Heat-insulating coating and novel internal half-surrounded masonry-type combined wall self-insulating system

A self-insulation system, heat insulation technology, applied in the direction of insulation, walls, building materials, etc., can solve the problems of easy cracking of the wall, poor fire safety, poor fire performance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

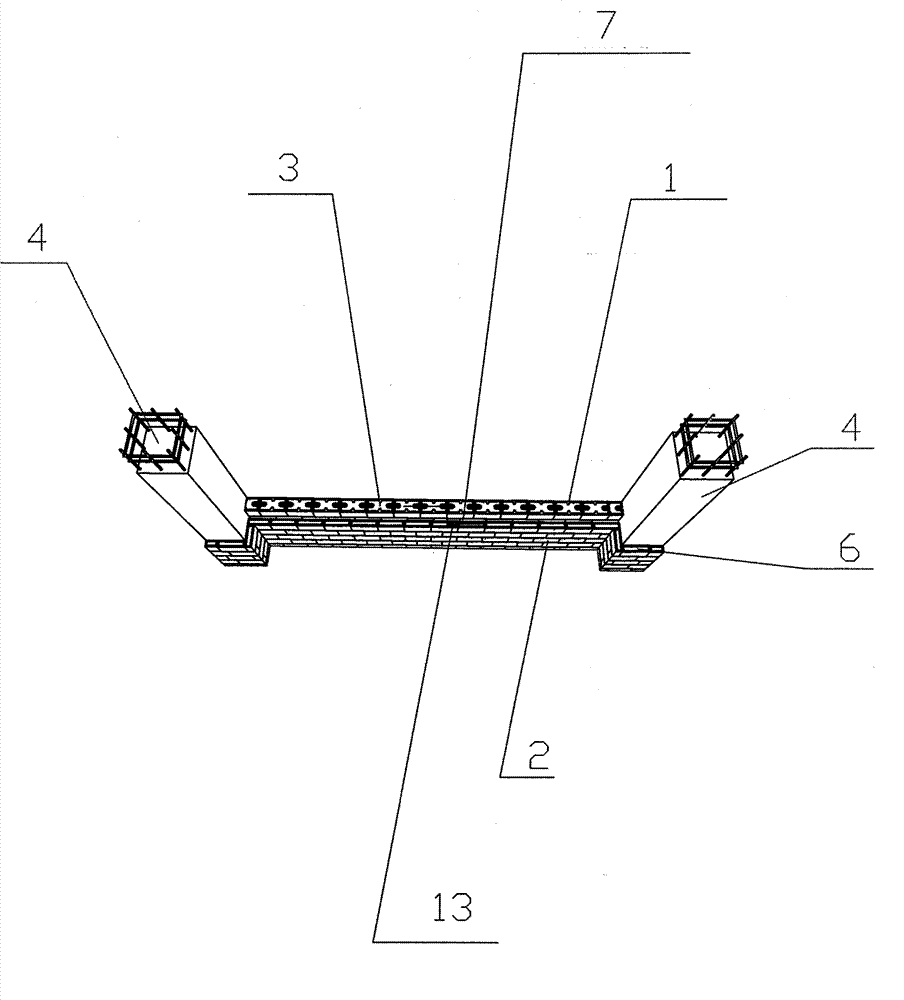

[0072] Such as figure 1 , Figure 4 As shown, a self-insulation system of thermal insulation paint and a new type of semi-inner composite wall is characterized in that the self-insulation system of the thermal insulation coating and a new type of semi-inner composite wall includes a type A composite thermal insulation block Self-insulation wall (1), B-type composite insulation block self-insulation wall (2), inclined brick self-insulation wall and beam insulation body, insulation wall around doors and windows, and oblique brick self-insulation wall at the top of the wall ; The specific method and structure are as follows:

[0073] (1) Method and structure of A-type composite thermal insulation block self-insulation wall (1): Use A-type composite thermal insulation block (3) to build A-type composite thermal insulation block self-insulation wall (1), A-type The two ends of the composite thermal insulation block self-thermal insulation wall (1) are connected to the column (4),...

Embodiment approach 2

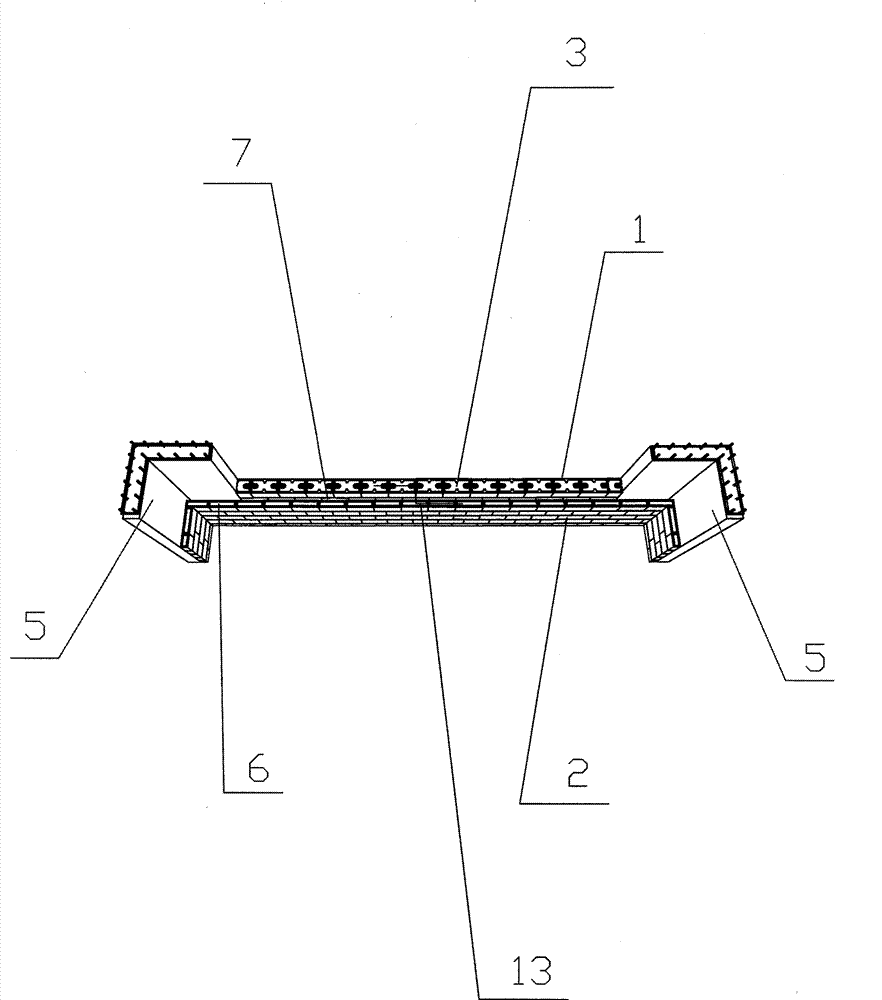

[0083] Such as figure 2 , Figure 5 As shown, a self-insulation system of thermal insulation paint and a new type of semi-inner composite wall is characterized in that the self-insulation system of the thermal insulation coating and a new type of semi-inner composite wall includes a type A composite thermal insulation block Self-insulation wall (1), B-type composite insulation block self-insulation wall (2), inclined brick self-insulation wall and beam insulation body, insulation wall around doors and windows, and oblique brick self-insulation wall at the top of the wall ; The specific method is as follows:

[0084] (1) Method and structure of A-type composite thermal insulation block self-insulation wall (1): Use A-type composite thermal insulation block (3) to build A-type composite thermal insulation block self-insulation wall (1), A-type The two ends of the composite thermal insulation block self-insulation wall (1) are connected to the shear wall (5), and the contact s...

Embodiment approach 3

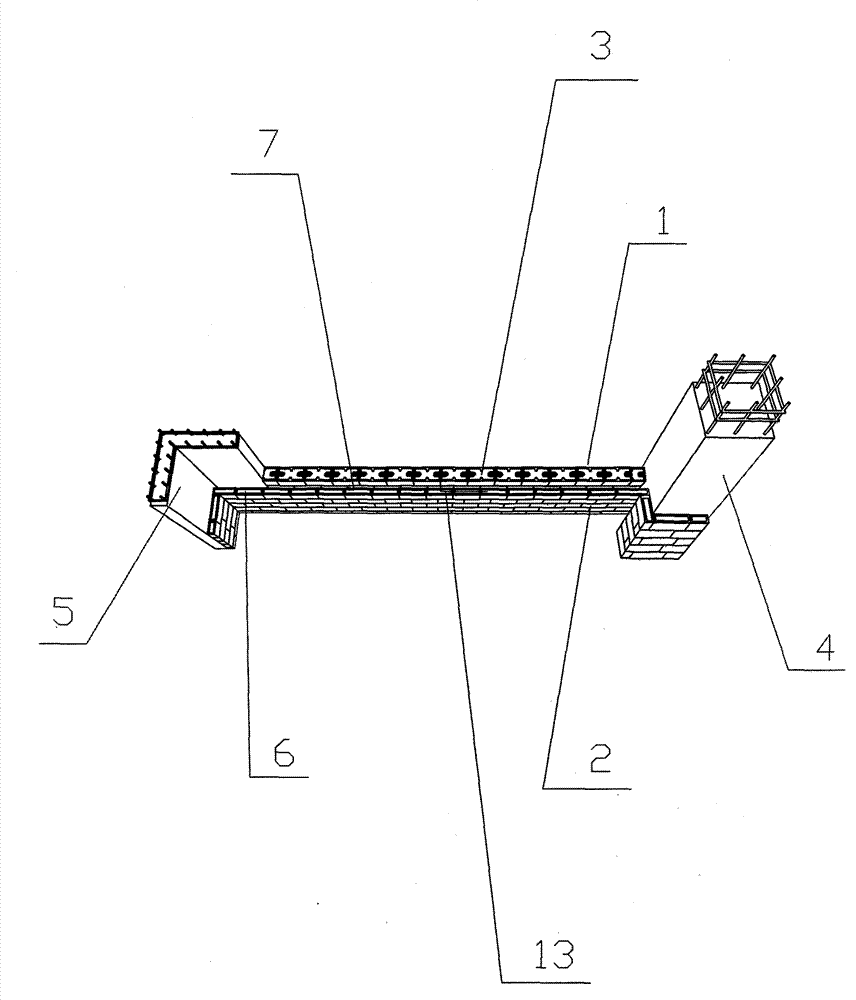

[0094] Such as image 3 , Image 6 As shown, a self-insulation system of thermal insulation paint and a new type of semi-inner composite wall is characterized in that the self-insulation system of the thermal insulation coating and a new type of semi-inner composite wall includes a type A composite thermal insulation block Self-insulation wall (1), B-type composite insulation block self-insulation wall (2), inclined brick self-insulation wall and beam insulation body, insulation wall around doors and windows, and oblique brick self-insulation wall at the top of the wall ; The specific method and structure are as follows:

[0095] (1) The method and structure of the A-type composite thermal insulation block self-insulation wall (1): use the A-type composite thermal insulation block (3) to build the A-type composite thermal insulation block self-insulation wall (1), and the A-type composite thermal insulation block The two ends of the insulation block self-insulation wall (1) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com