Patents

Literature

32results about How to "Avoid the impact of construction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

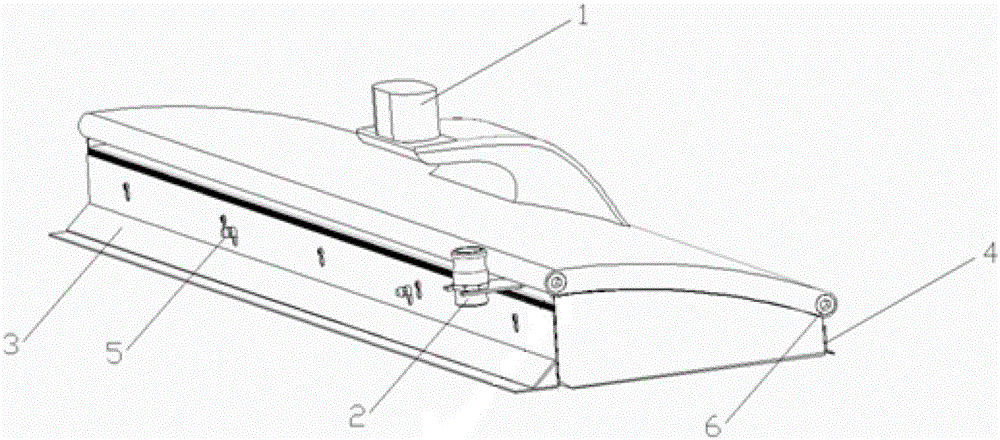

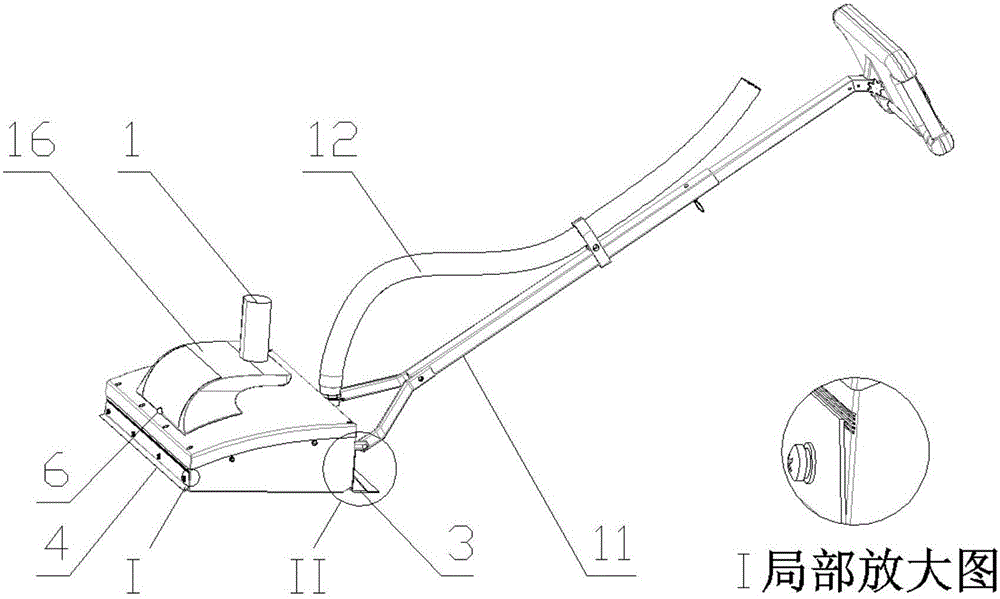

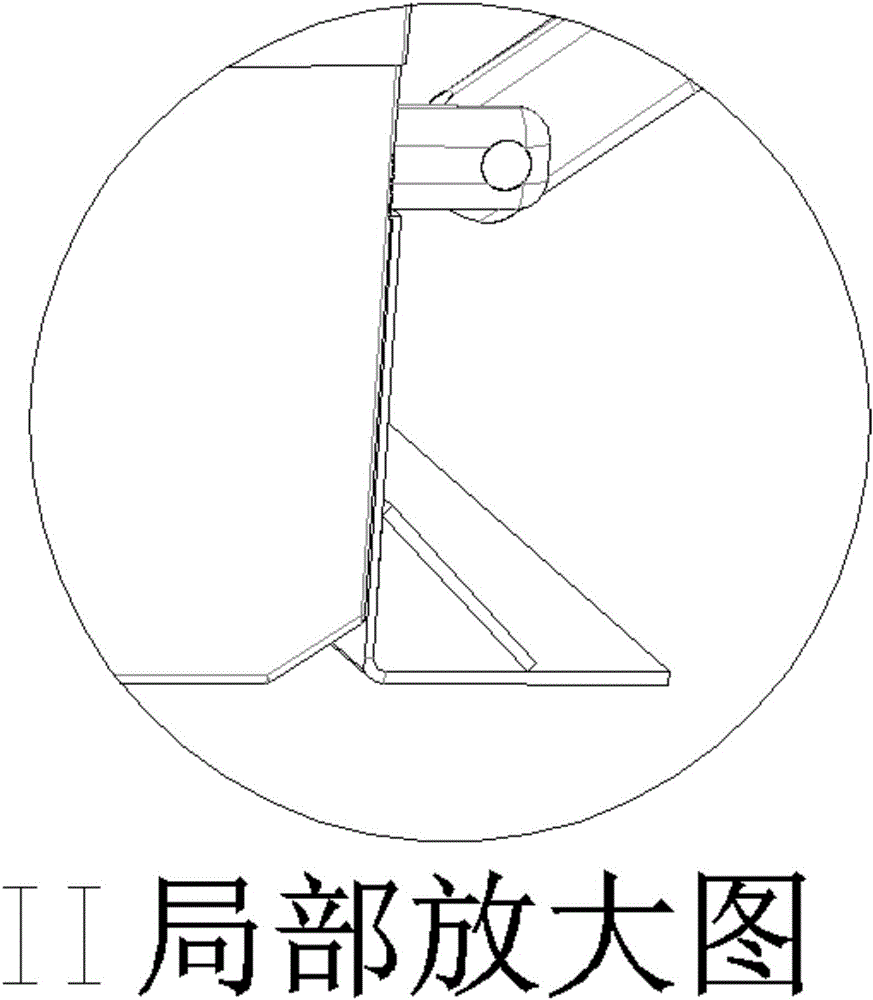

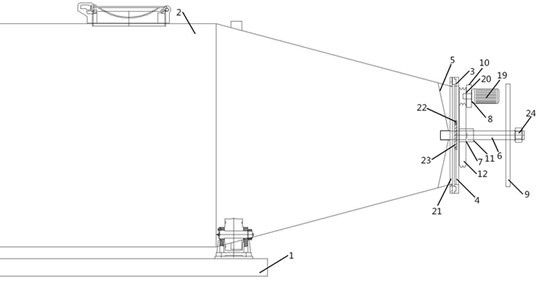

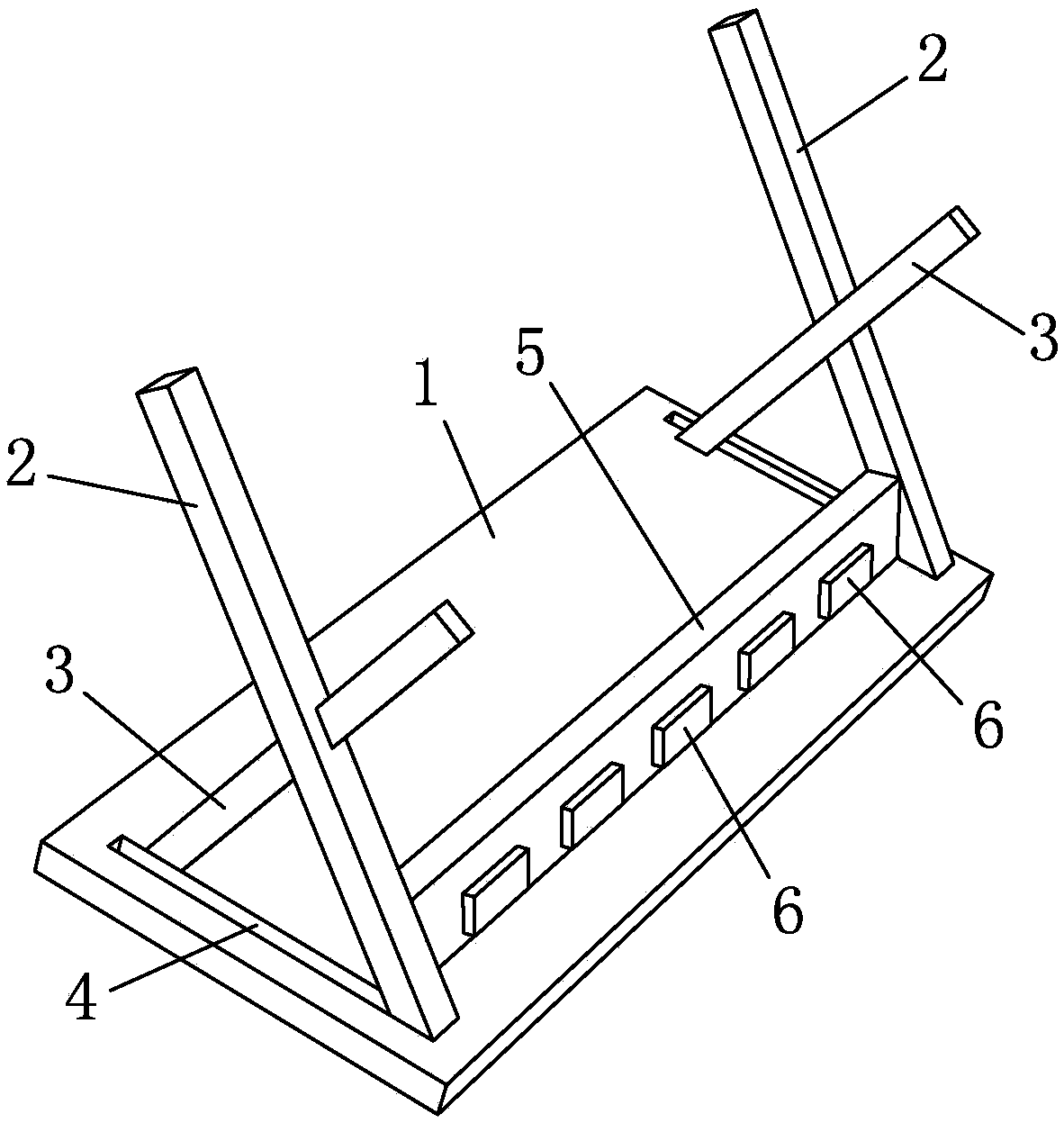

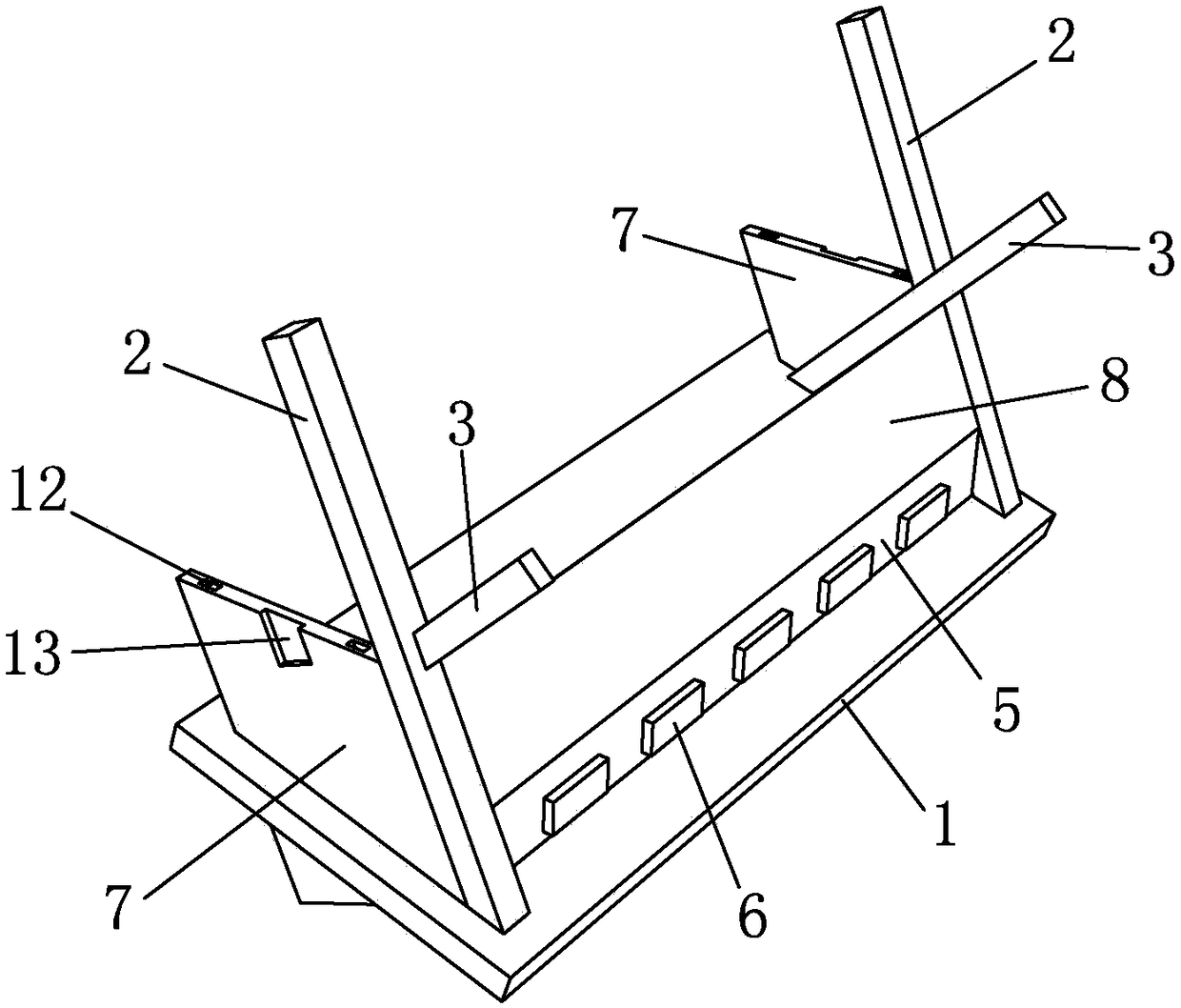

Intelligent ground leveling machine and leveling method thereof

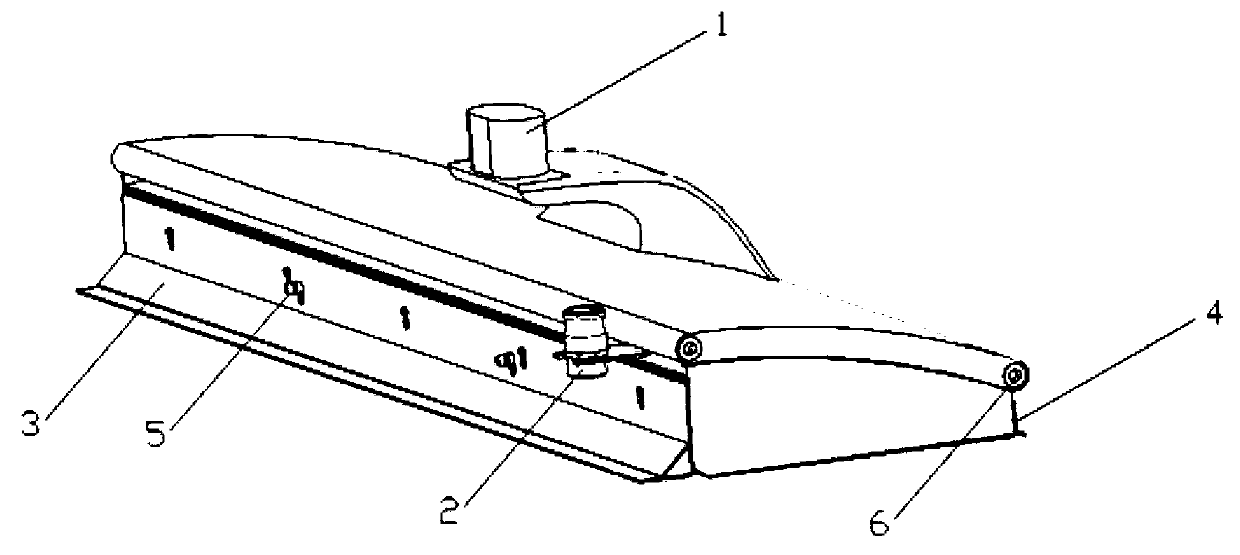

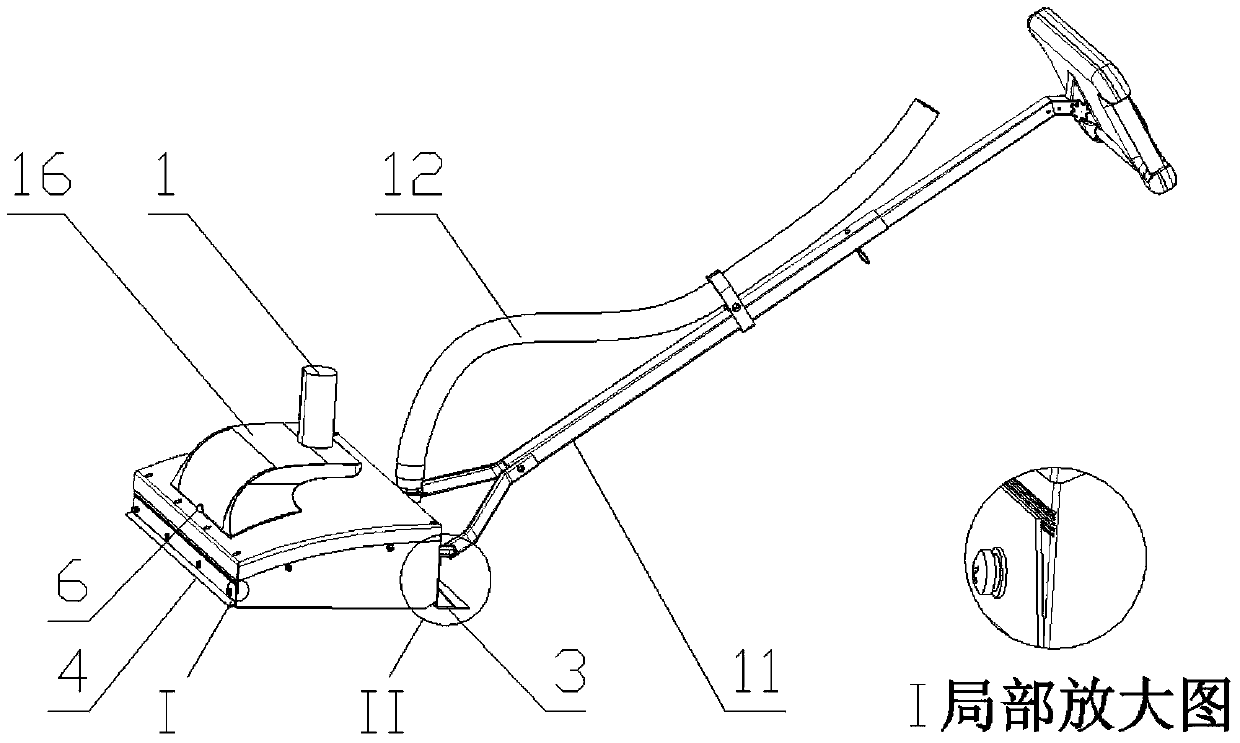

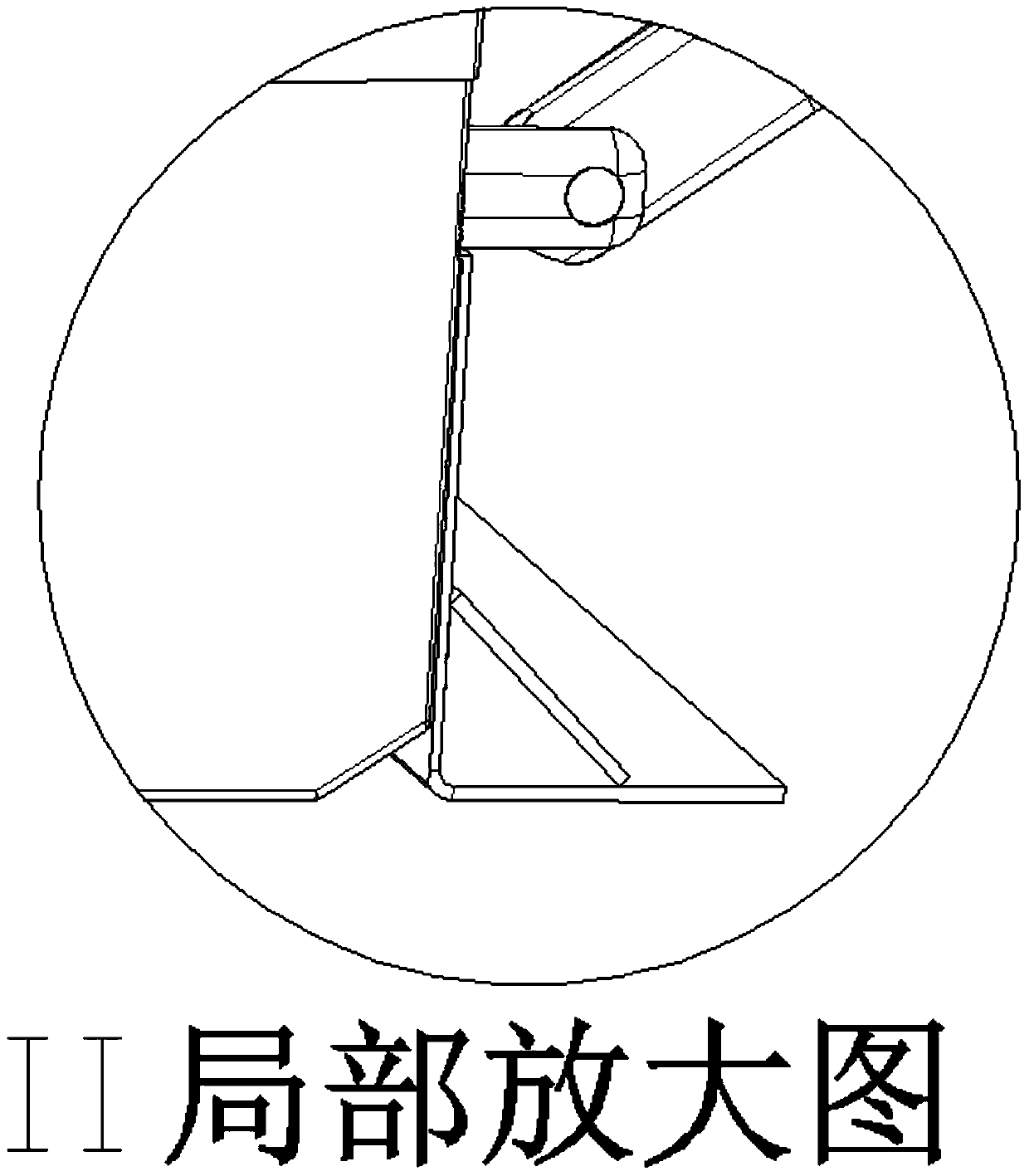

The invention discloses an intelligent ground leveling machine and a leveling method thereof. The intelligent ground leveling machine comprises a leveling machine main body, a laser receiving device, a spouting head, a stopping plate, a plurality of leveling regions, a scraping plate, a sensor and a control system. The upper limitation of the working of the leveling machine is limited by the laser receiving device, an inclined angle of the working of the leveling machine is monitored by utilizing the sensor and working parameters of the leveling machine are adjusted in real time by controlling a plurality of leveling regions through the control system, so that the leveling working in a relatively small area can be realized. The intelligent ground leveling machine has the advantages of small equipment structure, light weight of the whole leveling machine, high precision, energy saving and environmental friendliness and convenience for utilization.

Owner:浙江百施通智能科技有限公司

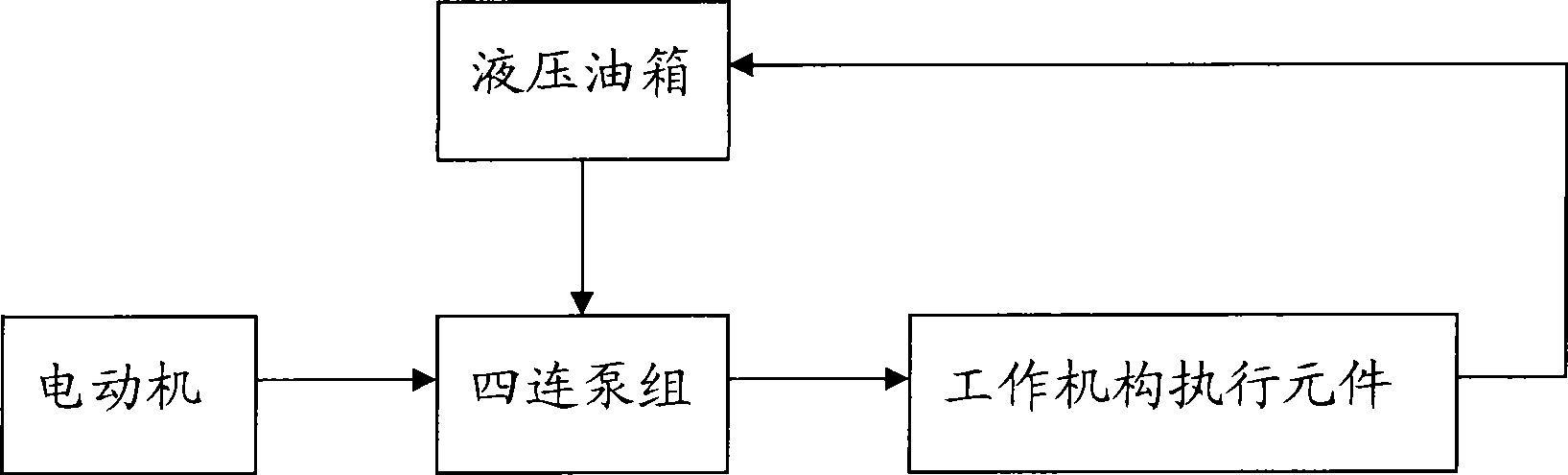

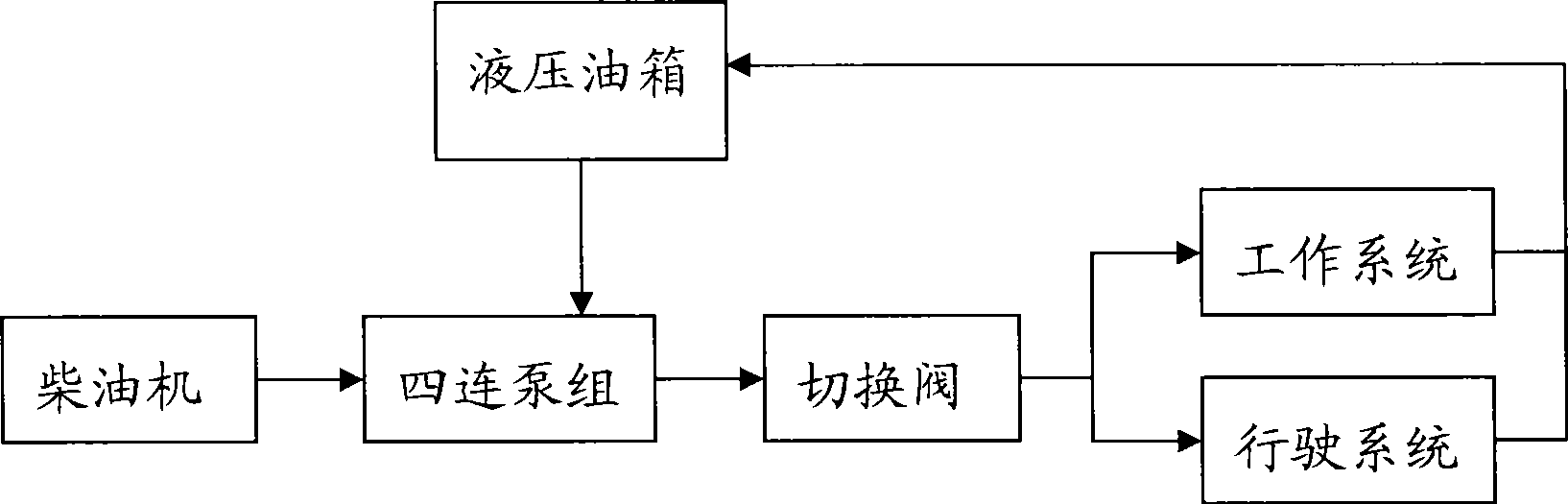

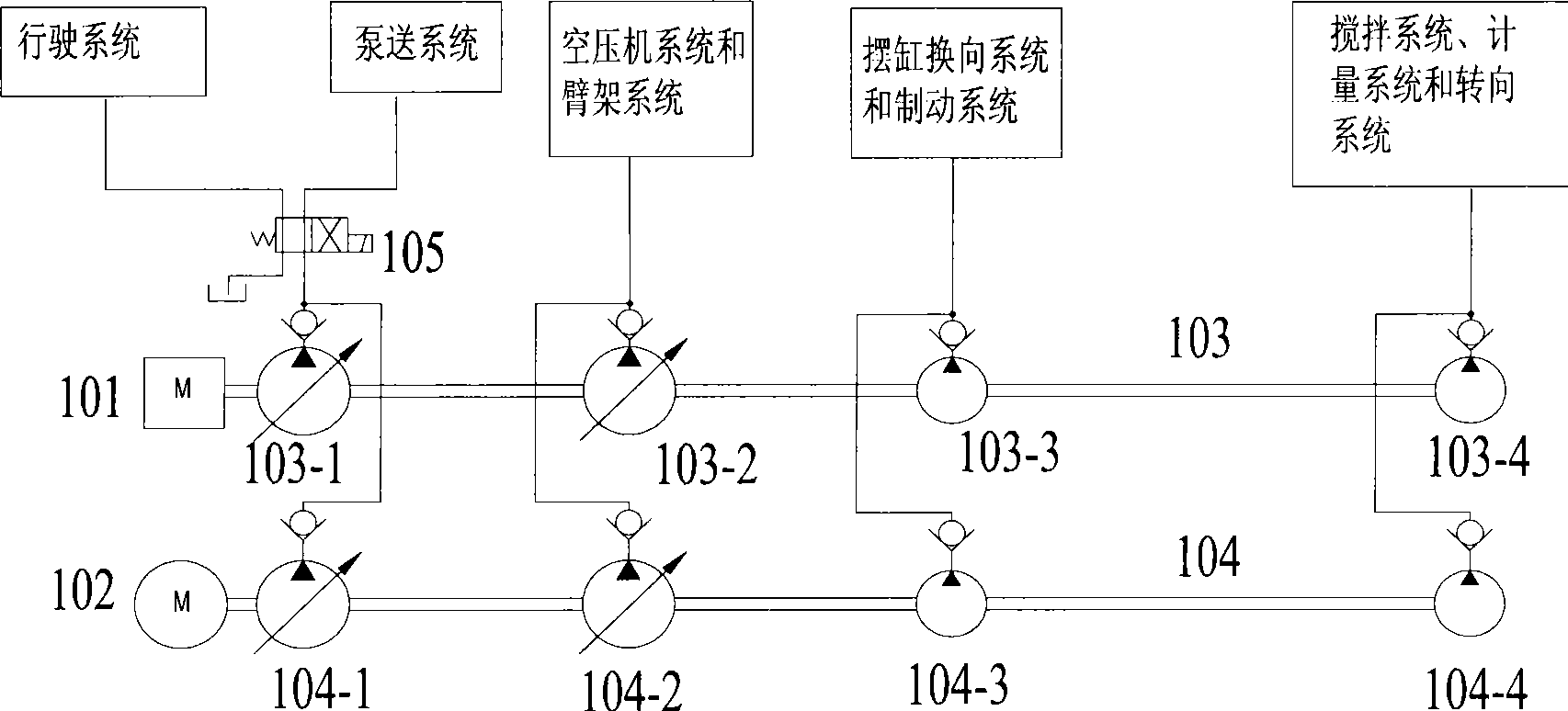

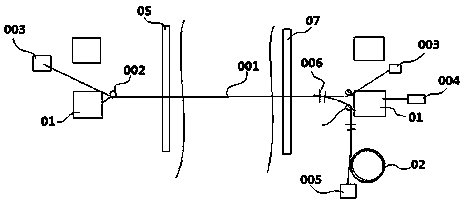

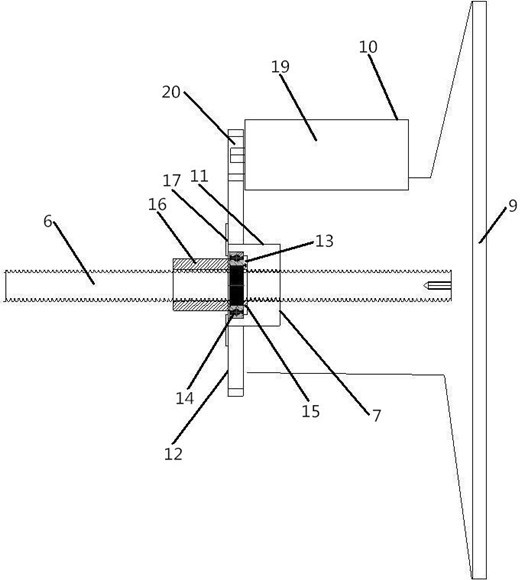

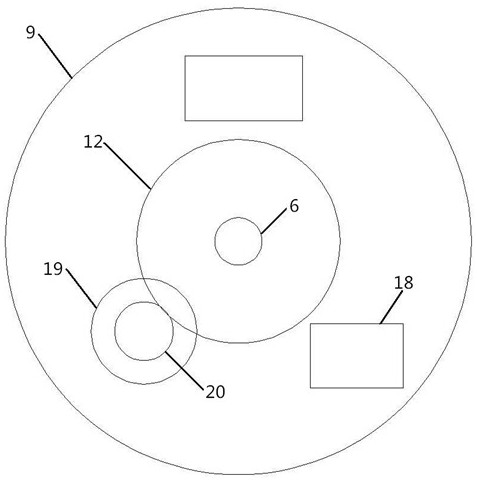

Power drive apparatus for concrete wet sprayer and concrete wet sprayer

ActiveCN101387158AEmission reductionReduce harmUnderground chambersBuilding material handlingSprayerFuel tank

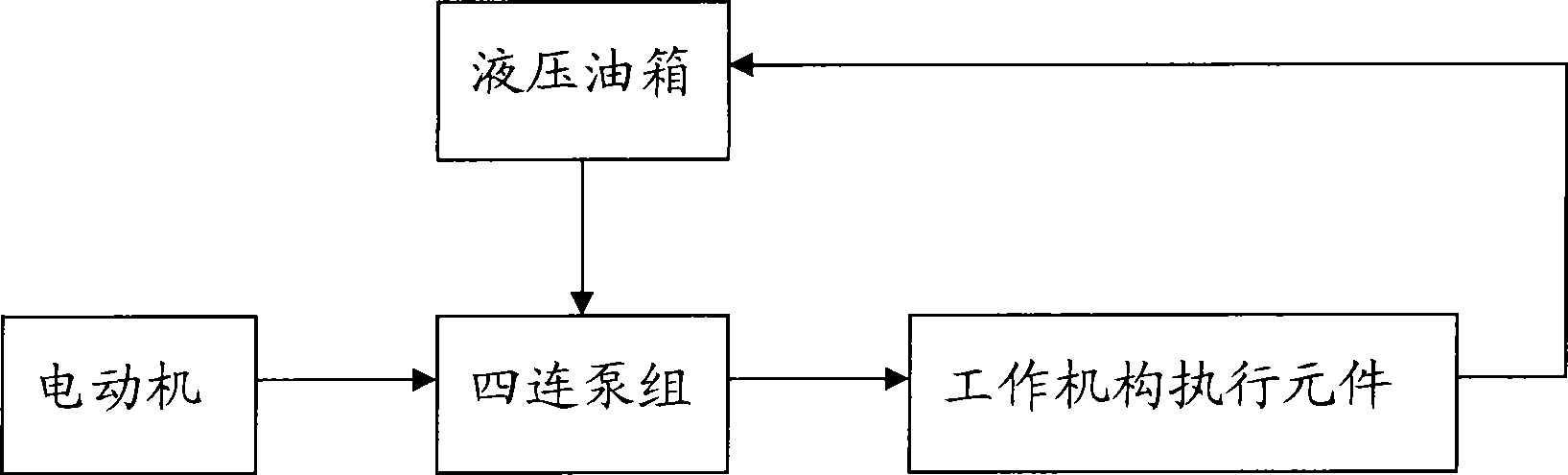

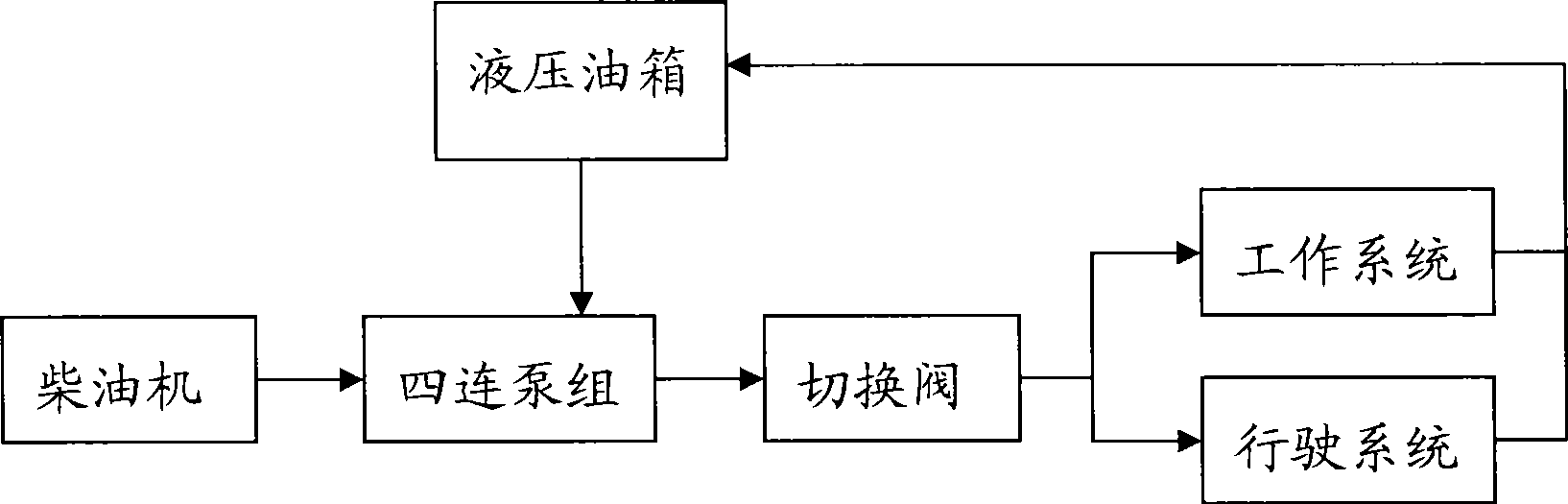

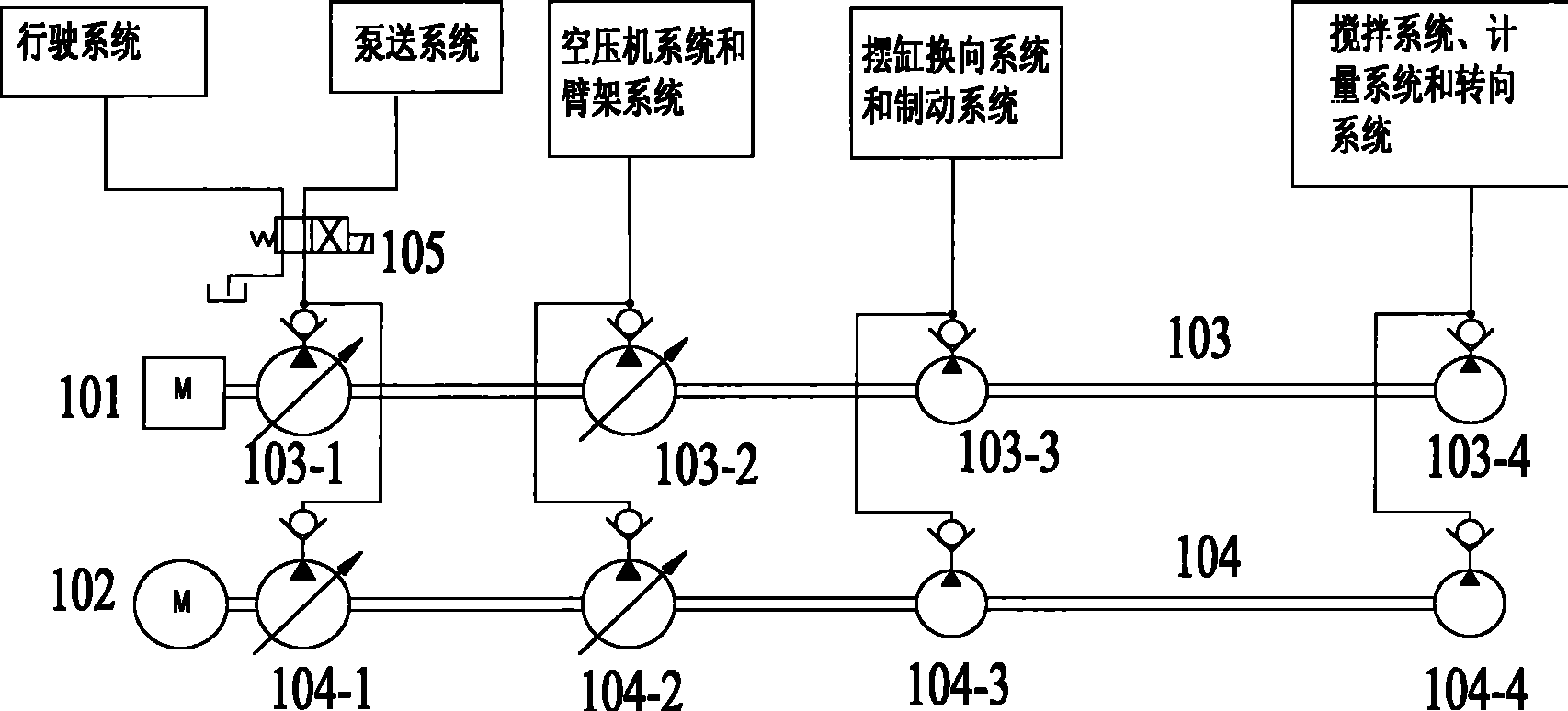

The invention relates to the technical field of concrete spraying and provides a power-driven device for a concrete wet spraying machine. The power-driven device for the concrete wet spraying machine is used for driving a work system and a running system, and comprises a motor, an engine, a hydraulic oil tank, a first four-link pump package, a second four-link pump package and a changeover valve. The power-driven device for the concrete wet spraying machine adopts the motor and the engine for double-power drive; when the concrete wet spraying machine is operated in a tunnel, the motor can be adopted for driving the work system to operate, thereby reducing emission of exhaust gas such as carbon dioxide and so on and reducing the harm of the exhaust gas on the body health of construction workers; under the condition of no power supplied, the concrete wet spraying machine can also adopt the diesel engine for driving the work system to operate, thereby avoiding the influence of conditions such as power failure or inconvenient power access, etc. on the construction, so as to make the engineering construction smoothly performed under a plurality of operating conditions. The invention also provides the concrete wet spraying machine.

Owner:SANY AUTOMOBILE MFG CO LTD

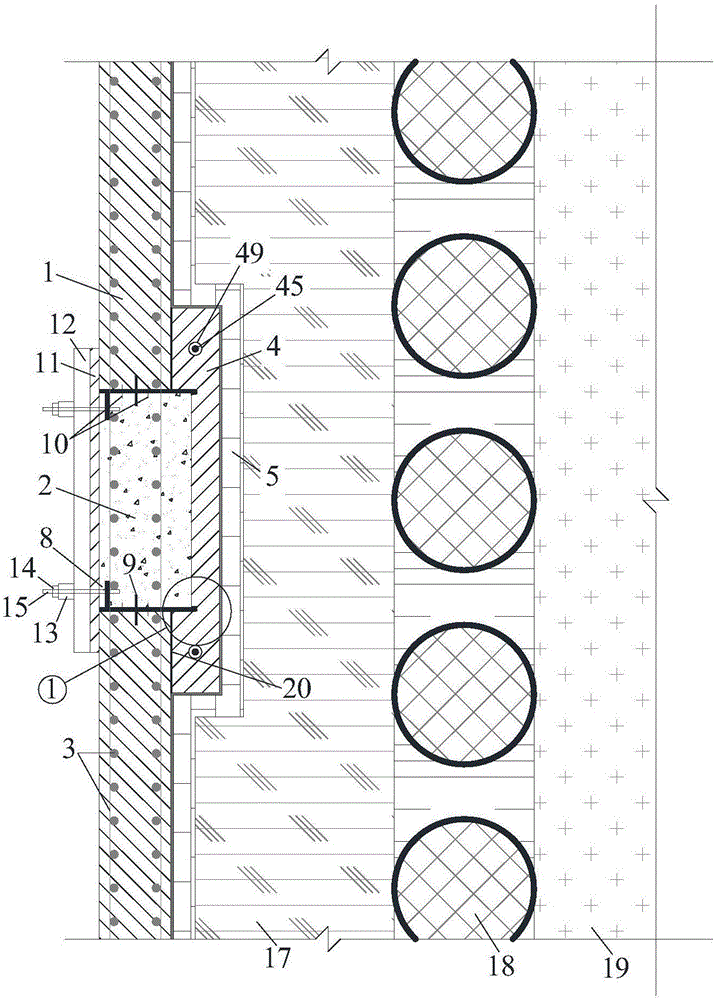

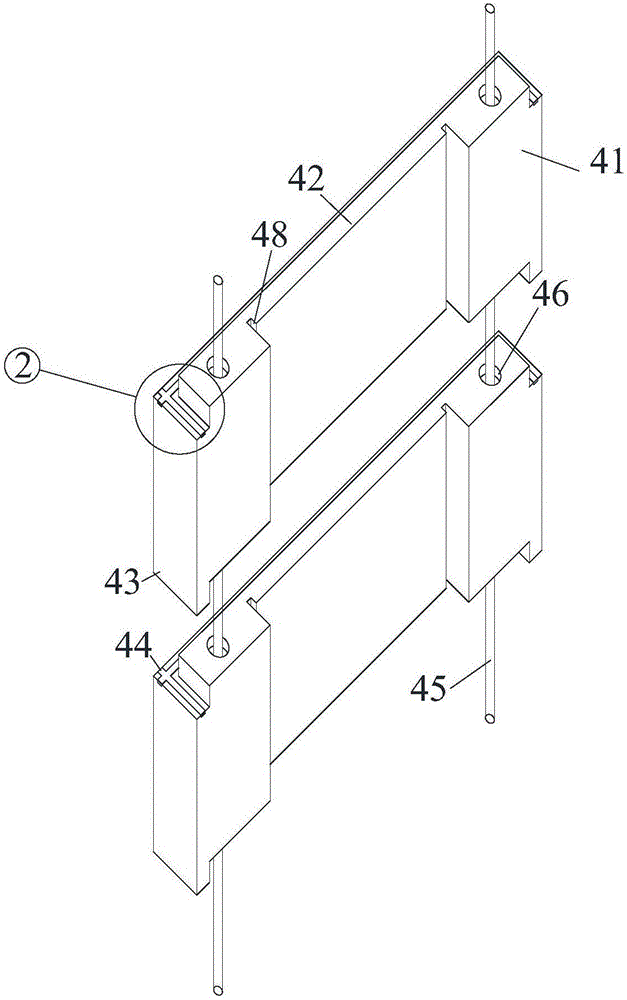

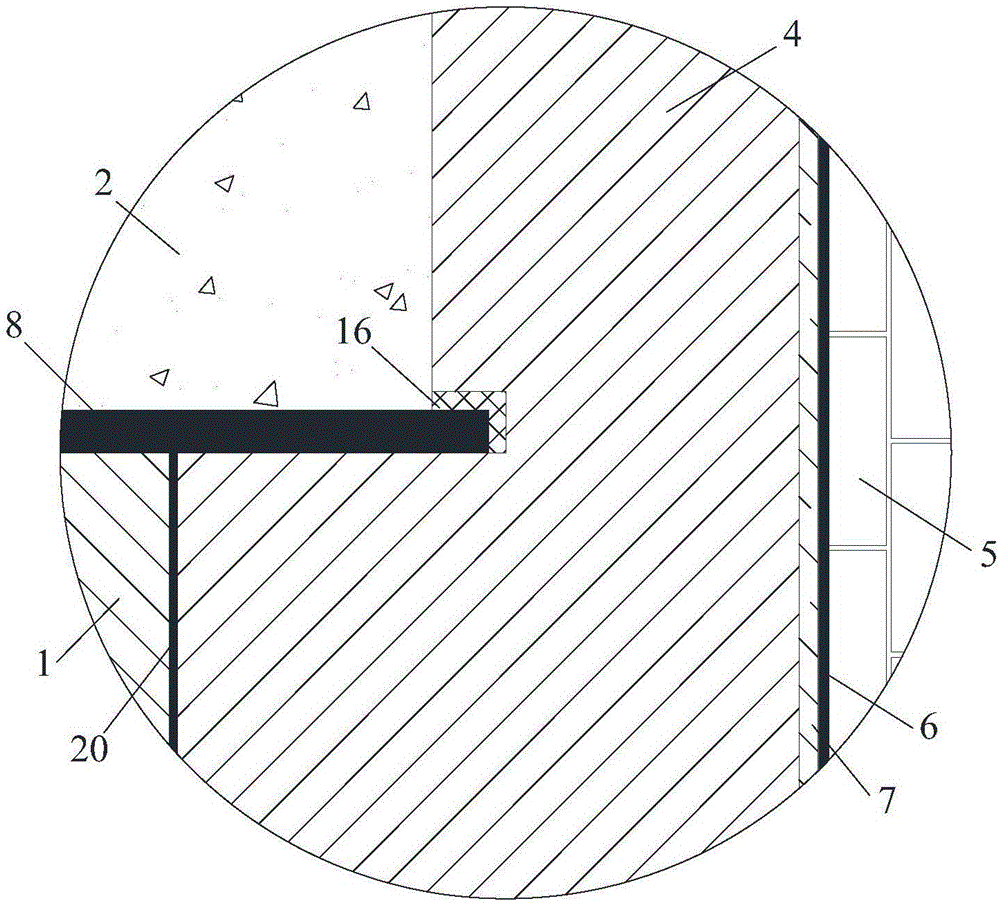

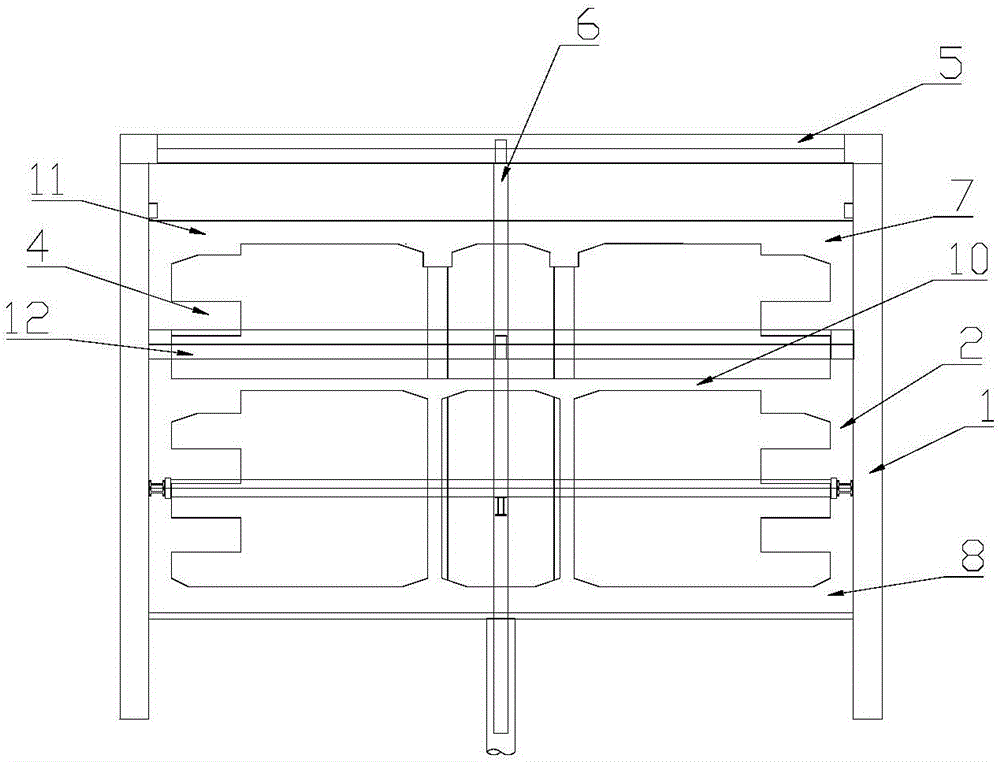

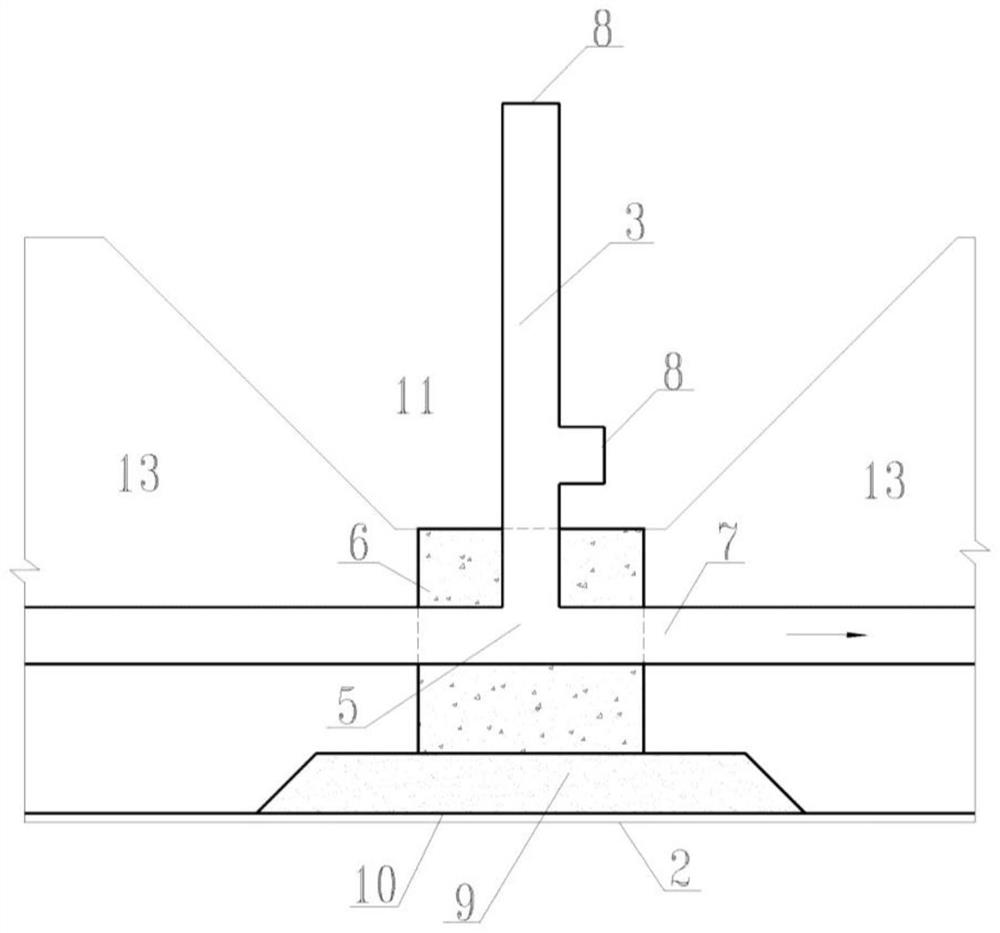

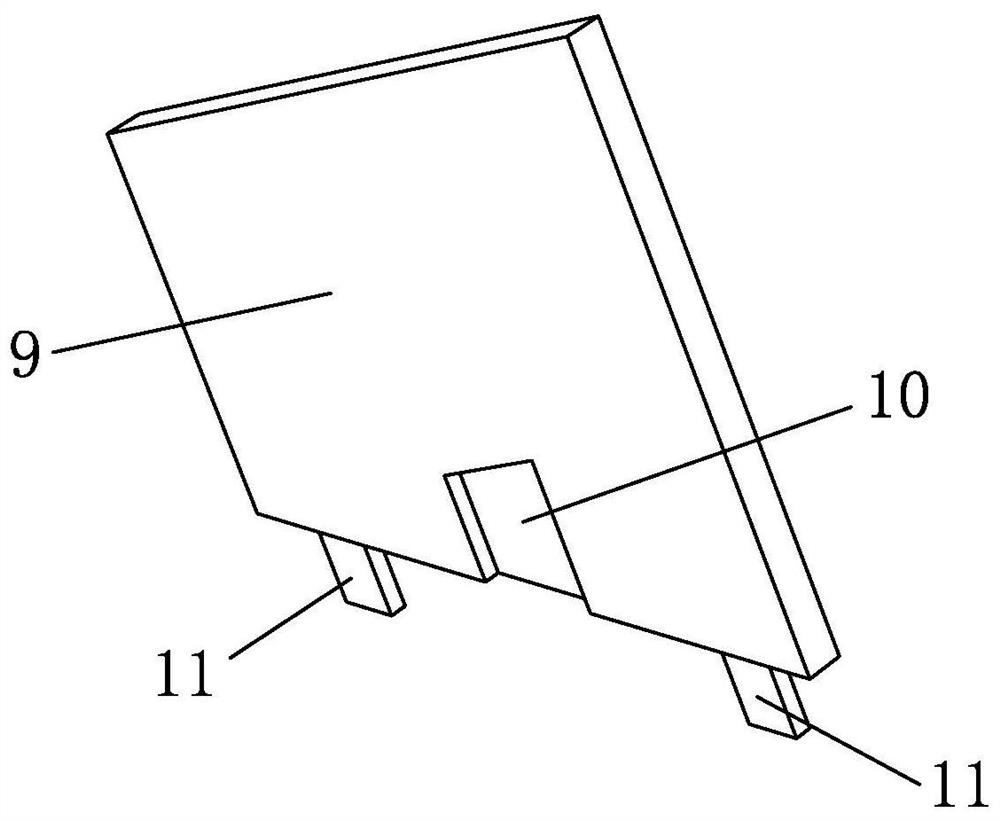

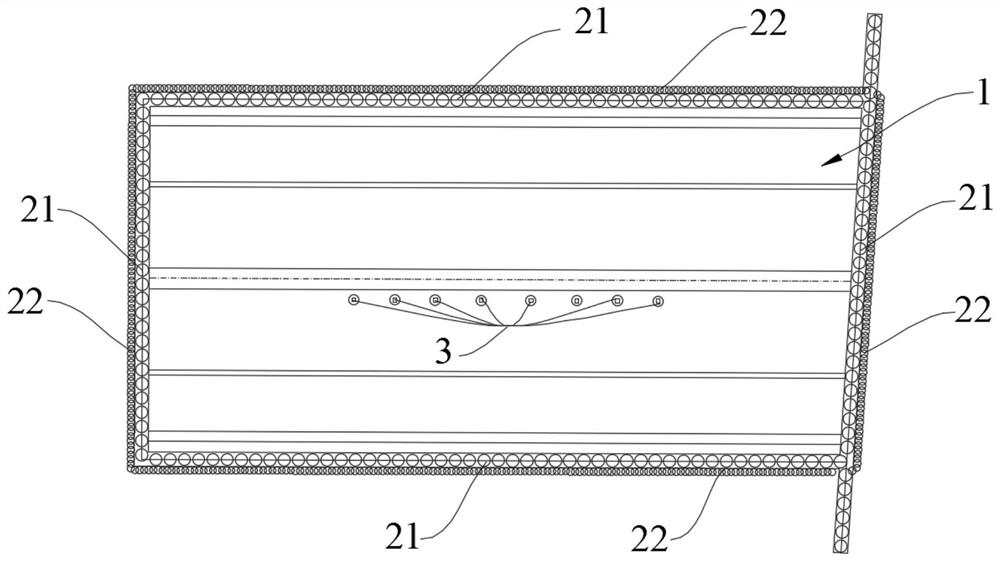

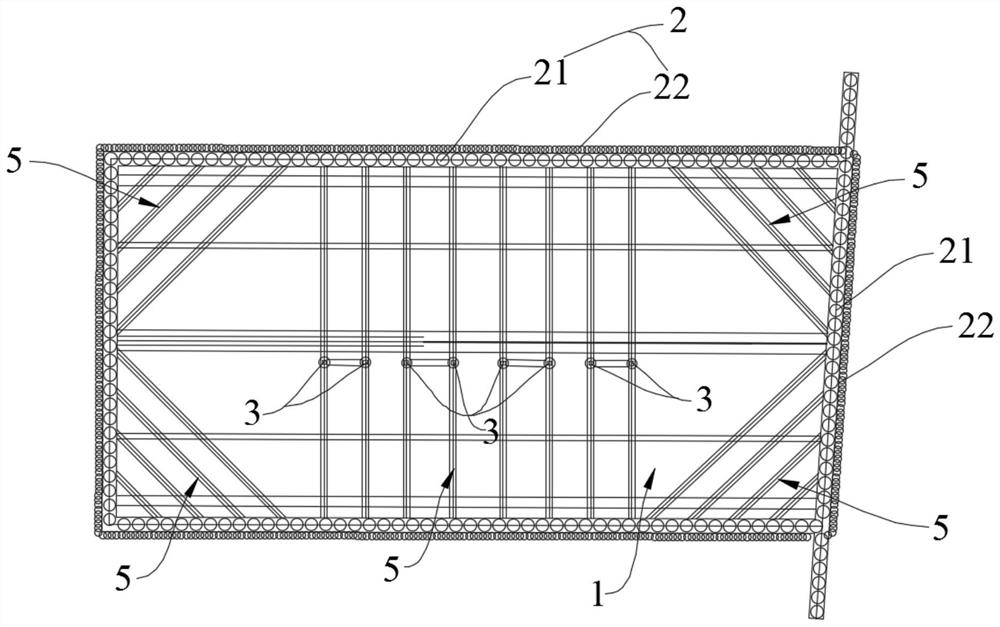

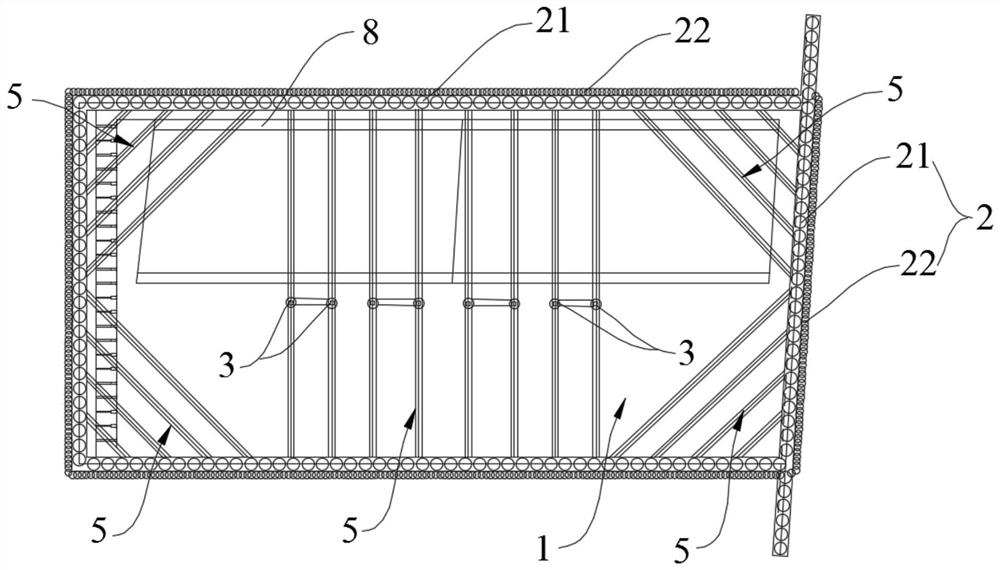

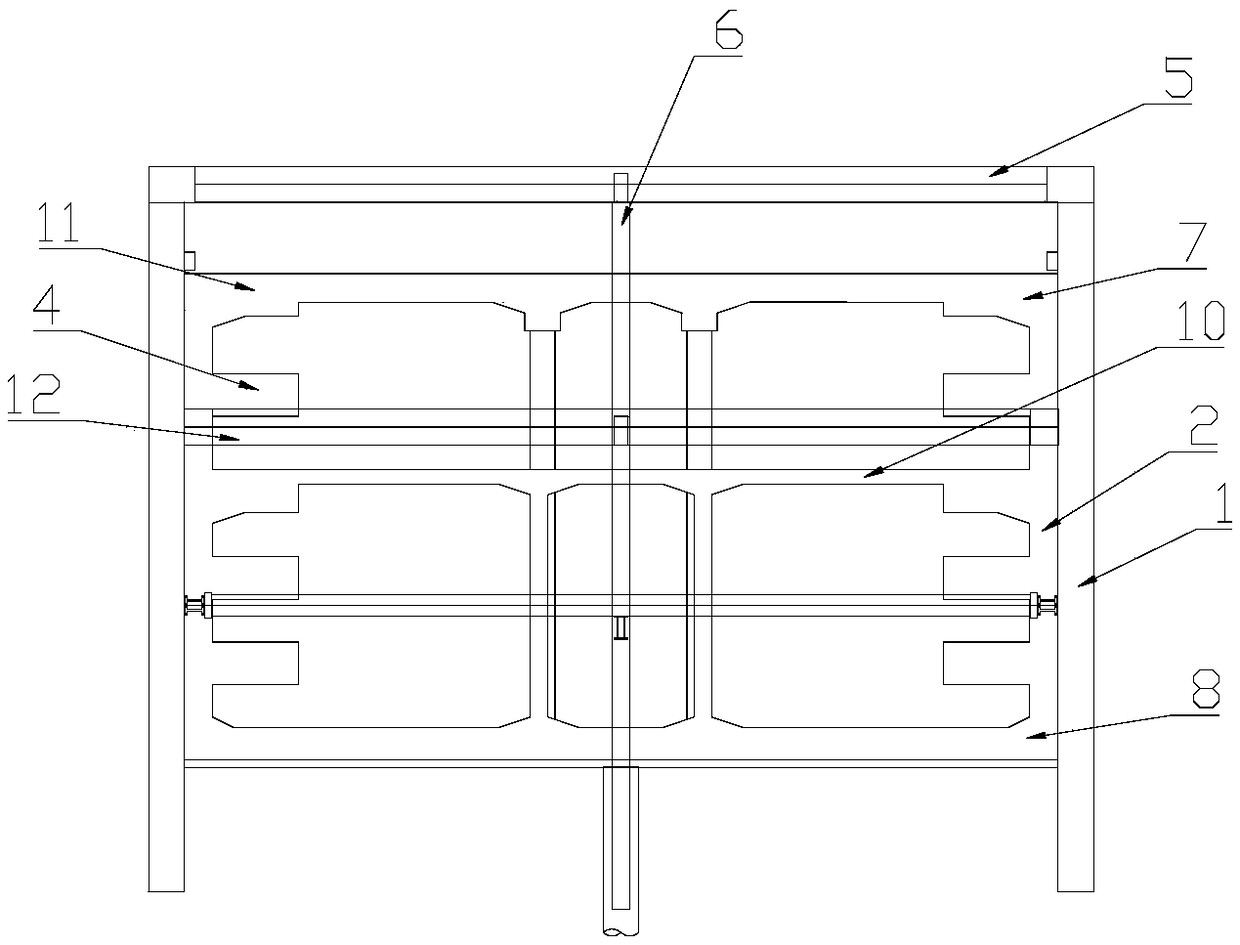

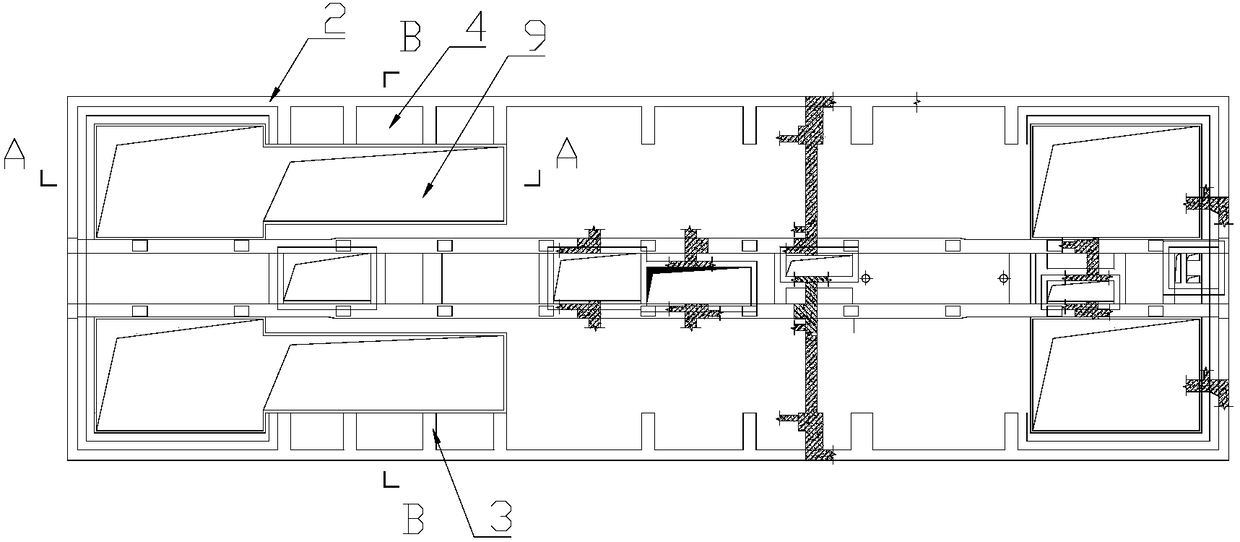

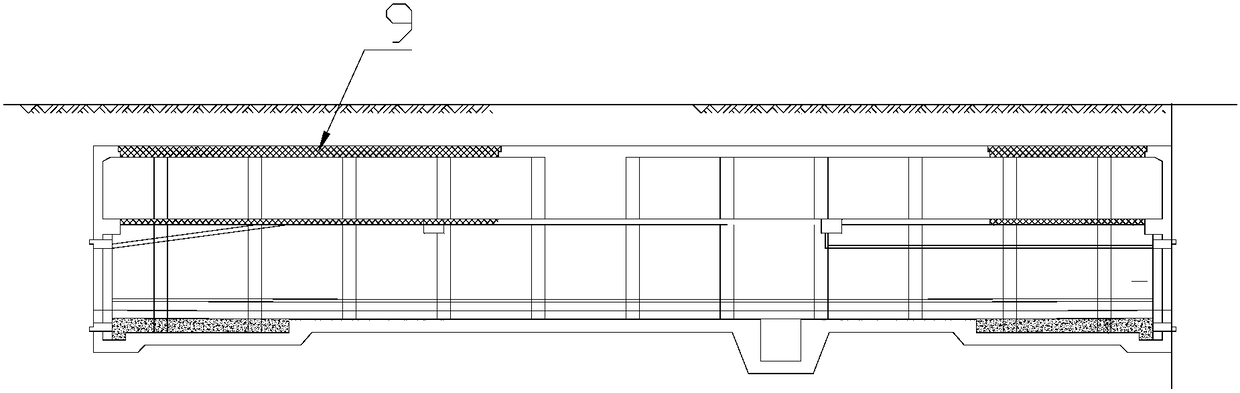

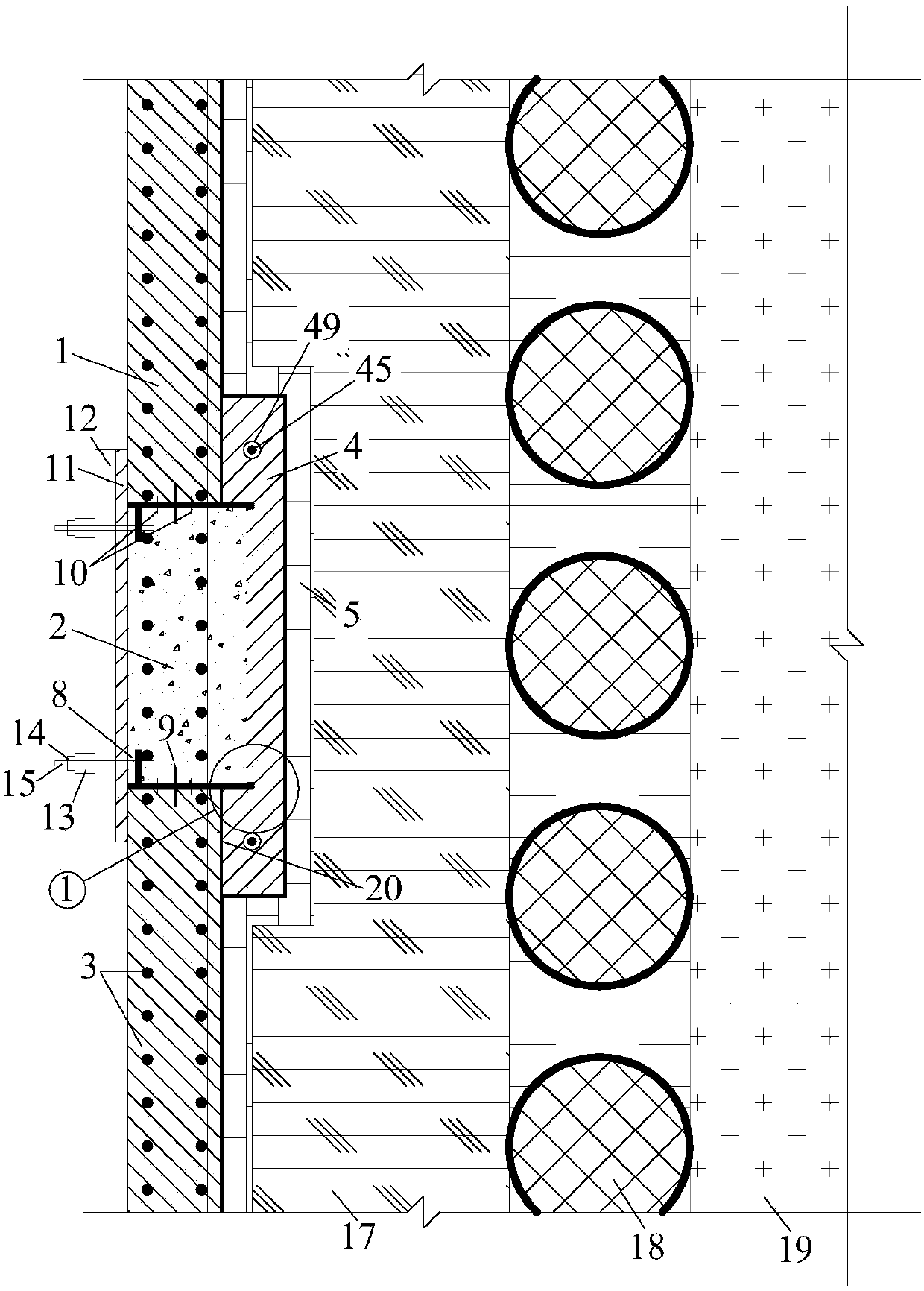

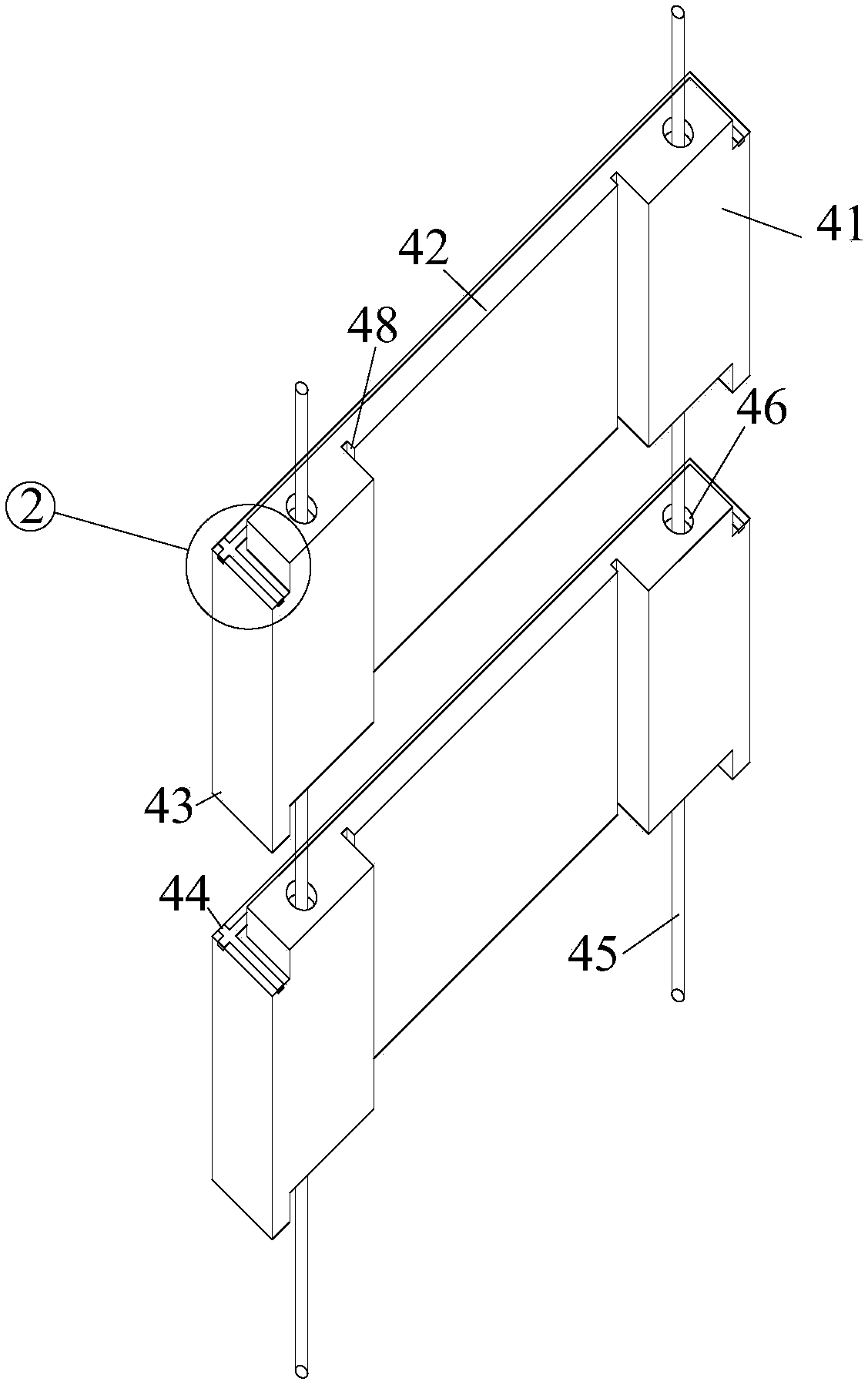

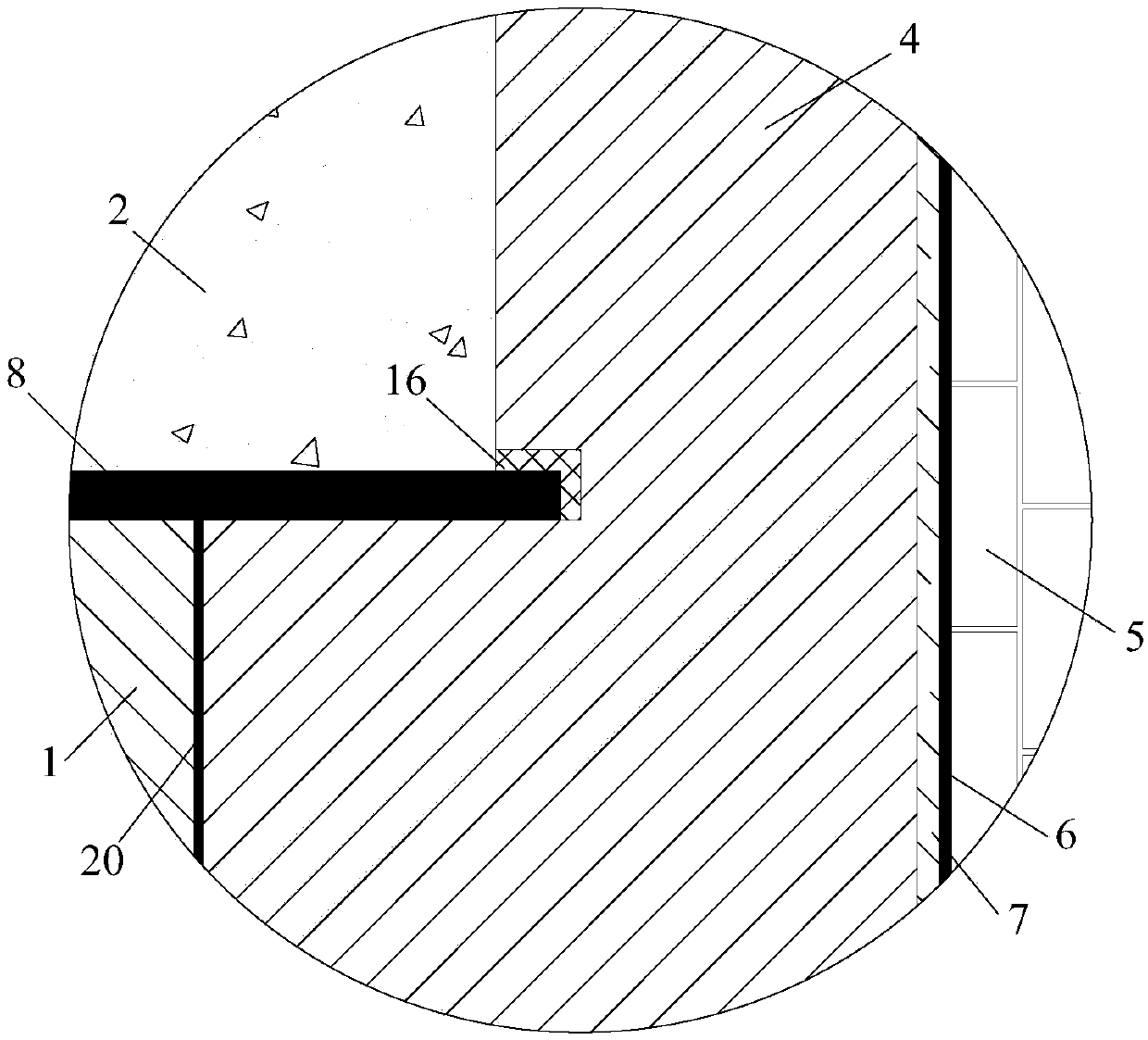

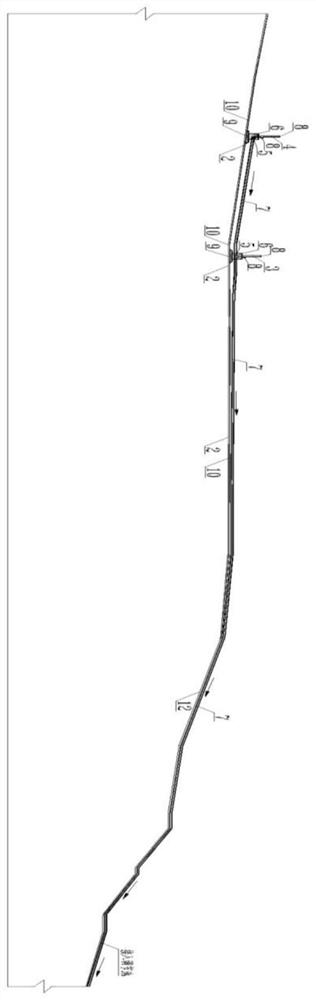

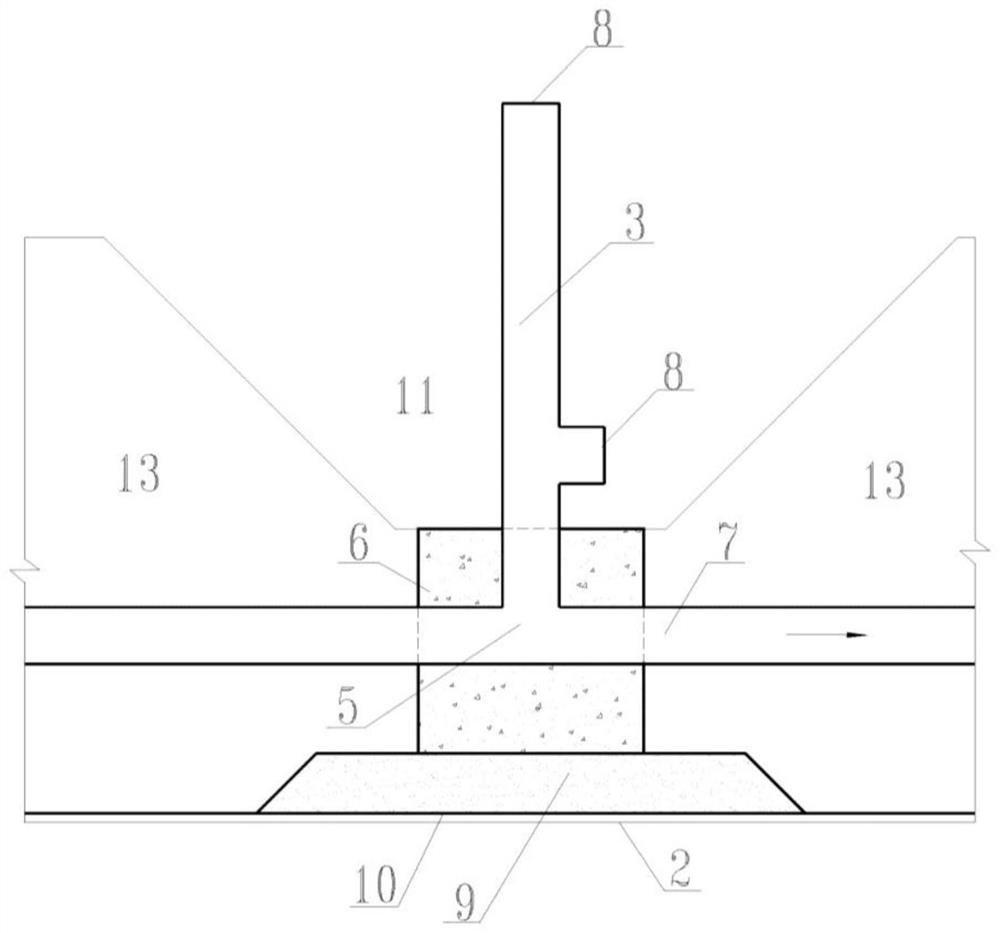

Basement exterior wall post-cast strip advanced sealing structure and basement exterior wall post-cast strip construction method

ActiveCN106120870AWaterproof and anti-seepageAvoid the impact of constructionArtificial islandsProtective foundationRebarSteel plates

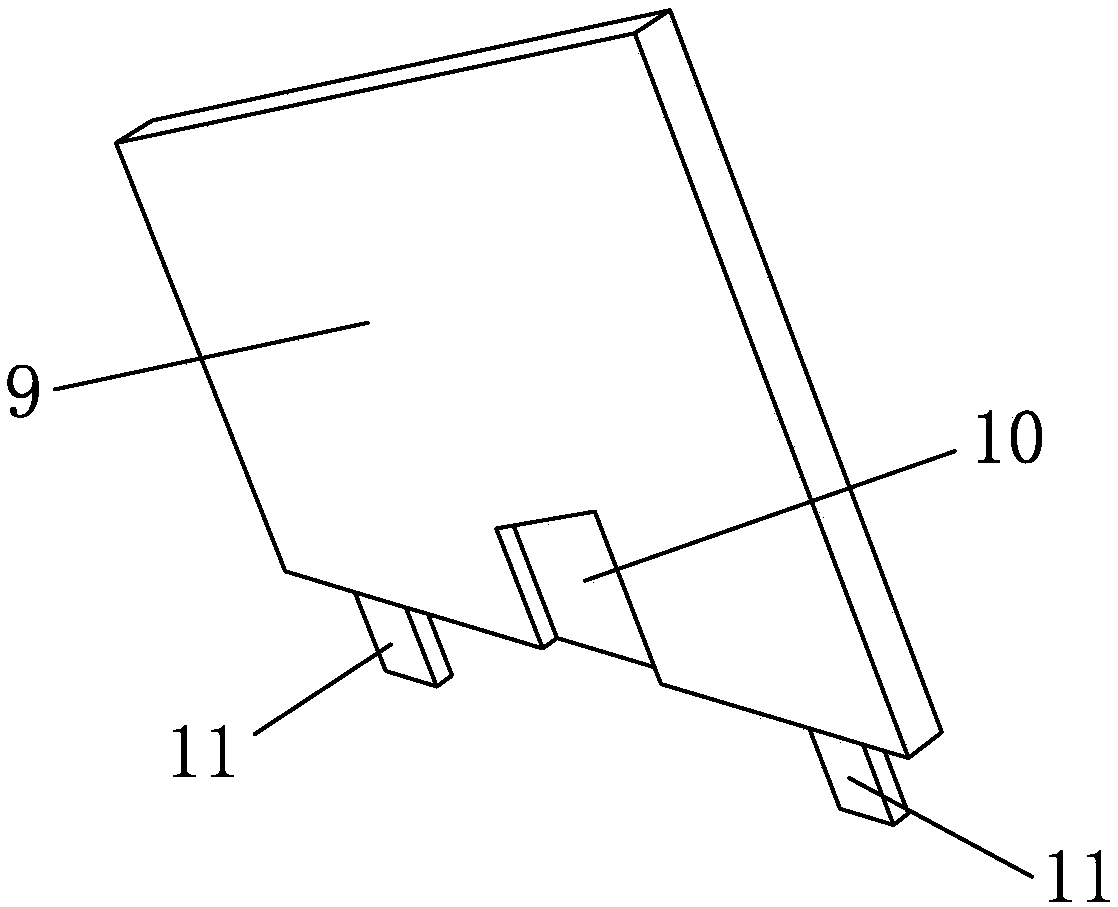

The invention relates to a basement exterior wall post-cast strip advanced sealing structure. The basement exterior wall post-cast strip advanced sealing structure is characterized by comprising a sealing plate (4), a brick masonry protection layer (5), a waterproof layer (6), a mortar leveling layer (7), a connecting steel plate (8), a water stop steel plate (9), connecting cotters (10) and the like; the sealing plate (4) is assembled on the outer side of the mortar leveling layer (7), protruding bars (43) at the upper end of the sealing plate (4) are embedded in grooves (44) in the lower end of the sealing plate (4) and are connected with the grooves (44) in the lower end of the sealing plate (4) into a whole through connecting ribs (45) in the perpendicular direction; one end of the connecting steel plate (8) is clamped in clamping grooves (48) in the sealing plate (4) and are provided with reinforcing steel bar penetrating holes, and horizontal bars penetrate in the reinforcing steel bar penetrating holes and are welded to the connecting steel plate (8); and the other end of the connecting steel plate (8) is provided with post-cast strip formwork fixing and connecting screw rods (15). The basement exterior wall post-cast strip advanced sealing structure belongs to the field of basement exterior wall and post-cast strip construction in industrial and civil construction body structures and has the beneficial effects that advanced water stop and soil retaining effects are good, and the construction speed is high; and good technological and economic benefits are achieved.

Owner:SHANGHAI JIASHI (GROUP) CO LTD

High-pier pouring forming method applied to bridge construction

ActiveCN103437288AGuaranteed temperature requirementsAvoid the impact of constructionBridge structural detailsBridge erection/assemblyCold weatherBuilding construction

The invention discloses a high-pier pouring forming method applied to bridge construction. The high-pier pouring forming method is characterized by comprising the following steps that (1) a heat insulation shed is built; (2) multiple sections of equilong templates are adopted to be superimposed to form a high-pier pier body template inside the heat insulation shed; (3) on the basis of the formed high-pier pier body template, a high-pier pier body with the same height as the high-pier pier body template is poured inside the heat insulation shed in one step; (4) all templates under the topside template are dismounted, and in addition, the topside template is used for the template installation support during the pouring of the lower section of pier body; (5), the pouring height of each section of later high-pier pier body is the sum of the heights of the templates except the topside template in the step (4), and the high-pier pier bodies are sequentially poured until the pouring is completed; and (6) the high-pier pier bodies are maintained in the heat insulation shed to carry out heat insulation maintenance until the final formation is realized. Through the scheme, the high-pier pouring forming method has the advantages that the influence of cold weather on the bridge construction is avoided, the construction quality is ensured, and high practical values and promotion values are realized.

Owner:CHINA RAILWAY CONSTR BRIDGE ENG BUREAU GRP OF THE FIFTH ENG +1

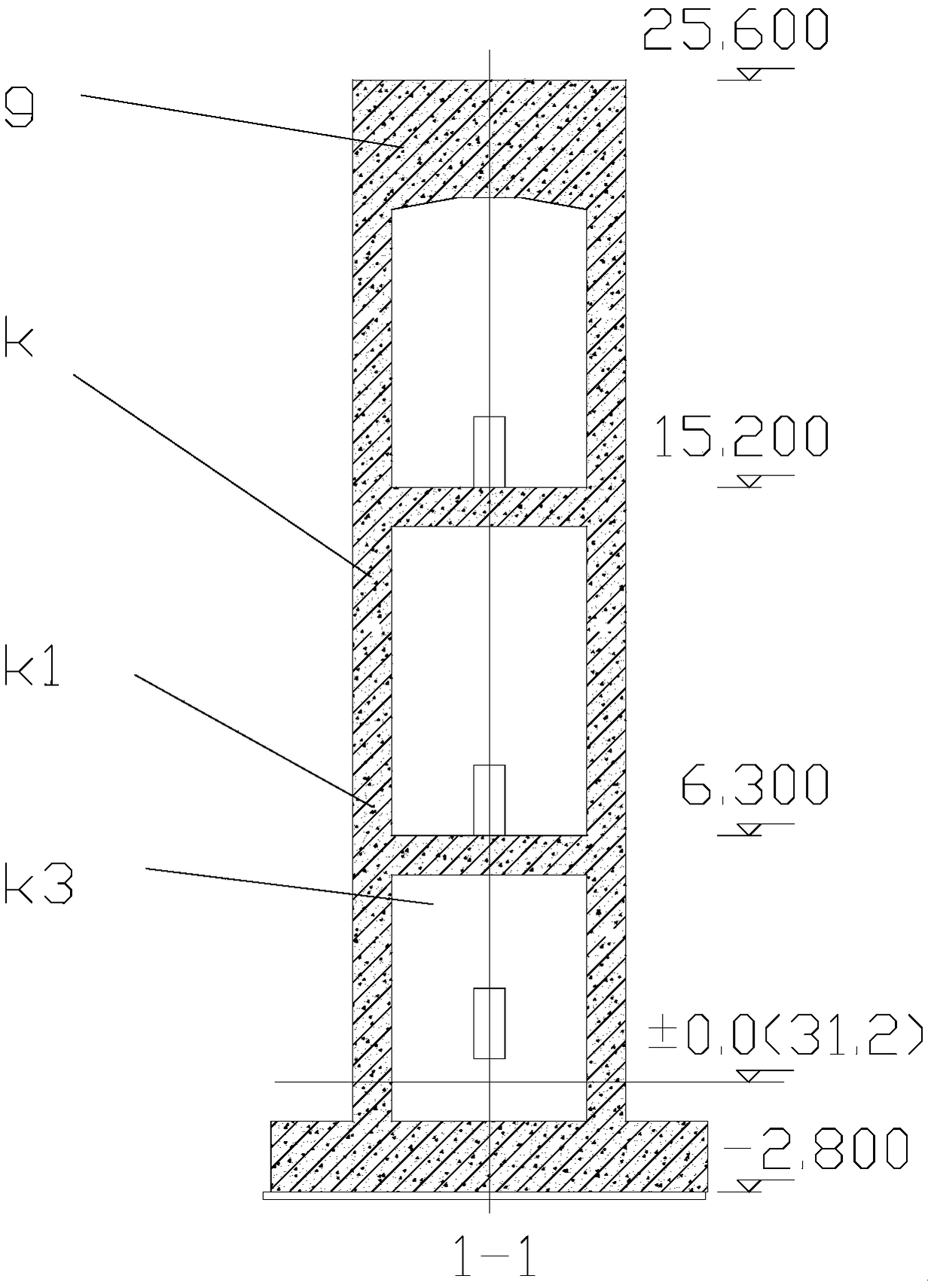

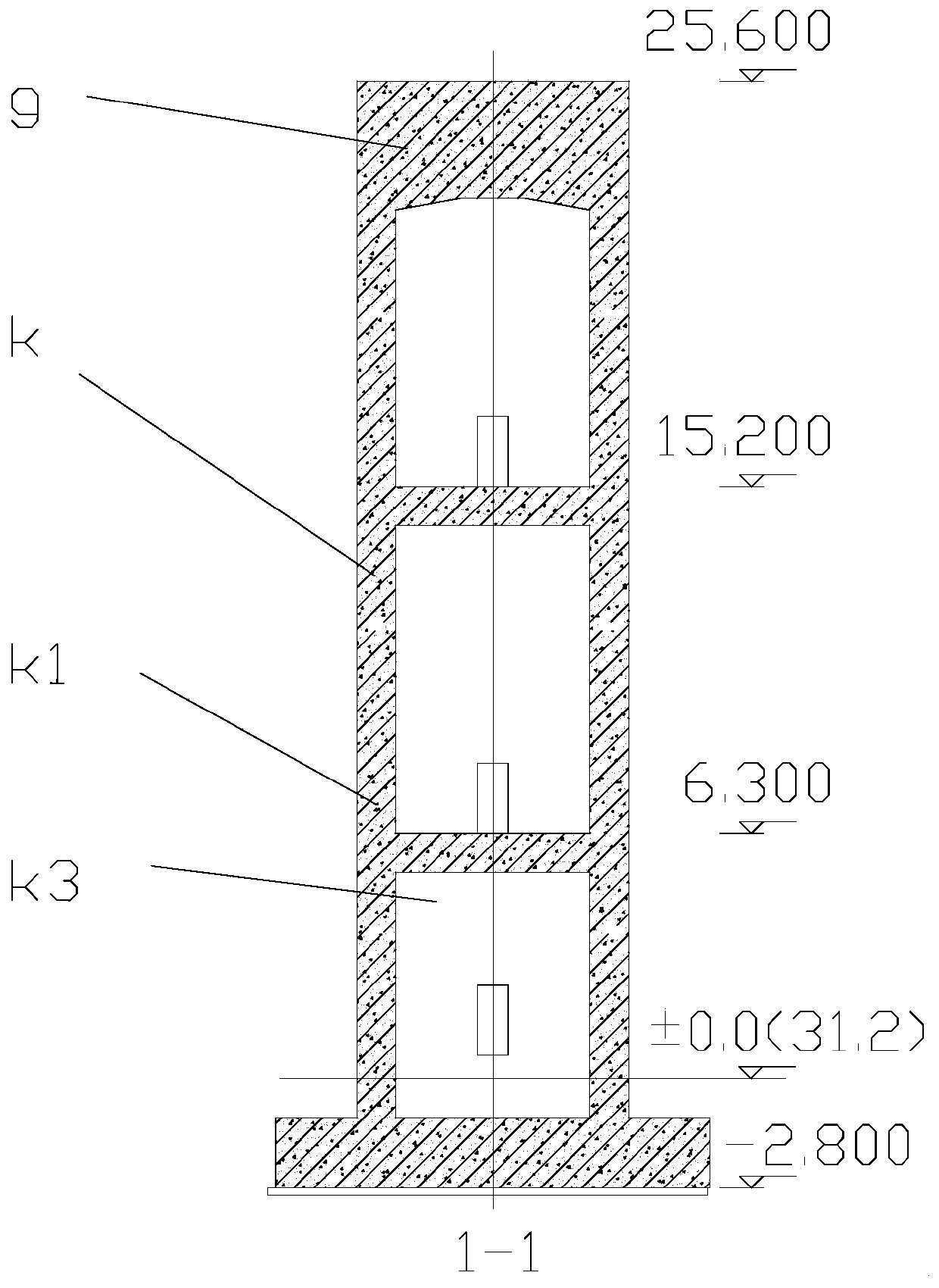

Metro internal-bracing-free track panel shaft and construction method thereof

ActiveCN105781570AAvoid influenceAvoid the impact of constructionUnderground chambersTunnel liningWaterstopWater leakage

The invention provides a construction method of a metro internal-bracing-free track panel shaft. The construction method includes following steps: (1), constructing a diaphragm wall; (2), constructing a foundation pit, and sequentially constructing a top beam and an internal bracing along with excavating; (3), constructing a baseplate, and demounting the internal bracing positioned downmost the foundation pit after strength of the baseplate reaches a certain degree; (4), constructing a side wall of a negative first floor, synchronously constructing a vertical coupled shear wall, a waist beam and a side wall within a range of a negative second floor; (5), constructing a middle plate, reserving a hole for the track panel shaft on the middle plate, and synchronously constructing a vertical coupled shear wall, a waist beam and a side wall within a range of the negative first floor; (7), constructing a top plate, reserving a hole for the track panel shaft on the top plate, and after strength of the top plate reaches a certain degree, demounting the internal bracing uppermost the foundation pit. The construction method has good water stopping effect, so that water leakage is avoided and big influence on surrounding environment during construction is avoided.

Owner:GUANGZHOU METRO DESIGN & RES INST

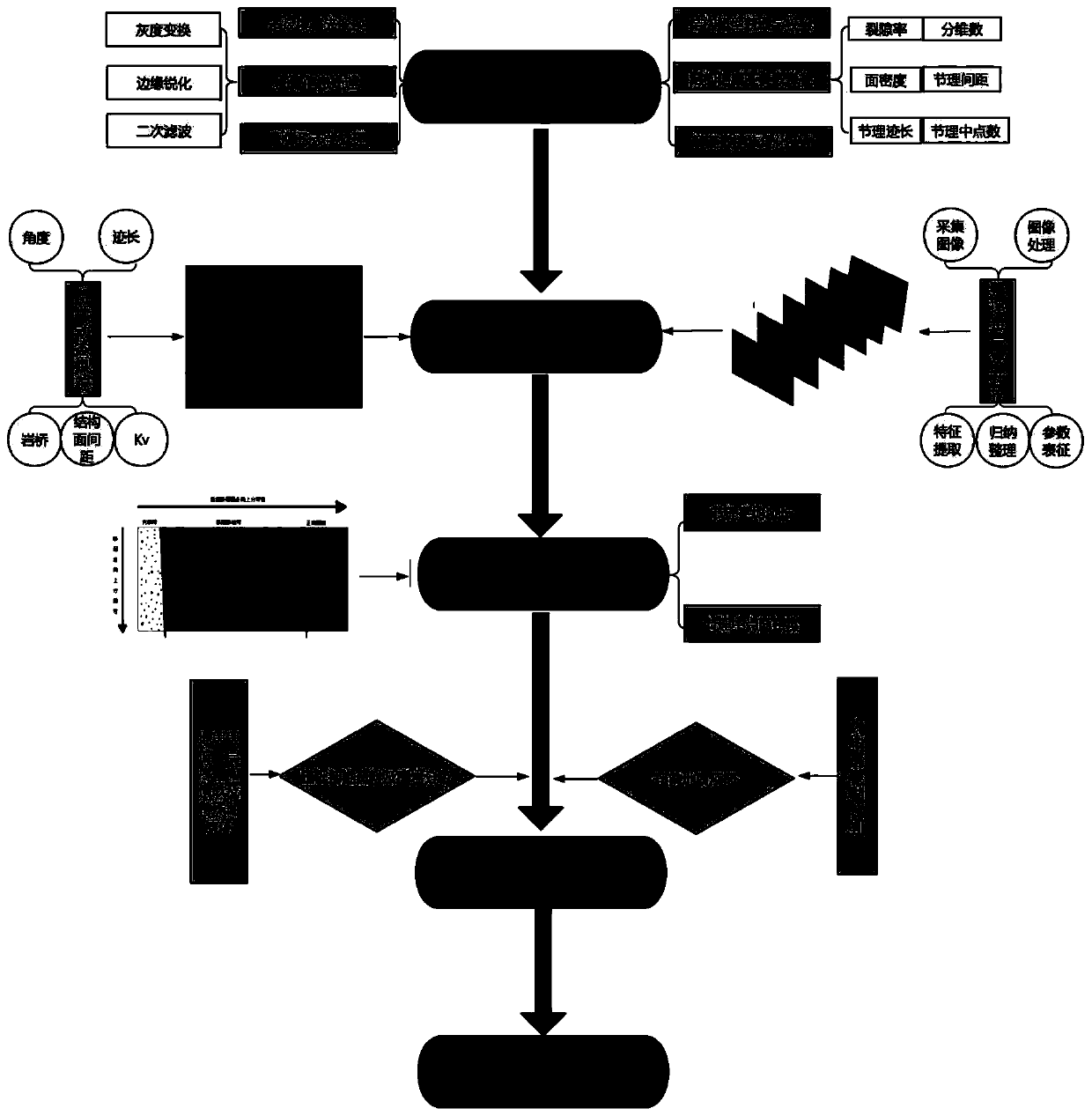

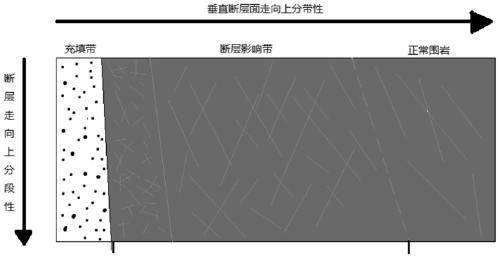

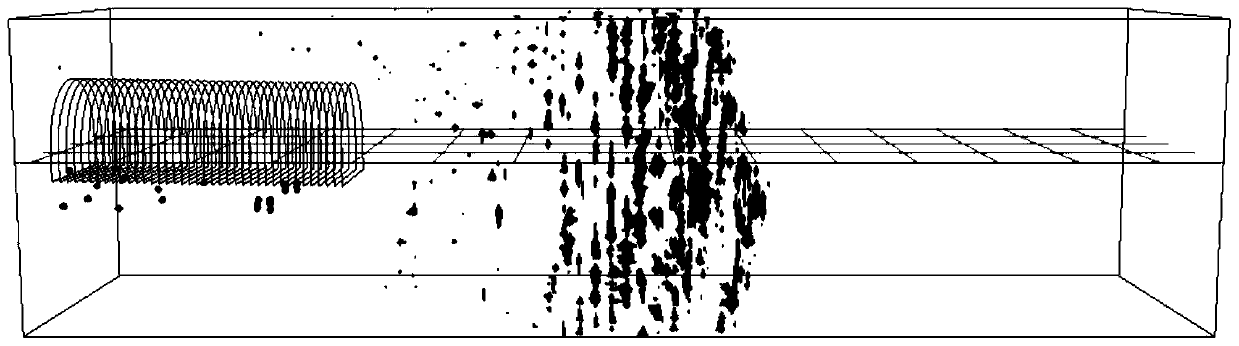

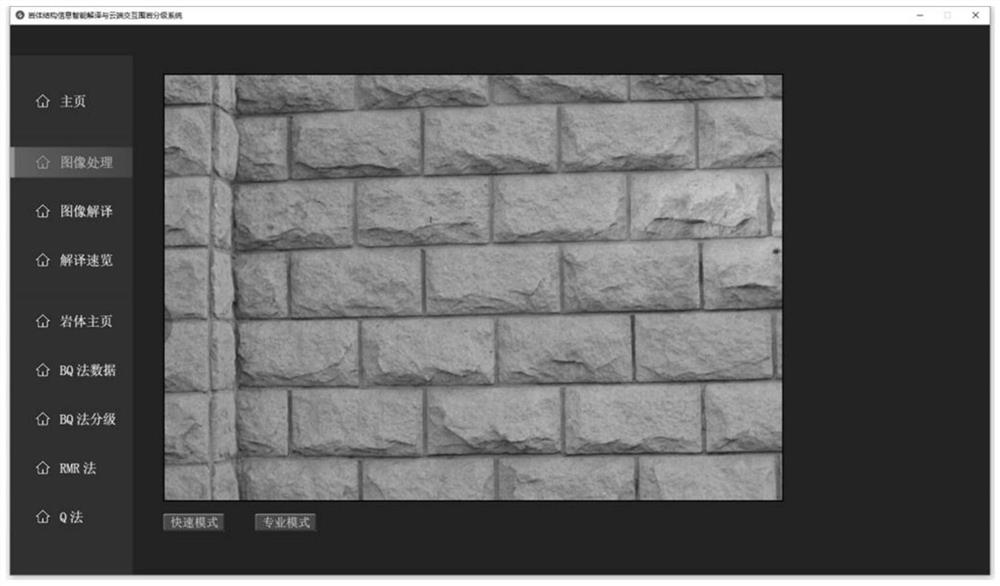

Underground engineering fractured rock mass occurrence special geologic body multi-source heterogeneous information fusion analysis and dynamic prediction method

InactiveCN111505733ARealize long-distance look-ahead predictionPrevent collapseSeismic signal processingOptical based geological detectionImaging processingGeophysics

The invention relates to the technical field of exploration, and provides an underground engineering fractured rock mass occurrence special geologic body multi-source heterogeneous information fusionanalysis and dynamic prediction method. The method comprises the following steps: realizing rapid acquisition of rock mass structure information by means of image processing and characteristic parameter extraction; determining a general fuzzy position of a special geologic body by utilizing an advanced geologic forecasting means; continuously and dynamically tracking and recording the tunnel facerock mass structure information, and achieving multi-source heterogeneous information fusion analysis and dynamic prediction of fractured rock mass occurrence special geologic bodies by utilizing joint development characteristics and occurrence rules near the fault and other special geologic bodies and integrating advanced geological prediction, engineering initial exploration data and a rock massstructure information base. According to the invention, continuous dynamic detection analysis is carried out on the front geologic body, various detection, processing and analysis modes are combined,all parameters and all modes are complementary and intercommunicated, advanced remote dynamic prediction can be carried out on the front special geologic body, the state of the special geologic bodyis analyzed, and engineering arrangement is convenient to optimize in advance.

Owner:SHANDONG UNIV OF SCI & TECH +1

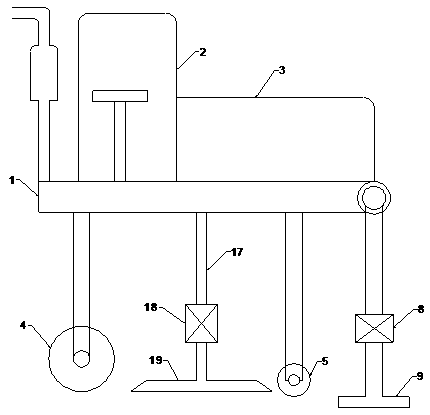

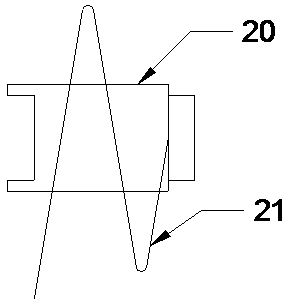

Ramming and groove digging mechanical device for building construction

InactiveCN109056870AAvoid the impact of constructionEasy to operateSoil-shifting machines/dredgersSoil preservationHydraulic cylinderDrive wheel

The invention discloses a ramming and groove digging mechanical device for building constructions. The device comprises a chassis, a cab room and a power room arranged on the chassis, and a driving wheel and driven wheels arranged below the chassis. Two sides of the chassis are respectively horizontally and fixedly connected with first hydraulic cylinders. Lifting columns are vertically arranged at an end part of piston rods of the first hydraulic cylinders. Second hydraulic cylinders are vertically and fixedly connected to lower ends of the lifting columns. Cylinder bodies of the second hydraulic cylinders are connected to the lifting columns. Ends of the piston rods are connected with ramming plates. A plurality of sequentially connected soil loosening structures is arranged horizontallybetween a left driven wheel and a right driven wheel. A groove digging structure assembly is arranged between the driving wheel and the driven wheels. According to the ramming and groove digging mechanical device for building construction, soil loosening and pushing grooves are performed in an area in a foundation beam frame at the same time in the walking process by taking the foundation beam asa track, and earth compaction is performed by using ramming plates at last, so that the effects of being easy to construct, quick and efficient, and capable of greatly saving manpower and material resources are achieved.

Owner:成都市创斯德机电设备有限公司

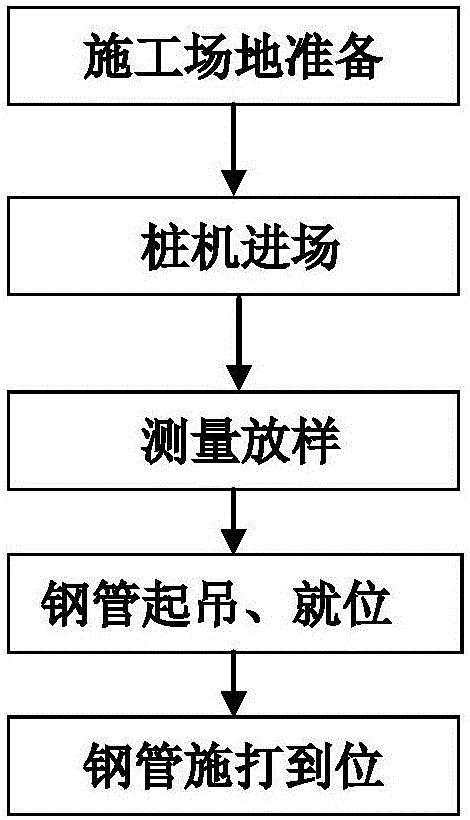

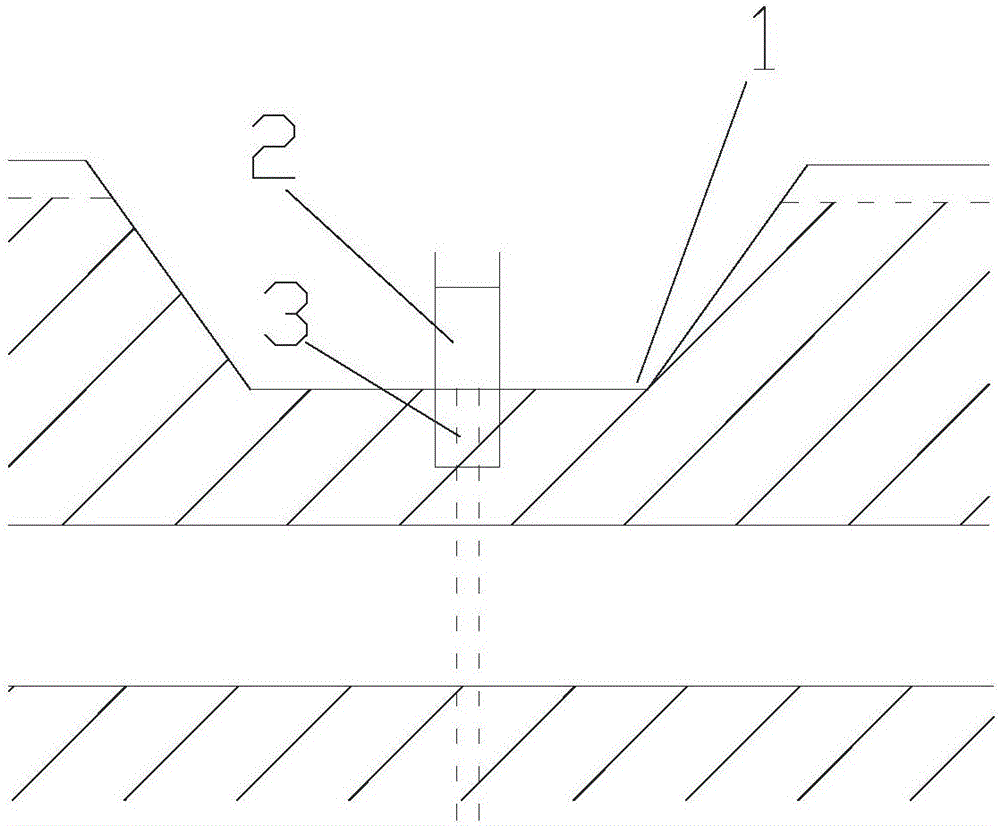

Geological drill hole confined water spewing water head balanced construction method

InactiveCN106522251AReduce churnAvoid the impact of constructionBulkheads/pilesConfined waterEngineering

The invention discloses a geological drill hole confined water spewing water head balanced construction method. The method comprises the following steps that S1, a construction site is prepared, specifically, before large-diameter steel tube construction, silt nearby geological drill holes is removed, the geological drill holes are not blocked, and a pile driver parking site is selected on a roadside outside a foundation pit; S2, a steel tube pile driver is transported into the site, specifically, the pile driver is selected according to the weight and length of steel tubes and then enters the set position; S3, survey setting-out is conducted, specifically, survey setting-out is conducted in steel tube driving positions, and the positions are marked; S4, the steel tubes are hoisted in place, specifically, the steel tube pile driver is used for hoisting the steel tubes to the positions over the marked positions, and correction is conducted manually and cooperatively; and S5, the steel tubes are driven in place, specifically, the steel tube pile driver is used for driving the steel tubes to the set positions, and the geological drill holes are located in the steel tubes. By adoption of the geological drill hole confined water spewing water head balanced construction method, the problem that confined water in the geological drill holes in the bottom of the foundation pit spews can be effectively solved; and the method is easy and convenient to operate, good in implement effect, and capable of effectively preventing influence of underground water on foundation pit construction.

Owner:GUANGZHOU JISHI CONSTR GRP

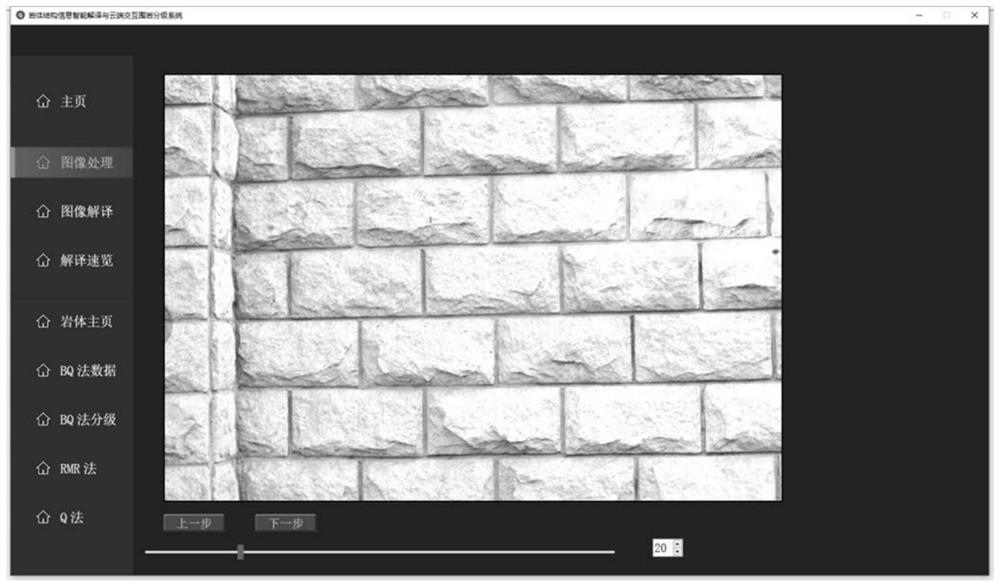

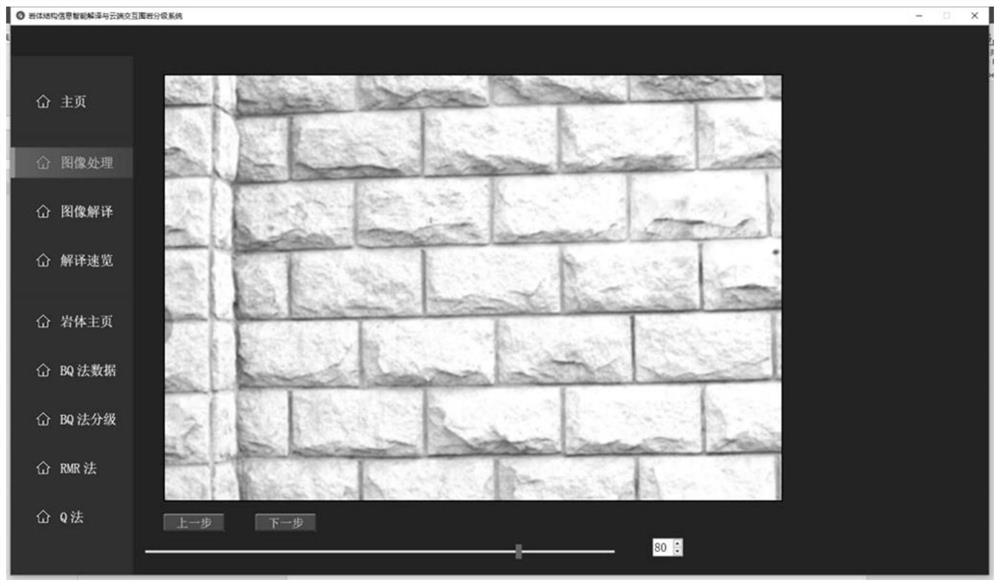

Underground engineering rock mass structure information intelligent interpretation and cloud remote surrounding rock grading method

InactiveCN111813977AImplement extractionDetailed analysisImage analysisCharacter and pattern recognitionFeature extractionData recording

The invention relates to an underground engineering rock mass structure information intelligent interpretation and cloud remote surrounding rock grading method. Research and development are performedbased on a platform C + +; the image characteristics of the fractured rock mass are fully considered; the tunnel face rock mass image is subjected to gray scale transformation, edge sharpening, secondary filtering and other operations, feature extraction of a rock mass structure is achieved based on a morphological algorithm, multi-parameter representation of the rock mass structure is conducted through the fracture rate, the fractal dimension, the surface density, the joint interval, the joint trace length, the joint middle point number and the like, and corresponding data recording and summarizing are conducted in time. The method is based on the engineering rock mass grading standard; a system reliability analysis theory is introduced for analyzing rock mass strength and rock mass integrity coefficient probability distribution rules, the performance functions of different surrounding rock grades are constructed, the reliability probability that the surrounding rock belongs to each evaluation grade is calculated through a Monte Carlo method, a corresponding rock mass structure cloud information data integration platform is constructed accordingly, and reliable data support is provided for tunnel construction and follow-up analysis.

Owner:SHANDONG UNIV OF SCI & TECH

Construction process of cable crane hoisting system

The invention discloses a construction process of a cable crane hoisting system, and belongs to the field of bridges. The construction process comprises the following steps of step (1), respectively carrying out the construction of foundation embedded parts of towers on both sides on transition piers on both sides of a bridge, and then assembling the towers on both sides and installing wind cableson the corresponding towers; step (2), installing cable saddles on the tops of the towers on both sides, and carrying out the construction of main anchors on both sides; step (3), installing a main bearing cable and installing a winch at the same time; step (4), carrying out the installation of a lifting trolley, a traction rope and a hoisting rope; and step (5), carrying out hoisting system inspection and trial hoisting. According to the scheme of the invention, the towers are erected on the tops of the bridge transition piers, the span of a cable system is reduced and the height of the towers is reduced; and the arrangement not only greatly saves the construction cost and speeds up the construction progress, but also ensures the construction safety of a cable crane used in a large-span,variable cross-section steel truss continuous rigid frame bridge, and the hoisting construction process is simple.

Owner:CCCC SHEC FOURTH ENG +1

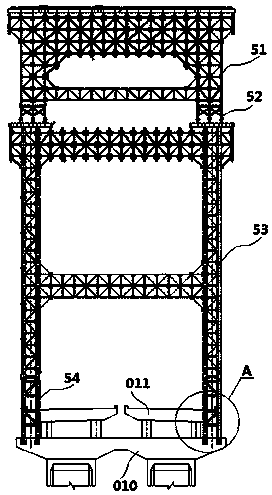

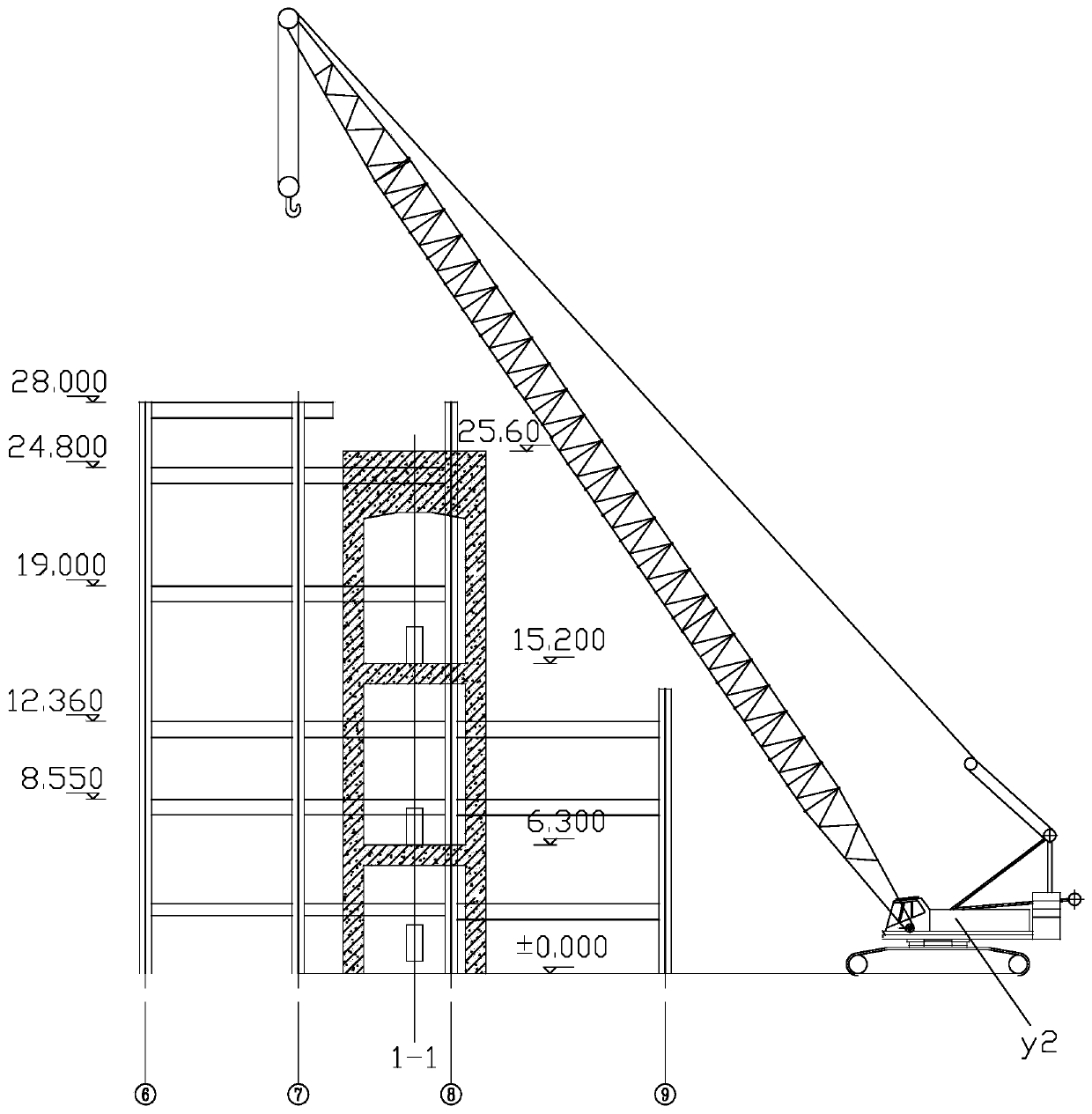

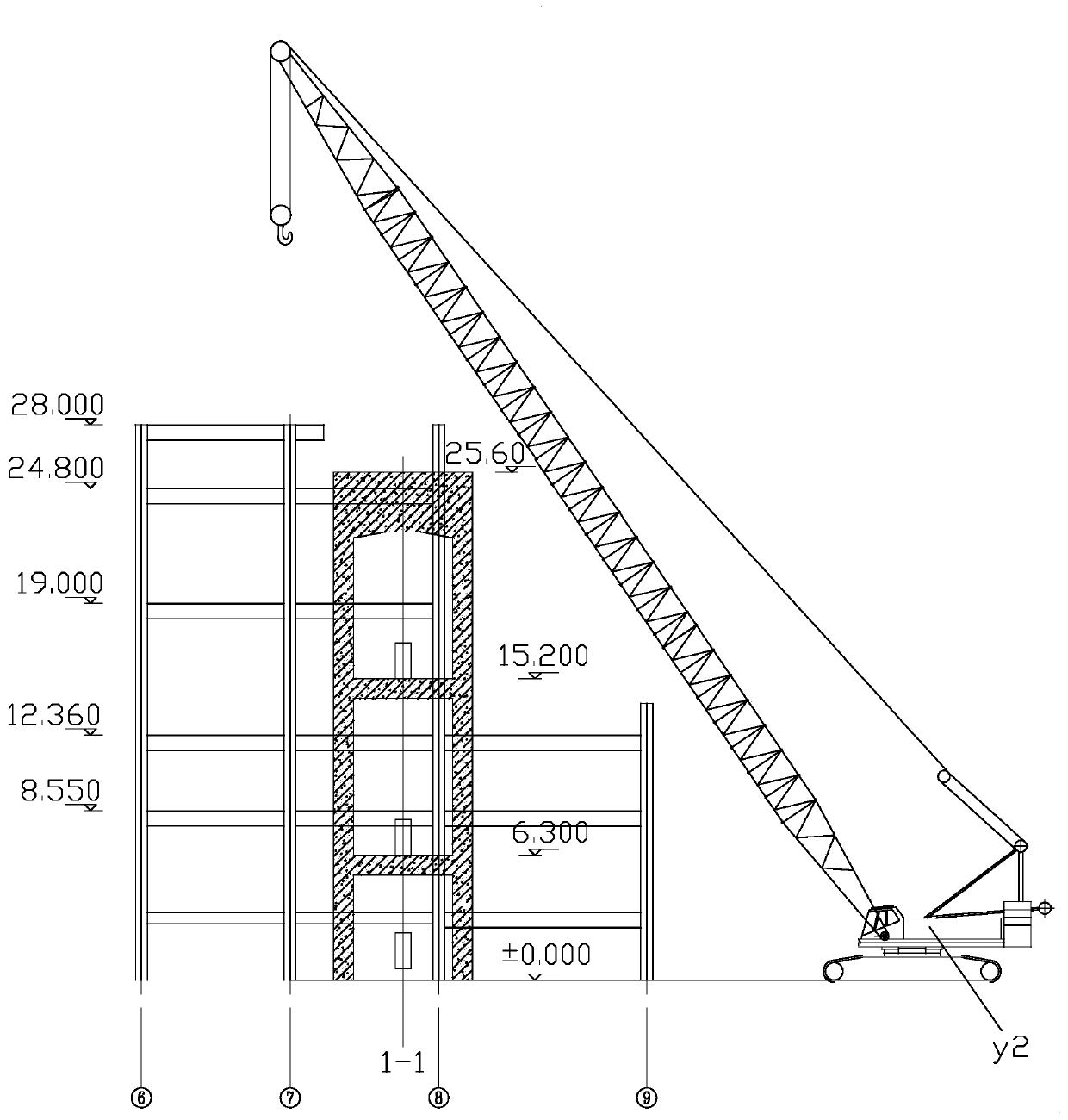

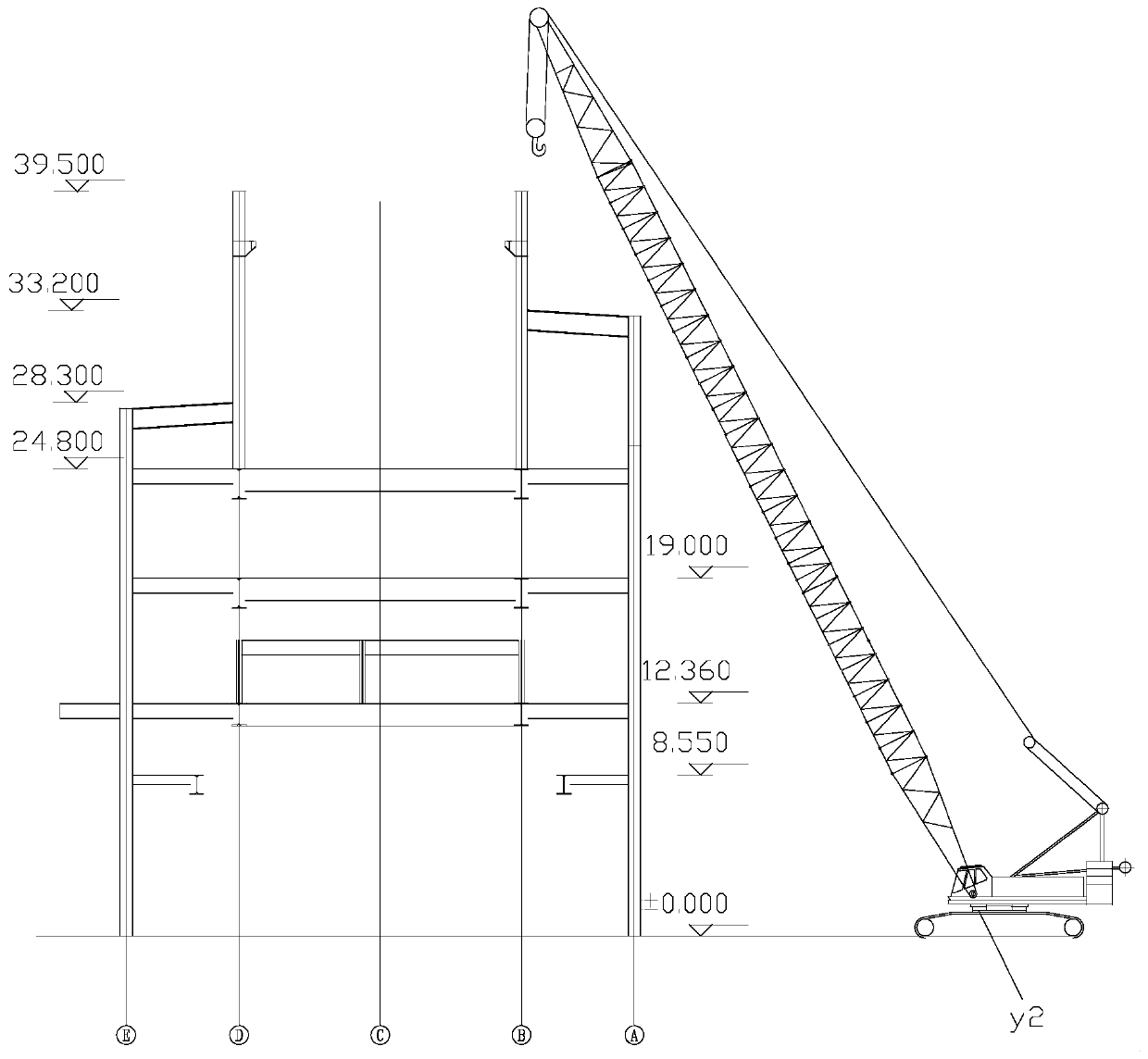

Electric furnace hearth insulation and furnace shell inverted installation technology

ActiveCN109000483AOvercoming poor structural strengthGuaranteed installation qualityLinings repairEngineeringHearth

The invention relates to the field of industrial capital construction and large piece installation, and provides an electric furnace hearth insulation and furnace shell inverted installation technology. By adopting the technology for installing an insulation plate between a furnace shell and a base, influence caused by outside conditions to construction is avoided, the defect that an insulation layer is naturally poor in structural strength, and thereby is prone to being damaged by external force during the installation process of a normal installation procedure is overcome as well, and the installation quality of the insulation plate is guaranteed. The electric furnace hearth insulation and furnace shell inverted installation technology comprises the construction technology of installingthe base, the construction technology of installing the furnace shell on the base in a splicing manner, and the construction technology of arranging the insulation plate between the base and the furnace shell in a lining manner.

Owner:CHINA 19TH METALLURGICAL CORP

Method for constructing energy-saving building by using prefabricating method

InactiveCN105040981AGuaranteed temperature requirementsGuaranteed Humidity RequirementsBuilding material handlingComputer moduleBuilding design

The invention discloses a method for constructing an energy-saving building by using a prefabricating method. A drawing of a building to be constructed is designed by an architectural design unit, when the drawing is designed, the whole building is divided into a plurality of building modules according to a stress principle, and the designed drawing of the building modules is transmitted to a prefabricating unit so as to prefabricate the building modules. A prefabricating method of the prefabricating unit which prefabricates the building modules comprises the following steps of (1) arranging a prefabricating field in an open environment and setting up a prefabricated house of which parameters of an inner environment can be adjusted; (2) arranging a pedestal for prefabricating the building modules in the prefabricating house; (3) setting up prefabricated modules corresponding to the single building modules on the pedestal by using steel according to a drawing standard of the single building modules; (4) performing concreting on the constructed prefabricated modules; and (5) solidifying the building modules. The problem that difficulty of building construction in the prior art is high in cold days is solved.

Owner:CHENGDU DIANSHI CREATIVE TECH

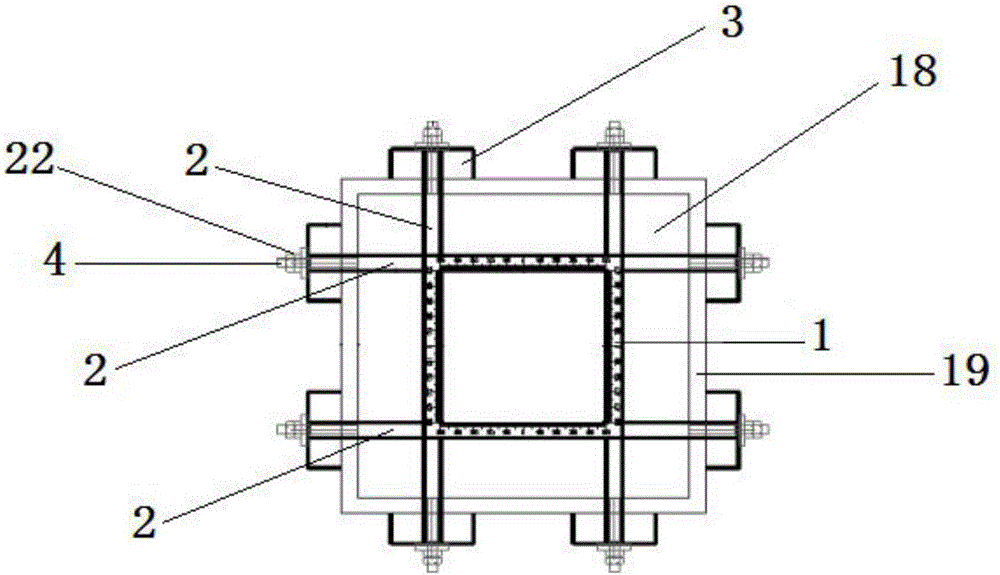

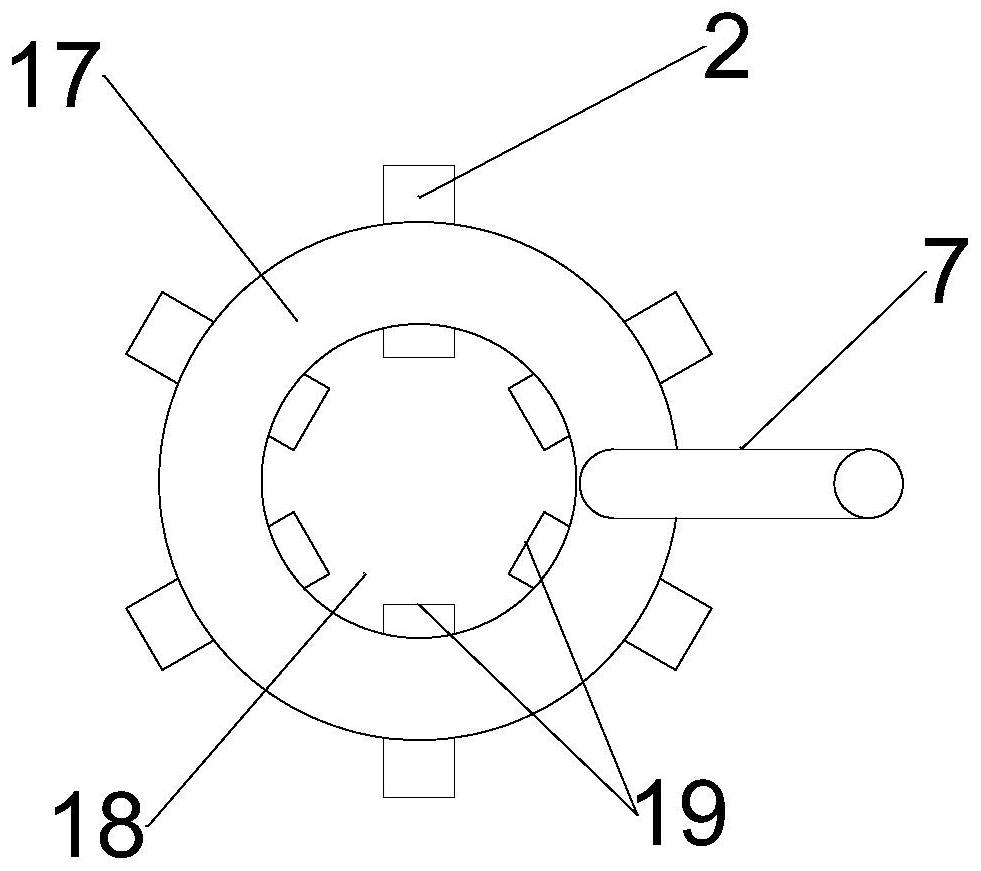

Positioning device for anchor bolts and construction method of positioning device

The invention discloses a positioning device for anchor bolts. The positioning device comprises a pile body index dial. The outer wall of the pile body index dial is uniformly and circumferentially connected with telescopic tubes perpendicular to the surface of the outer wall of the pile body index dial at intervals. Device positioning blocks are fixed to the ends of the telescopic tubes. Device positioning bolts are arranged in the device positioning blocks correspondingly. A plurality of sets of first clamping strips capable of moving left and right are connected between the surfaces of the opposite inner walls of the front side and the rear side of the pile body index dial. Every two opposite semicircular grooves located in the two first clamping strips of the same set form a positioning groove matched with a thread on one anchor bolt. A plurality of sets of second clamping strips capable of moving front and back are connected between the surfaces of the opposite inner walls of the left side and the right side of the pile body index dial. Every two opposite semicircular grooves located in the two second clamping strips of the same set form a positioning groove matched with a thread on one anchor bolt. A gap exists between the first clamping strips and the second clamping strips in the longitudinal direction. The positioning device is simple in structure, easy to machine, high in positioning precision, easy to operate and capable of being recycled.

Owner:DONGFENG DESIGN INST

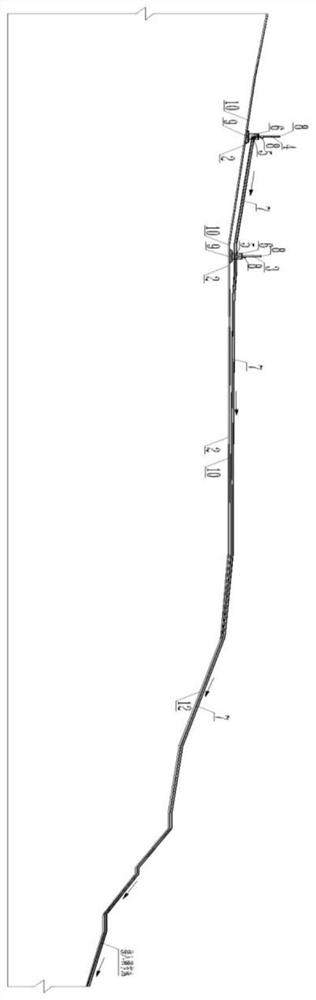

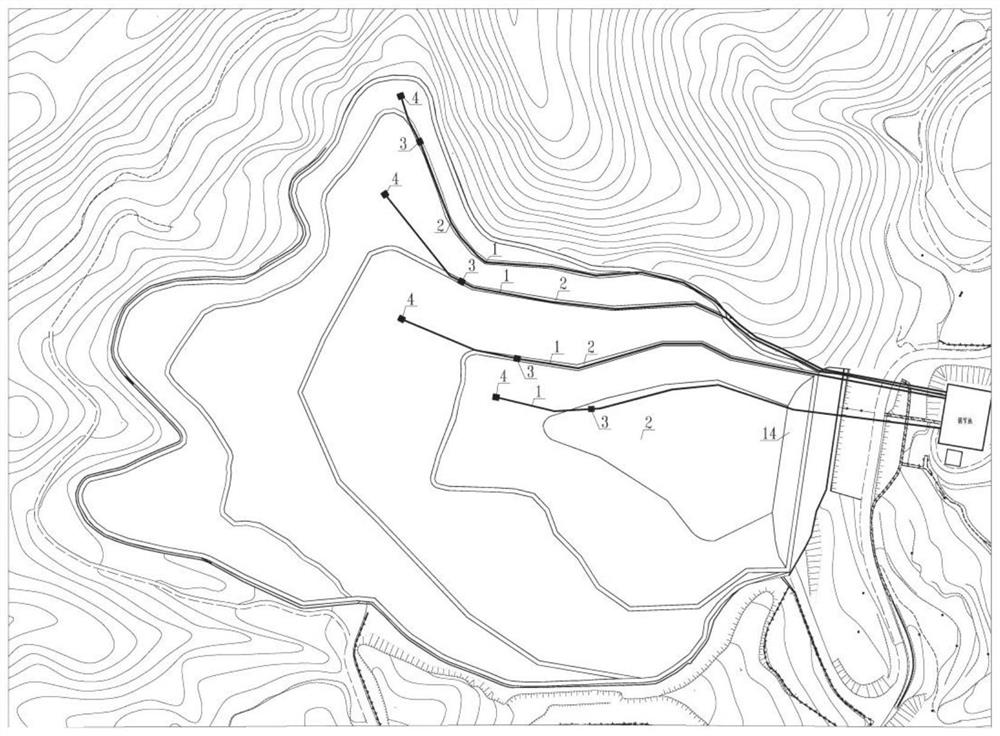

Upstream-type tailing pond multi-level independent flood drainage system

ActiveCN111719660ALower the altitudeReduce the overall heightSewerage structuresClimate change adaptationEnvironmental engineeringFlood discharge

The invention provides an upstream-type tailing pond multi-level independent flood drainage system. The upstream-type tailing pond multi-level independent flood drainage system is composed of multi-level sub-flood drainage systems. Each sub-flood drainage system is composed of a 1# flood drainage well, a 2# flood drainage well, a joint pipe, a concrete base and a flood drainage pipe, and the 2# flood drainage wells are located at the upstream positions of the 1# flood drainage wells. The bottoms of the 1# flood drainage wells and the 2# flood drainage wells separately communicate with the flood drainage pipes through the joint pipes, the joint pipes are buried in concrete bases, and the flood drainage pipes drain the flood to a regulating pond outside the reservoir along the horse road, the bottom of the reservoir and the bank slope. The welding range with an anti-seepage membrane is reduced, and the risk of leakage is reduced, because the anti-seepage membrane is not required during construction, the upstream-type tailing pond multi-level independent flood drainage system can be used in the construction of novel tailing pond projects, and can be widely used in the hidden danger control projects of flood drainage failure or expansion projects with insufficient flood discharge capacity.

Owner:CHINA POWER CONSRTUCTION GRP GUIYANG SURVEY & DESIGN INST CO LTD

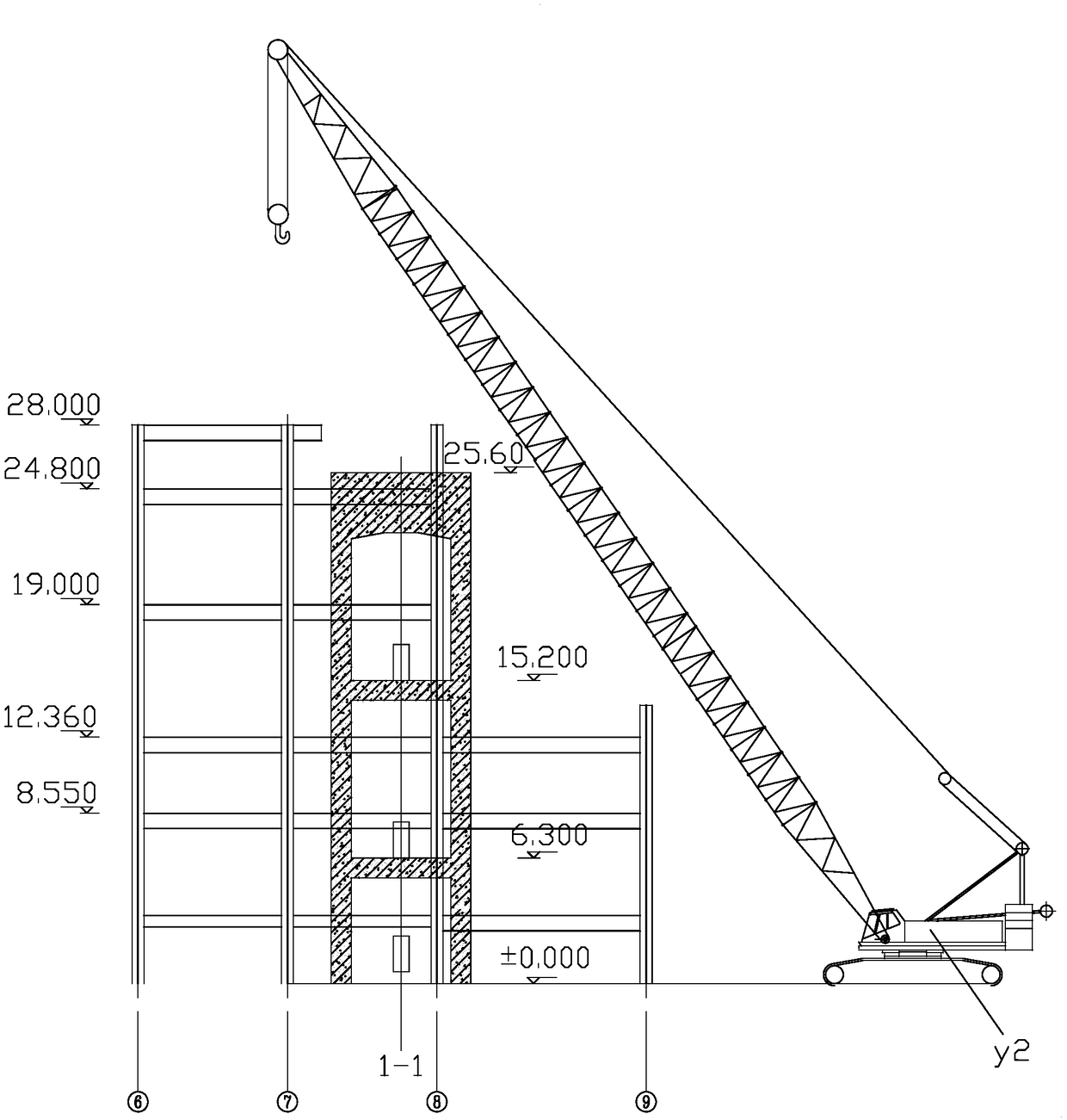

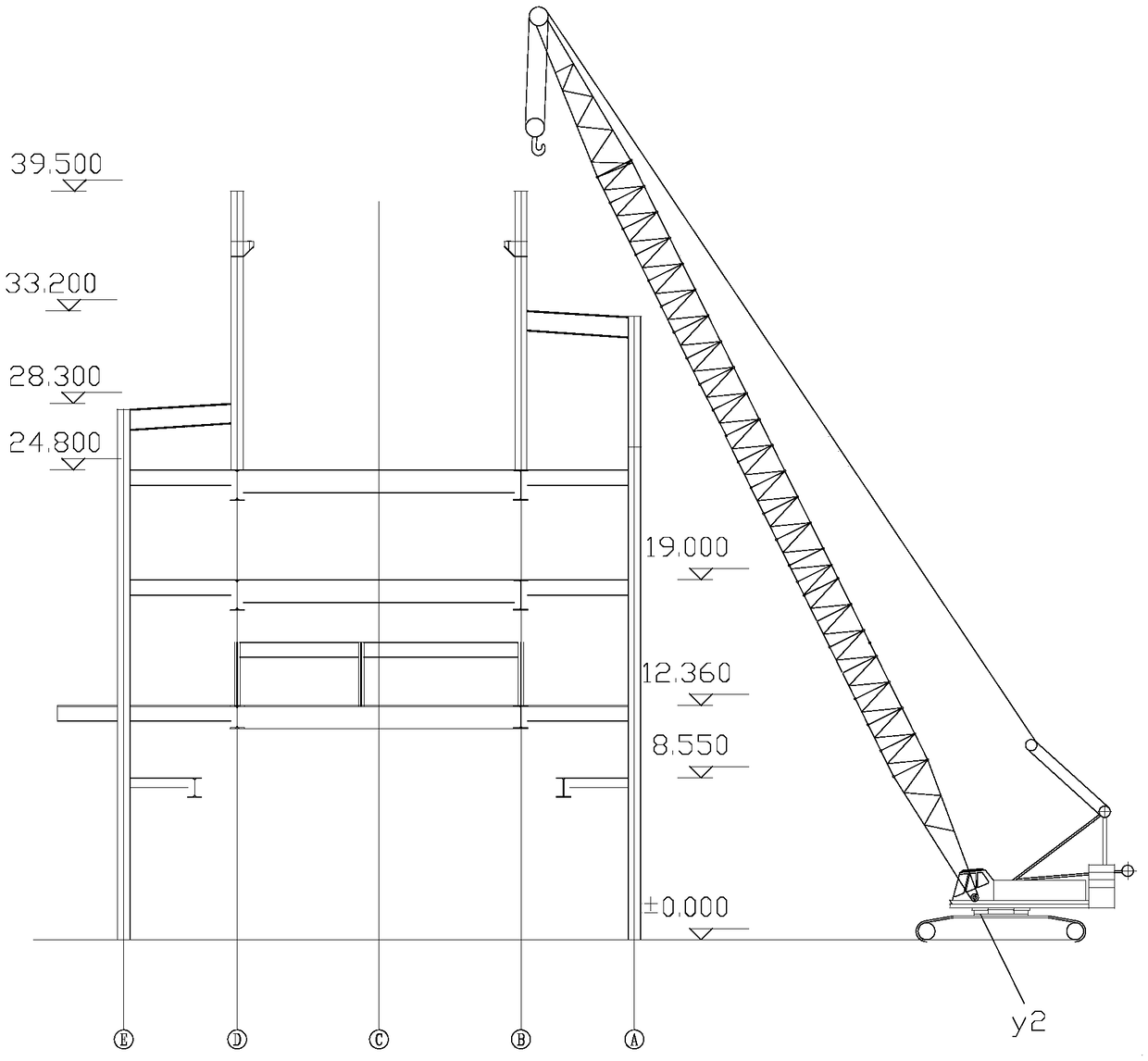

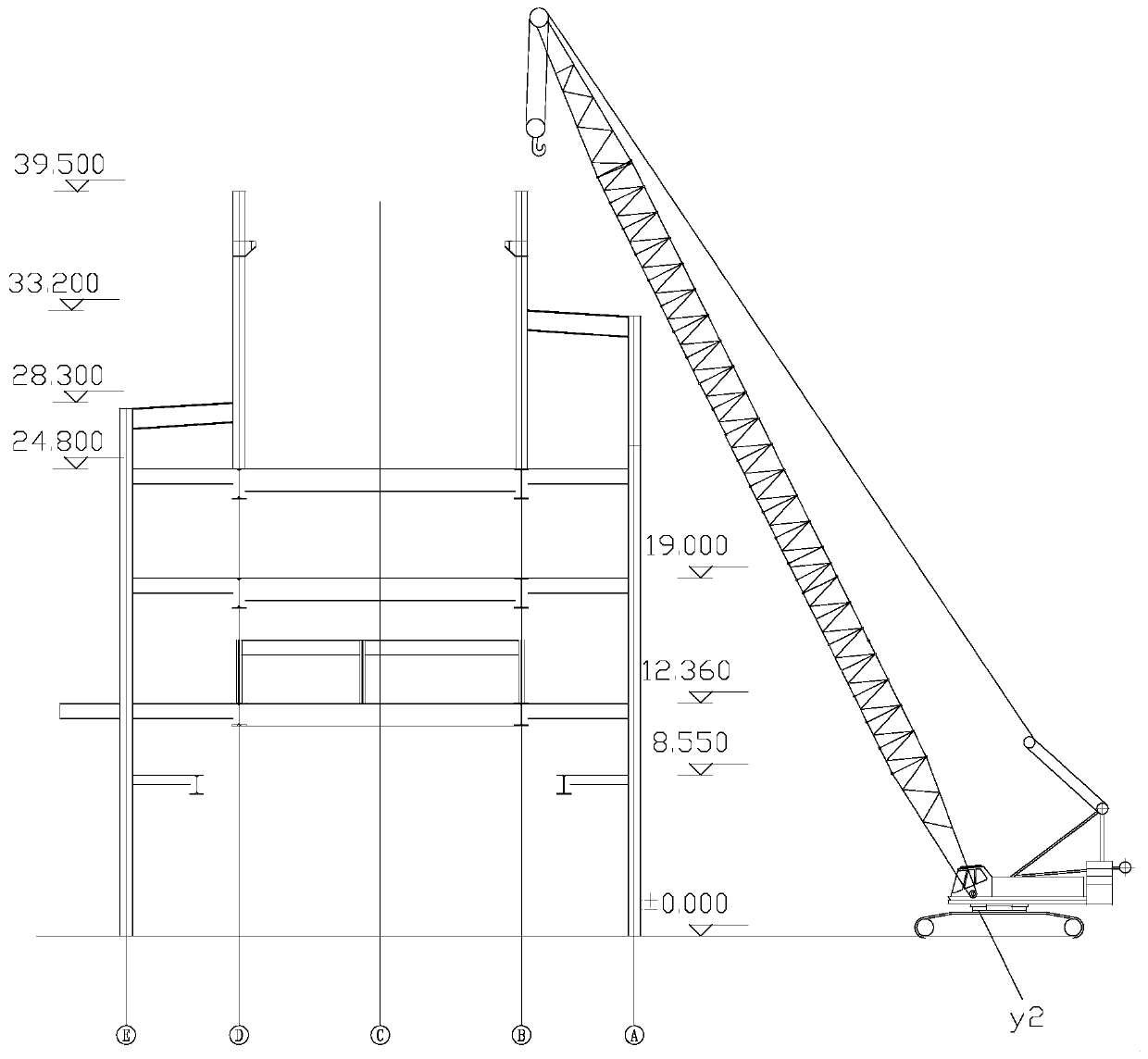

Lifting and installation process of electric furnace body

ActiveCN109231007BGuaranteed installation qualitySafe installationCranesLoad-engaging elementsThermodynamicsIndustrial engineering

The invention relates to the field of industrial infrastructure and large part installation and provides an electric furnace body lifting and installing process. By adopting the process to install aninsulating plate between a furnace shell and a substrate, external conditions are prevented from influencing construction, the defect that the insulating layer is easily subjected to external force action and damaged is overcome as well when the insulating layer is installed according to a normal installation sequence as the self structure strength of the insulating layer is poor, and insulated installation quality is guaranteed; the influence on furnace lid lifting and installing operation is overcome as well after a factory building roof and a rain-proof system are formed, and the furnace lid can be safely and conciselyeasily lifted and installed; the electric furnace body lifting and installing process comprises furnace bottom insulation and furnace shell inverse installation technologyas well as furnace lid inverse installation and furnace lid installing technology which utilizes mobile lifting equipment and a winch to cooperate with a pulley block.

Owner:CHINA 19TH METALLURGICAL CORP

A construction method of pouring block stone face protection structure for slope embankment in river and sea reclamation area

ActiveCN108457246BStable blocking effectPrevent sinkingWater resource protectionCoastlines protectionStructural engineeringRevetment

Owner:ZHEJIANG UNIV OF WATER RESOURCES & ELECTRIC POWER

Construction method of underpass project

ActiveCN112554201BEnsure safetyAvoid the impact of constructionExcavationsTunnelsArchitectural engineeringPier

The invention provides a construction method of an underpass project, which belongs to the technical field of building construction. In the present invention, the construction of the underpass project is carried out in sections. First, the first jacking frame on the second side of the foundation pit is pushed to a preset position below the existing line, and the first permanent frame is poured on the second side of the foundation pit. Construct multiple piers at the top of the first permanent frame, remove the temporary columns, and use the piers to replace the support of the temporary columns; construct a second jacking frame on the first side of the foundation pit and push it to the bottom of the existing line Preset positions, and then construct a second permanent frame on the first side of the foundation pit. The invention adopts the method of sub-section construction to construct the underpass project, avoids the influence of the temporary column on the construction, ensures the possibility of jacking with braces under adverse geological conditions, and ensures the safety of the adjacent foundation pit.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP

A construction method for underground wells without internal support rails

ActiveCN105781570BAvoid the impact of constructionGood water stop effectUnderground chambersTunnel liningWater leakageUltimate tensile strength

The invention provides a construction method of a metro internal-bracing-free track panel shaft. The construction method includes following steps: (1), constructing a diaphragm wall; (2), constructing a foundation pit, and sequentially constructing a top beam and an internal bracing along with excavating; (3), constructing a baseplate, and demounting the internal bracing positioned downmost the foundation pit after strength of the baseplate reaches a certain degree; (4), constructing a side wall of a negative first floor, synchronously constructing a vertical coupled shear wall, a waist beam and a side wall within a range of a negative second floor; (5), constructing a middle plate, reserving a hole for the track panel shaft on the middle plate, and synchronously constructing a vertical coupled shear wall, a waist beam and a side wall within a range of the negative first floor; (7), constructing a top plate, reserving a hole for the track panel shaft on the top plate, and after strength of the top plate reaches a certain degree, demounting the internal bracing uppermost the foundation pit. The construction method has good water stopping effect, so that water leakage is avoided and big influence on surrounding environment during construction is avoided.

Owner:GUANGZHOU METRO DESIGN & RES INST

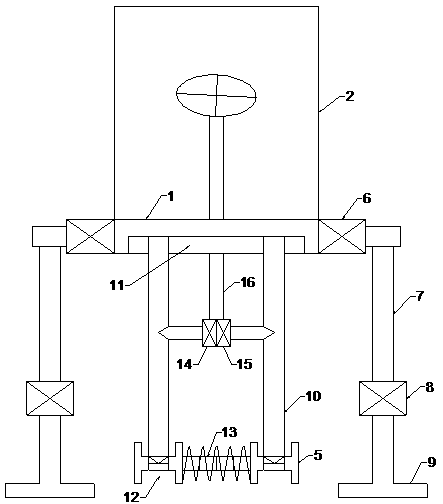

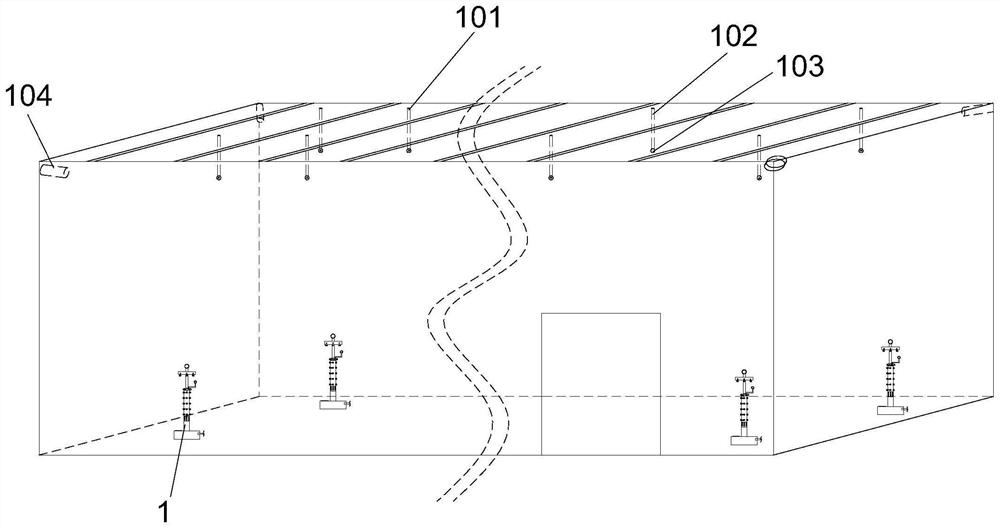

An intelligent dynamic tracking three-dimensional dust removal system and dust removal method

ActiveCN113209751BDoes not affect normal workImprove work efficiencyCombination devicesGas treatmentDust controlControl cell

The invention discloses an intelligent dynamic tracking three-dimensional dust removal system, which relates to the technical field of dust removal devices and methods. It includes a point positioning dust removal mechanism, a visual sensor, a radar positioning device, a first dust concentration sensor, a control unit, a top atomization dust removal mechanism, and The water dust recovery and separation mechanism and the point positioning dust removal mechanism are distributed in the workers' workplace. The visual sensor, radar positioning device, and first dust concentration sensor are respectively located on the point positioning dust removal mechanism and are connected to the control unit signal through wires. , the control unit controls the point positioning dust removal mechanism for dust removal according to the preset program. The point positioning dust removal mechanism is equipped with an explicit dust removal unit and an implicit dust removal unit. The bottom of the implicit dust removal unit is connected to the water. Dust recovery and separation mechanism connection. The invention can realize automatic fully explicit or fully implicit or dynamic tracking dust removal.

Owner:李海娥

Advance closed structure and construction method of post-cast belt on basement exterior wall

ActiveCN106120870BWaterproof and anti-seepageAvoid the impact of constructionArtificial islandsProtective foundationBasementBrick masonry

The invention relates to a basement exterior wall post-cast strip advanced sealing structure. The basement exterior wall post-cast strip advanced sealing structure is characterized by comprising a sealing plate (4), a brick masonry protection layer (5), a waterproof layer (6), a mortar leveling layer (7), a connecting steel plate (8), a water stop steel plate (9), connecting cotters (10) and the like; the sealing plate (4) is assembled on the outer side of the mortar leveling layer (7), protruding bars (43) at the upper end of the sealing plate (4) are embedded in grooves (44) in the lower end of the sealing plate (4) and are connected with the grooves (44) in the lower end of the sealing plate (4) into a whole through connecting ribs (45) in the perpendicular direction; one end of the connecting steel plate (8) is clamped in clamping grooves (48) in the sealing plate (4) and are provided with reinforcing steel bar penetrating holes, and horizontal bars penetrate in the reinforcing steel bar penetrating holes and are welded to the connecting steel plate (8); and the other end of the connecting steel plate (8) is provided with post-cast strip formwork fixing and connecting screw rods (15). The basement exterior wall post-cast strip advanced sealing structure belongs to the field of basement exterior wall and post-cast strip construction in industrial and civil construction body structures and has the beneficial effects that advanced water stop and soil retaining effects are good, and the construction speed is high; and good technological and economic benefits are achieved.

Owner:SHANGHAI JIASHI (GROUP) CO LTD

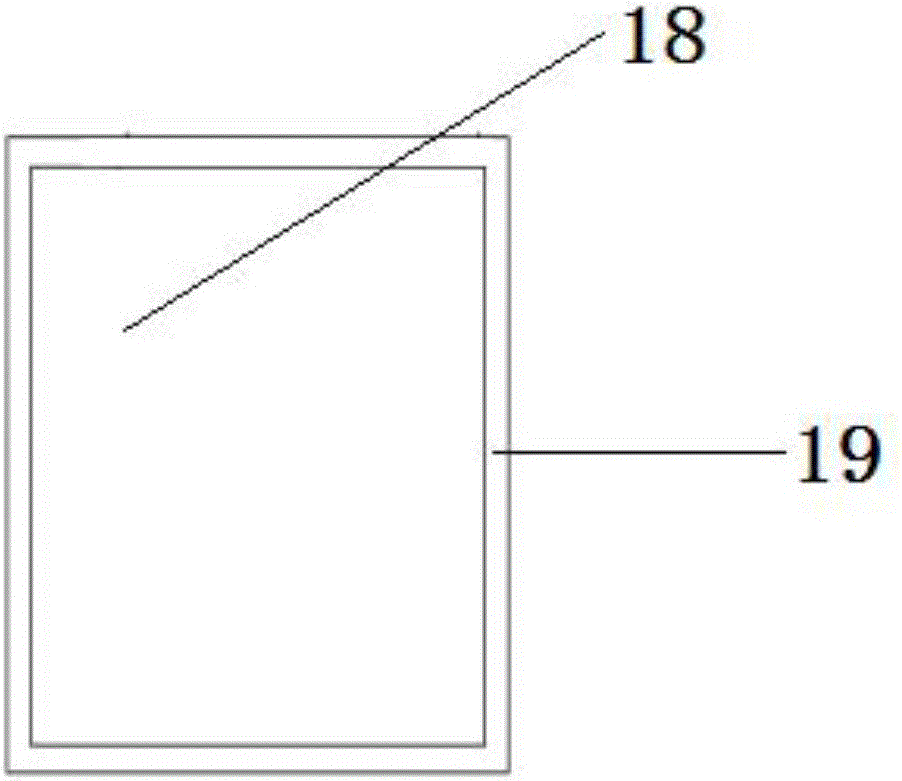

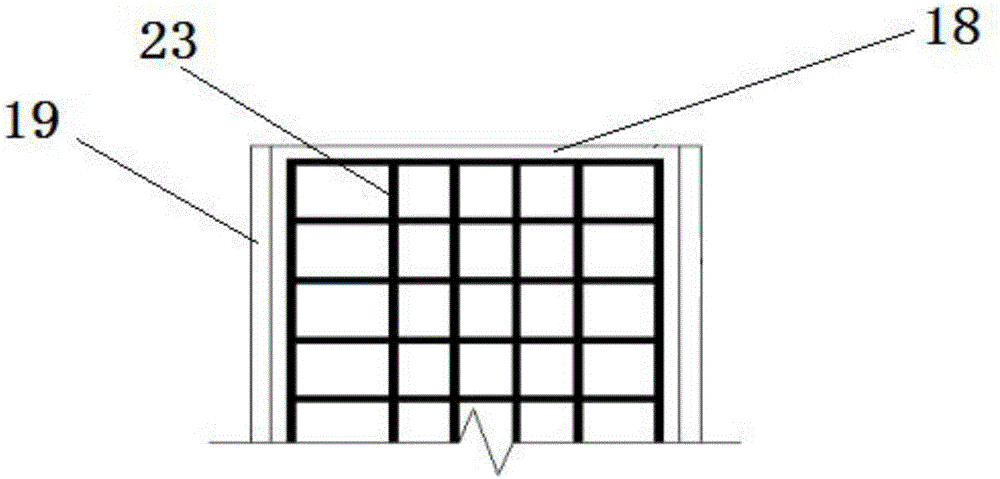

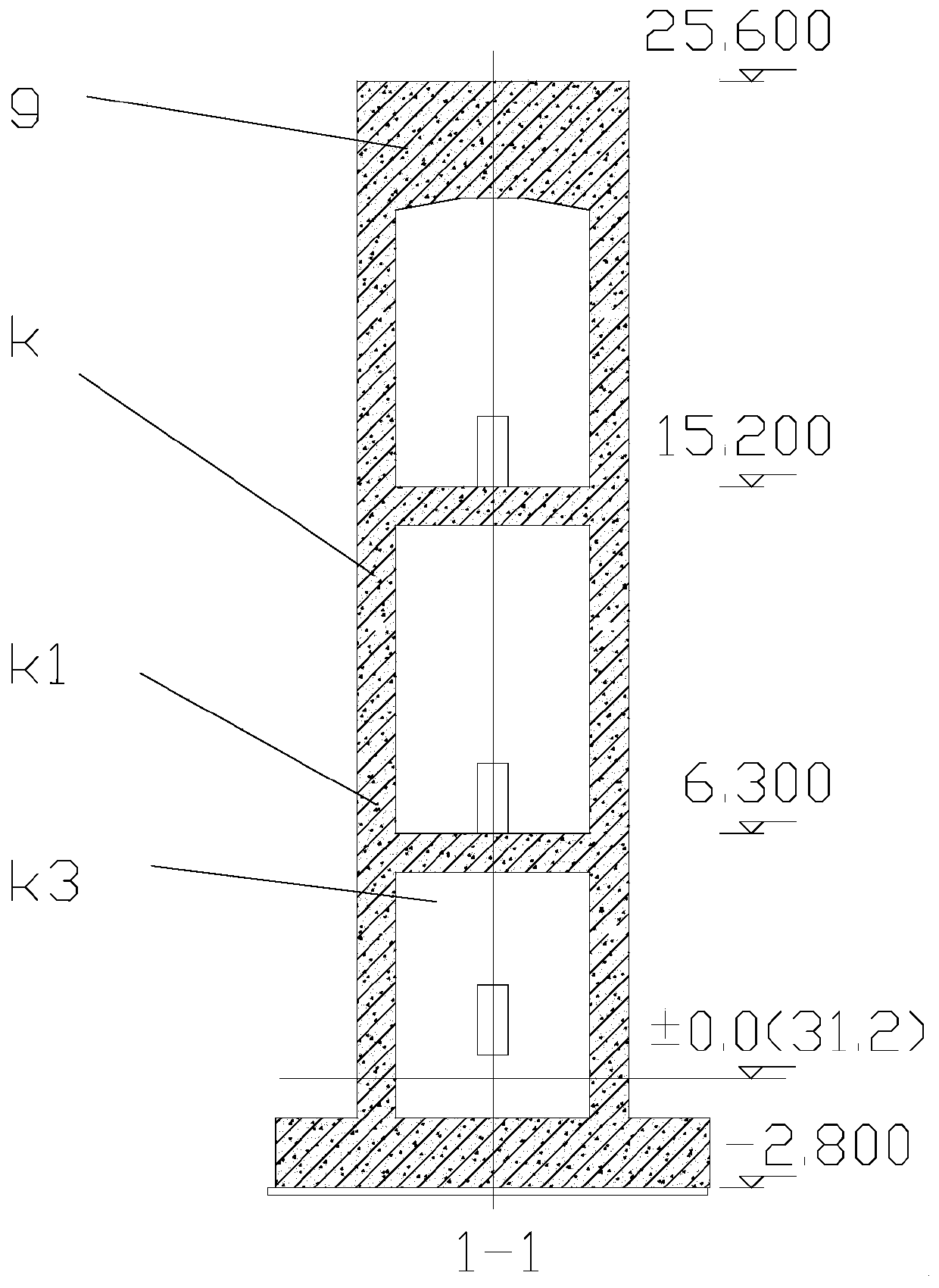

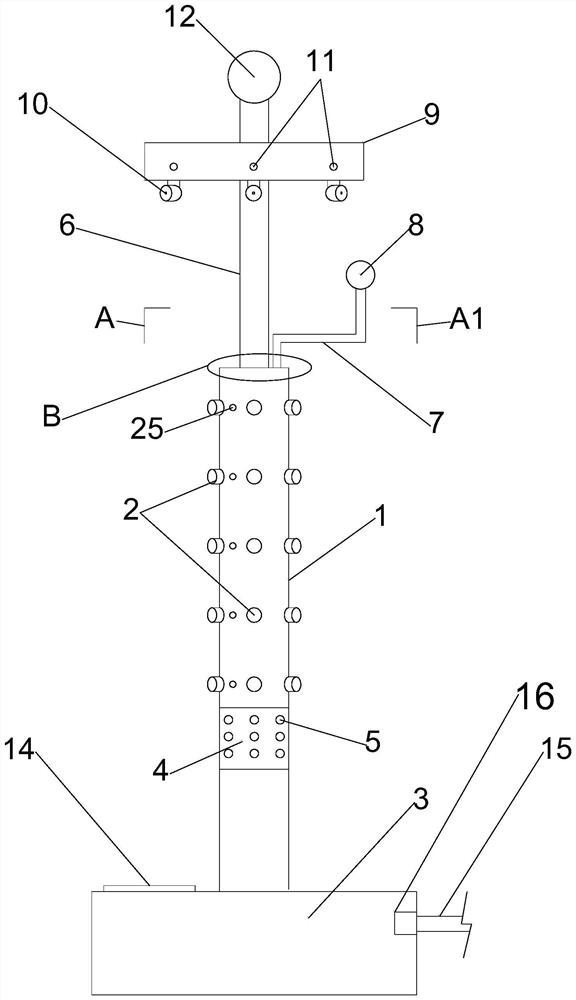

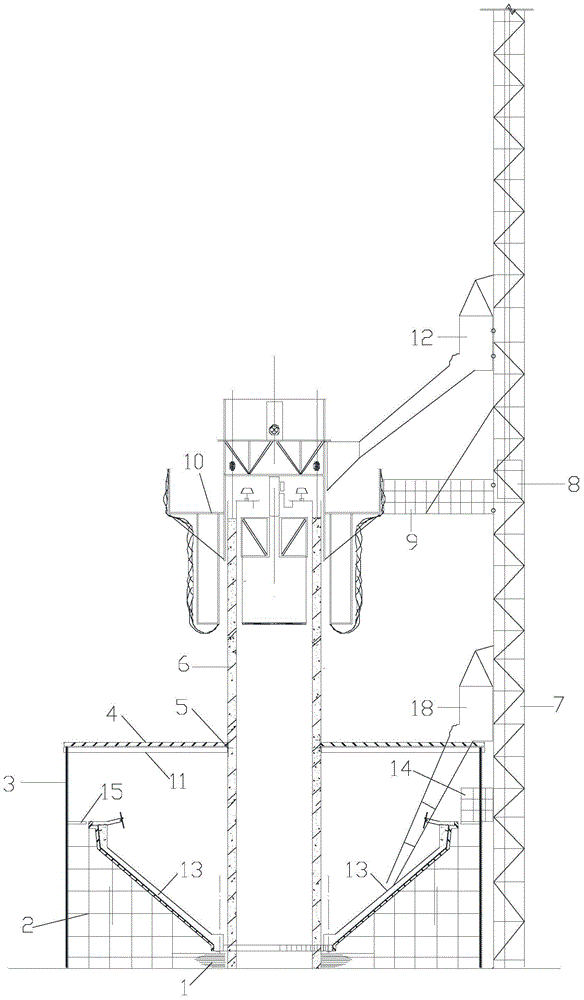

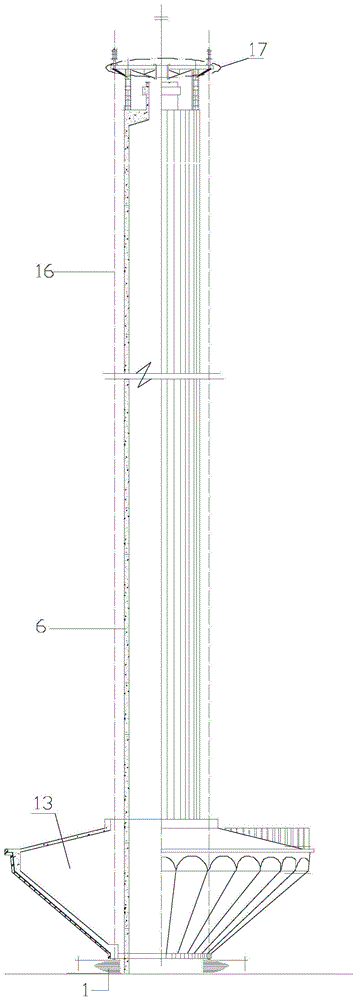

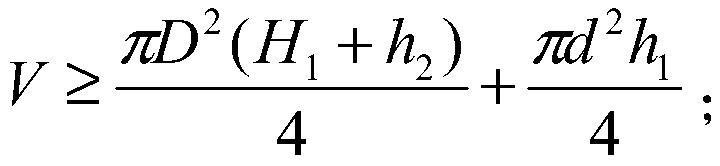

Construction method and device of large inverted conical shell water tower

ActiveCN104847160BAvoid the impact of constructionShorten the construction periodTowersTransport systemArchitectural engineering

The invention discloses a method and a device for constructing large reversed conical shell water towers, and relates to the technical field of building construction. By the aid of the method and the device, the problem of long construction periods of existing modes for constructing large reversed conical shell water towers can be solved. The technical scheme includes erecting protective sheds on the peripheries of certain positions of shafts after the heights of shaft slip forms of the water towers surpass those of water tanks of the water towers and enabling the protective sheds to at least completely cover integral prefabricated platforms of the water tanks in the vertical directions; carrying out water tank prefabricated construction below the protective sheds, carrying out shaft slip form construction above the protective sheds, conveying raw materials for shaft slip form construction and water tank prefabricated construction by the same derrick and synchronously carrying out shaft slip form construction and water tank prefabricated construction. The certain positions of the shafts are not shorter than the water tanks. The method and the device have the advantages that influence of water tower shaft construction on water tank construction can be prevented by the protective sheds, the construction periods can be effectively shortened owing to synchronous construction, and the construction periods of each single water tower can be shortened by a month; the raw materials are conveyed for shaft slip form construction and water tank prefabricated construction by the aid of the same derrick, accordingly, secondary erecting of prefabricated water tank transport systems can omitted, and construction materials and labor power can be saved.

Owner:CHINA 19TH METALLURGICAL CORP

Segmental assembly method of whole hole box girder applied to bridge construction

ActiveCN103437287BAvoid the impact of constructionIncrease temperatureBridge erection/assemblyPre stressSteel bar

The invention discloses a full-span box girder segment assembling method applied to bridge construction. The full-span box girder segment assembling method comprises the following steps that (1) full-span box girder segments to be assembled are transported to the tail part of a bridge fabrication machine by a girder transporting trolley; (2) a warm shed is arranged on the bridge fabrication machine so that the warm shed completely wraps the whole bridge fabrication machine; (3) the full-span box girder segments are suspended and placed in the preset positions by the bridge fabrication machine, and in addition, a jack is used for carrying out space position regulation so that the full-span box girder segments are placed according to the specified line shape; (4) wet joint steel bars are bound at the end parts of the full-span box girder segments, a wet joint template is installed, and in addition, wet joint concrete is poured; (5) the wet joint concrete is subjected to covering maintenance until the intensity and the elasticity modulus reache the design requirement; (6) the prestress tensioning is carried out, then, the bridge fabrication machine is emptied and forwards moves to pass through a hole, and the assembling of the next full-span box girder segments is carried out; and (7) a maintenance shed is built for carrying out later-period maintenance on wet joints. The full-span box girder segment assembling method has the advantages that the construction in cold weather can be realized under the condition of ensuring the construction quality, and high practical values and promotion values are realized.

Owner:CHINA RAILWAY CONSTR BRIDGE ENG BUREAU GRP OF THE FIFTH ENG +1

Pile forming construction method for complex geological pile foundation

InactiveCN112922009AAvoid the impact of constructionImprove construction qualityBulkheads/pilesKarstStructural engineering

The invention relates to the technical field of complex geological pile foundation construction, and particularly discloses a pile forming construction method for a complex geological pile foundation. When the content of karst caves and cracks reaches 70% or above, the karst caves and the cracks are injected to be compact through karst grouting, and then pile foundation drilling is conducted; and when the content of the karst caves and the cracks of the pile foundation reaches 30% or below, pile foundation drilling is conducted through a follow-up steel casing. According to the pile forming construction method for the complex geological pile foundation, the influence of complex geology on pile foundation construction is effectively avoided, the construction quality is effectively improved, construction is conducted according to the different occupied amounts of the karst caves and the cracks in each pile foundation through different methods, and the construction cost is greatly reduced.

Owner:CHINA RAILWAY NO 8 ENG GRP CO LTD

Power drive apparatus for concrete wet sprayer and concrete wet sprayer

ActiveCN101387158BEmission reductionReduce harmUnderground chambersBuilding material handlingSprayerFuel tank

The invention relates to the technical field of concrete spraying and provides a power-driven device for a concrete wet spraying machine. The power-driven device for the concrete wet spraying machine is used for driving a work system and a running system, and comprises a motor, an engine, a hydraulic oil tank, a first four-link pump package, a second four-link pump package and a changeover valve.The power-driven device for the concrete wet spraying machine adopts the motor and the engine for double-power drive; when the concrete wet spraying machine is operated in a tunnel, the motor can be adopted for driving the work system to operate, thereby reducing emission of exhaust gas such as carbon dioxide and so on and reducing the harm of the exhaust gas on the body health of construction workers; under the condition of no power supplied, the concrete wet spraying machine can also adopt the diesel engine for driving the work system to operate, thereby avoiding the influence of conditionssuch as power failure or inconvenient power access, etc. on the construction, so as to make the engineering construction smoothly performed under a plurality of operating conditions. The invention also provides the concrete wet spraying machine.

Owner:SANY AUTOMOBILE MFG CO LTD

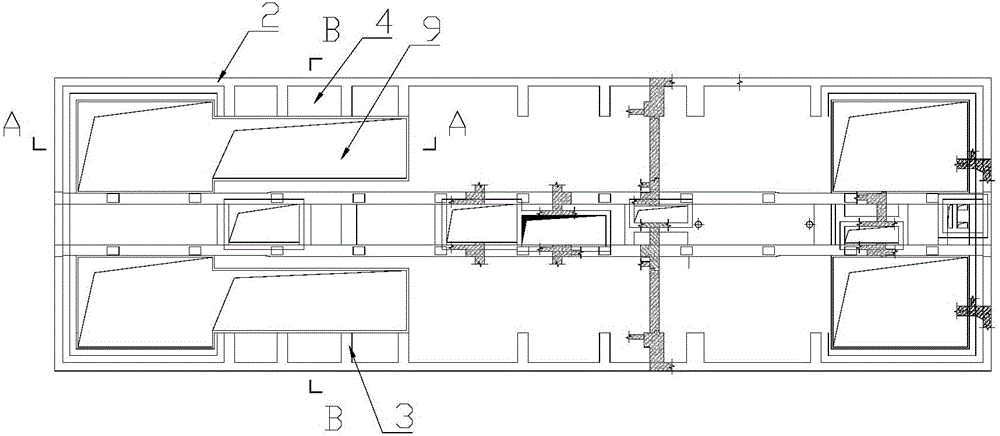

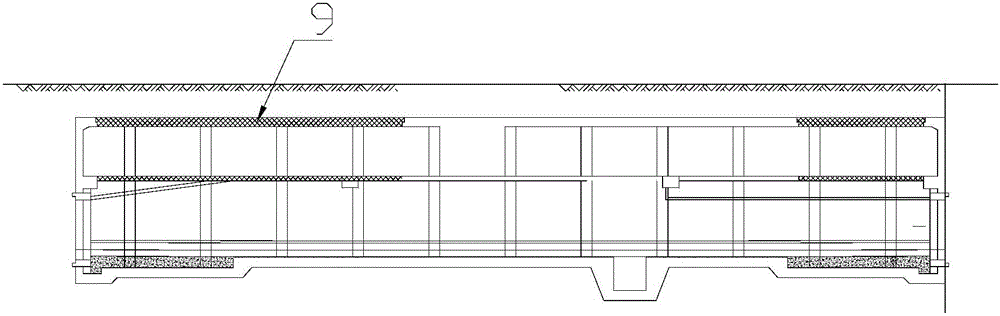

Tank body structure of tunnel concrete tank truck

PendingCN113386264AReduce labor intensitySimple and fast operationCement mixing apparatusArchitectural engineeringTank truck

A tank body structure of a tunnel concrete tank truck comprises a tank body installed on a base, a tank body sealing device is arranged at the tail end of the tank body and comprises a rear cover, a support and a lead screw, the support is fixedly connected to the tail end of the tank body, and the lead screw penetrates through the center of the rear cover and is connected with the rear cover in a sleeved manner. The tank body structure is characterized in that a rear cover push-pull device capable of driving the rear cover to slide back and forth on the lead screw is installed on the lead screw at the outer side of the rear cover, a driving device capable of driving the rear cover push-pull device to operate is arranged at the outer side of the rear cover, and the driving device comprises a manual driving device and / or an electric driving device. The tank body structure is simple, operation is convenient, and rapid opening and closing of the rear cover can be achieved.

Owner:湖北四通专用汽车有限公司

High Pier Concrete Forming Method Applied to Bridge Construction

ActiveCN103437288BGuaranteed temperature requirementsAvoid the impact of constructionBridge structural detailsBridge erection/assemblyCold weatherStructural engineering

Owner:CHINA RAILWAY CONSTR BRIDGE ENG BUREAU GRP OF THE FIFTH ENG +1

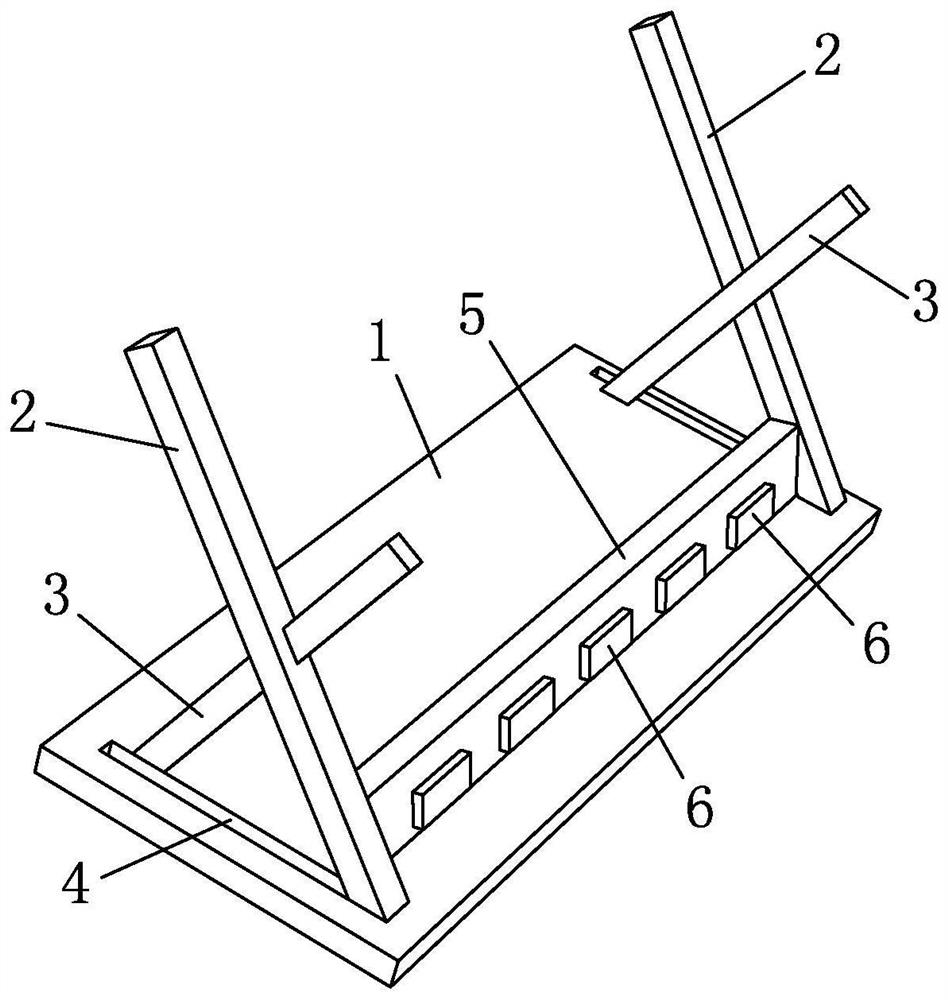

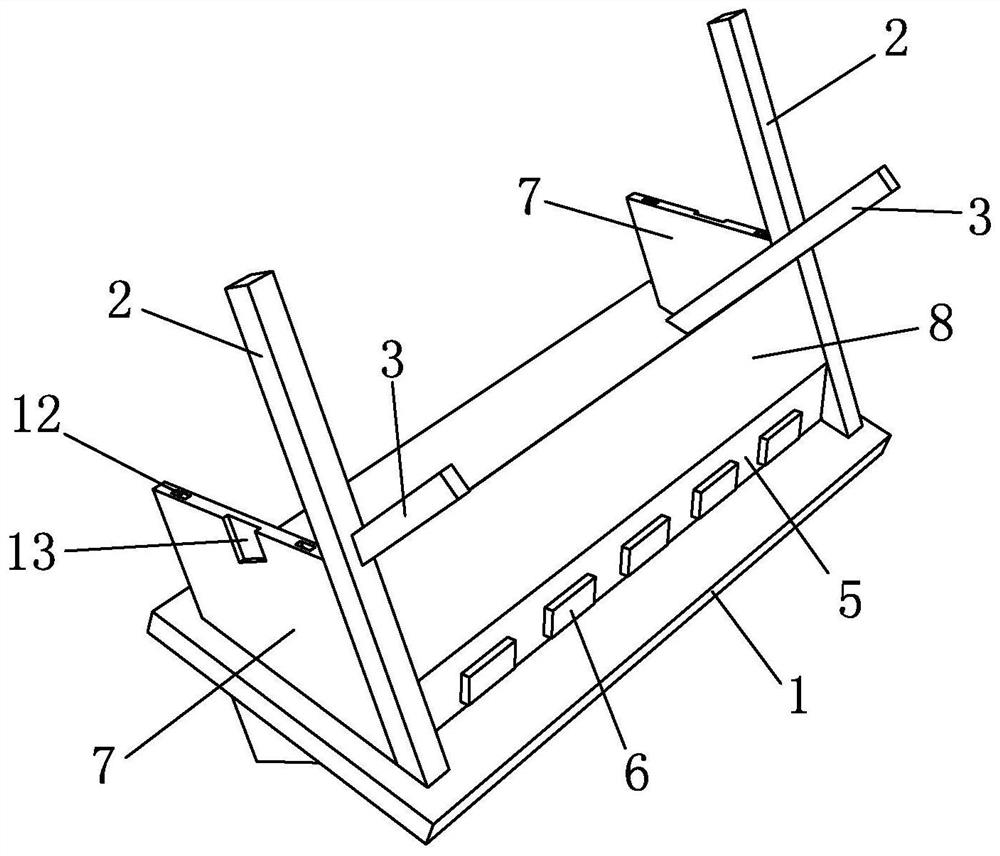

Construction method of grouted stone block revetment structure for sloping dike in river and sea reclamation area

ActiveCN108457246AStable blocking effectPrevent sinkingWater resource protectionCoastlines protectionRevetmentUltimate tensile strength

The invention discloses a construction method of a grouted stone block revetment structure for a sloping dike in a river and sea reclamation area. The construction method comprises the following stepsof a clearing the base layer of the sloping dike, b installing material stopping supports, c piling up the first layer of stone blocks, d piling up the second layer of stone blocks, e piling up the third layer of stone blocks, f conducting overall wetting, g continuously pouring concrete, h dismantling devices and i detecting the quality. According to the construction method, the stone blocks arepiled up layer by layer, after each layer of stone blocks are piled up, a protective measure is taken, it is guaranteed that the surface of each layer of stone blocks is flat, the piling-up gap of each layer of stone blocks is controlled so that the gaps between the layered stone blocks can be gradually reduced from top to bottom, the stone blocks which are piled up layer by layer mutually generate action force, the poured concrete can fully permeate into the gaps between the stone blocks and is solidified, shrinkage cracks are avoided, and it is guaranteed that the concrete can reach the corresponding strength and durability; besides, by the adoption of the construction method, the construction period is shortened, the height of each layer of piled-up stone blocks can be conveniently controlled, and the force borne by each layer of stone blocks is strictly controlled.

Owner:ZHEJIANG UNIV OF WATER RESOURCES & ELECTRIC POWER

Intelligent ground leveling machine and its leveling method

The invention discloses an intelligent ground leveling machine and a leveling method thereof. The intelligent ground leveling machine comprises a leveling machine main body, a laser receiving device, a spouting head, a stopping plate, a plurality of leveling regions, a scraping plate, a sensor and a control system. The upper limitation of the working of the leveling machine is limited by the laser receiving device, an inclined angle of the working of the leveling machine is monitored by utilizing the sensor and working parameters of the leveling machine are adjusted in real time by controlling a plurality of leveling regions through the control system, so that the leveling working in a relatively small area can be realized. The intelligent ground leveling machine has the advantages of small equipment structure, light weight of the whole leveling machine, high precision, energy saving and environmental friendliness and convenience for utilization.

Owner:浙江百施通智能科技有限公司

A multi-stage independent flood drainage system for upstream tailings pond

ActiveCN111719660BLower the altitudeReduce the overall heightSewerage structuresClimate change adaptationMining engineeringDrainage tubes

The present invention provides an upstream tailings pond multi-stage independent flood drainage system, which is composed of multi-level sub-flood drainage systems, each sub-flood drainage system consists of 1# flood drainage well, 2# flood drainage well, joint pipe, Concrete base and flood discharge pipe. 2# flood discharge well is located upstream of 1# flood discharge well. The bottom of 1# flood discharge well and 2# flood discharge well are respectively connected to the flood discharge pipe through joint pipes. The joint pipes are buried in the concrete Inside the foundation, the flood discharge pipe discharges the flood water to the adjustment pool outside the reservoir along the horseway or the bottom of the reservoir and the bank slope. The invention reduces the welding range with the anti-seepage membrane and reduces the risk of leakage. At the same time, because the construction does not need to wear the anti-seepage membrane, it can not only be used in new tailings pond projects, but also can be widely used in hidden danger control projects for flood drainage failure Or expansion projects with insufficient flood drainage capacity.

Owner:CHINA POWER CONSRTUCTION GRP GUIYANG SURVEY & DESIGN INST CO LTD

A kind of electric furnace bottom insulation and furnace shell flip-chip technology

ActiveCN109000483BGuaranteed installation qualityAvoid the impact of constructionLinings repairInsulation layerProcess engineering

The invention relates to the field of industrial capital construction and large piece installation, and provides an electric furnace hearth insulation and furnace shell inverted installation technology. By adopting the technology for installing an insulation plate between a furnace shell and a base, influence caused by outside conditions to construction is avoided, the defect that an insulation layer is naturally poor in structural strength, and thereby is prone to being damaged by external force during the installation process of a normal installation procedure is overcome as well, and the installation quality of the insulation plate is guaranteed. The electric furnace hearth insulation and furnace shell inverted installation technology comprises the construction technology of installingthe base, the construction technology of installing the furnace shell on the base in a splicing manner, and the construction technology of arranging the insulation plate between the base and the furnace shell in a lining manner.

Owner:CHINA 19TH METALLURGICAL CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com