Anti-seepage water conservancy structure, construction method and anti-seepage method

A construction method and water conservancy technology, which is applied in the field of anti-seepage water conservancy structures, can solve the problems of increasing the risk of embankment collapse and troublesome repairing process, and achieve the effect of improving stability and simple repairing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

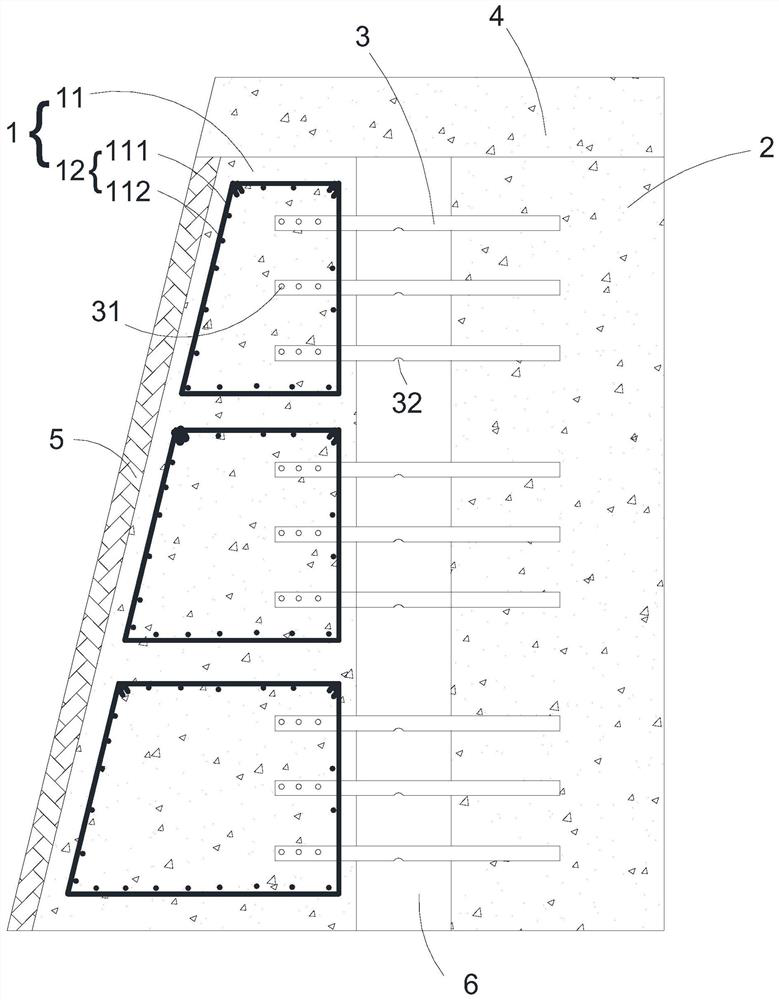

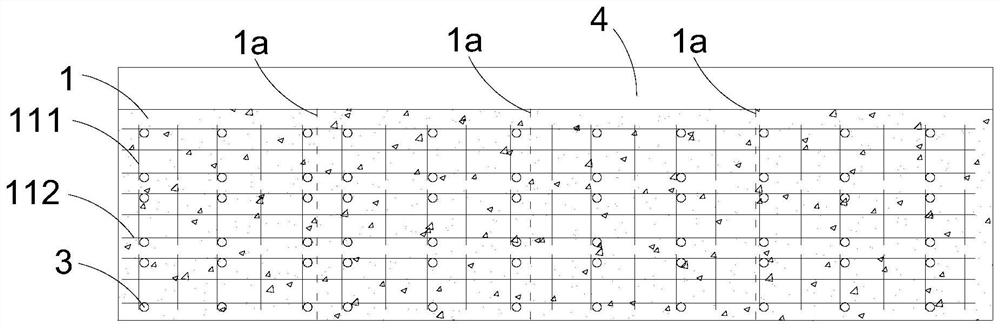

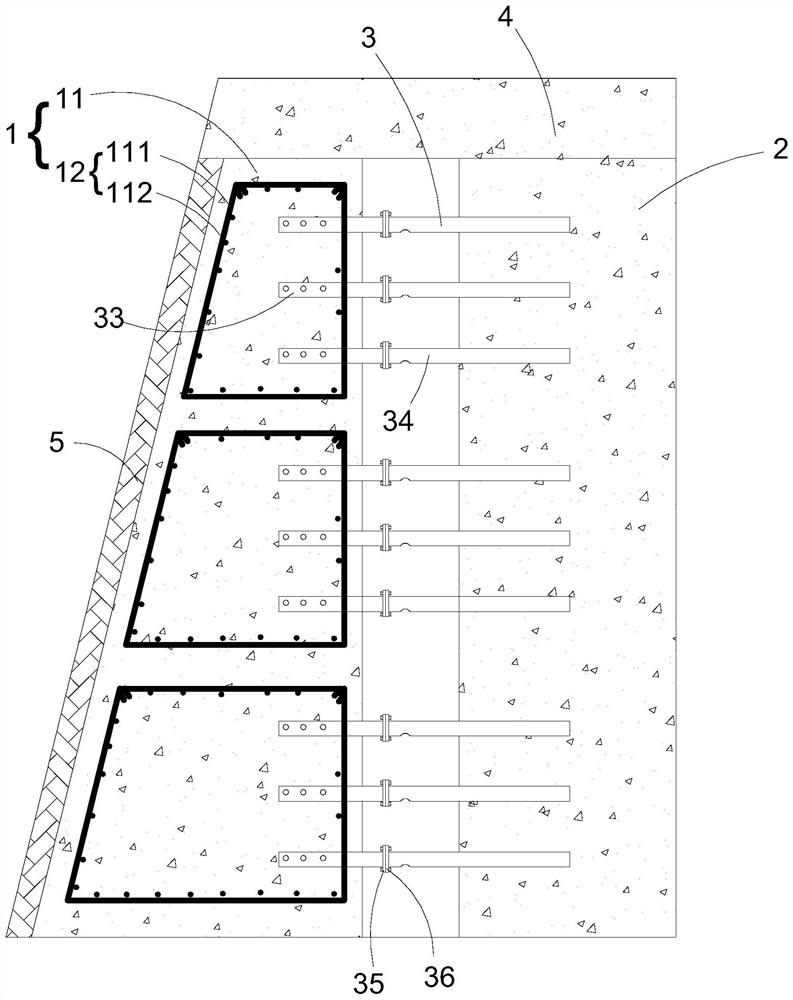

[0030] see figure 1 and figure 2 . The present invention provides an anti-seepage hydraulic structure, which includes a first wall body 1 , a second wall body 2 , a compression rib structure and a top cover 5 . Wherein, the first wall body 1 includes a first concrete structure 11 and a first tendon structure 12 , and the first tendon structure 12 is embedded in the first concrete structure 11 . Specifically, the first rib structure 12 includes a plurality of substantially parallel longitudinal ribs 112 and a stirrup 111 fixedly connecting the longitudinal ribs 112 together. The second wall body 2 is spaced apart from the first wall body 1, and the second wall body 2 includes a second concrete structure and a second bar structure (not shown in the figure), and the second bar structure is embedded in the second concrete structure. Specifically, the second rib structure includes a plurality of longitudinal ribs 112 arranged substantially in parallel, and a stirrup 111 fixedly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com