Construction method of high-strength sealing wall with anti-seepage function in mine roadway

A construction method and closed wall technology, applied in mining equipment, mining equipment, earthwork drilling and mining, etc., can solve the problems of wall leakage, single structure, poor anti-seepage, etc., and achieve small water seepage, high safety, and construction convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

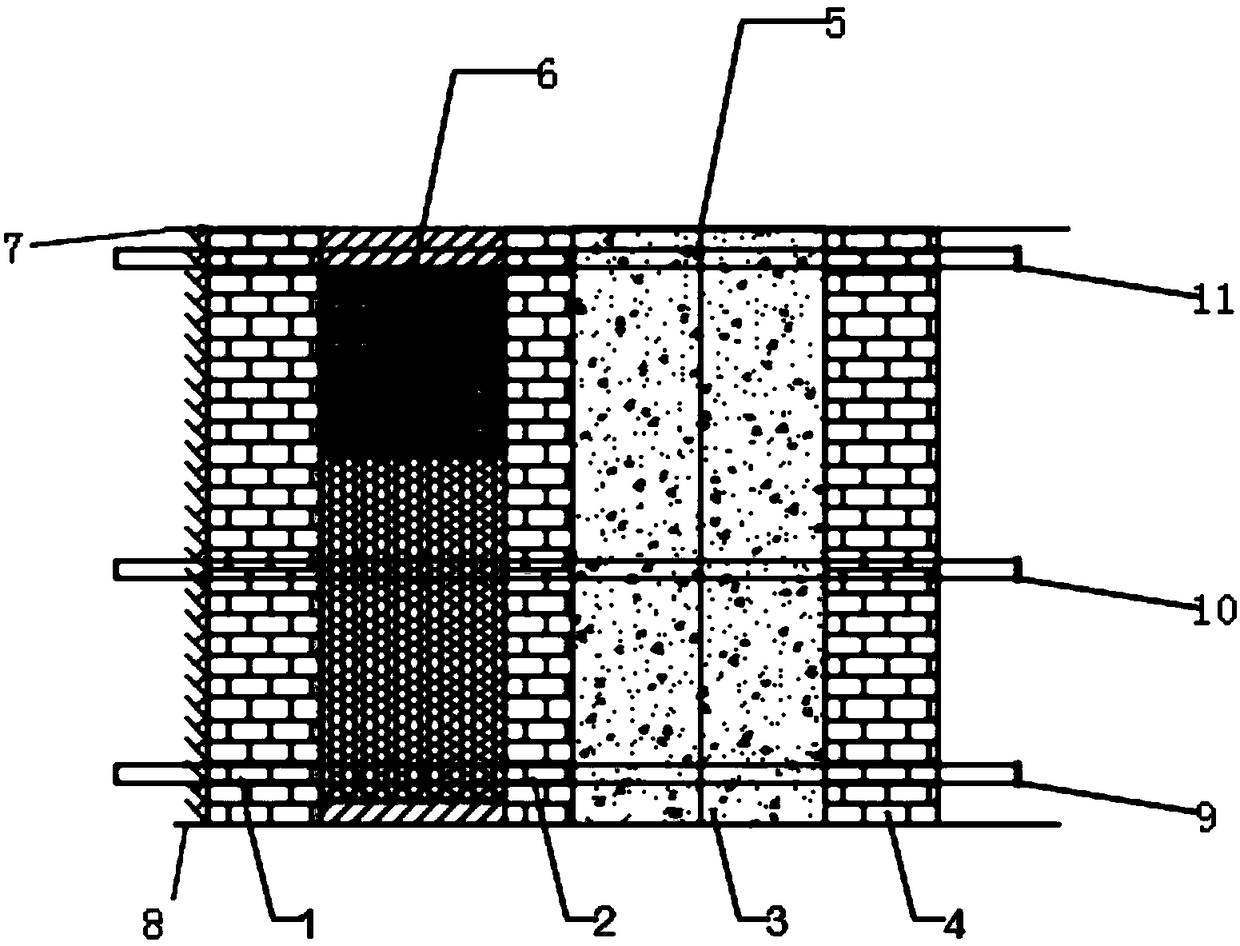

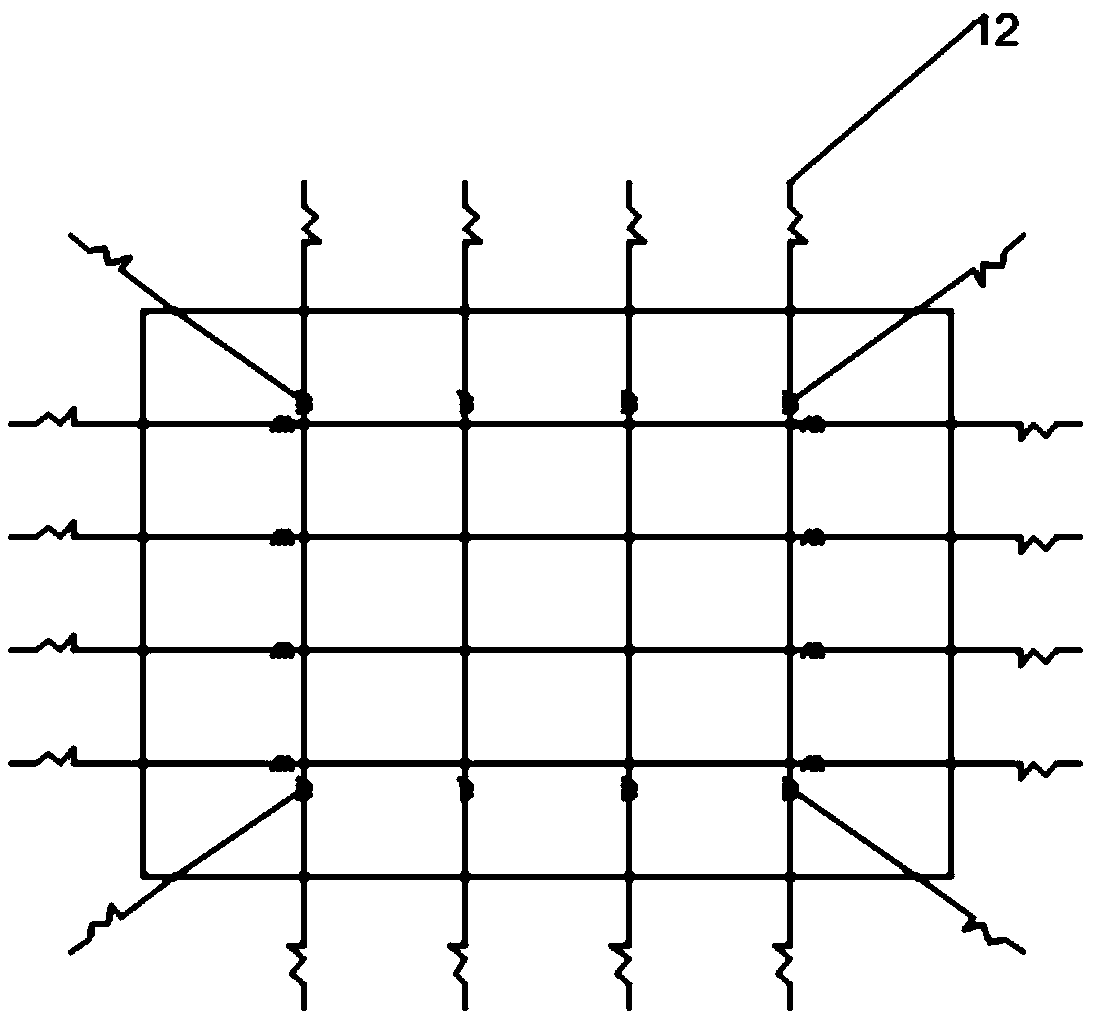

[0041] The embodiment of the present invention proposes the specific steps of the airtight wall construction of the coal mine mentioned above:

[0042] A construction method for a mine roadway anti-seepage high-strength airtight wall, the specific steps are as follows:

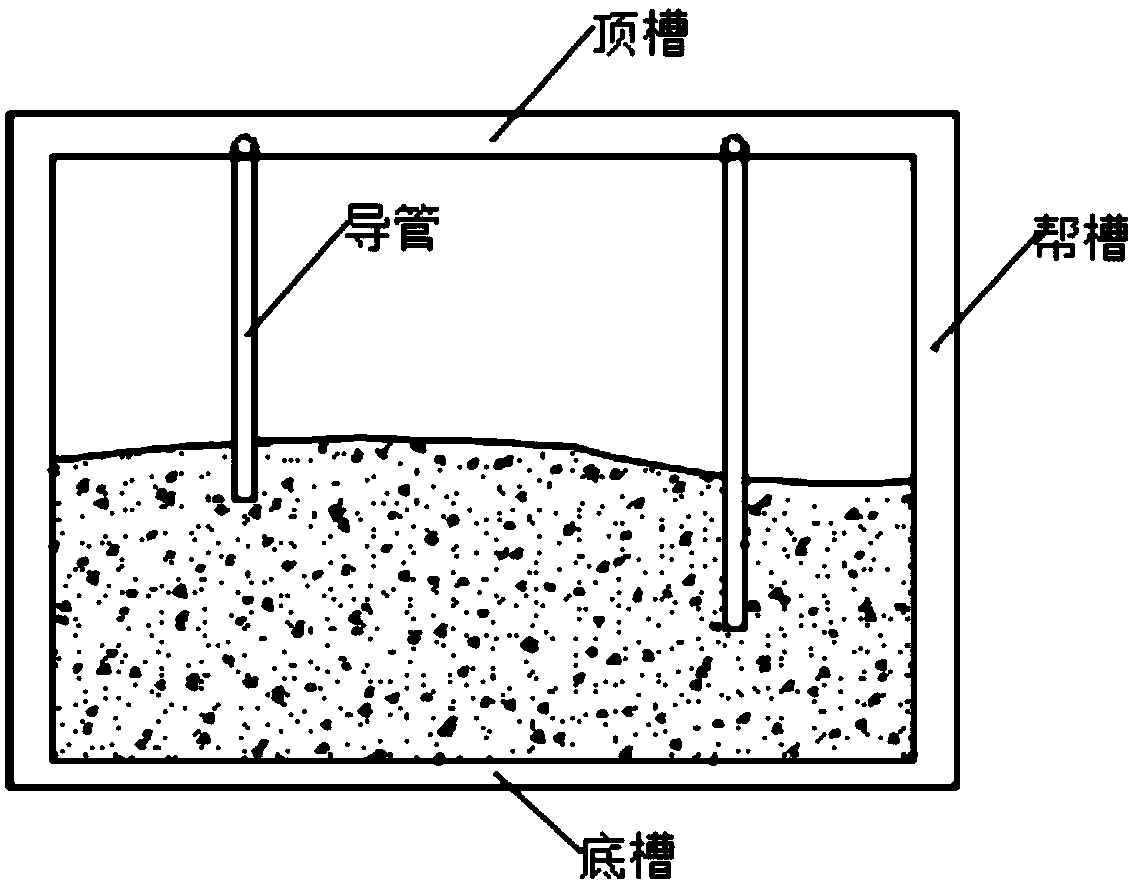

[0043] Step 1, Grooving:

[0044] The roof 7, the bottom plate 8 and the two sides of the roadway are cut, which are respectively the first, second, third and fourth cuts, wherein the second, third and fourth cuts are adjacent cuts and can be combined into one cut. Each cut is arranged in parallel, and each cut includes a top groove, a side groove and a bottom groove. Less than 300mm, the top groove depth is not less than 500mm, the top groove width is 0.3m, the bottom groove width is 0.2m, and the side groove width is 0.5m, and the groove width matches the wall width so that the wall can be fixed. All electrical conductors are completely disconnected (metal mesh, iron wire), and the coal, gangue, and other ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com