A kind of electric furnace bottom insulation and furnace shell flip-chip technology

A furnace shell and electric furnace technology, applied in lining repair and other directions, can solve problems such as damage and poor structural strength of insulating plates, and achieve the effect of ensuring installation quality and overcoming poor structural strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

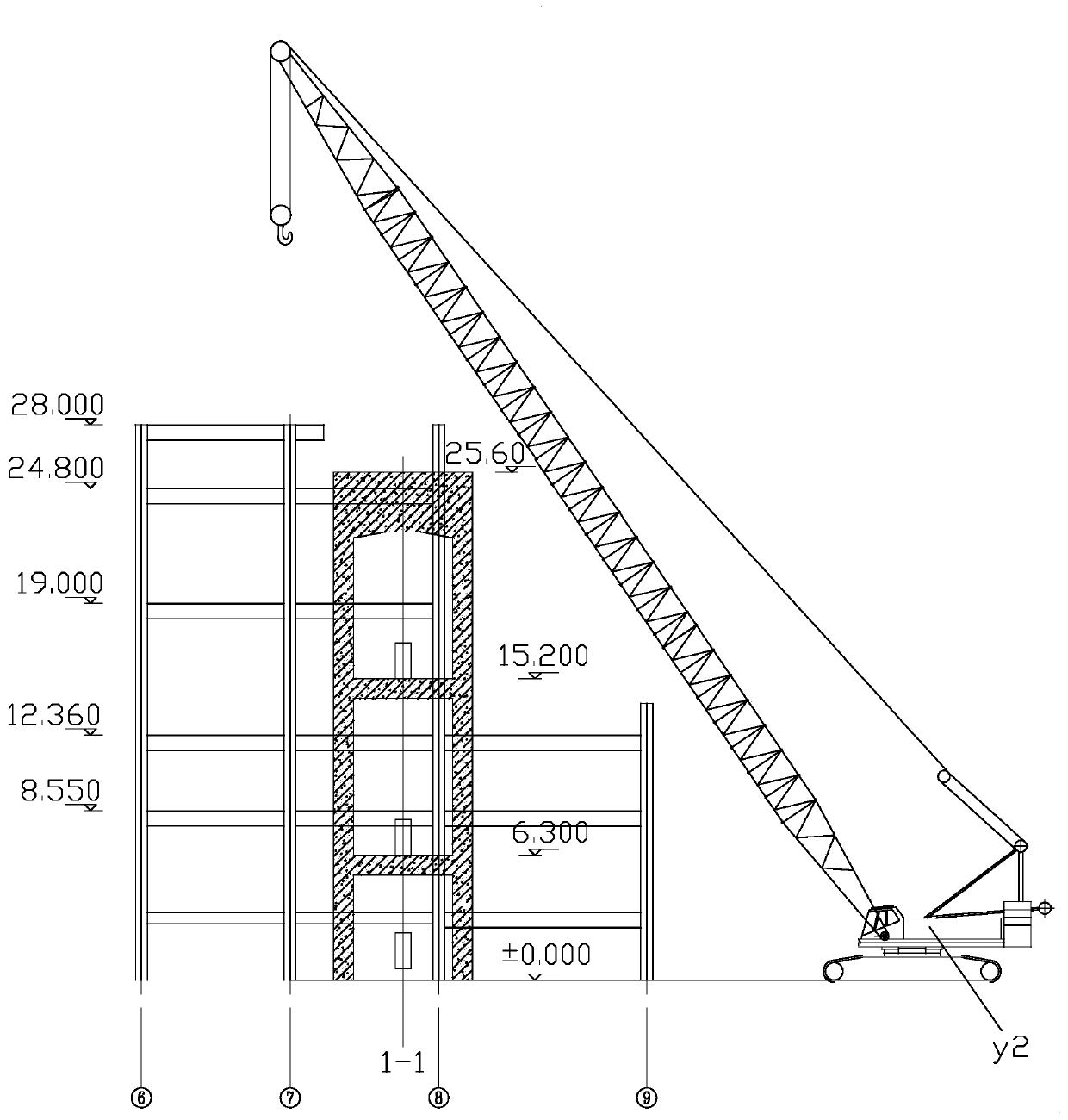

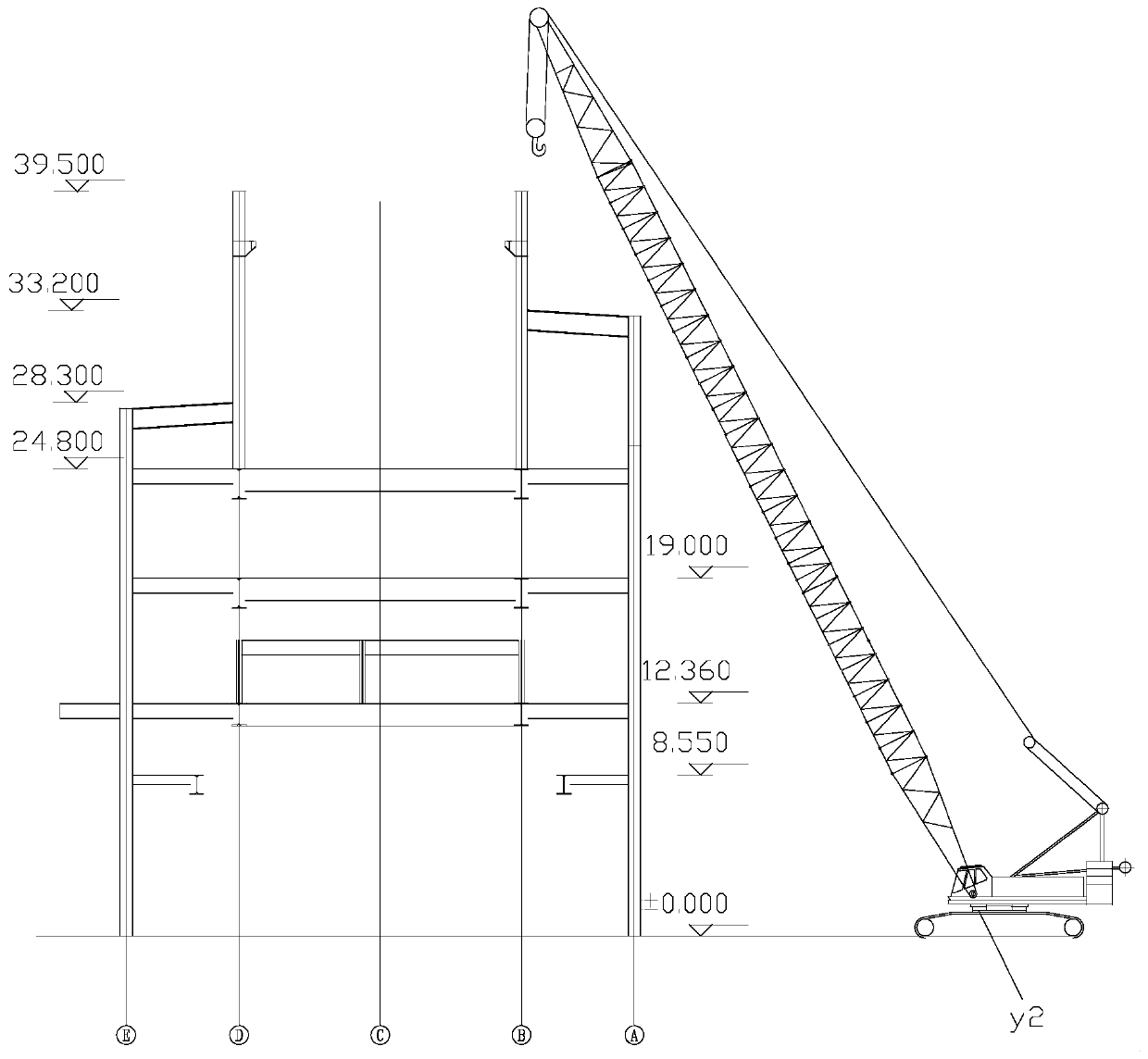

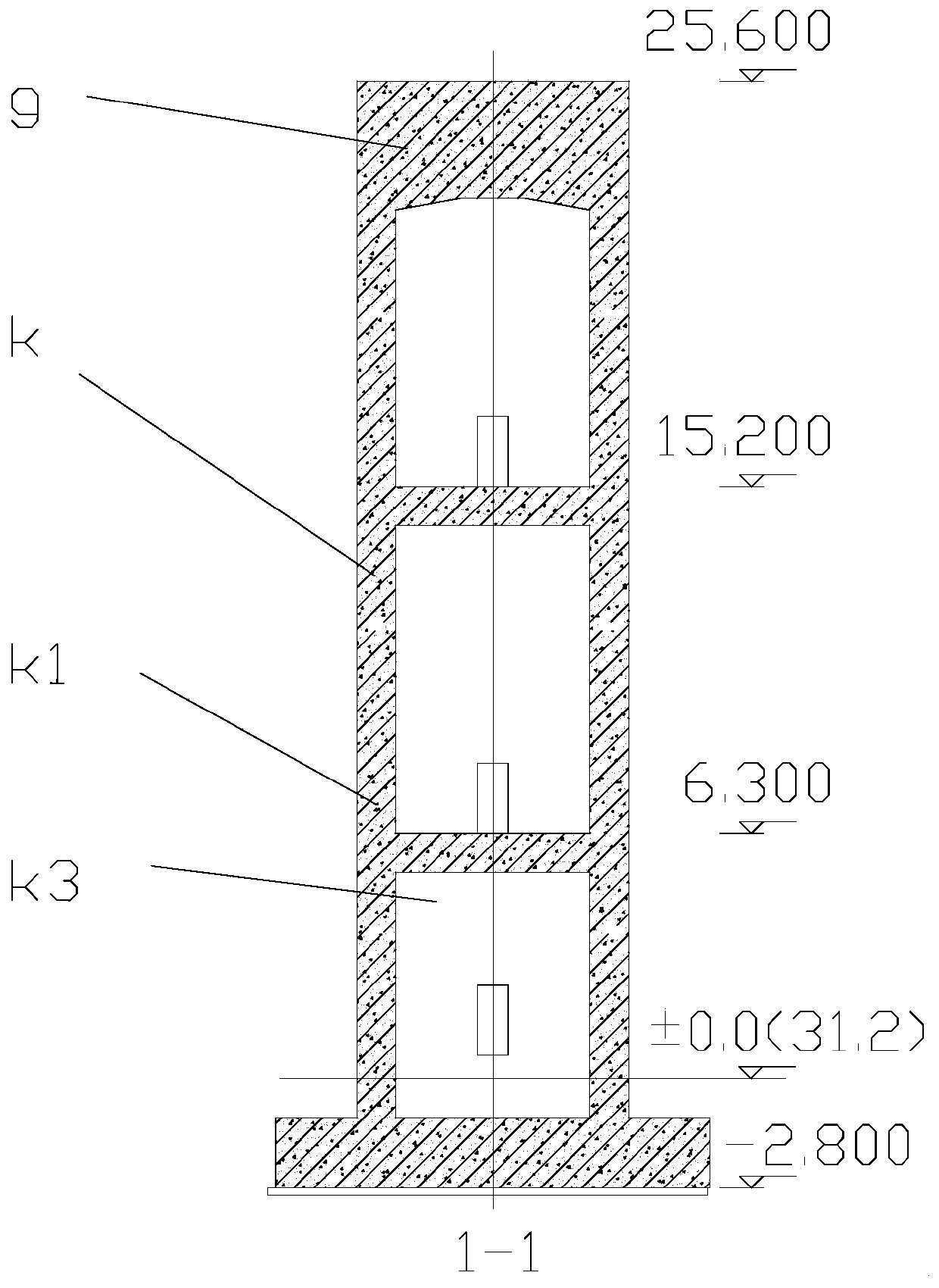

[0060] Below in conjunction with accompanying drawing, with regard to specific embodiment, this technology is further described:

[0061] see Figure 1-Figure 6 , Figure 9 , Figure 10 , Figure 22 The bottom insulation and furnace shell inversion process of the electric furnace shown includes the base z laid on the foundation c1 of the electric furnace workshop c (also referred to as the factory building in this example), the furnace shell k placed on the base z, the lining The insulating plate j between the base z and the furnace shell k; the base z includes the furnace bottom steel beam z1 installed on the foundation c1, the bottom plate z2 laid on the furnace bottom steel beam z1, and constitutes the components of the furnace bottom steel beam z1 It is I-beam z3; the furnace shell k includes several split furnace shells k1 uniformly distributed along the axis of the electric furnace, and each adjacent two split furnace shells k1 are lapped and fixedly connected by seve...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com