Geological drill hole confined water spewing water head balanced construction method

A construction method and pressurized water technology, which is applied in the direction of foundation structure engineering, construction, sheet pile walls, etc., can solve the problems of geological borehole pressurized water gushing, etc., and achieve balanced water head height, avoid subsidence, and high economic utility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below, in conjunction with accompanying drawing and specific embodiment, the present invention is described further:

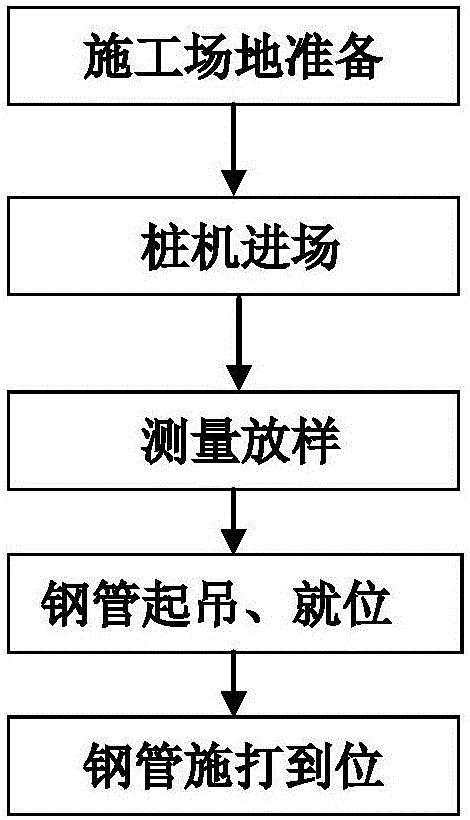

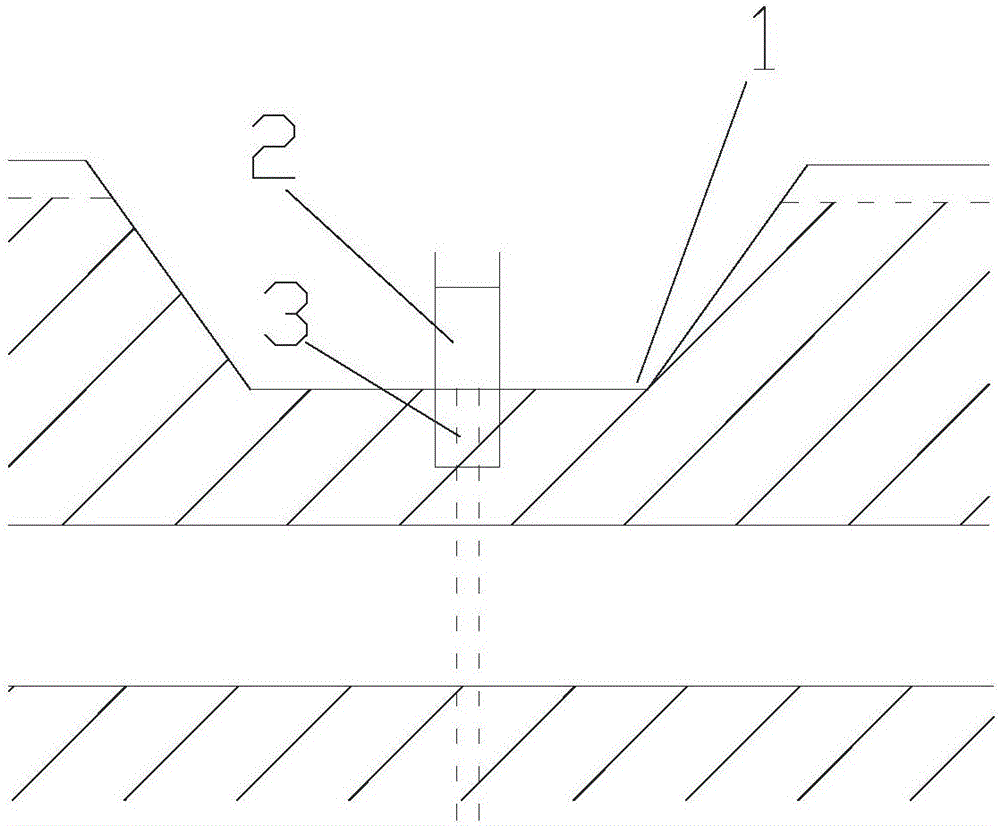

[0024] Such as figure 1 and figure 2 As shown, the geological borehole pressurized water gushing water head balance construction method includes the following steps:

[0025] S1: Preparation of the construction site. Before the construction of the large-diameter steel pipe 2, remove the sediment near the geological borehole 3, do not block the geological borehole, and park the pile driver outside the foundation pit 1.

[0026] S2: The steel pipe 2 pile driver enters the site, and the pile driver is selected according to the weight and length of the steel pipe 2, and the pile driver enters the set position.

[0027] S3: Measure and set out, measure and set out at the position where the steel pipe 2 is shot, and mark the position.

[0028] S4: The steel pipe 2 is hoisted and placed in place, the steel pipe 2 is hoisted by the steel pipe 2 pile driver ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com