Forming method of large-diameter thin-wall high-barrel type ultrahigh-strength steel D406A ring forging

A technology of ultra-high strength steel and forming method, applied in furnace type, furnace, heat treatment furnace, etc., can solve the problems of poor dimensional stability of forgings, many mandrels, etc., achieve less machining allowance, reduce production cycle, improve comprehensive performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

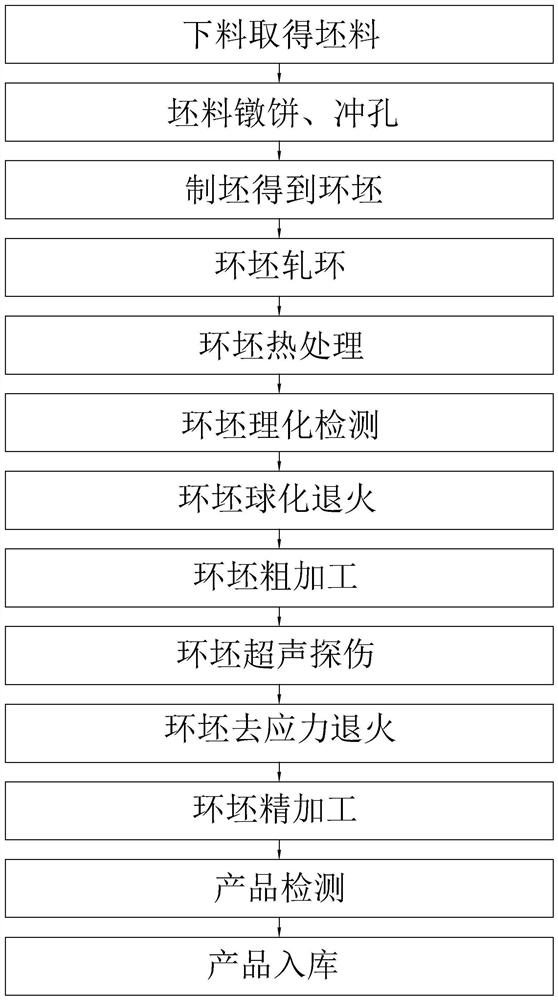

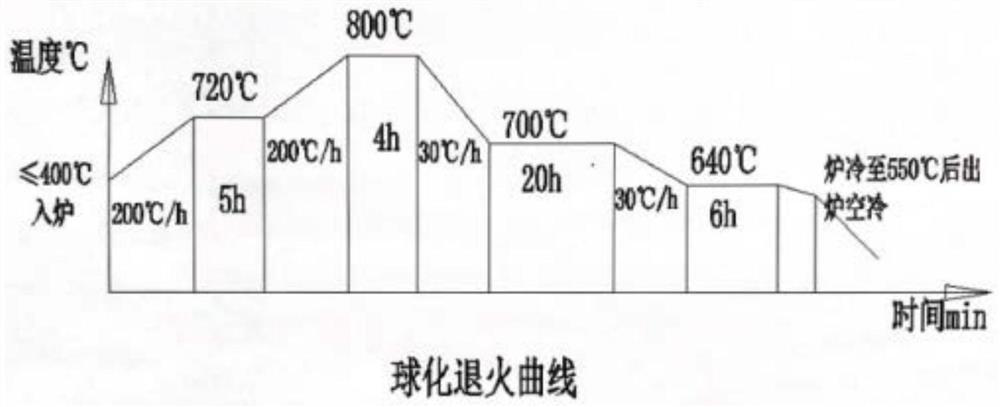

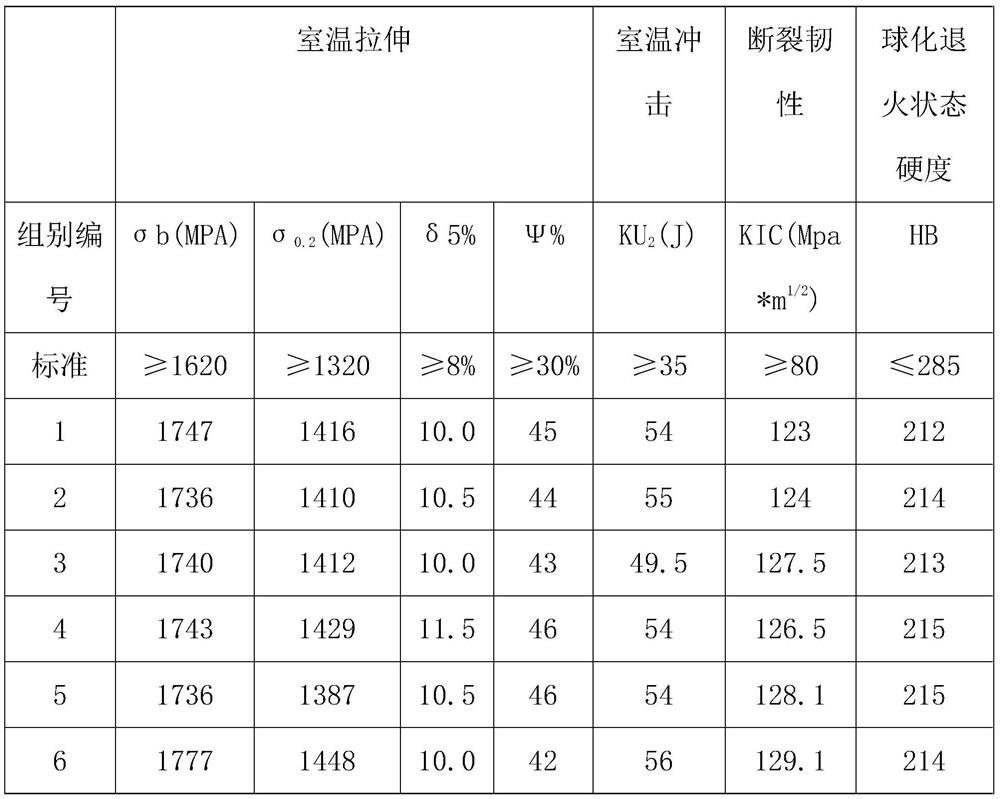

[0026] Embodiment 1: A method for forming a large-diameter, thin-walled, high-tube type ultra-high-strength steel D406A ring forging, such as figure 1 shown, including the following steps:

[0027] S1: blanking to obtain a blank, the size of the blank is Φ400(+3 / 0)mm*330(+3 / 0)mm, and the weight is 325kg.

[0028] S2: Billet upsetting and punching. It includes two working steps: the first working step: the billet is put into the furnace under the condition of less than 750°C, the temperature is raised to 1080°C at a rate of 250°C / h, and then kept for 120 minutes. The second working step: billet upsetting, punching to size: Φ465±10*Φ300±10*380±5mm. Avoid heating up too fast, and produce Widmanstatten structure in the blank structure, resulting in a decrease in the toughness of the structure. The reason why the heat treatment temperature is selected at 1080°C is that as the temperature increases, the degree of refinement of the martensite grains increases, and the finer grains...

Embodiment 2

[0040] Embodiment 2: A method for forming a large-diameter, thin-walled, high-tube type ultra-high-strength steel D406A ring forging, the steps different from those in Embodiment 1 are:

[0041] S2: Billet upsetting and punching. The first step: the billet is put into the furnace at a temperature of less than 750°C, and the temperature is raised to 1080°C at a rate of 320°C / h, and then kept for 120 minutes.

[0042] S4: ring blank rolling ring. It includes two working steps. The first working step: put the ring billet into the furnace at a temperature of less than 750°C, raise the temperature to 1080°C at a rate of 320°C / h, and then hold it for 30 minutes.

[0043] S5: Heat treatment of the ring billet. Including two working steps, normalizing: put the ring billet into the furnace at room temperature, raise the temperature to 720°C at a rate of 300°C / h, then keep it for 2 hours, then raise the temperature to 930°C again, keep it for 3 hours, and take it out of the furnace an...

Embodiment 3

[0045] Embodiment 3: A method for forming a large-diameter, thin-walled, high-tube type ultra-high-strength steel D406A ring forging, the steps different from those in Embodiment 1 are:

[0046] S2: Billet upsetting and punching. The first step: the billet is put into the furnace at a temperature of less than 750°C, and the temperature is raised to 1080°C at a rate of 400°C / h, and then kept for 120 minutes.

[0047] S4: ring blank rolling ring. It includes two working steps. The first working step: put the ring billet into the furnace at a temperature of less than 750°C, raise the temperature to 1080°C at a rate of 400°C / h, and then hold it for 30 minutes.

[0048] S5: Heat treatment of the ring billet. Including two working steps, normalizing: put the ring billet into the furnace at room temperature, raise the temperature to 720°C at a rate of 400°C / h, then keep it for 2 hours, then raise the temperature to 930°C again, keep it for 3 hours, and take it out of the furnace and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystal size | aaaaa | aaaaa |

| crystal size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com