Intelligent ground leveling machine and its leveling method

A leveling machine and ground technology, applied in the processing of building materials, construction, building structure, etc., can solve the problems of large volume, mortar accumulation, small unit area, etc., achieve high operational flexibility, compact equipment structure, overcome the low precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The present invention will be further described below in conjunction with the accompanying drawings and embodiments of the specification, which are only explanations and illustrations of the present invention, and cannot be used as limitations on the scope of protection of the present invention.

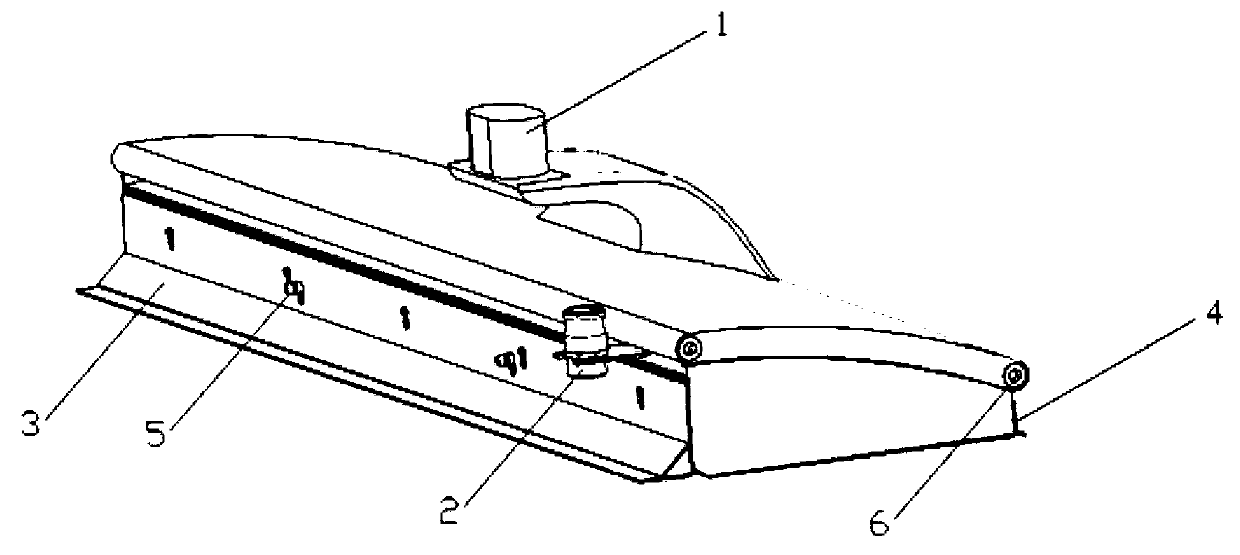

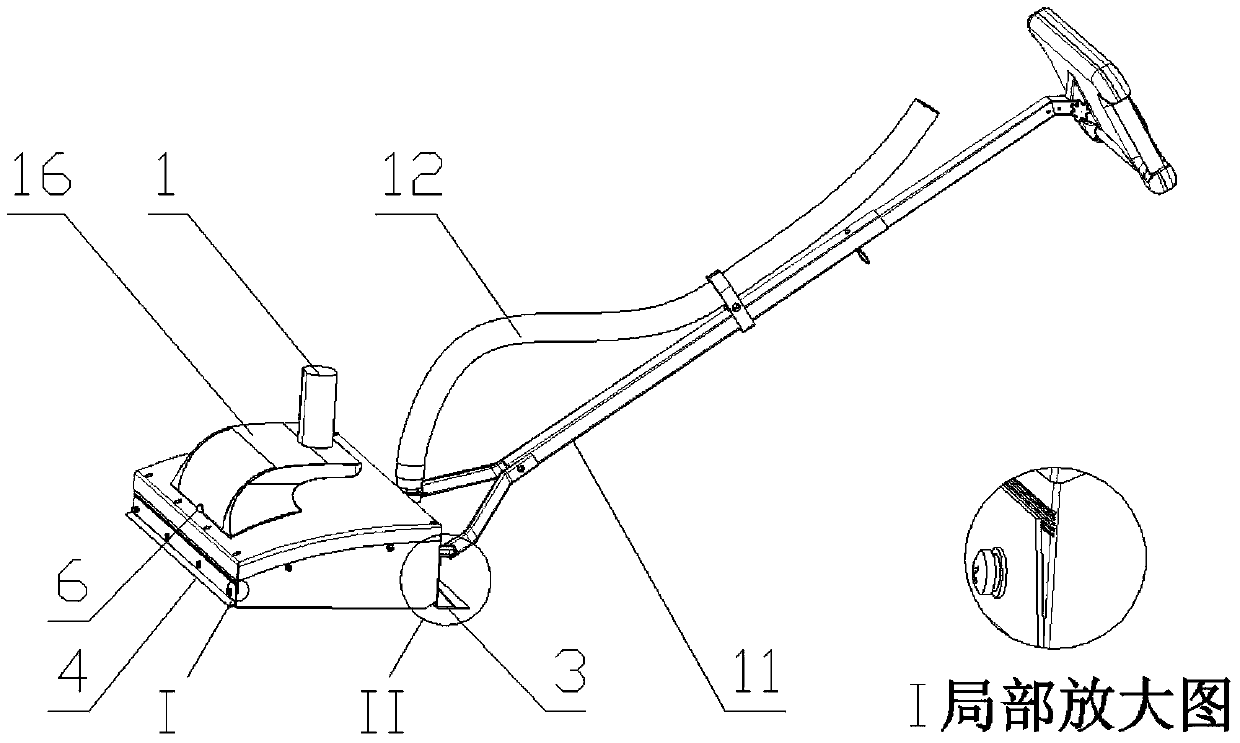

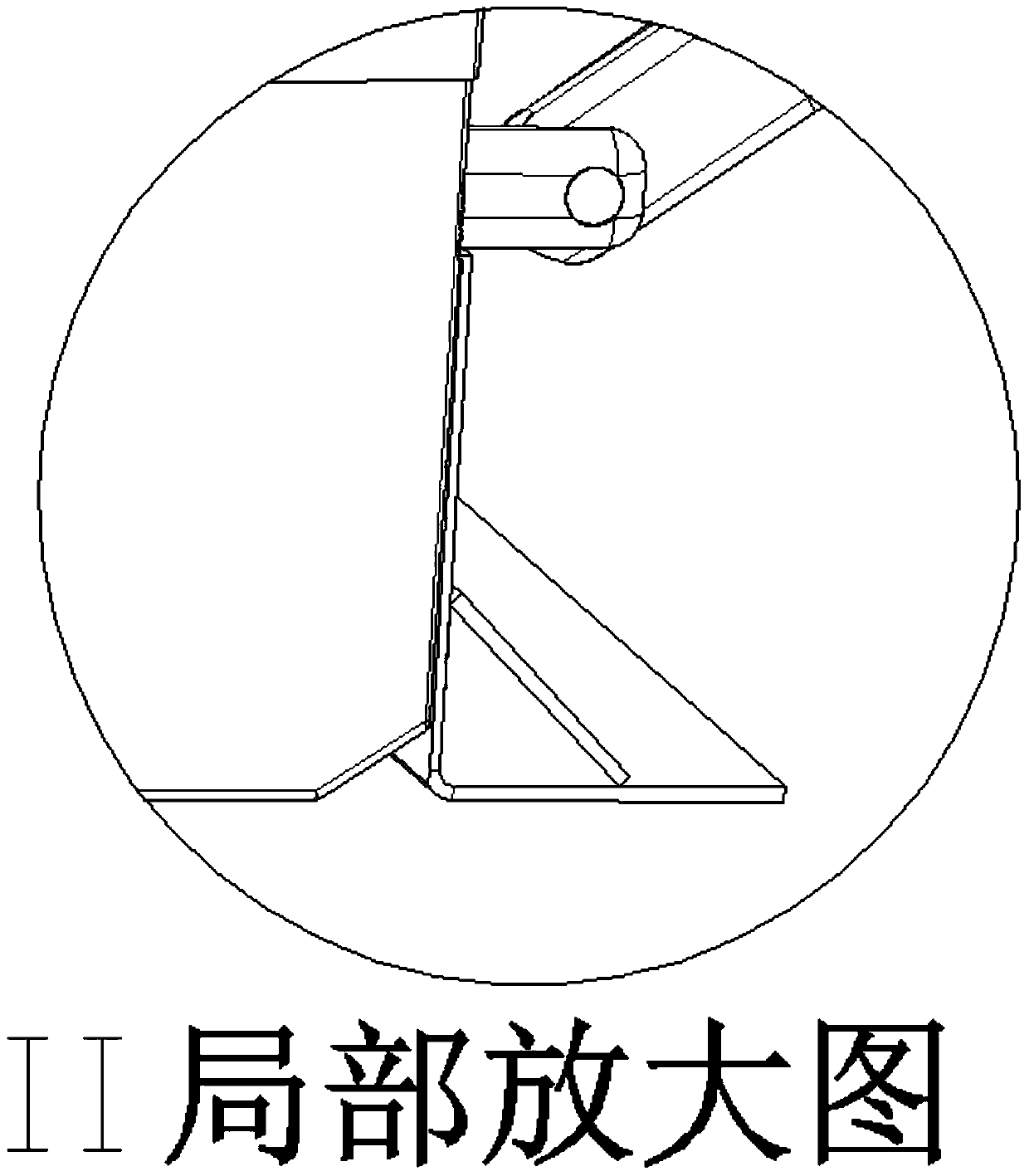

[0051] Such as figure 1 As shown, the present invention provides an intelligent ground leveling machine, which includes: a leveling machine main body, a laser receiving device 1, a spray head 2, a stop plate 3, and a plurality of leveling areas 7 (see Figure 7 ), the squeegee 4, the degree of inclination detection sensor, the moving speed detection sensor and the control system, wherein the spray head 2 and the squeegee 4 are selected as the components used in this embodiment, and these two components may not be available in actual use , if the leveling machine can choose external spraying equipment or choose to manually spray grouting in front of the leveling machine directi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com