Lifting and installation process of electric furnace body

An installation process, electric furnace technology, applied in the direction of transportation and packaging, load hanging components, cranes, etc., can solve the problems of damage, poor structural strength of the insulating layer, etc., to ensure the quality of installation, overcome poor structural strength, and simple lifting Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

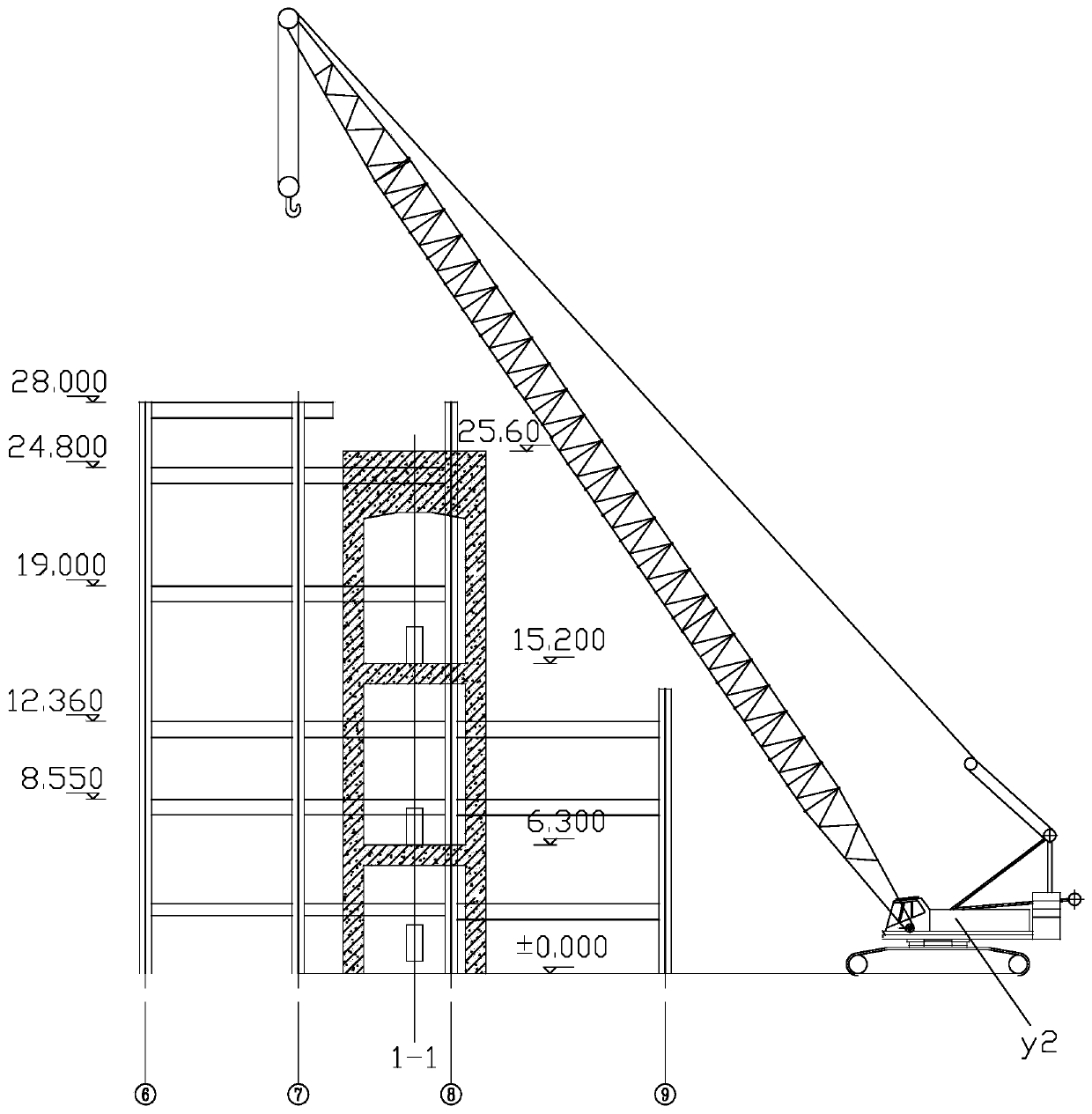

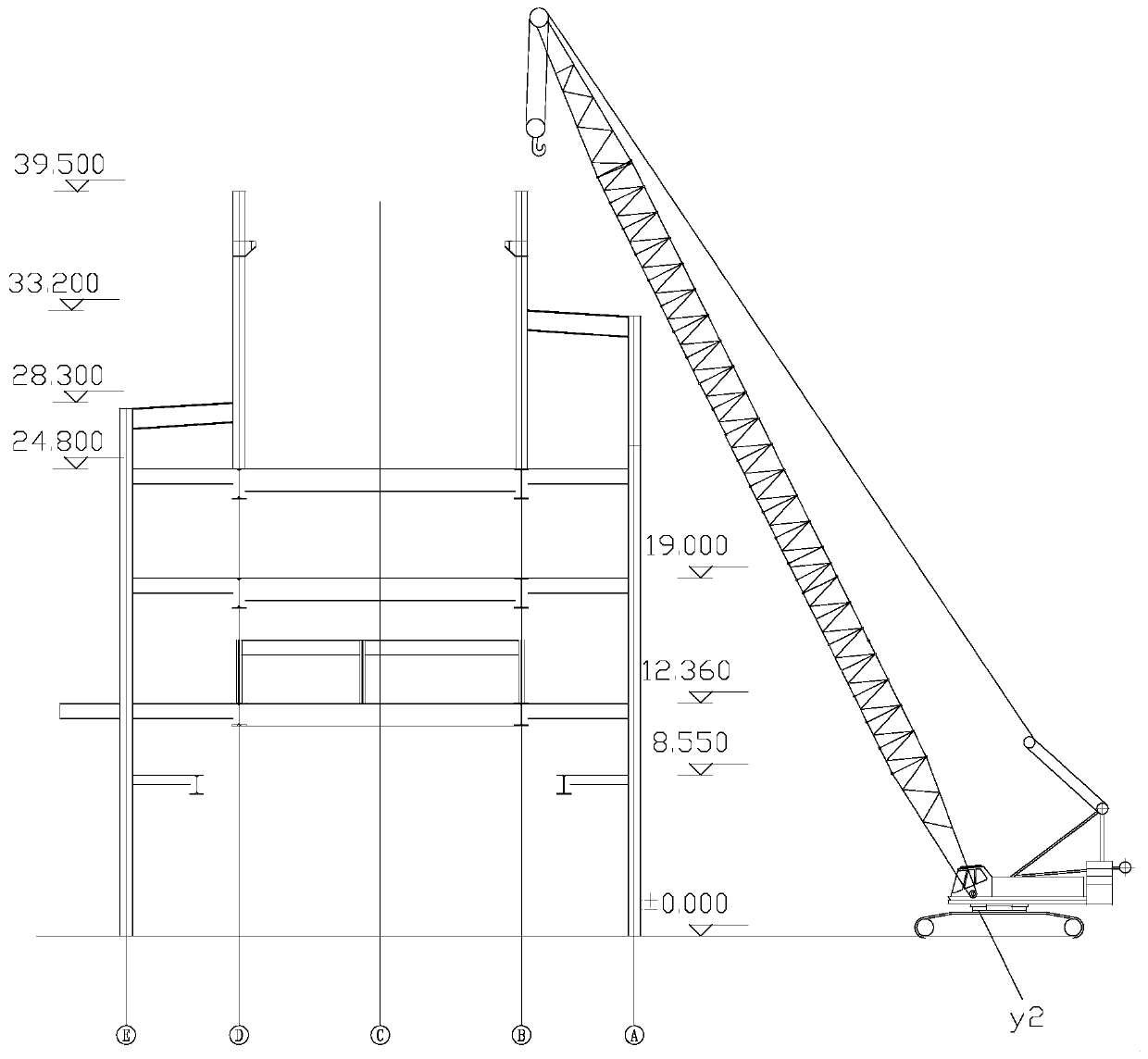

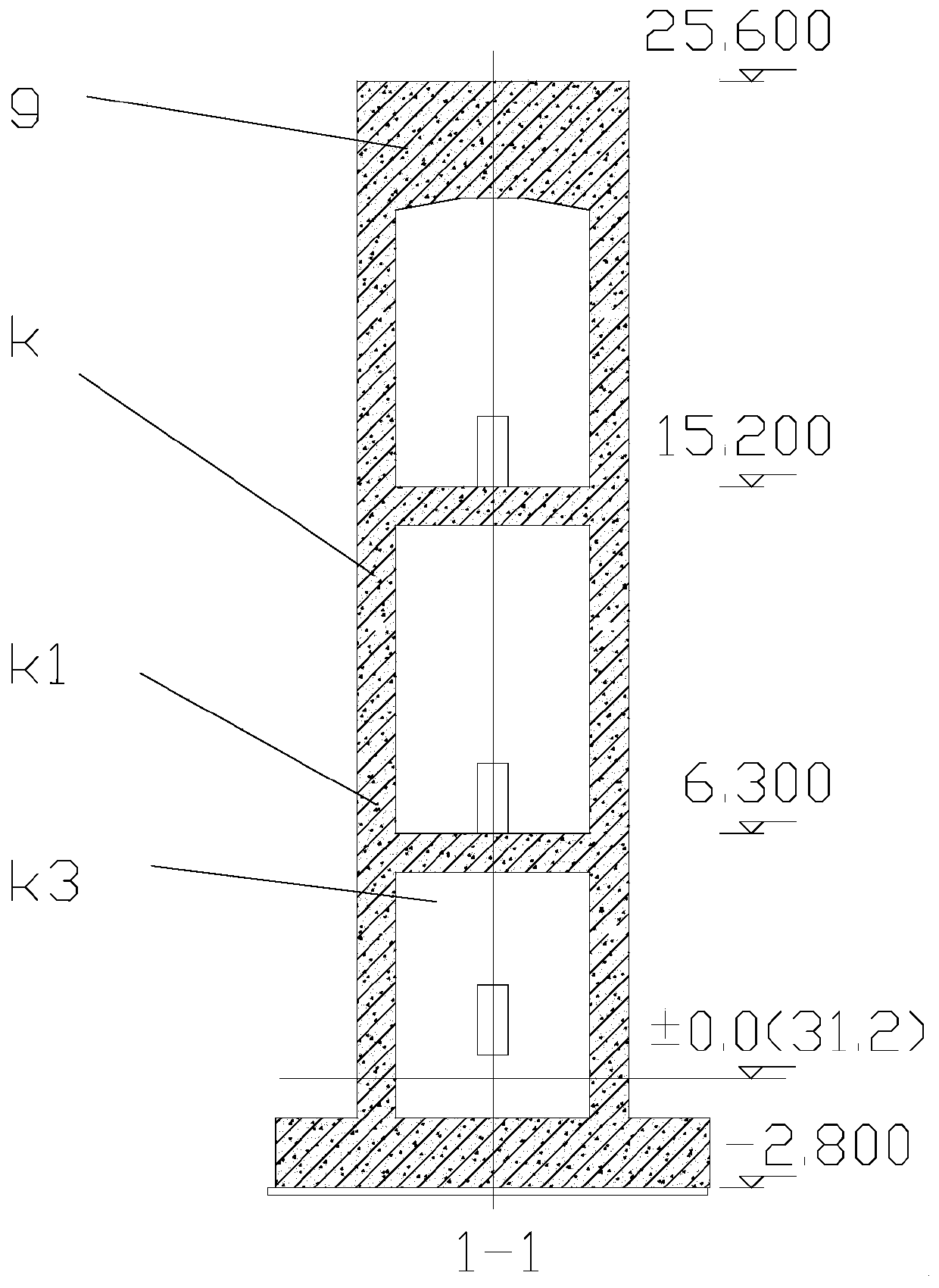

[0087] Below in conjunction with accompanying drawing, with regard to specific embodiment, this technology is further described:

[0088] A lifting and installation process for an electric furnace body, including furnace bottom insulation and furnace shell inversion technology, as well as a furnace cover inversion technology and a furnace cover installation technology using mobile lifting equipment, a hoist and a pulley block.

[0089] see Figure 1-Figure 6 , Figure 9 , Figure 10 , Figure 22 As shown, the furnace bottom insulation and furnace shell inversion technology includes the base z laid on the foundation c1 of the electric furnace workshop c (also referred to as a factory building in this example), the furnace shell k placed on the base z, and the lining on the base The insulating plate j between z and the furnace shell k; the base z includes the furnace bottom steel beam z1 installed on the foundation c1, the bottom plate z2 laid on the furnace bottom steel beam...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com