Hot-melting glue-spraying type processing technique of geosynthetic clay liner

A bentonite waterproof blanket and processing technology, which is applied to layered products, lamination devices, lamination, etc., can solve the problems of low peel strength affecting the anti-seepage effect of the waterproof blanket, and achieve the goal of not easy to scatter and lose, high peel strength, The effect of smooth appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

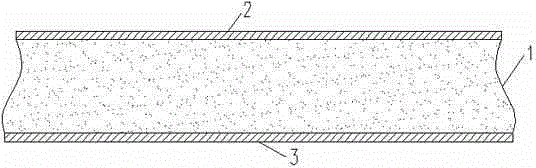

[0021] A processing technology of a hot-melt glue-sprayed bentonite waterproof blanket, which is characterized in that the raw materials are woven geotextiles, bentonite and non-woven geotextiles, and the woven geotextiles are plastic flat yarn woven geotextiles or filament woven geotextiles; Non-woven geotextiles are polyester needle-punched non-woven geotextiles or polypropylene needle-punched non-woven geotextiles. The specific processing steps are as follows:

[0022] (1) Unwinding, the woven geotextile and non-woven geotextile are laid flat by the unwinding device;

[0023] (2) Spread the bentonite, evenly spread the bentonite between the woven geotextile and the non-woven geotextile, and compact it;

[0024] (3) Composite acupuncture, through mechanical acupuncture technology, the upper layer of woven geotextile, bentonite, and the lower layer of non-woven geotextile are tightly compounded;

[0025] (4) Hot-melt, through the hot-melt shaping of the hot roller, the fiber...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com