Basement exterior wall post-cast strip advanced sealing structure and basement exterior wall post-cast strip construction method

A technology for basement exterior walls and closed structures, which is applied to underwater structures, infrastructure projects, artificial islands, etc. complex problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described in detail below with reference to the accompanying drawings and examples. The following examples are explanations of the present invention and are not limited to the following examples.

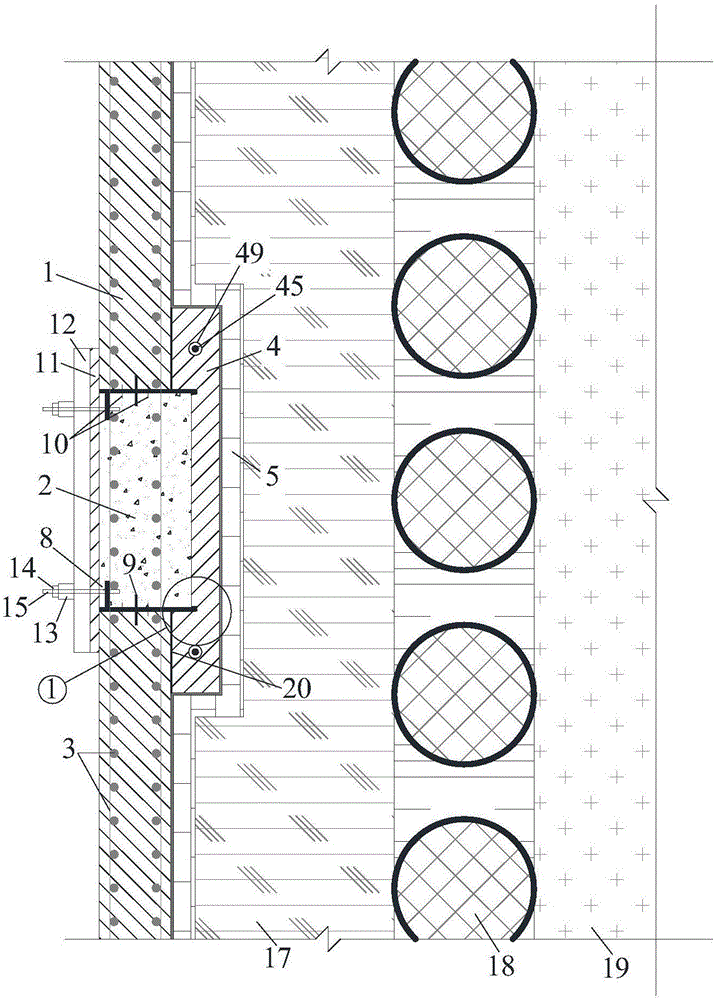

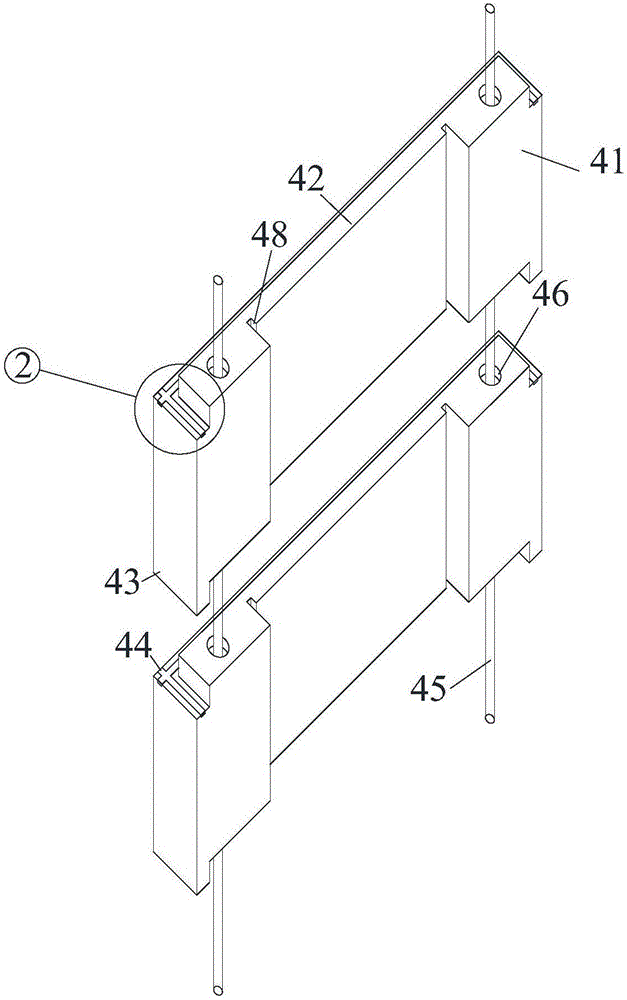

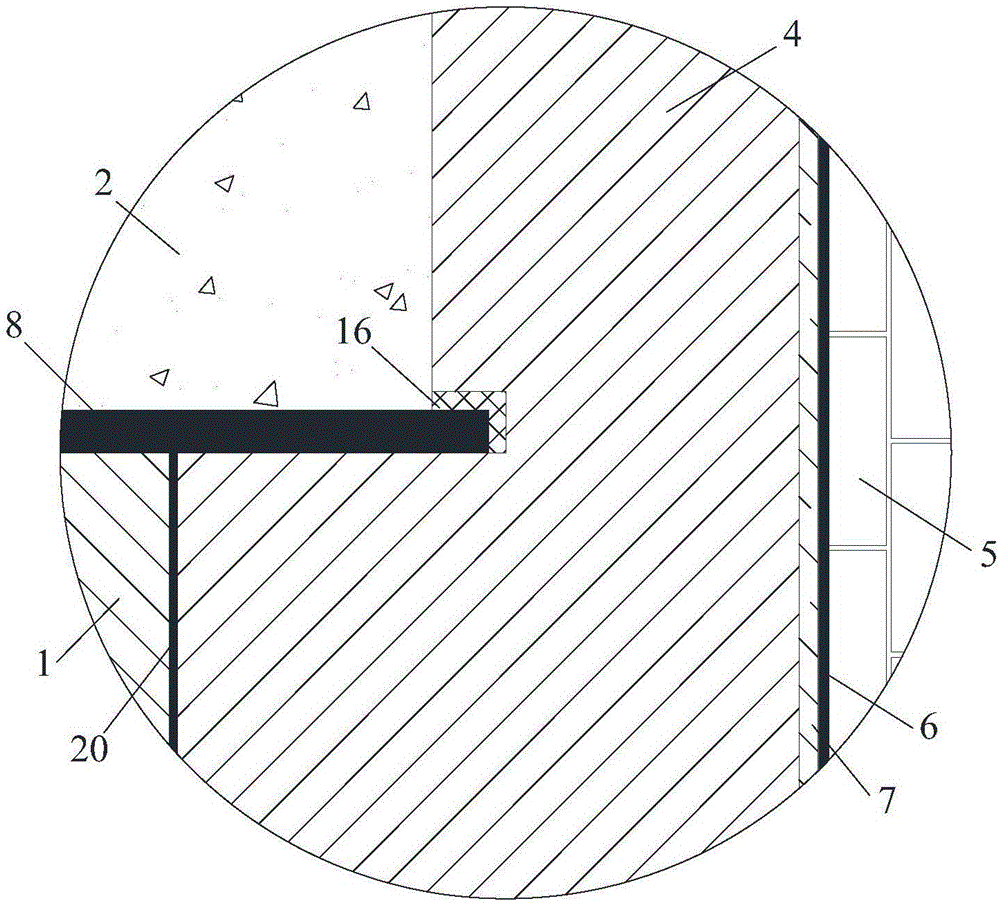

[0032] figure 1 It is the plan view of the advanced closed structure of the post-casting zone of the basement exterior wall, figure 2 It is a three-dimensional schematic diagram of the advanced closed plate and connection of post-casting belt, image 3 is the detail of node 1, image 3 It is the 3D detail drawing of node 2 details.

[0033] refer to Figure 1~3 As shown, the width of the post-casting belt is 800mm, the thickness of the basement exterior wall is 300mm, and the advanced closed structure includes a closed plate 4, a brick masonry protective layer 5, a waterproof layer 6, a mortar leveling layer 7, a connecting steel plate 8, a waterproof steel plate 9, and a connecting plate Stud 10 etc.

[0034] The outer contour size...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com