High-corrosion-resistance pre-hydrated mineral impermeable material and preparation method thereof

An anti-seepage material and prehydration technology, applied in the field of anti-seepage materials, can solve the problems of unsatisfactory anti-seepage effect and poor corrosion resistance of sheet materials, and achieve the improvement of tensile strength, corrosion resistance and stability sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

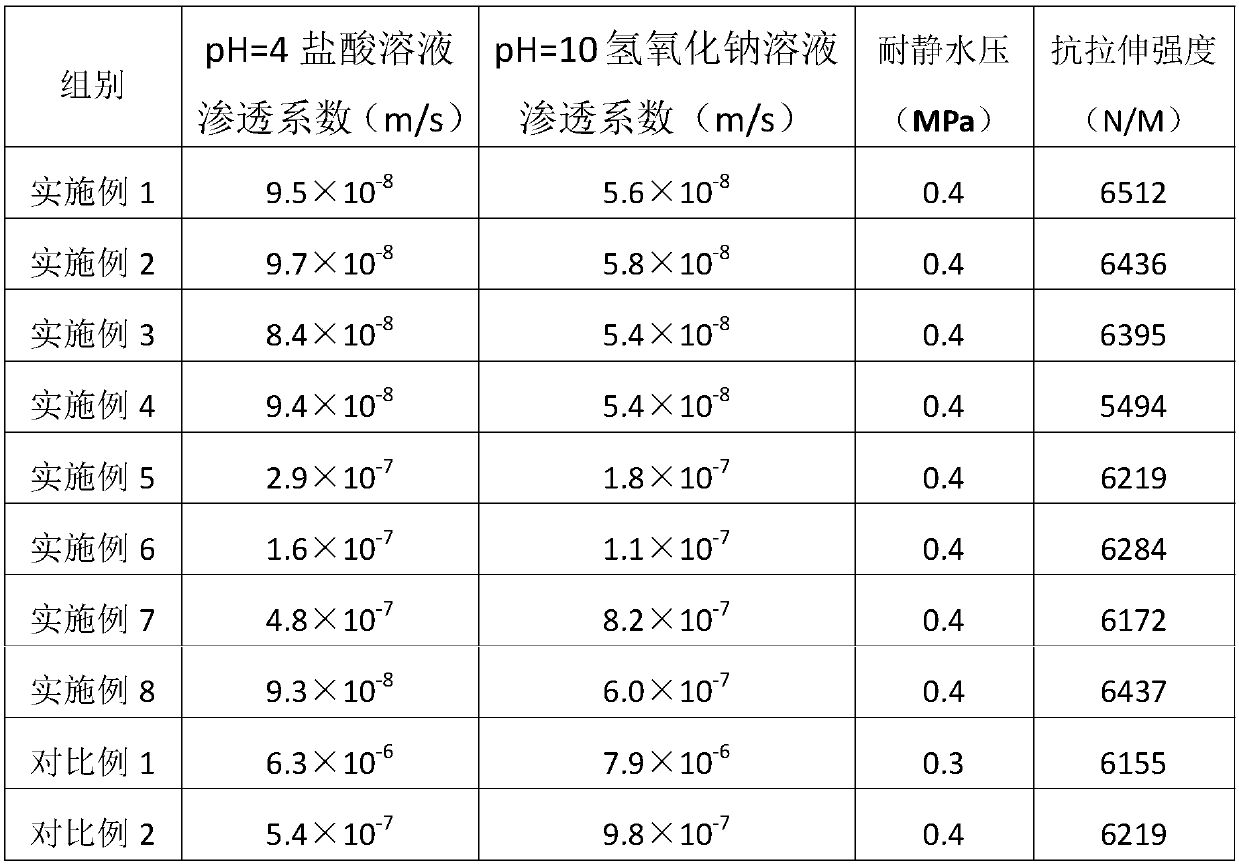

Examples

Embodiment 1

[0033] The high-corrosion-resistant pre-hydration mineral anti-seepage material of this embodiment is composed of a basalt fiber layer, a mineral anti-seepage layer and an anti-seepage membrane arranged in sequence from top to bottom;

[0034] The basalt fiber layer is a grid-like material made of basalt fibers, and the inner layer is also attached with polyester filaments; the polyester filaments are attached to one side of the basalt fibers during the basalt weaving process, and the polyester filaments and basalt fibers The weight ratio is 1:10. The mass per unit area of the basalt fiber layer is 800g / m 2 ;

[0035] The mineral anti-seepage layer includes the following components: 40 parts by weight of bentonite; 30 parts by weight of kaolin; 6 parts by weight of high molecular polymer; 60 parts by weight of water. The mass per unit area of the mineral anti-seepage layer is 2000g / m 2 ; Wherein, the bentonite is sodium ion bentonite, and the content of montmorillonite ...

Embodiment 2

[0042] The high-corrosion-resistant pre-hydration mineral anti-seepage material of this embodiment is composed of a basalt fiber layer, a mineral anti-seepage layer and an anti-seepage membrane arranged in sequence from top to bottom;

[0043] The basalt fiber layer is a grid-like material made of basalt fibers, and the inner layer is also attached with polyester filaments; the polyester filaments are attached to one side of the basalt fibers during the basalt weaving process, and the polyester filaments and basalt fibers The weight ratio is 1:15. The mass per unit area of the basalt fiber layer is 2000g / m 2 ;

[0044] The mineral anti-seepage layer includes the following components: 80 parts by weight of bentonite; 10 parts by weight of kaolin; 3 parts by weight of high molecular polymer; 40 parts by weight of water. The mass per unit area of the mineral anti-seepage layer is 3000g / m 2 ; Wherein, the bentonite is sodium ion bentonite, and the content of montmorillonite...

Embodiment 3

[0051] The high-corrosion-resistant pre-hydration mineral anti-seepage material of this embodiment is composed of a basalt fiber layer, a mineral anti-seepage layer and an anti-seepage membrane arranged in sequence from top to bottom;

[0052] The basalt fiber layer is a grid-like material made of basalt fibers, and the inner layer is also attached with polyester filaments; the polyester filaments are attached to one side of the basalt fibers during the basalt weaving process, and the polyester filaments and basalt fibers The weight ratio is 1:20. The mass per unit area of the basalt fiber layer is 1400g / m 2 ;

[0053] The mineral anti-seepage layer includes the following components: 60 parts by weight of bentonite; 20 parts by weight of kaolin; 10 parts by weight of high molecular polymer; 20 parts by weight of water. The mass per unit area of the mineral anti-seepage layer is 4000g / m 2 ; Wherein, the bentonite is sodium ion bentonite, and the content of montmorillonit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Mass per unit area | aaaaa | aaaaa |

| Mass per unit area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com