Metro internal-bracing-free track panel shaft and construction method thereof

A construction method and technology of supporting rails, which are applied in shaft linings, underground chambers, shaft equipment, etc., can solve problems such as the impact of water-stop effects, restrictions on applicable conditions, and high construction risks, so as to avoid water leakage and reduce construction costs. Site, reduce the effect of engineering investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

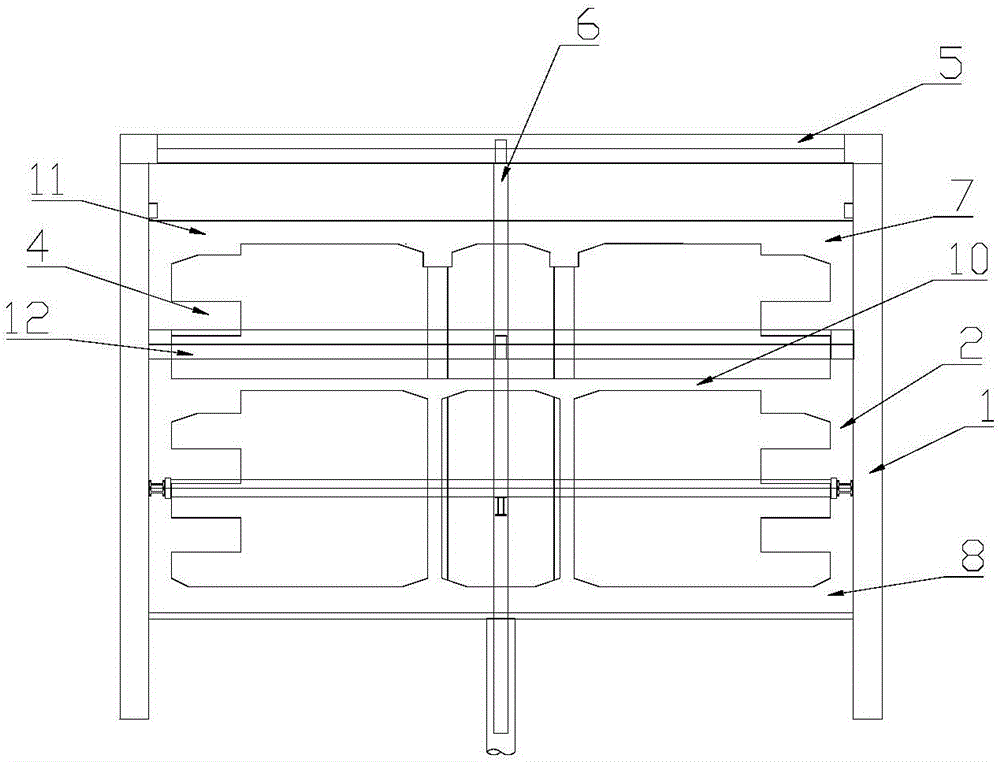

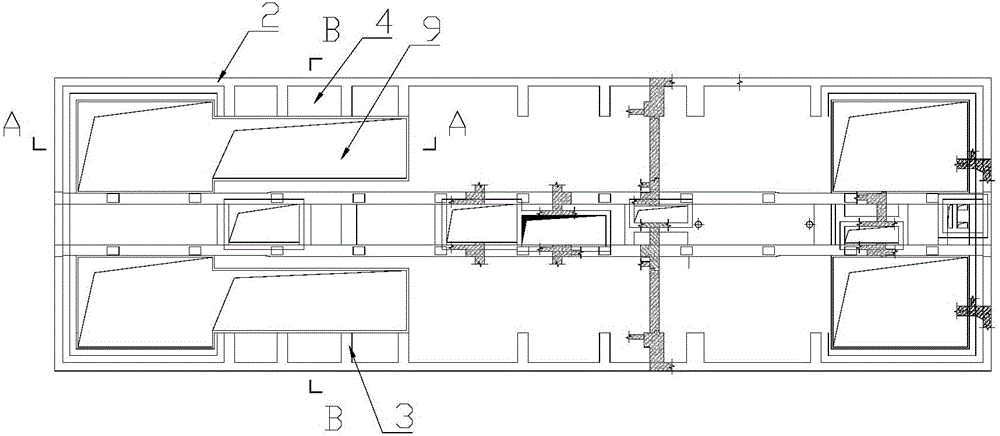

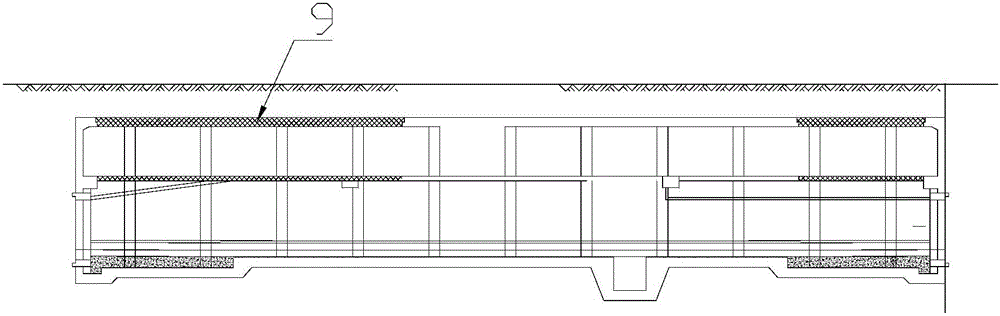

[0037] Such as Figure 1-Figure 4 As shown, the present invention provides a subway well without internal support rails, including an enclosure structure and a main structure, the enclosure structure includes an oppositely arranged ground connection wall 1, and the main structure is arranged on the enclosure structure Inside, it includes a side wall 2, at least one vertical leg wall 3 and at least one waist beam 4 arranged on the side wall 2, and the side wall 2 is arranged close to the wall 1.

[0038] The ground connection wall 1 is a reinforced concrete structure, and a crown beam 5 is arranged on the top of the ground connection wall, and the crown beam 5 connects the opposite ground connection walls 1 . The enclosure structure also includes a central column 6 and an inner support 12 arranged between the opposite side walls 2, the central column 6 is connected by a connecting beam, the top of the central column is connected with the inner support, and the inner support 12 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com