Anti-freeze high-corrosion-resistance prehydration mineral impermeable material and preparation method thereof

A technology of anti-seepage material and prehydration, applied in chemical instruments and methods, building components, lamination, etc., can solve problems affecting construction, unsatisfactory anti-seepage effect of sheet materials, poor corrosion resistance, etc., to achieve Not easy to fall off, good anti-freezing effect, and effect of improving corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

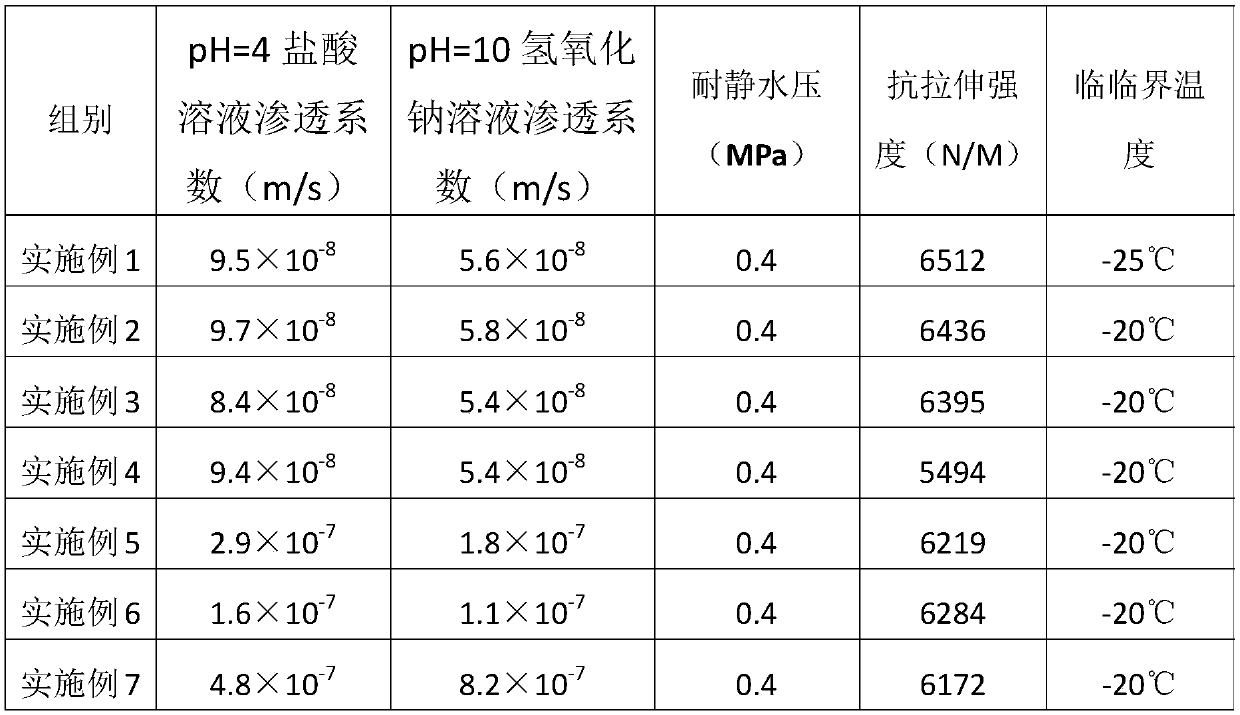

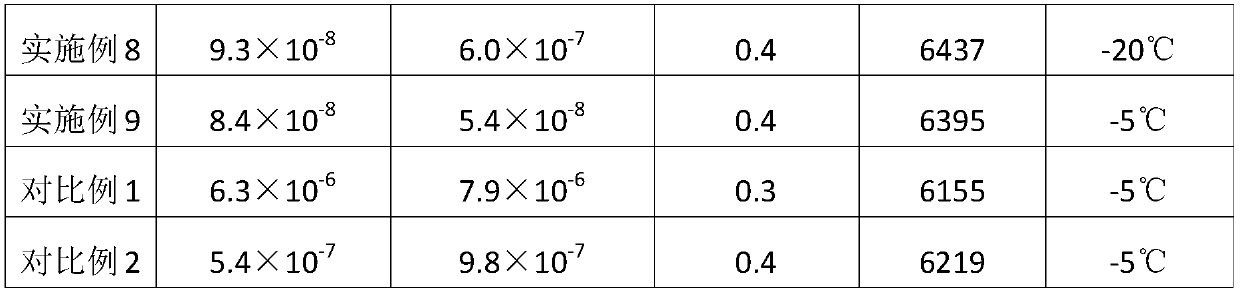

Examples

Embodiment 1

[0033] The frost-resistant high-corrosion prehydration mineral anti-seepage material of this embodiment is composed of a basalt fiber layer, a mineral anti-seepage layer and an anti-seepage membrane arranged in sequence from top to bottom;

[0034] The basalt fiber layer is a grid-like material made of basalt fibers, and the inner layer is also attached with polyester filaments; the polyester filaments are attached to one side of the basalt fibers during the basalt weaving process, and the polyester filaments and basalt fibers The weight ratio is 1:10. The mass per unit area of the basalt fiber layer is 800g / m 2 ;

[0035] The mineral anti-seepage layer includes the following components: 40 parts by weight of bentonite; 30 parts by weight of kaolin; 6 parts by weight of high molecular polymer; 8 parts by weight of antifreeze; 60 parts by weight of water. The mass per unit area of the mineral anti-seepage layer is 2000g / m 2 ; Wherein, the bentonite is sodium ion bentonit...

Embodiment 2

[0041] The frost-resistant high-corrosion-resistant pre-hydrated mineral anti-seepage material of the present embodiment is composed of a basalt fiber layer, a mineral anti-seepage layer and an anti-seepage membrane that are arranged in sequence from top to bottom;

[0042] The basalt fiber layer is a grid-like material woven from basalt fibers, and the inner layer is also attached with polyester filaments; the polyester filaments are attached to one side of the basalt fibers during the basalt weaving process, and the polyester filaments are connected with the basalt fibers. The weight ratio is 1:15. The mass per unit area of the basalt fiber layer is 2000g / m 2 ;

[0043] The mineral impermeable layer includes the following components: 80 parts by weight of bentonite; 10 parts by weight of kaolin; 3 parts by weight of high molecular polymers; 5 parts by weight of antifreeze; and 40 parts by weight of water. The mass per unit area of the mineral impermeable layer is 3000g...

Embodiment 3

[0050] The frost-resistant high-corrosion-resistant pre-hydrated mineral anti-seepage material of the present embodiment is composed of a basalt fiber layer, a mineral anti-seepage layer and an anti-seepage membrane that are arranged in sequence from top to bottom;

[0051] The basalt fiber layer is a grid-like material woven from basalt fibers, and the inner layer is also attached with polyester filaments; the polyester filaments are attached to one side of the basalt fibers during the basalt weaving process, and the polyester filaments are connected with the basalt fibers. The weight ratio is 1:20. The mass per unit area of the basalt fiber layer is 1400g / m 2 ;

[0052] The mineral impermeable layer includes the following components: 60 parts by weight of bentonite; 20 parts by weight of kaolin; 10 parts by weight of high molecular polymers; 10 parts by weight of antifreeze; and 20 parts by weight of water. The mass per unit area of the mineral impermeable layer is 400...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com