Upstream-type tailing pond multi-level independent flood drainage system

A tailings pond and upstream technology, applied in the field of tailings ponds, can solve problems such as cumbersome construction, high technical requirements for construction, and impact on seepage prevention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

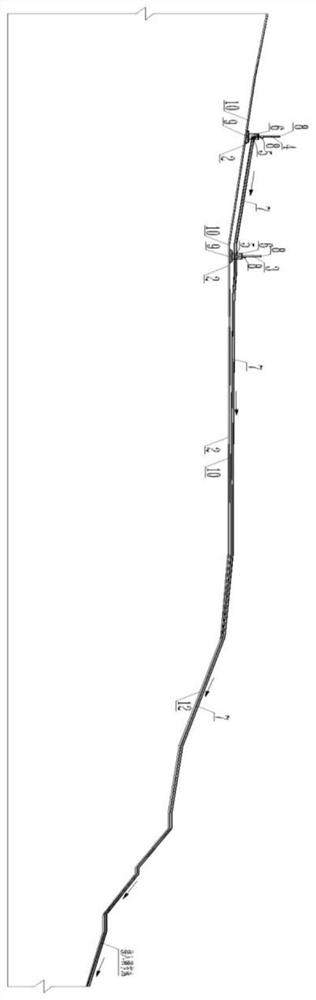

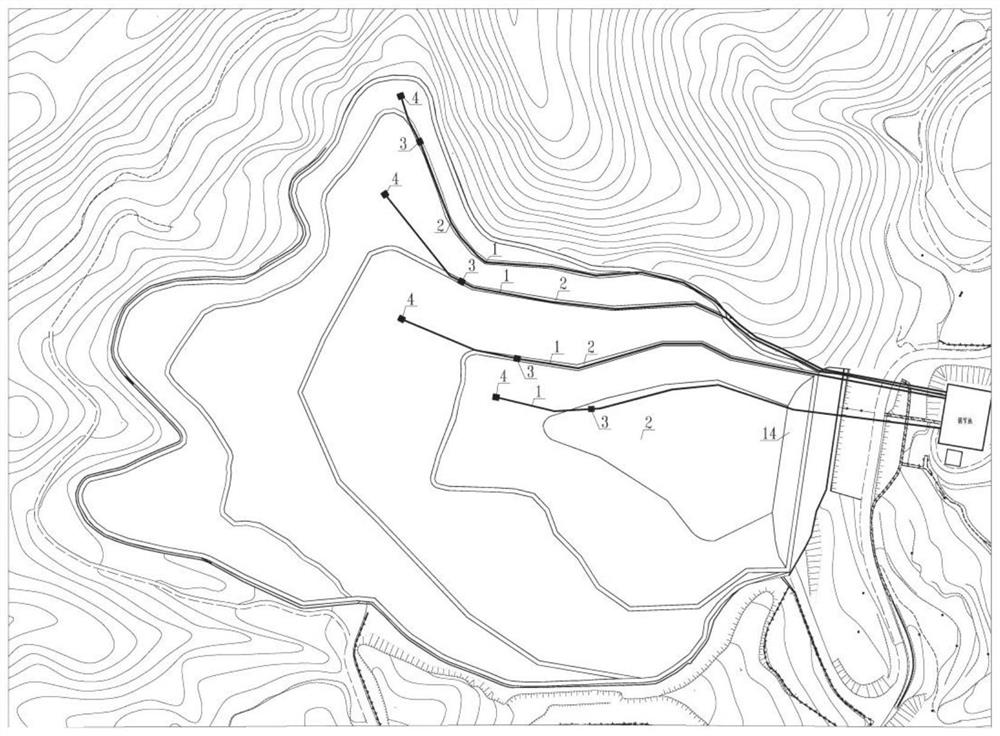

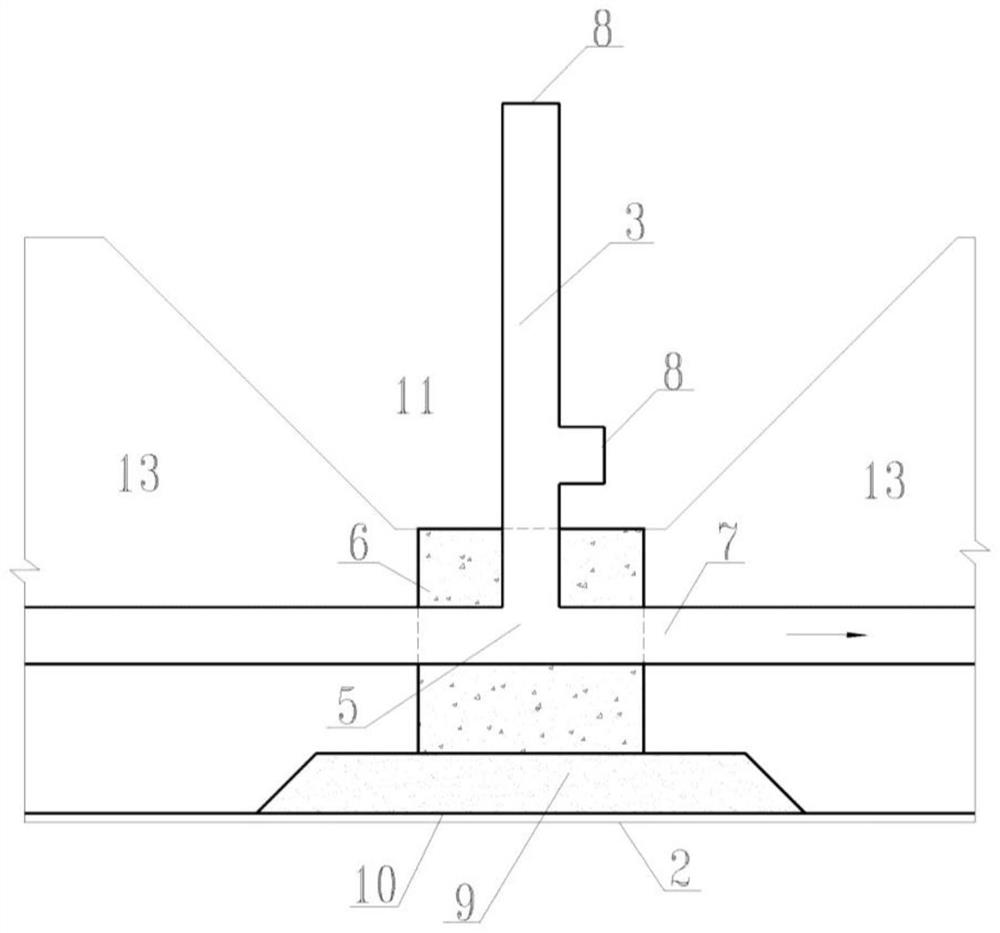

[0039] Using the above scheme, the flood drainage system is composed of multi-level sub-flood drainage system 1, each sub-flood drainage system 1 is composed of 1# flood drainage well 3, 2# flood drainage well 4, joint pipe 5, concrete base 6 and flood drainage The 2# flood drainage well 4 is located at the upstream position of the 1# flood drainage well 3, the bottom of the 1# flood drainage well 3 and the 2# flood drainage well 4 are respectively connected with the flood drainage pipe 7 through the joint pipe 5, and the joint pipe 5 is buried In the concrete foundation 6, the flood discharge pipe 7 discharges the floodwater to the adjustment pond outside the reservoir along the horseway 2 or the reservoir bottom 15 and the bank slope 12.

[0040] Each level of sub-flood drainage system 1 is independently arranged along the reservoir bottom 15 and all levels of horse trails 2, and is not directly arranged on the slag body 13, which avoids the impact of the slag body 13 settlemen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com