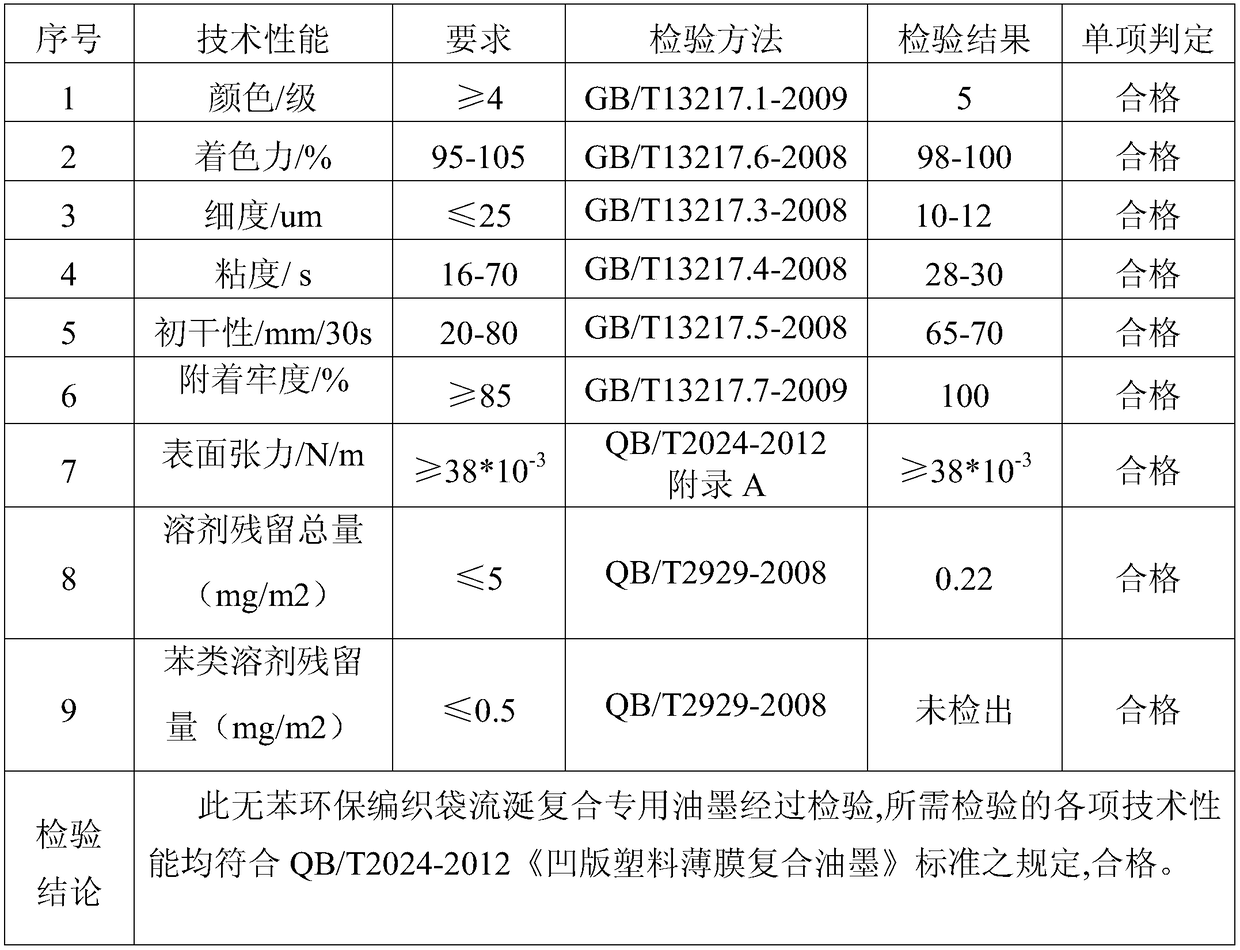

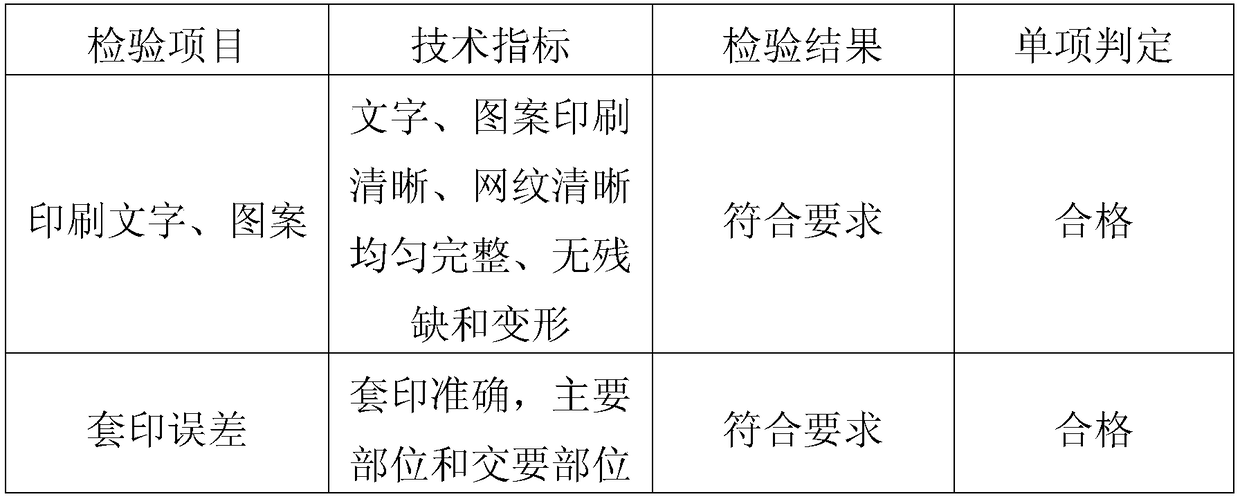

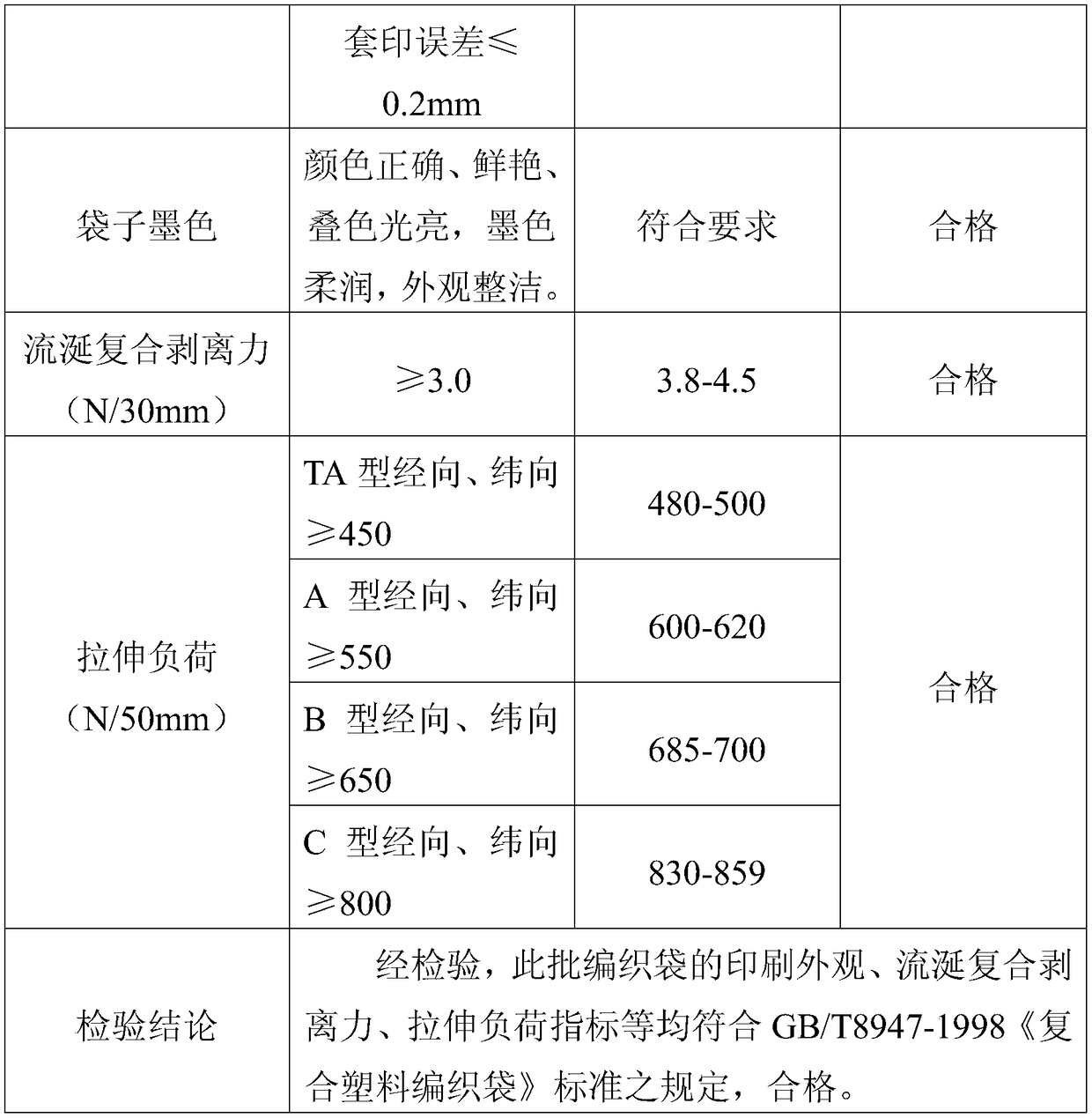

Image

Examples

Embodiment 1

[0057]A benzene-free environment-friendly woven bag salivation compound special ink, the white ink includes the following raw materials in parts by weight:

[0058] 12 parts ethyl acetate

[0059] 29 parts of 25% ester-soluble chlorinated EVA solution

[0060] 8 parts of 50% ester-soluble DM solution

[0061] Rutile titanium dioxide 20 parts

[0062] Filling 15 parts

[0063] 20% ester-soluble modified chlorinated polypropylene liquid 15 parts

[0064] 1 part of environmentally friendly modified PP extrusion compound strengthening agent;

[0065] The filler is selected from colloidal calcium or superfine kaolin;

[0066] Described 25% ester-soluble chlorinated EVA liquid is prepared by following method:

[0067] According to the weight ratio, pump 50 parts of ethyl acetate into the mixing tank, adjust the speed of the disperser to 300-400r / min, slowly put in 25 parts of chlorinated EVA block resin, adjust the speed to 1200-1500r / min, and seal and stir at 120- 150 minute...

Embodiment 2

[0077] A benzene-free environment-friendly woven bag salivation compound special ink, the white ink includes the following raw materials in parts by weight:

[0078] 13 parts ethyl acetate

[0079] 25% ester-soluble chlorinated EVA solution 32 parts

[0080] 4 parts of 50% ester-soluble DM solution

[0081] Rutile titanium dioxide 18 parts

[0082] 14 fillings

[0083] 20% ester-soluble modified chlorinated polypropylene liquid 17.8 parts

[0084] 1.2 parts of environmentally friendly modified PP extrusion compound strengthening agent;

[0085] The filler is selected from colloidal calcium or superfine kaolin;

[0086] Others are with embodiment 1.

Embodiment 3

[0088] A benzene-free environment-friendly woven bag salivation compound special ink, the white ink includes the following raw materials in parts by weight:

[0089] 14 parts ethyl acetate

[0090] 26 parts of 25% ester-soluble chlorinated EVA solution

[0091] 5 parts of 50% ester-soluble DM solution

[0092] Rutile titanium dioxide 23 parts

[0093] Filling 12 parts

[0094] 20% ester-soluble modified chlorinated polypropylene liquid 18.5 parts

[0095] 1.5 parts of environmentally friendly modified PP extrusion compound strengthening agent;

[0096] The filler is selected from colloidal calcium or superfine kaolin;

[0097] Others are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com