An intelligent dynamic tracking three-dimensional dust removal system and dust removal method

A dust removal system and dynamic tracking technology, applied in chemical instruments and methods, separation methods, radio wave measurement systems, etc., can solve the problems of dust removal equipment and technology without tracking and identification function, little meaning of dust removal, and unfavorable promotion and use, etc. To avoid the difficulty of judging the degree of pollution, reduce the cost of dust removal, improve work efficiency and production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

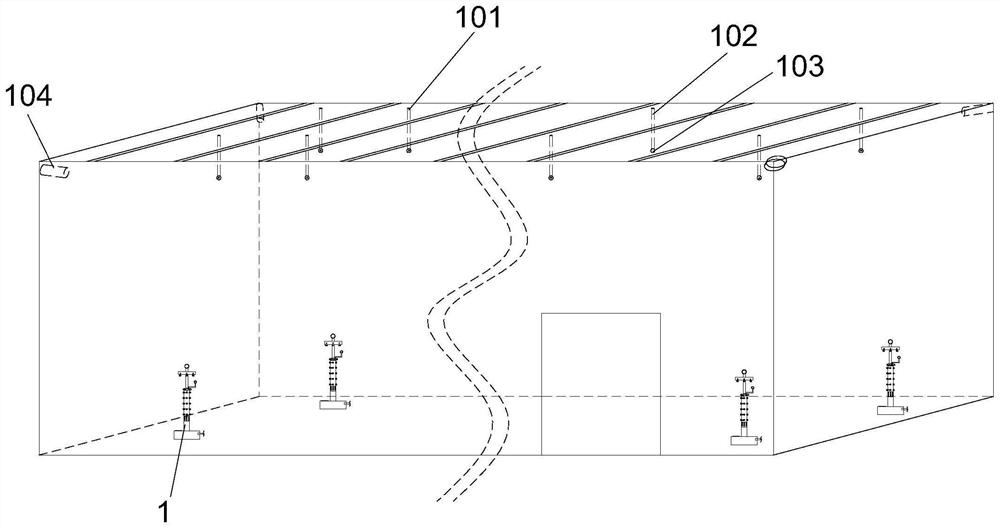

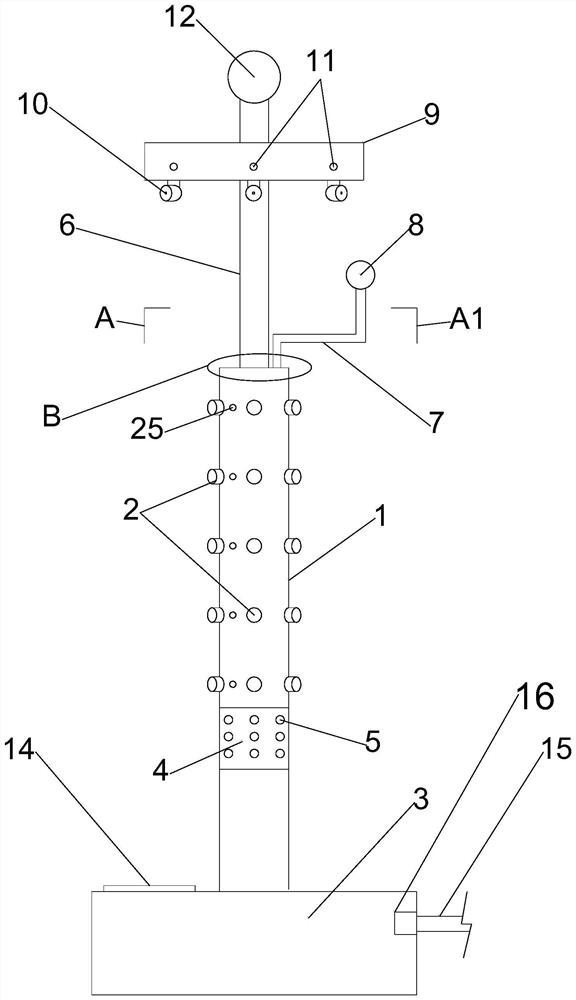

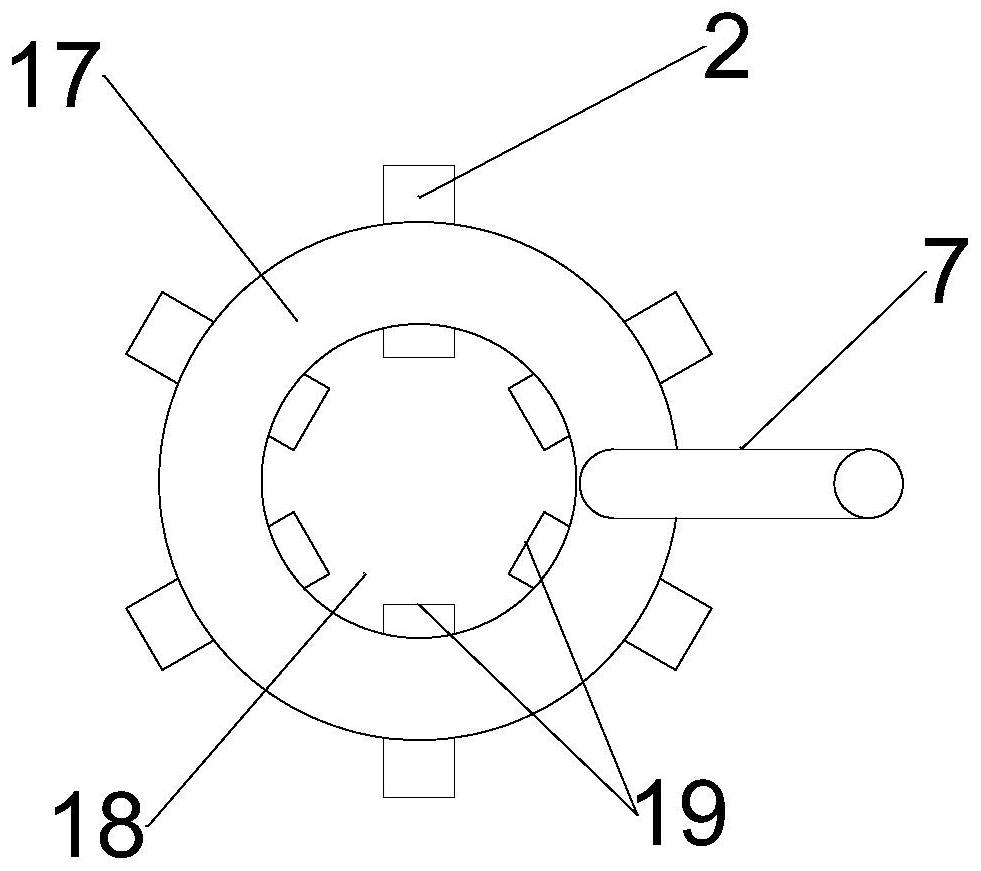

[0052] An intelligent dynamic tracking three-dimensional dust removal system, such as Figure 1-3 As shown, it includes a point positioning dust removal mechanism, a visual sensor 10, a radar positioning device 11, a first dust concentration sensor 25, a control unit (not shown in the figure), and a water dust recovery and separation mechanism. The point positioning dust removal mechanism is distributed In the worker's workplace, the visual sensor 10, the radar positioning device 11, and the first dust concentration sensor 25 are respectively installed on the point positioning dust removal mechanism, and are respectively connected to the control unit by signals through wires.

[0053] The control unit controls the point-positioning dust-removing mechanism to perform dust removal according to a preset program, and the point-positioning dust-removing mechanism is provided with an explicit dust-removing unit and an implicit dust-removing unit. The recovery and separation mechanis...

Embodiment 2

[0066] like Figure 1-3 shown:

[0067] A dust removal method for an intelligent dynamic tracking three-dimensional dust removal system, including a fully explicit dust removal mode, a fully internal implicit dust removal mode, and a dynamic tracking dust removal mode;

[0068] When there is no moving target (such as workers walking back and forth, such as moving goods mounted on vehicles) that the first atomizing nozzle can interfere with, and there is no static target (such as a moving target installed on a vehicle) that can be interfered with by the first atomizing nozzle Some materials that cannot be infiltrated with water), and when the first dust concentration sensor 25 detects that the dust concentration exceeds the standard, the full external display dust removal mode is enabled, and the steps of the full external display dust removal mode include:

[0069] Step A1, when the first dust concentration sensor 25 detects that the environmental dust pollution around the du...

Embodiment 3

[0083] An intelligent dynamic tracking three-dimensional dust removal system includes a point positioning dust removal mechanism, a visual sensor, a radar positioning device, a first dust concentration sensor, a control unit, and a water dust recovery and separation mechanism. In the workplace, the visual sensor, the radar positioning device and the first dust concentration sensor are respectively set on the point positioning dust removal mechanism, and are respectively connected with the control unit signal through the wire, and the control unit controls the point positioning dust removal according to the preset program The point positioning dust removal mechanism is provided with an external explicit dust removal unit and an internal implicit dust removal unit, and the bottom of the internal implicit dust removal unit is connected with the water and dust recovery and separation mechanism.

[0084] The intelligent dynamic tracking three-dimensional dust removal system also inc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com