Cold forging-based manufacturing method for boss used for vehicle engine fuel track and manufacture device

A manufacturing method and fuel rail technology, applied in forging/pressing/hammer devices, forging presses, forging presses, etc., can solve problems such as poor processing, decreased reliability of quality assurance, large structure, etc., and achieve minimum cutting and microstructure Excellent compactness and high dimensional precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

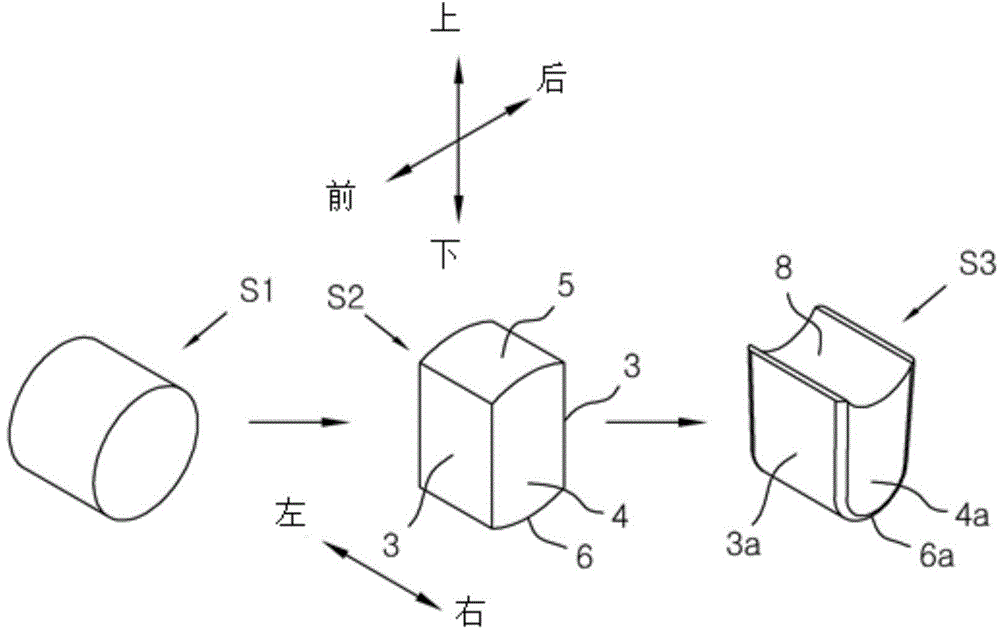

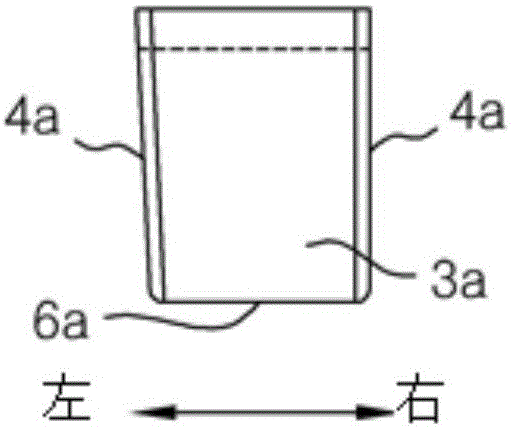

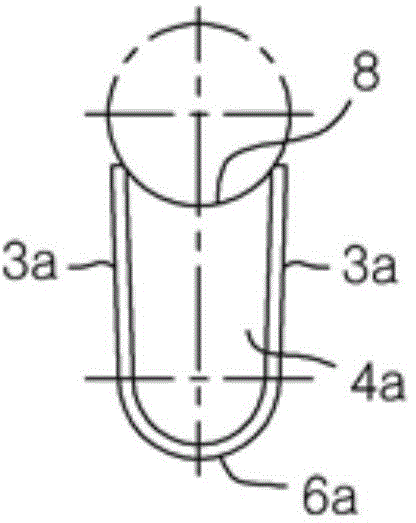

[0044] Referring to the accompanying drawings, the cold forging-based method and device for manufacturing a boss for a vehicle engine fuel rail according to an embodiment of the present invention will be described in detail below. Such as Figure 1 to Figure 8 As shown, the cold forging-based method for manufacturing a boss for a vehicle engine fuel rail according to the present invention includes a cutting step S10, a first forging step S20, a softening heat treatment step S30, a second molded body coating step S40, a second forging step S50 and Finishing step S60. In the cutting step S10, the round steel rod 1 is cut to manufacture a cylindrical first molded body S1. In the first forging step S20, the outer peripheral portion of the cylindrical truncated body S1 is pressurized to form a second formed body S2 having front and rear planar portions 3 and upper and lower convex curve portions 5, 6. In the softening heat treatment step S30, the second molded body S2 is annealed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com