Structure reinforced cable duct module

A kind of cable ducting and reinforced technology, applied in cable installation, cable installation in underground pipes, electrical components, etc., can solve the problems of long construction period, affecting people's daily life, complicated connection methods, etc., to improve the bearing capacity performance and overall stiffness, improved joint mechanical properties, and the effect of simplifying the design process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

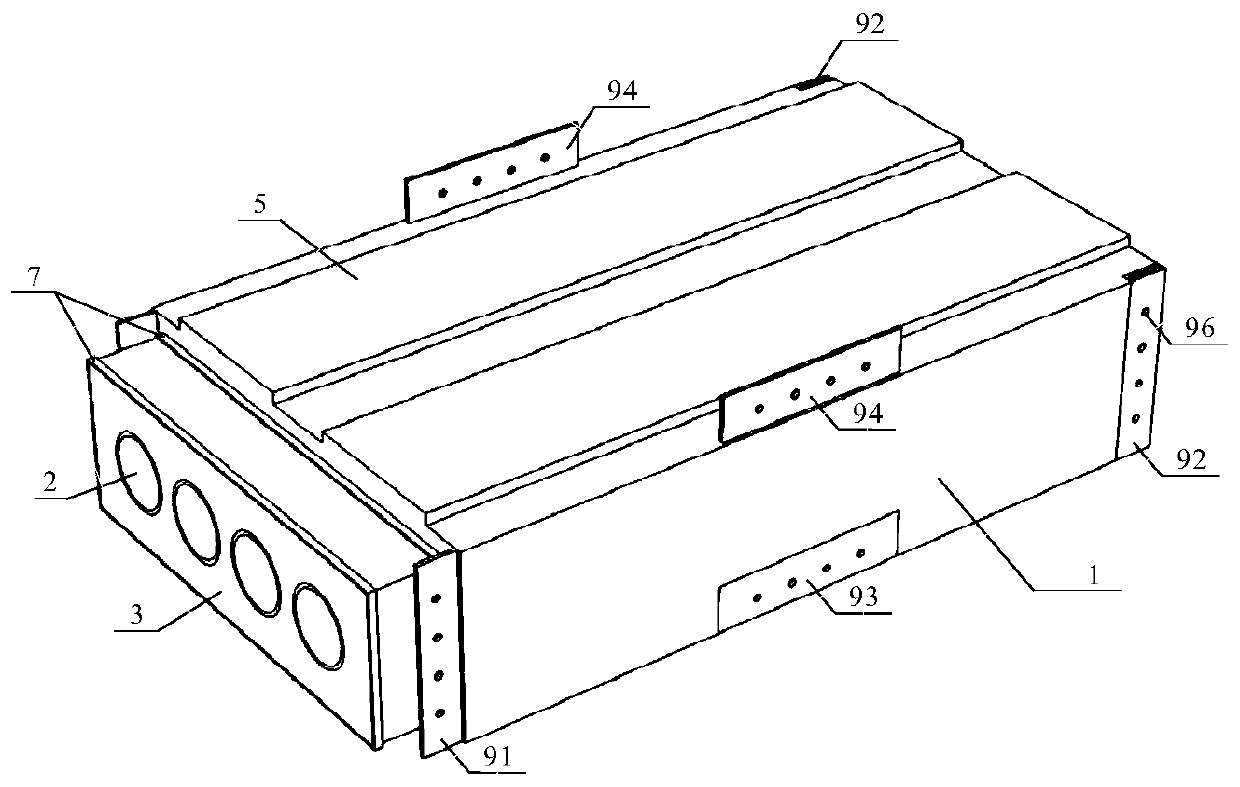

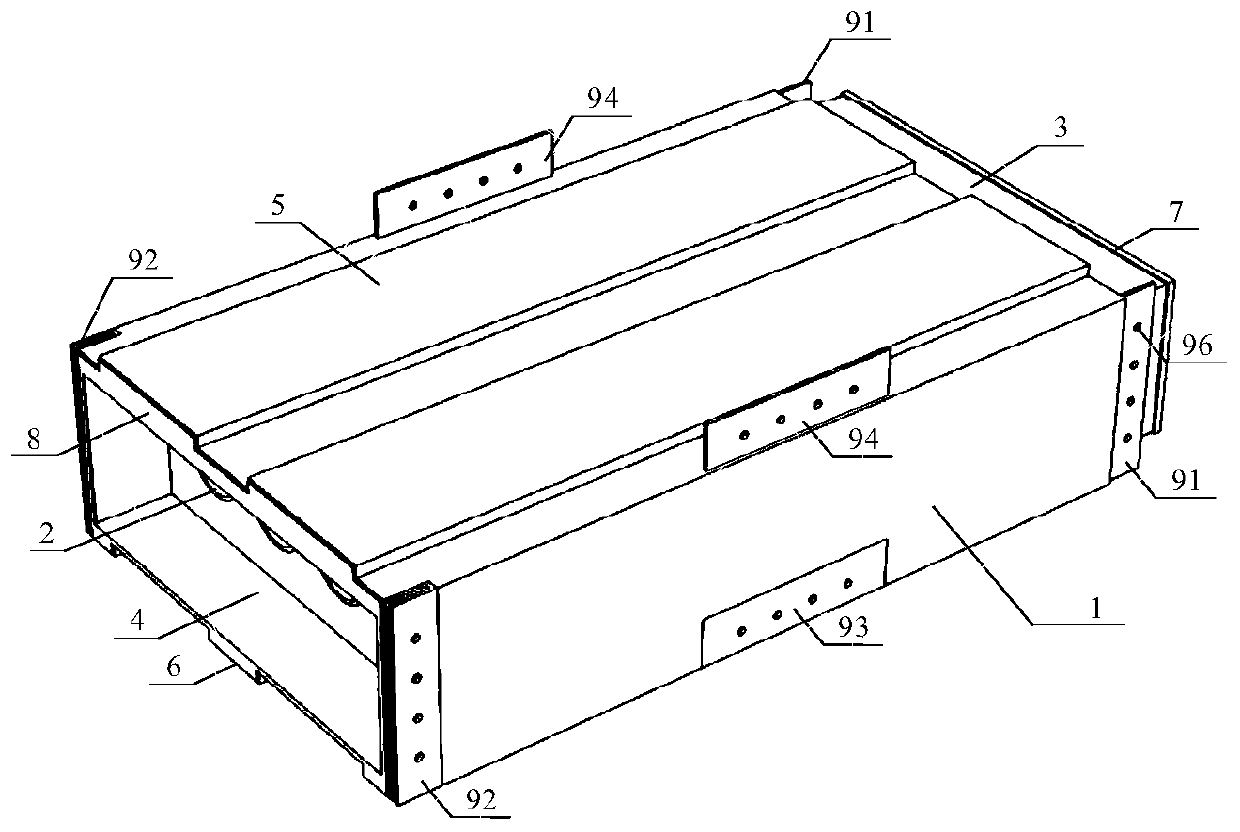

[0034] Such as Figure 1~2 As shown, it is a structure-reinforced cable conduit module of the present invention. The cable conduit module 1 is a prefabricated structure as a whole, and a power cable conduit 2 is provided inside for cables to pass through. The specific value of the pipe diameter can be determined according to the actual line and cable conditions. Other types of piping such as communication can be laid.

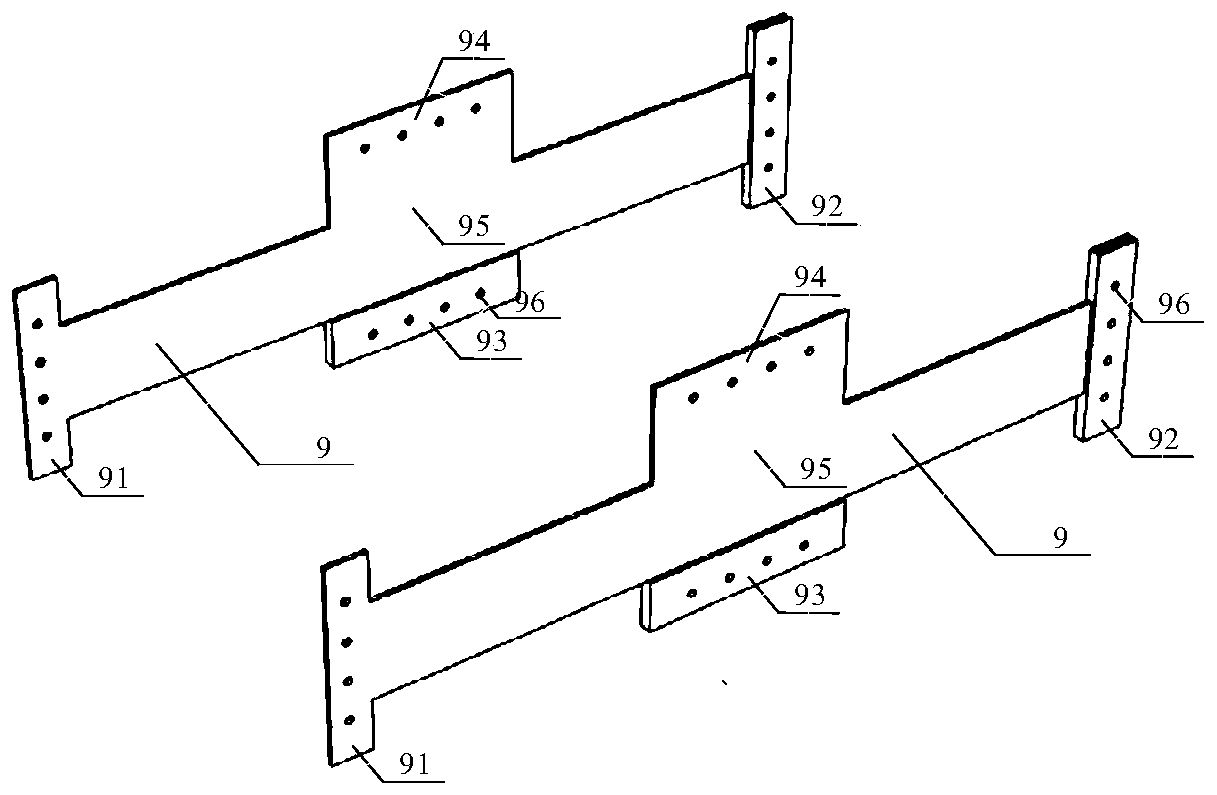

[0035] Such as Figure 1~6 As shown, the longitudinal front end of the cable pipe module 1 is provided with a socket 3, and two sealing waterproof rubber rings 7 are arranged on the socket 3 to ensure the waterproof and anti-seepage performance at the pipe joint; A socket 4 matching the socket 3 is set at the end of the socket 4, and a layer of anti-collision rubber pad 8 is arranged on the outermost side of the socket 4 to prevent damage to the pipe structure caused by the collision of the joint during the socket lap construction; The pipe arrangement with m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com