Anti-seepage structure of corridors at structural joint of rolling dam and construction method of anti-seepage structure

A technology of structural joints and rolling dams, which is applied in water conservancy projects, sea area projects, coastline protection, etc., can solve the problems of cumbersome construction process and long construction period, and achieve the effects of shortening construction period, simplifying construction and ensuring anti-seepage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030]The technical solutions of the present invention will be described below, but the scope of claims is not limited to the above.

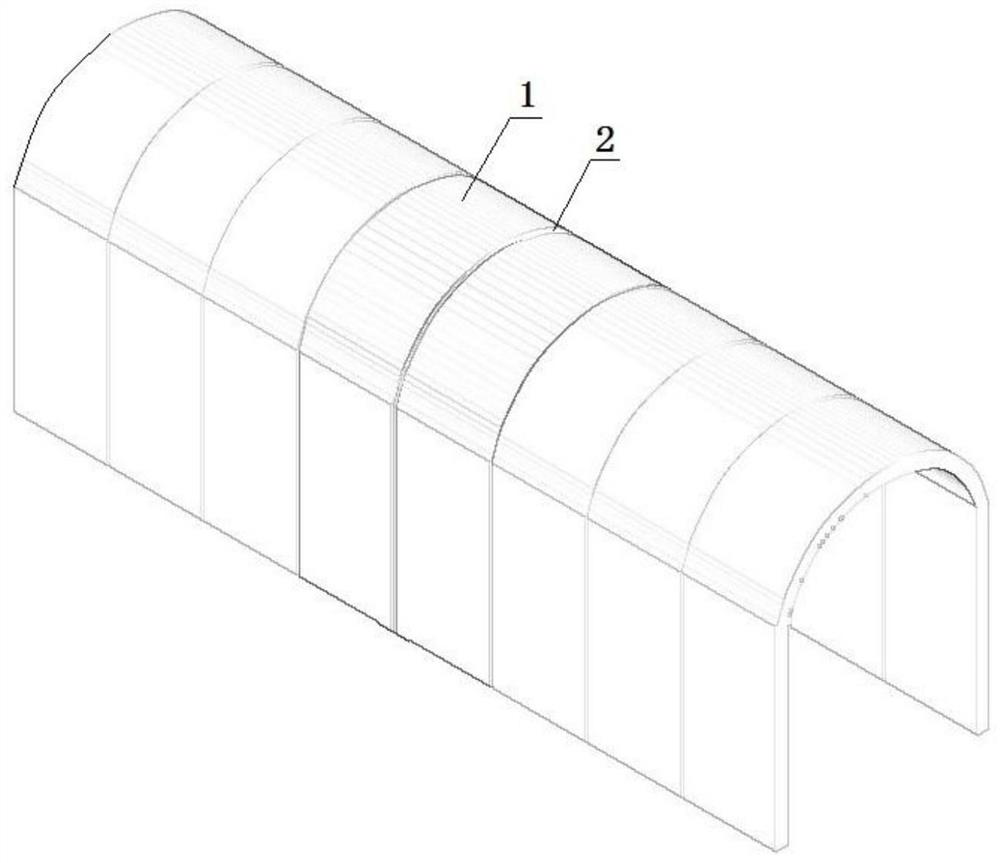

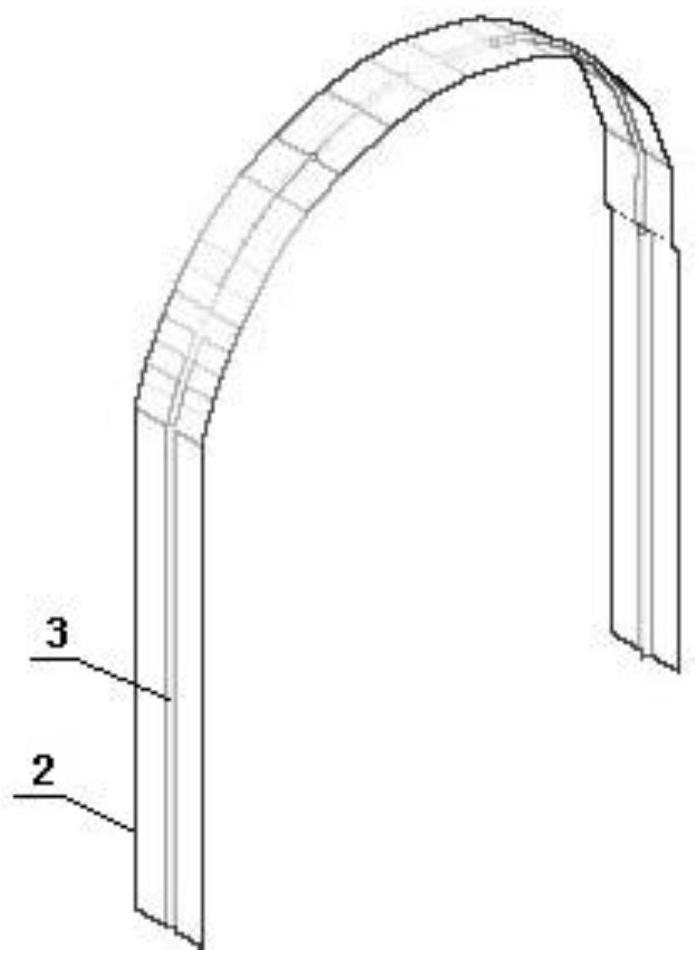

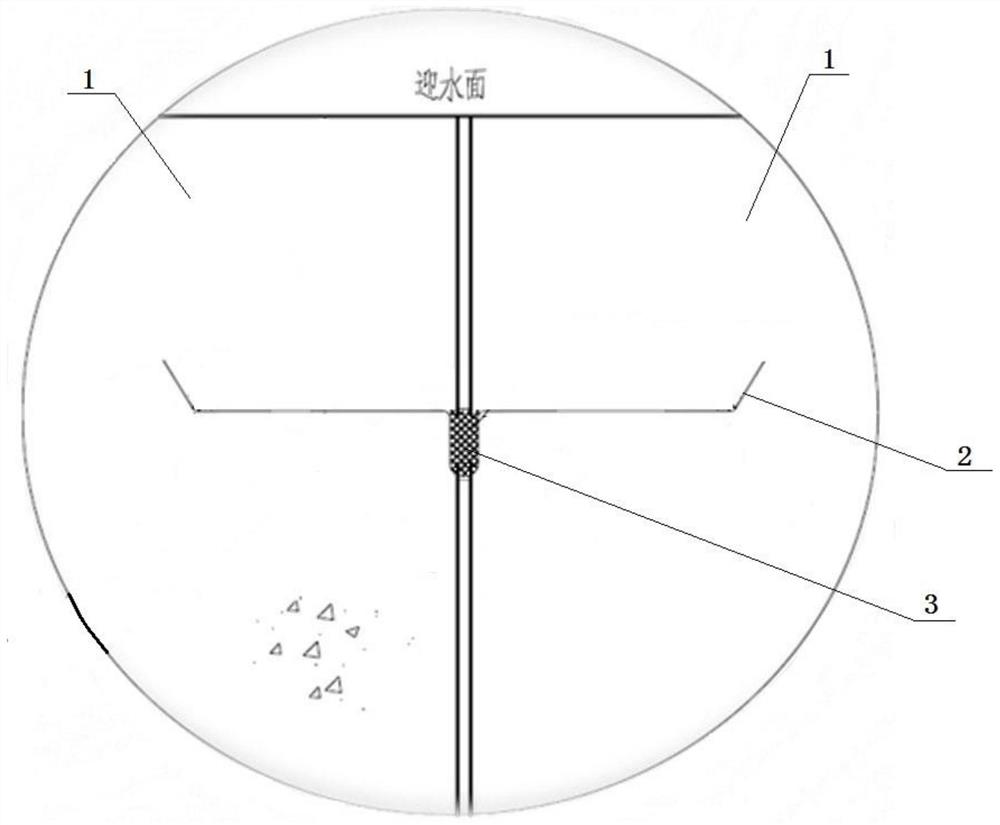

[0031]Such asFigure 1 to 3As shown, a corridor-proof structure of a rolling dam structure is a rolling dam structure, including a water supply member 2 and a cassage channel A1, and the two corridors A1 are connected by a water member 2. The corridor A1 is formed in a concrete, and the hydraulic member 2 is formed into formal formation and is prefabricated with the two corridor channels A1. Corridor A1 once concrete pouring formation, the water seizure 2 integrates molding, which helps to simplify construction, shorten the construction period, and improve construction efficiency. At the time of use, the two corridors A1 can be connected by double the water member 2 as needed.

[0032]The gallery channel A1 and the water supply member 2 are all U-shaped, and the shape and size of the water supply member 2 matches the corner channel A1.

[0033]The drying membe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com