Thrust balancing device for cryogenic fluid machinery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

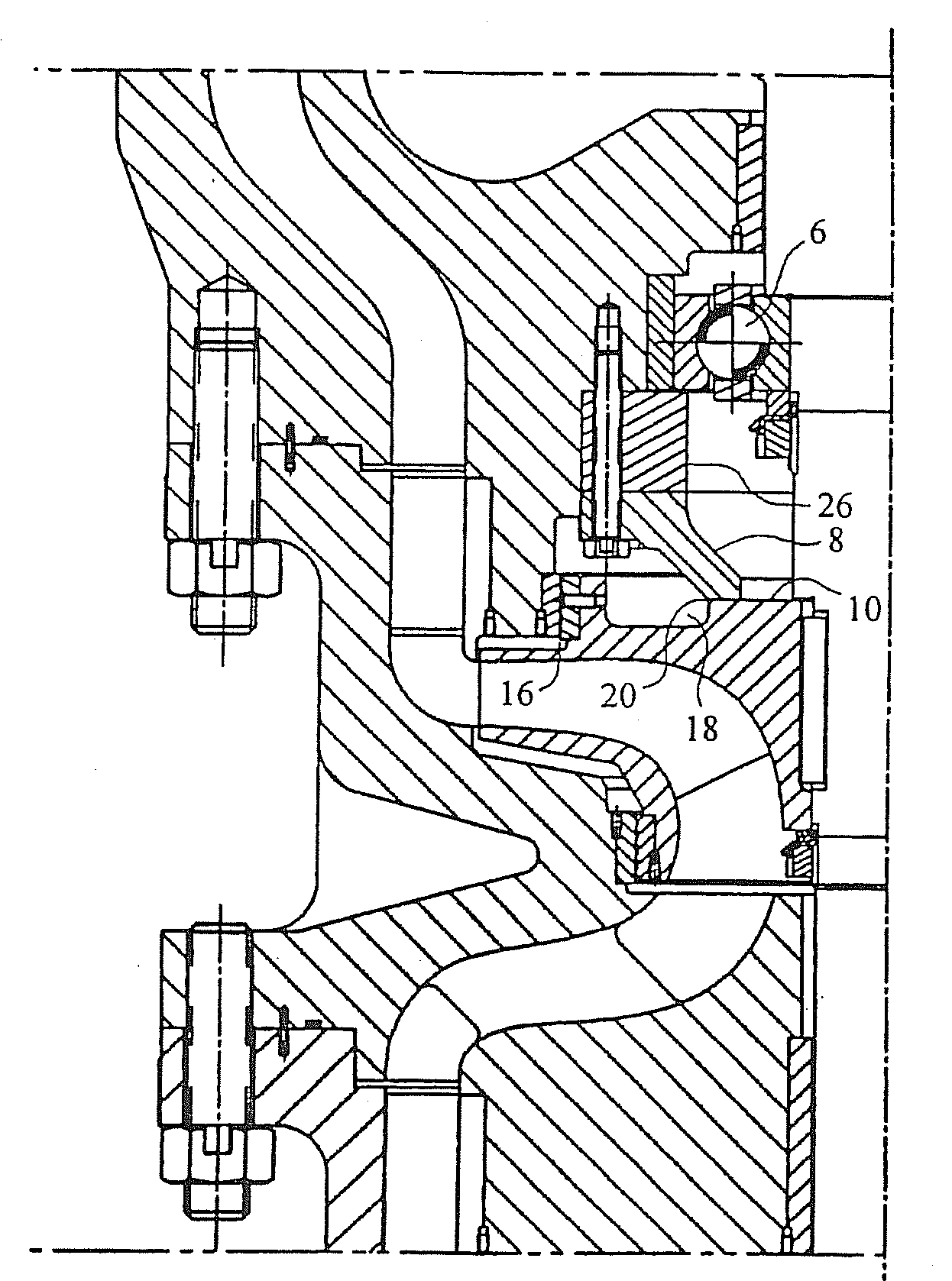

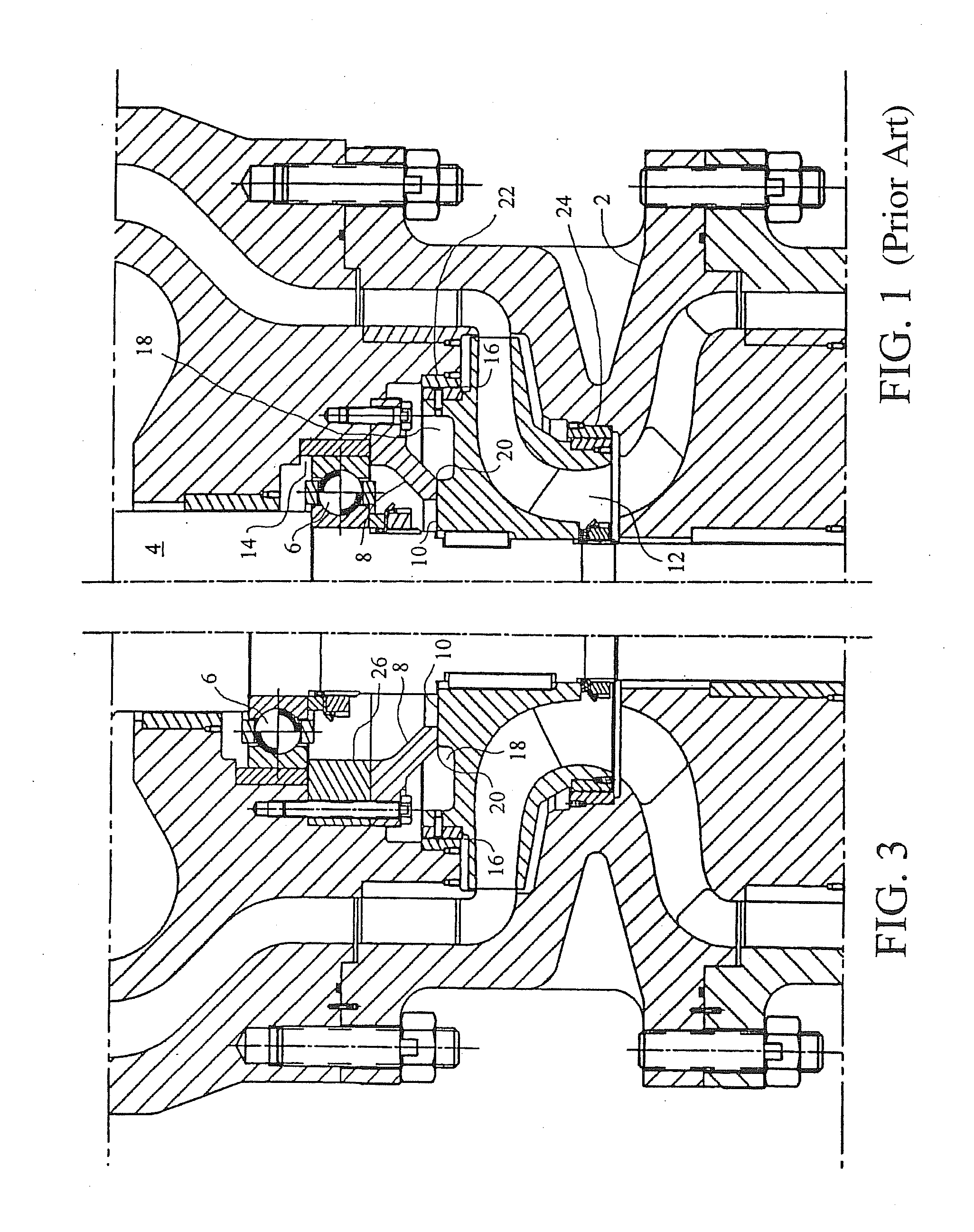

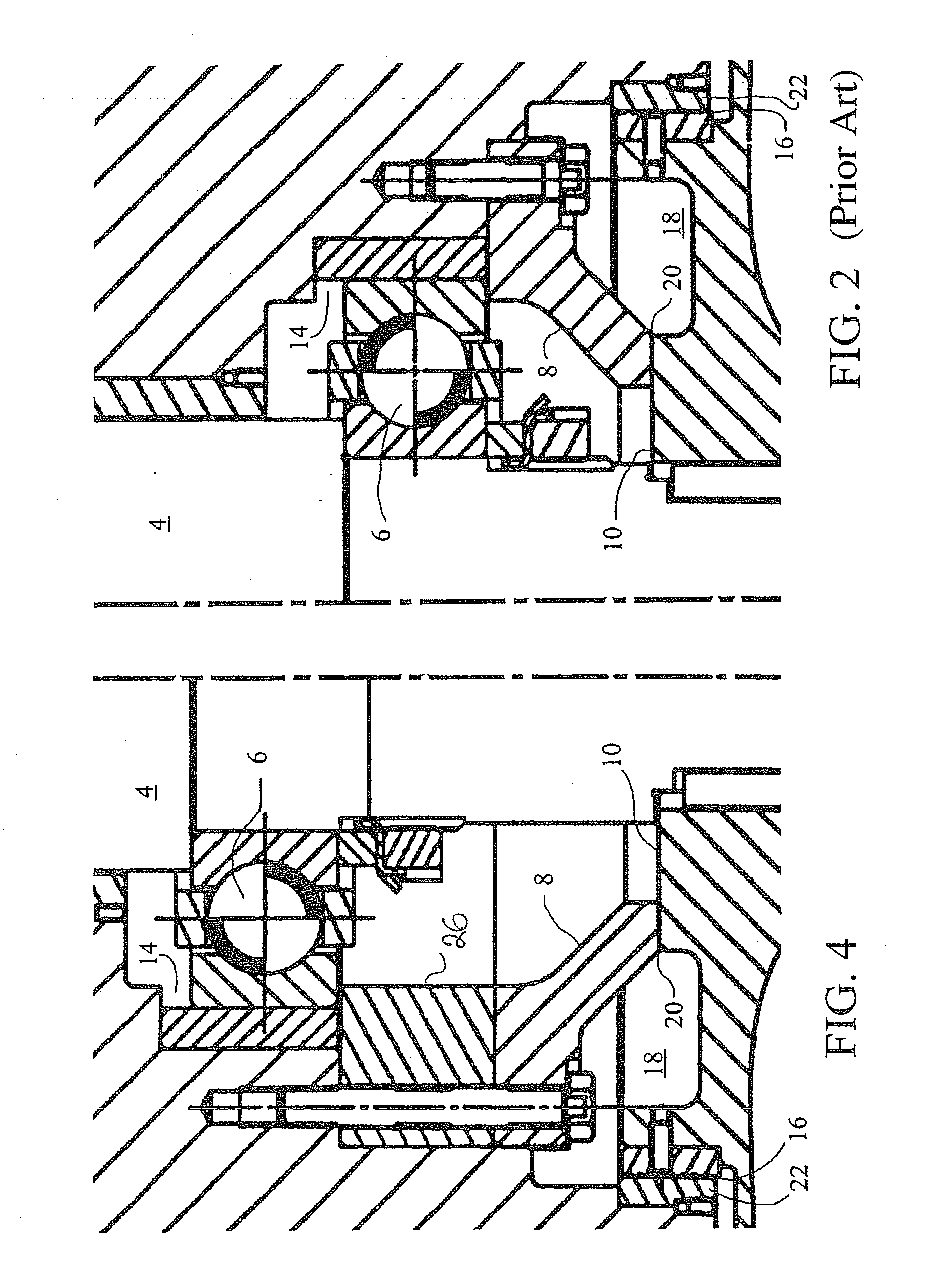

[0014]Referring to FIGS. 1 and 2, a prior art machine with a conventional thrust equalizing mechanism is illustrated to have a housing 2, a shaft 4, a lower bearing 6, a stationary thrust plate 8, a throttle ring 10 affixed to the shaft, a runner 12, a gap 14 above the lower bearing which allows the shaft (and the bearing and throttle ring) to rise in response to any unbalance thrust from below, a fixed orifice 16 which communicates product fluid to a chamber 18 disposed above the throttle ring, a variable orifice 20 defined between thrust plate and the throttle ring, an upper wearing ring 22, and a lower wearing ring 24. The operation of the thrust equalizing mechanism is simple. The upper wearing ring 22 is larger in diameter than the lower wearing ring 24 resulting in a net resultant force in the upper direction. Due to this upward force, the shaft 4, and all its rotating components move upward, the upward movement of the throttle ring 10 reducing the variable orifice 20 between ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com