Construction method and device of large inverted conical shell water tower

A construction method and technology of a construction device are applied in the construction method and device field of a large inverted cone shell water tower, which can solve the problems of long construction period of the construction method, and achieve the effects of saving construction materials and labor, improving efficiency and sufficient time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

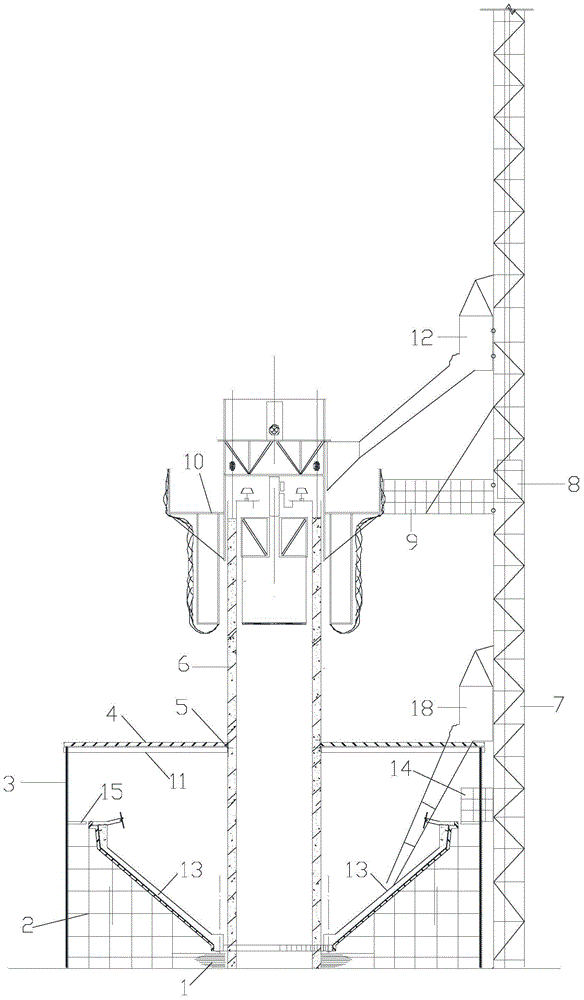

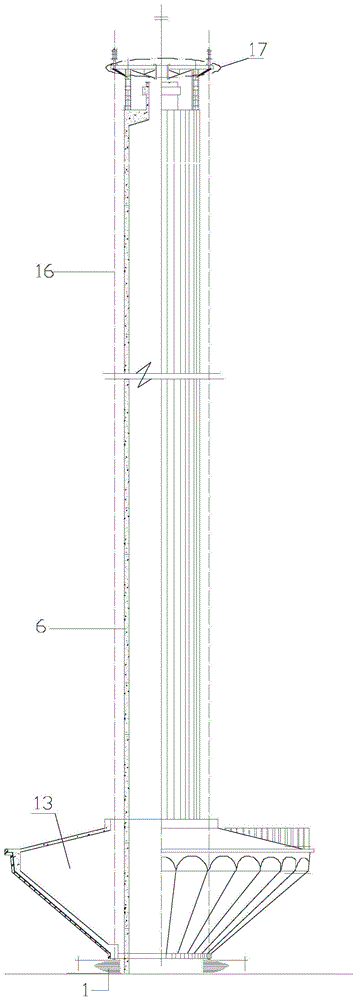

[0023] The present invention will be further described below in conjunction with accompanying drawing.

[0024] Such as figure 1 As shown, the "construction method for large-scale inverted cone water tower" of the present invention first erects the derrick 7 and performs sliding form construction on the cylinder body 6. When the height of the cylinder body sliding form exceeds the height of the water tank 13 of the water tower, the cylinder body 6 is not lowered Set up protective shed around water tank 13 height places. In order to shorten the construction period as much as possible, the protection shed can be erected when the height of the lowest part of the sliding form just exceeds the design height of the water tank 13; in order to facilitate the smooth prefabrication of the water tank 13 under the protection shed, the height of the protection shed should be appropriately high the height of the water tank 13; in order to ensure the safety of the prefabricated construction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com