Power drive apparatus for concrete wet sprayer and concrete wet sprayer

A power-driven, wet spraying machine technology, which is applied in shaft equipment, earthwork drilling, wellbore lining, etc., can solve the problems of large exhaust gas emissions from diesel engines, exhaust gas cannot be removed in time, and health injuries of construction workers, so as to reduce emissions, The effect of simplifying the structure and reducing the damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The content of the present invention will be described below in conjunction with the accompanying drawings. The following description is only exemplary and explanatory, and should not have any limiting effect on the protection scope of the present invention.

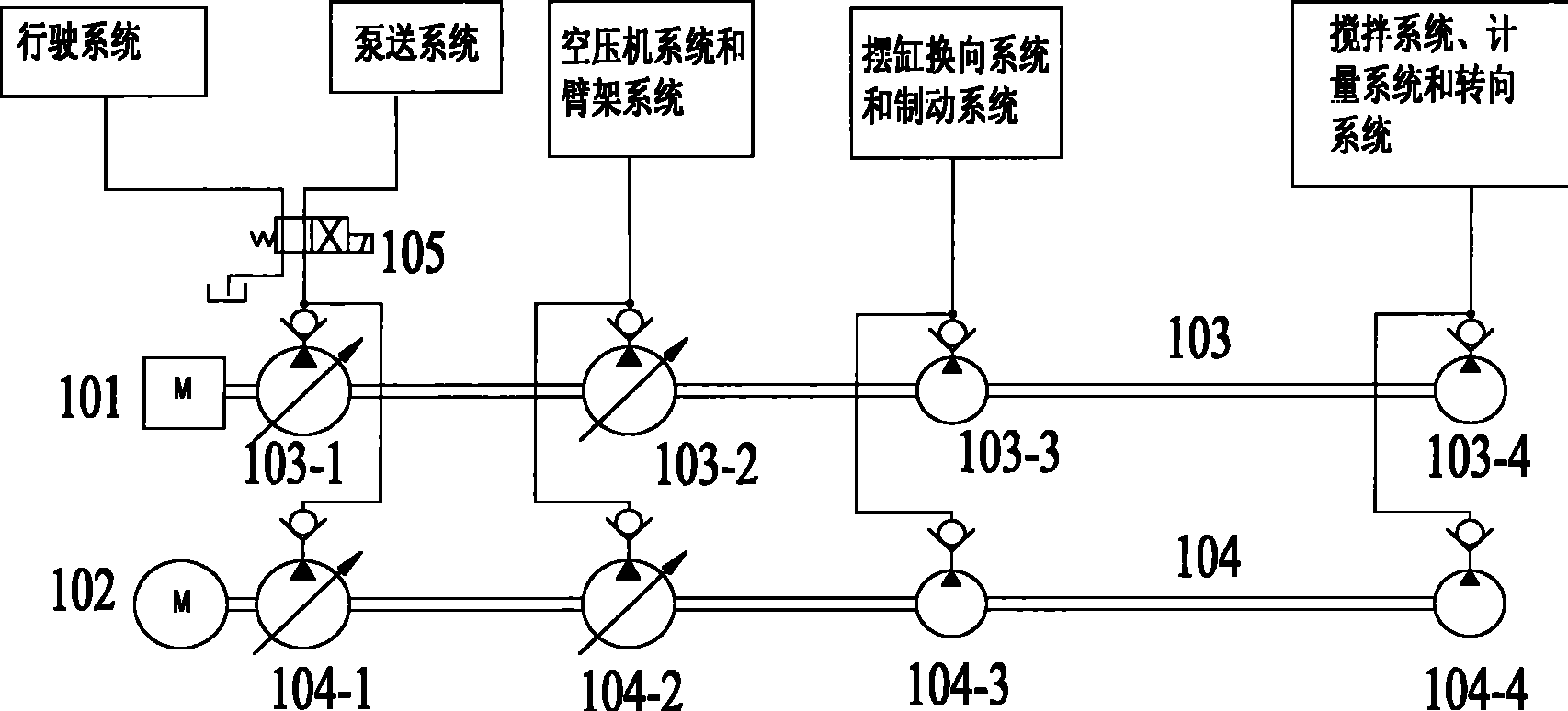

[0031] Please see image 3 , image 3 It is a structural schematic diagram of the driving device for wet concrete spraying machine provided by the first embodiment of the present invention.

[0032] like image 3 As shown, the power drive device for concrete wet spraying machine is used to drive the pumping system, driving system, air compressor system, boom system, swing cylinder reversing system, braking system, mixing system, metering system, steering system , including an electric motor 101, a diesel engine 102, a hydraulic oil tank, a first four-connected pump group 103, a second four-connected pump group 104, and an electromagnetic reversing valve 105; wherein, the first four-connected pump group includes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com