Air-permeable fish tank and its manufacturing method

A technology for breathable fish tanks and fish tanks, which is applied in fish farming, ceramic products, and other household appliances, etc. It can solve the problems that it is not suitable for ordinary household promotion, it is difficult to achieve anti-seepage and ventilation at the same time, and poor anti-seepage performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

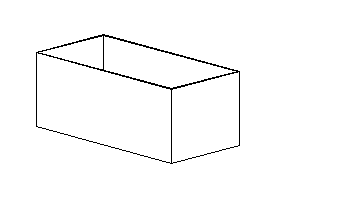

[0068] figure 1 For the breathable fish tank of the present invention, the anti-permeation gas fish tank 1 has an open cavity, and the fish tank is covered with pores of 0.002-0.086mm formed between adjacent aggregate particles. The pores can allow gas molecules to pass through smoothly, and the hydrophobic properties of the hydrophobic binder can effectively prevent the penetration of liquid water molecules.

[0069] The aggregate particles are a mixture of quartz sand and slag at a weight ratio of 5:1, the particle size of the quartz sand is 0.02-0.1 mm, the particle size of the slag is 0.08-0.15 mm, and the hydrophobic binder contains Fluorine epoxy resin binder 2,2-bisphenol-based hexafluoropropane diglycidyl ether, hydrophobic binder and aggregate particles are used at a weight ratio of 1:49.

[0070] Described fish jar 1 is to make by following method:

[0071] a. Mix the aggregate particles with the hydrophobic binder and pour into the mixer to stir evenly;

[0072...

Embodiment 2

[0076] The air-permeable fish tank in this embodiment has an open cavity, and the fish tank is covered with pores of 0.003-0.065 mm formed between adjacent aggregate particles. The pores within this size range can allow gas molecules to pass through smoothly, and It can effectively prevent the penetration of liquid water molecules.

[0077] The aggregate particles are formed by mixing ceramsite and glass microspheres at a weight ratio of 3:1, the particle size of the ceramsite is 0.01-0.075 mm, and the particle size of the glass microspheres is 0.04-0.08 mm.

[0078] The hydrophobic binder is a silicon-containing epoxy resin binder diphenylsilane modified bisphenol A epoxy resin, and the hydrophobic binder and aggregate particles are used in a weight ratio of 3:97.

[0079] The aggregate particles are coated with hydrophobic epoxy resin, and the hydrophobic epoxy resin is 2wt% of the aggregate particles. The hydrophobic epoxy resin is a mixture of polyamide resin modified epo...

Embodiment 3

[0090] figure 1 It is a ventilating fish tank in this embodiment, which is a cavity with an opening formed by four side walls, front, rear, left, and right sides and a bottom wall, wherein the front side wall is made of transparent glass. The rest of the side wall and the bottom wall of the fish tank are covered with pores of 0.002-0.086 mm formed between adjacent aggregate particles. The pores within this size range can allow gas molecules to pass through smoothly, and can effectively prevent liquid water molecules through.

[0091] The aggregate particles are formed by mixing ceramsite and quartz sand at a weight ratio of 1:3, the particle size of the ceramsite is 0.02-0.045 mm, and the particle size of the quartz sand is 0.015-0.1 mm.

[0092] The hydrophobic binder is a silicone binder methylphenylpolysiloxane resin, and the hydrophobic binder and aggregate particles are used in a weight ratio of 3:97.

[0093] The aggregate particles are coated with hydrophobic polytet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com