River bottom microbial grouting ecological anti-seepage system and construction method thereof

A construction method and microbial technology, applied in the fields of botanical equipment and methods, water conservancy engineering, marine engineering, etc., can solve the problems of no material exchange and insufficient ecology, and achieve convenient construction, good ecology, and ensure project quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

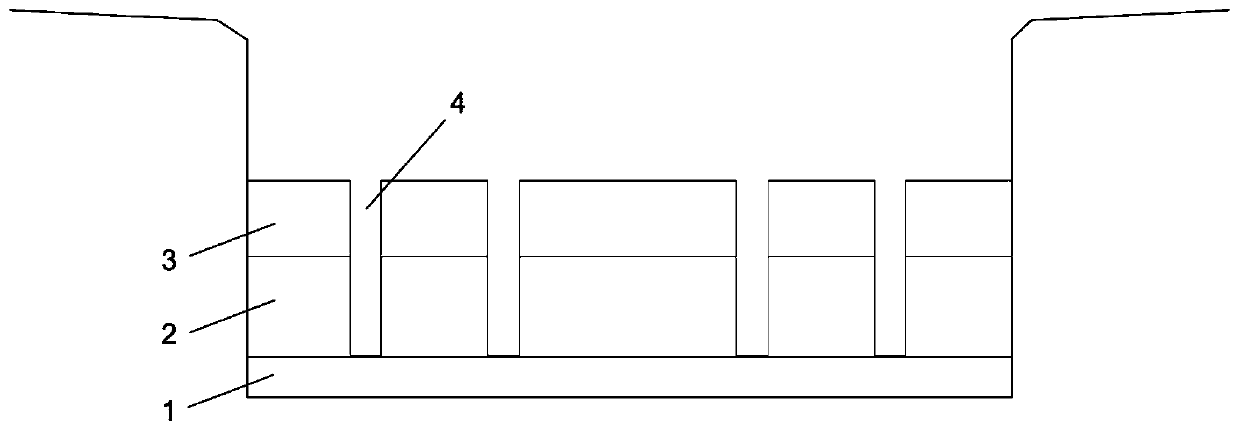

[0030] see figure 1 , this embodiment discloses an ecological anti-seepage system for microbial grouting at the bottom of the river, including a base layer 1 at the bottom of the river, a compacted clay layer 2 and an ecological layer 3 laid layer by layer at the bottom of the river.

[0031] The base layer 1 at the bottom of the river course is undisturbed river bottom soil compacted by rolling. The base layer 1 at the bottom of the channel is the bottom base layer of the system. In actual engineering, trenches are formed by excavating and cleaning down along the shape of the bottom of the river channel. Backfill 20cm of undisturbed soil in the trench and perform compaction treatment to form the base layer 1 at the bottom of the channel.

[0032] The compacted clay layer 2 is clay compacted by rolling, and is an anti-seepage layer at the bottom of the river. The compacted clay layer 2 is made of clay with a plasticity index > 20 and a clay content of 35% to 50%. The thick...

Embodiment 2

[0038] This embodiment discloses a construction method for the ecological anti-seepage system of river bottom microbial grouting described in Embodiment 1, comprising the following steps:

[0039] 1) Remove the surface humus, silt and soft soil layer at the bottom of the channel, excavate downward to form a trench, and backfill the trench with 20cm of undisturbed soil, and compact the undisturbed soil to form the base layer 1 at the bottom of the channel.

[0040] 2) Bedding and rolling the clay until the degree of compaction meets the requirements, forming a compacted clay layer 2 .

[0041] 3) An ecological layer 3 is laid on the top of the compacted clay layer 2 .

[0042] 4) Use the fork planting method to grow aquatic plants. Make tool with a bamboo pole or wooden pole with a fork, the stem portion of plant is forked into ecological layer 3 to introduce cartilaginous grass or foxtail algae plants, to provide good ecology.

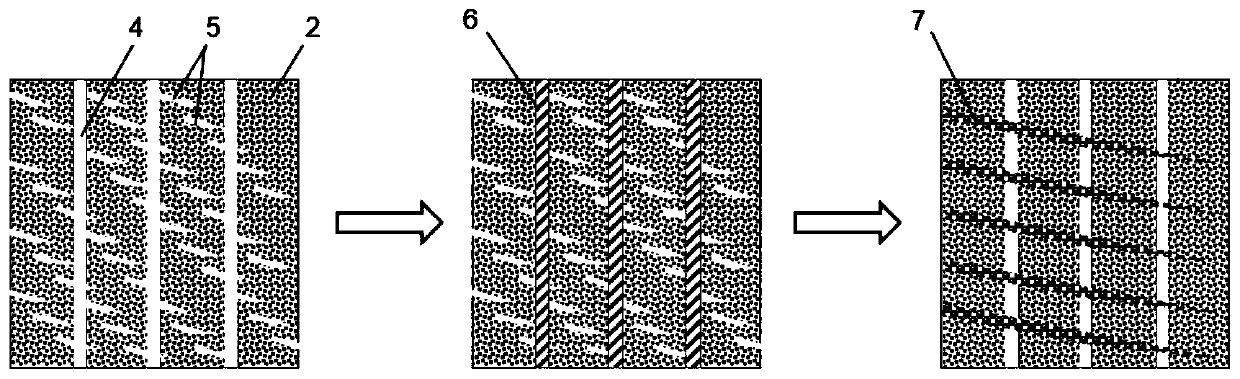

[0043] 5) Arrange grouting holes 4 .

[0044]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com