Preparation method of paper pulp molded tableware

A pulp molding and preparation process technology, applied in textiles and papermaking, etc., can solve the problems of undisclosed pulp ratio and specific process conditions, insufficient tensile strength and tear resistance, and easy mildew of pulp molded tableware. and other problems, to achieve the effect of reducing moisture absorption and mildew, improving product qualification rate and not easy to tear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

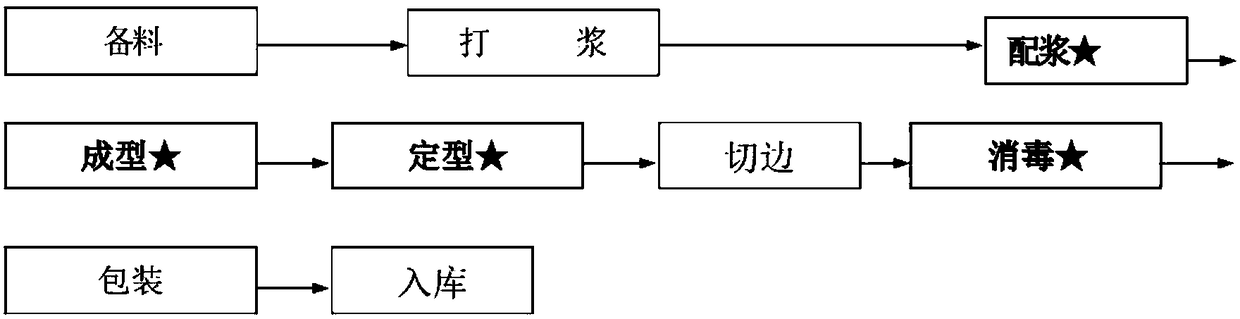

Method used

Image

Examples

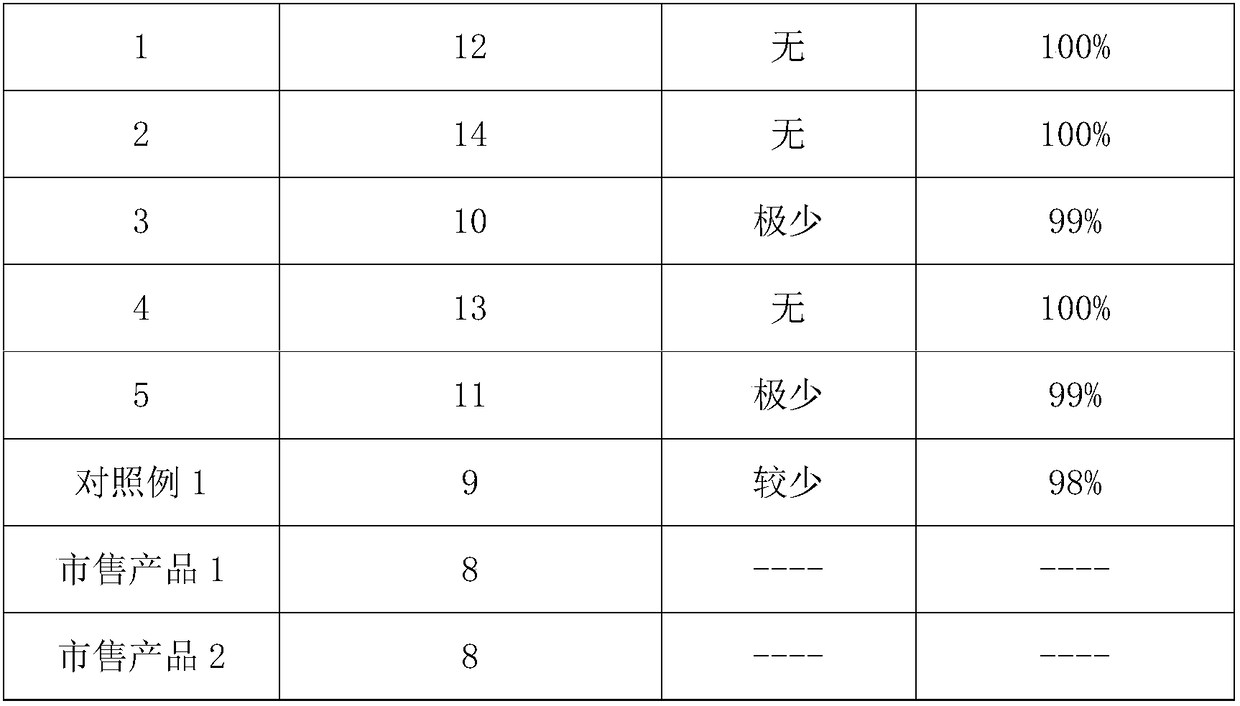

Embodiment 1

[0065] The key control point conditions are: according to the weight ratio, oil repellent: pulp = 0.40: 100; waterproof agent: pulp = 3.7: 100; wet strength agent: pulp = 3.2: 100; modified starch: pulp = 2.0: 100; forming Conditions: vacuum degree 0.07MPa; shaping conditions: time 30s, temperature 170°C, air pressure 0.3MPa.

Embodiment 2

[0067] The key control point conditions are: oil repellent: pulp = 0.44:100; waterproofing agent: pulp = 4.0:100; wet strength agent: pulp = 3.0:100; modified starch: pulp = 2.0:100; molding conditions: vacuum 0.04MPa; shaping conditions: time 50s, temperature 180°C, air pressure 0.5MPa.

Embodiment 3

[0069] The key control point conditions are: oil repellant: pulp = 0.43:100; waterproofing agent: pulp = 3.8:100; wet strength agent: pulp = 3.4:100; modified starch: pulp = 1.8:100; molding conditions: vacuum 0.05MPa; setting conditions: time 70s, temperature 160 ℃, air pressure 0.5MPa.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com