Construction process of cable crane hoisting system

A cable crane and construction technology technology, which is applied in cable cranes, cranes, transportation and packaging, etc., can solve the difficulty of horizontal and vertical transportation of components to the construction work surface, the mountain bridge has no rear balance section assembly site, and enlarge the pier. Beam joints and other problems, to achieve the effect of simple construction process, reducing span, and speeding up the construction progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

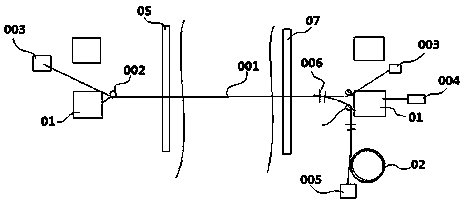

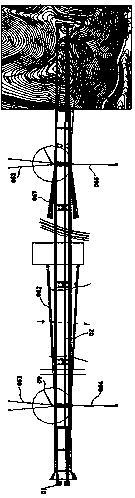

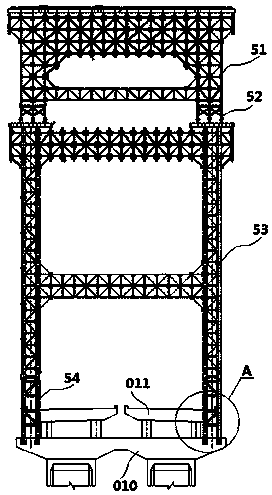

[0066] A construction process of a cable crane hoisting system according to the present invention, which includes a main anchor 01, a main load-bearing cable 02, a wind cable, a lifting trolley, a cable saddle, and a left-bank tower 05 and a right-bank tower 07. The steps are as follows:

[0067] (1) On the transition pier 010 on both sides of the bridge, construct the foundation embedded parts of the tower 05 on the left bank and the tower 07 on the right bank, and then assemble the tower 05 on the left bank and the tower 07 on the right bank, and install wind turbines on the corresponding towers. cable;

[0068] (2) Install the cable saddle on the top of the tower 05 on the left bank and the tower 07 on the right bank, and simultaneously carry out the construction of the main anchor 01 on both banks;

[0069] (3) Install the main bearing cable 02 and at the same time install the traction and lifting hoist;

[0070] (4) Carry out the installation of hoisting trolley, tractio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com