Rapid construction method for prevention seepage integrating vibrating-jetting with controlled cement grouting

A technology of cement grouting and construction method, applied in water conservancy engineering, infrastructure engineering, marine engineering and other directions, can solve the problems of difficult to guarantee construction quality, large equipment investment, long construction period, etc., to reduce construction costs, speed up construction progress, The effect of reducing the cost per item

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The construction steps of the present invention are as follows:

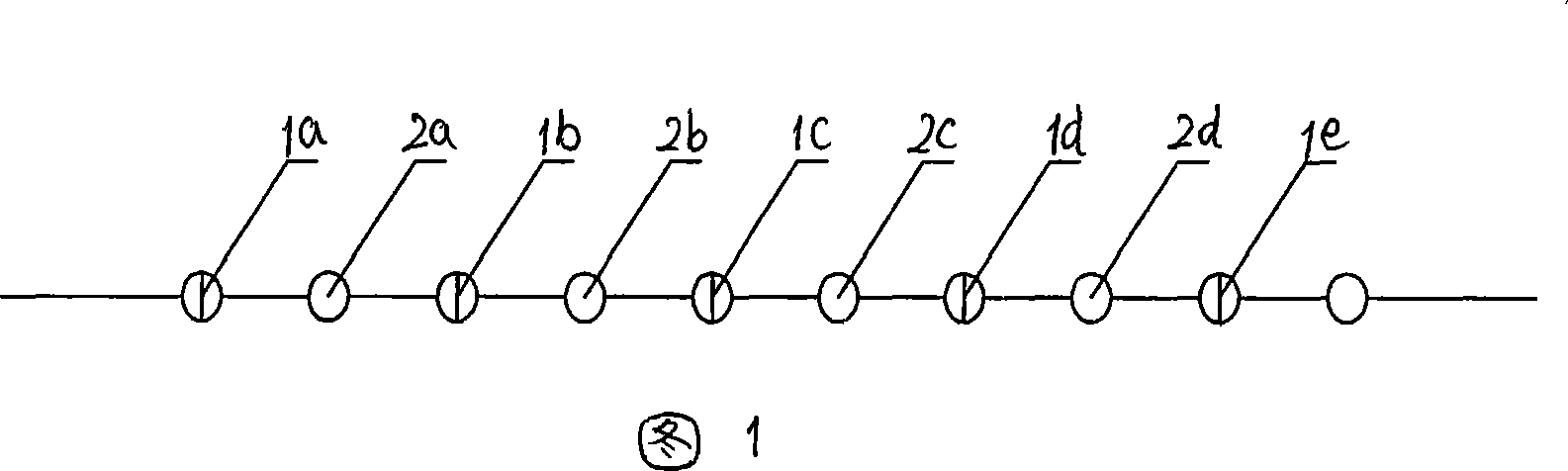

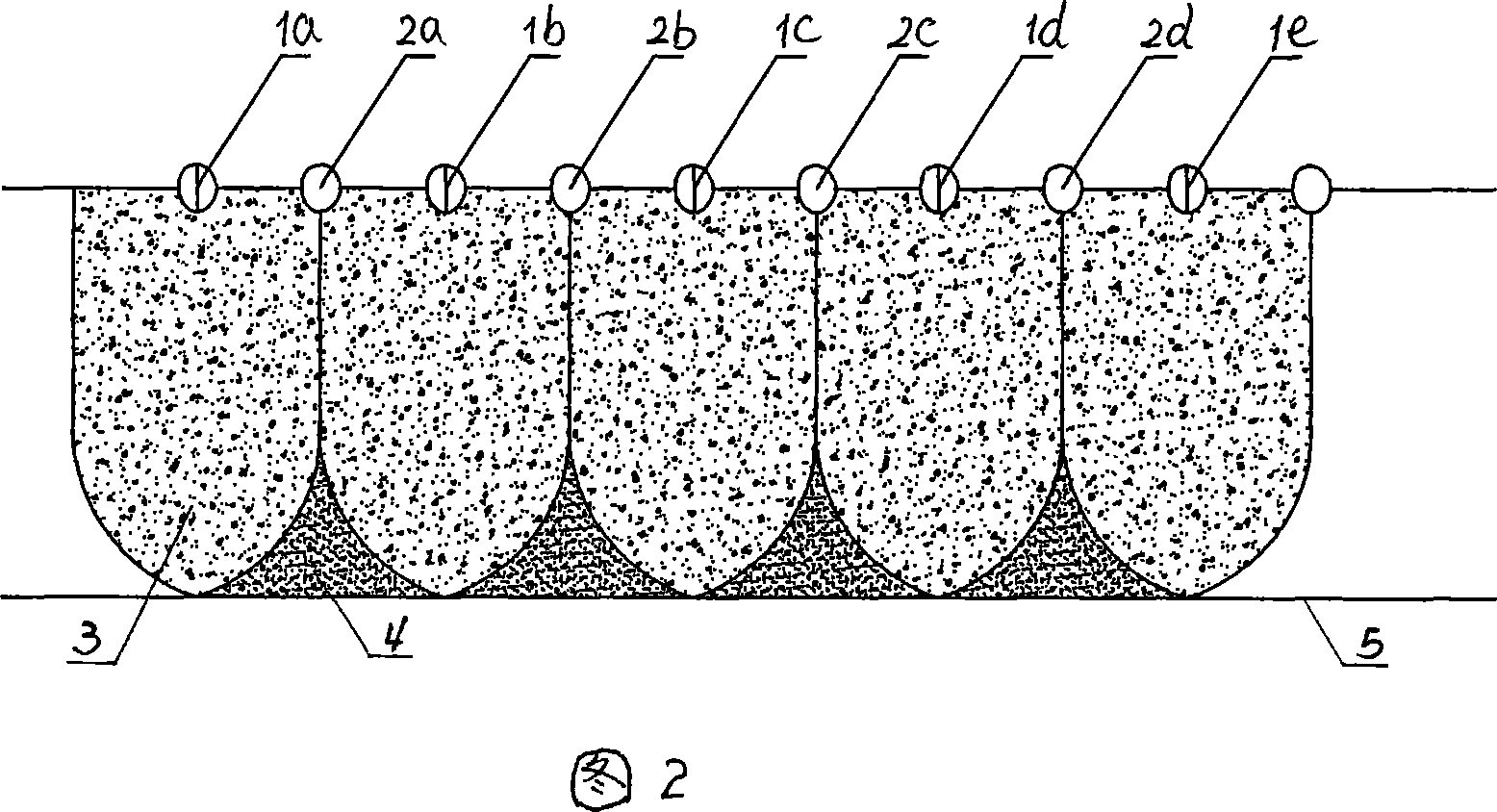

[0024] a. Use a drilling rig to make holes at equal intervals along the center line of the anti-seepage wall to be built, and form an anti-seepage body with a single row of holes, the hole distance is 1-1.25m, and the vibro-jet holes and control cement grouting holes are located in the above-mentioned single row of holes In the form of one-by-one interval arrangement (that is, the vibro-jet holes are drilled first);

[0025] b. According to the anti-seepage bottom line determined by the design, first perform high-pressure jet grouting on all the vibro-jetting holes; form a high-pressure jet grouting body at the position of the vibrating jet holes;

[0026] c. After the construction of the vibrating spray holes on both sides is completed, then drill holes in the controlled cement grouting holes, and then pour the admixture into the concrete according to a specific ratio (the ratio of cement slurry to quick...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com