Patents

Literature

256 results about "Foxtail" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A foxtail is a spikelet or cluster of a grass, that serves to disperse its seeds as a unit. Thus, the foxtail is a type of diaspore or plant dispersal unit. Some grasses that produce a foxtail are themselves called "foxtail", also "spear grass". They can become a health hazard for dogs and other domestic animals, and a nuisance for people.

Molecular marker SIsv0372 in close linkage with foxtail millet herbicide resistant gene

ActiveCN101974521AEasy Assisted BreedingAssisted Breeding FastMicrobiological testing/measurementVector-based foreign material introductionNucleotideDNA fragmentation

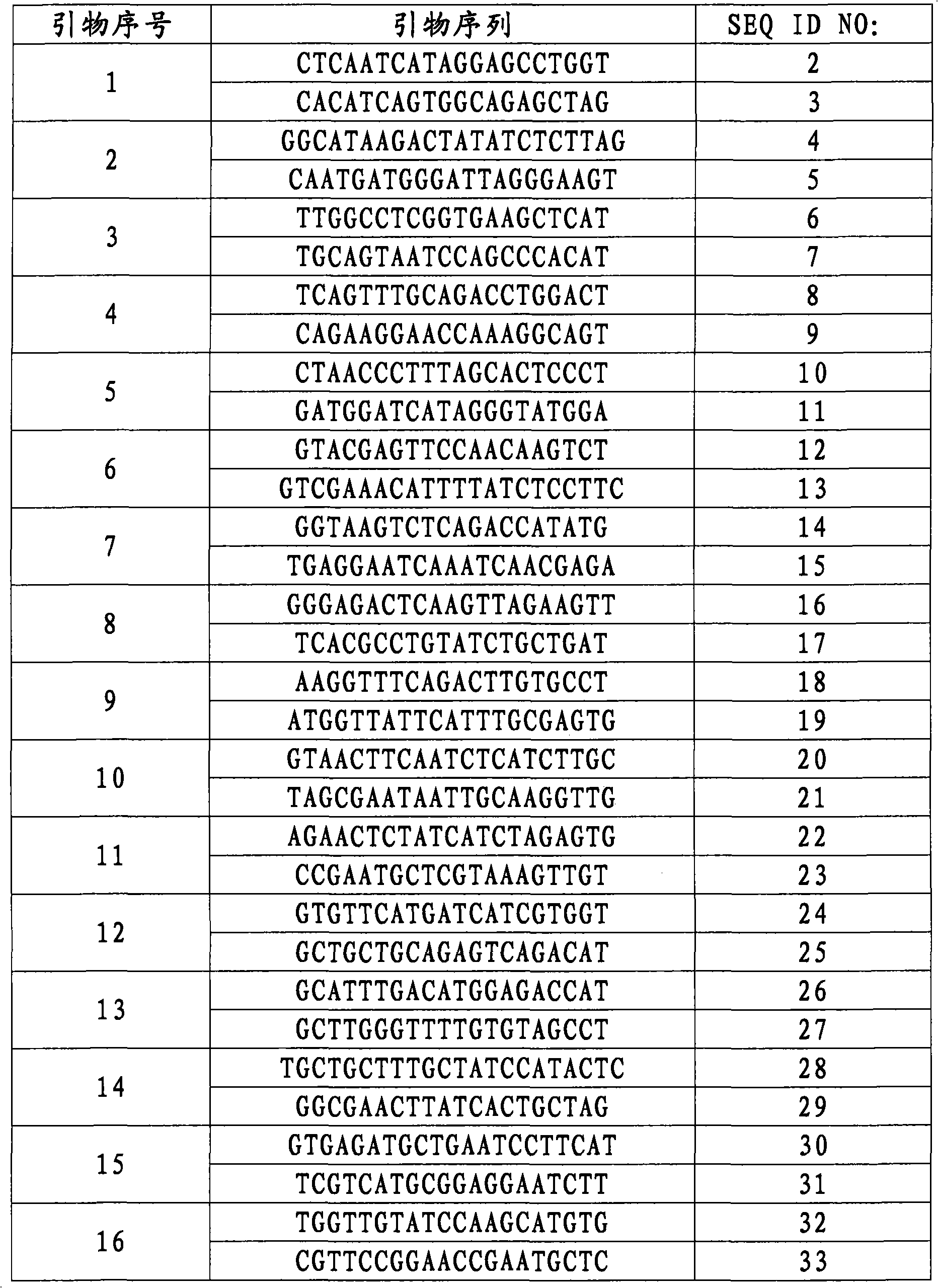

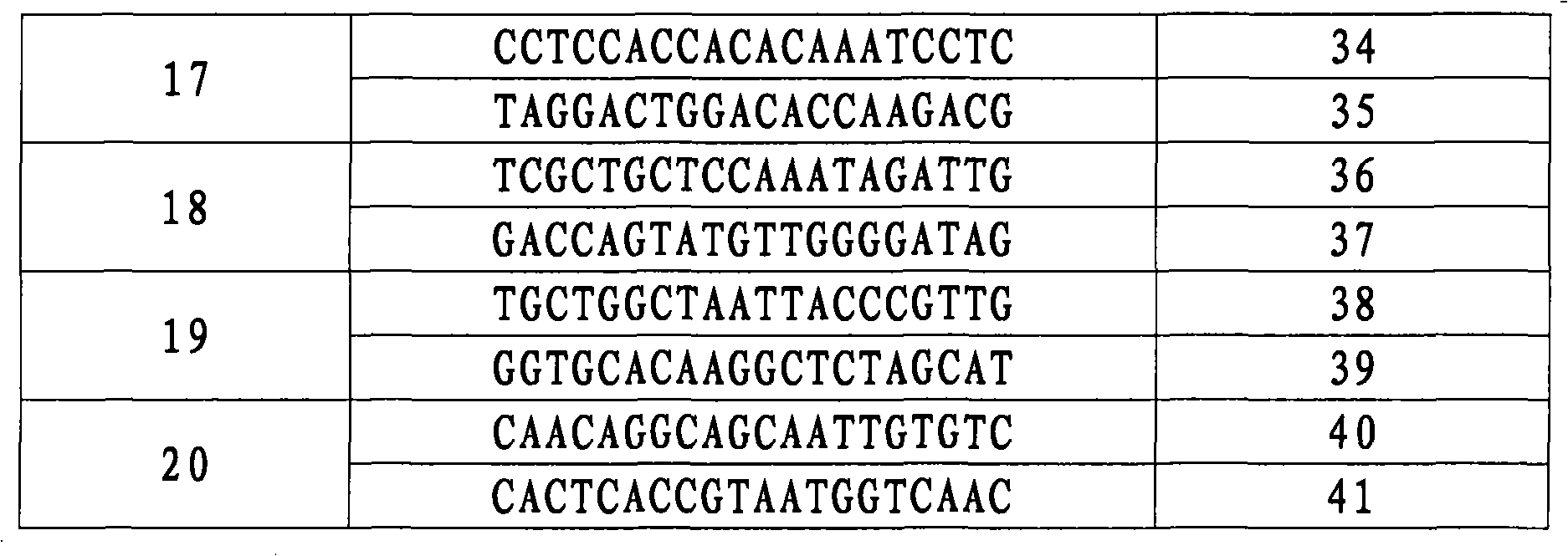

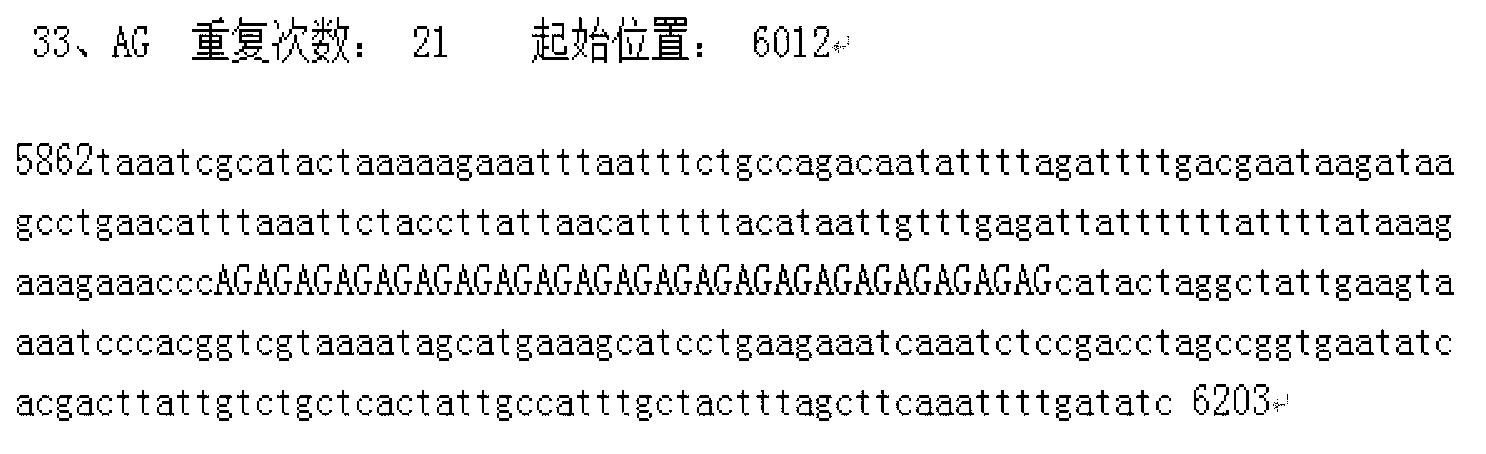

The invention belongs to the field of molecular biology and relates to a molecular marker, in particular to a molecular marker in close linkage with a foxtail millet herbicide resistant gene, with a nucleotide sequence of the molecular marker shown as SEQID NO:1, or a DNA fragment containing the nucleotide sequence shown in the SEQ ID NO:1 in a foxtail millet genome. The invention also relates to primers of the molecular marker, application of the molecular marker in the positioning of the foxtail millet herbicide resistant gene or in foxtail millet inheritance breeding, a foxtail millet herbicide resistant gene positioning method, and a foxtail millet breeding method. The invention finds the molecular marker SIsv0372 which is in close linkage with the foxtail millet herbicide resistant gene, associates the foxtail millet genome DNA sequence and the foxtail millet herbicide resistant gene, and better benefits the establishment of a foxtail millet molecular marker assisted breeding system.

Owner:深圳华大基因农业控股有限公司

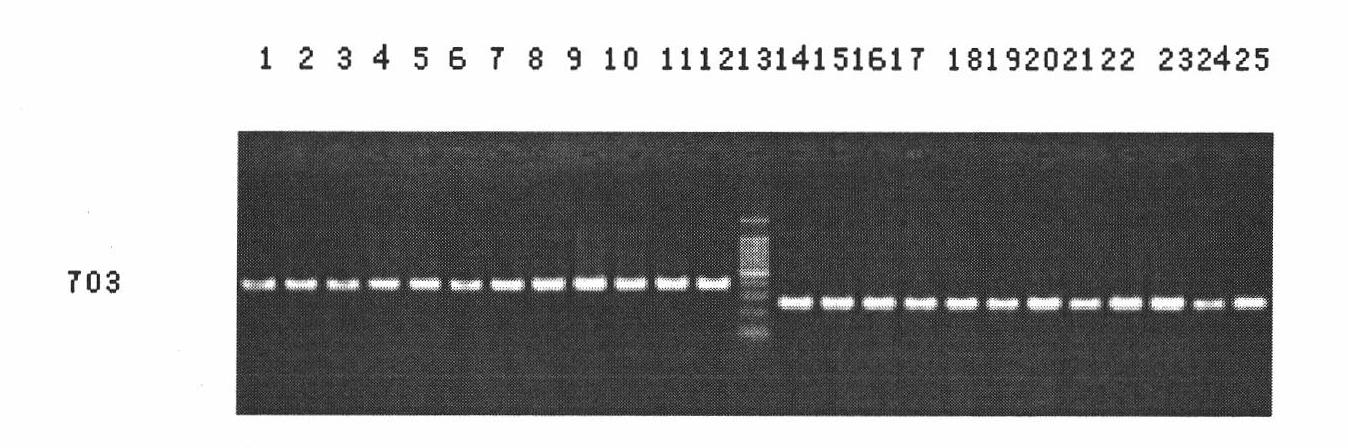

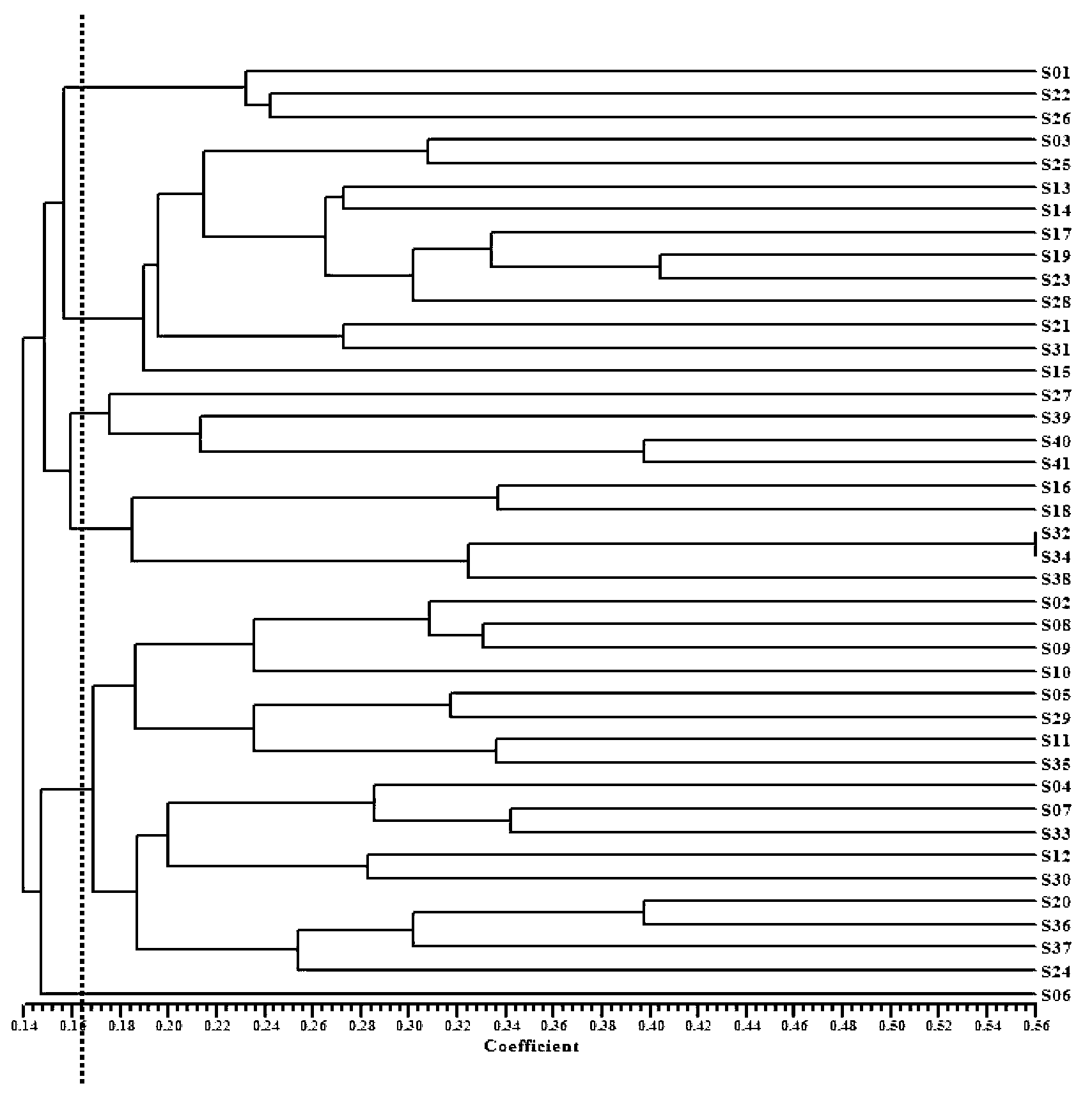

SSR (Simple Sequence Repeat) core primer group developed based on whole genome sequence of foxtail millet and application of SSR core primer group

ActiveCN103060318AImproved geneticsEvenly distributedMicrobiological testing/measurementDNA preparationAgricultural scienceGenetic diversity

The invention discloses an SSR (Simple Sequence Repeat) core primer group developed based on whole genome sequence of foxtail millet and an application of the SSR core primer group, and belongs to the technical field of molecular biology. The core primer group comprises 30 pairs of primers, wherein nucleotide sequences are represented by SEQ ID NO. 1-60. The primer has advantages of clear electrophoretic band and rich polymorphism, and is uniformly distributed and stable in amplification. The invention also provides the application of the SSR core primer group in identifying the genetic diversity and variety of the foxtail millet. The primer group can be used for precisely and quickly identifying the variety of the foxtail millet and precisely reflecting a genetic relationship among the varieties of the foxtail millet.

Owner:CROP RES INST SHANDONG ACAD OF AGRI SCI

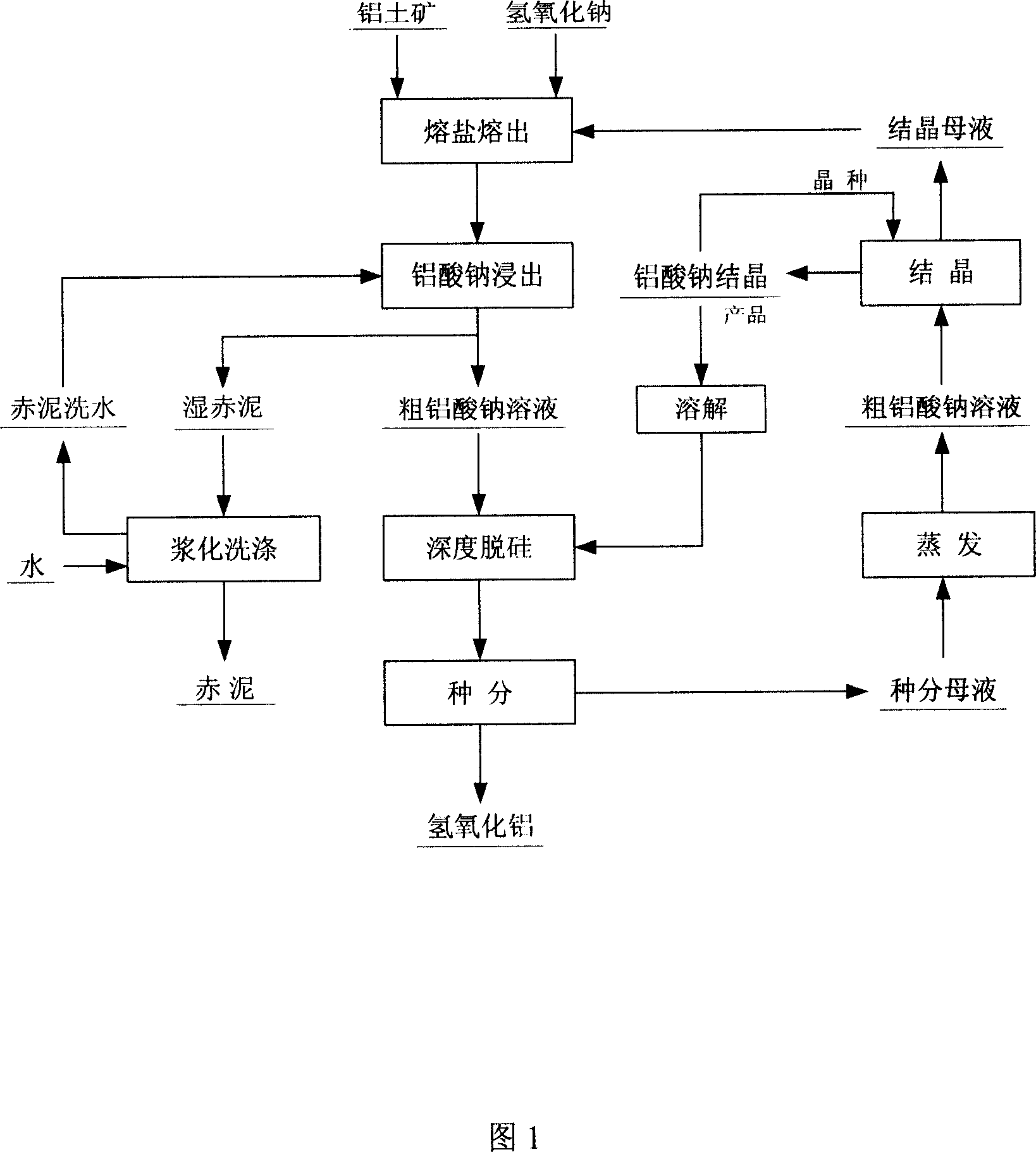

Technique for processing bauxite to produce hydroted alumina with sodium hydroxide molten salt growth method

InactiveCN101108740AReduce energy consumptionSimple processAlkali-metal aluminates/aluminium-oxide/aluminium-hydroxide preparationRed mudAluminium hydroxide

The invention relates to a process that the sodium hydroxide molten salt method is adopted to treat the bauxite to produce the aluminium hydroxide, which comprises that the sodium hydroxide solution blended evenly and the bauxite are heated to carry out the molten salt stripping reaction; the stripping grog is leached and the red mud is separated to gain the sodium aluminate solution which carries out deep desilication; the sodium aluminate solution seeds are decomposed to gain the aluminium hydroxide crystal and seeded precipitation spent liquor; the seeded precipitation spent liquor is evaporated and crystallized and the crystallized mother liquor returns to the molten salt stripping step; the sodium aluminate crystallization returns to the seeded precipitation step after dissolved by adding water. The invention has the advantages that: the digestion temperature is 500 DEG C. to 800 DEG C. lower than that of the traditional sintering method, which can greatly reduce the energy consumption; the invention is operated under normal pressure with simple flow and convenient operation; the invention can process middle-low grade-diasporite bauxite, which conforms to the realistic need of aluminium oxide development in our country; the dissolving rate of the aluminium oxide is high; any accessories are not added and the red mud amount is small, thereby the sodium loss and the aluminum loss are small and valuable metals inside are easily recycle; the product has good quality.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

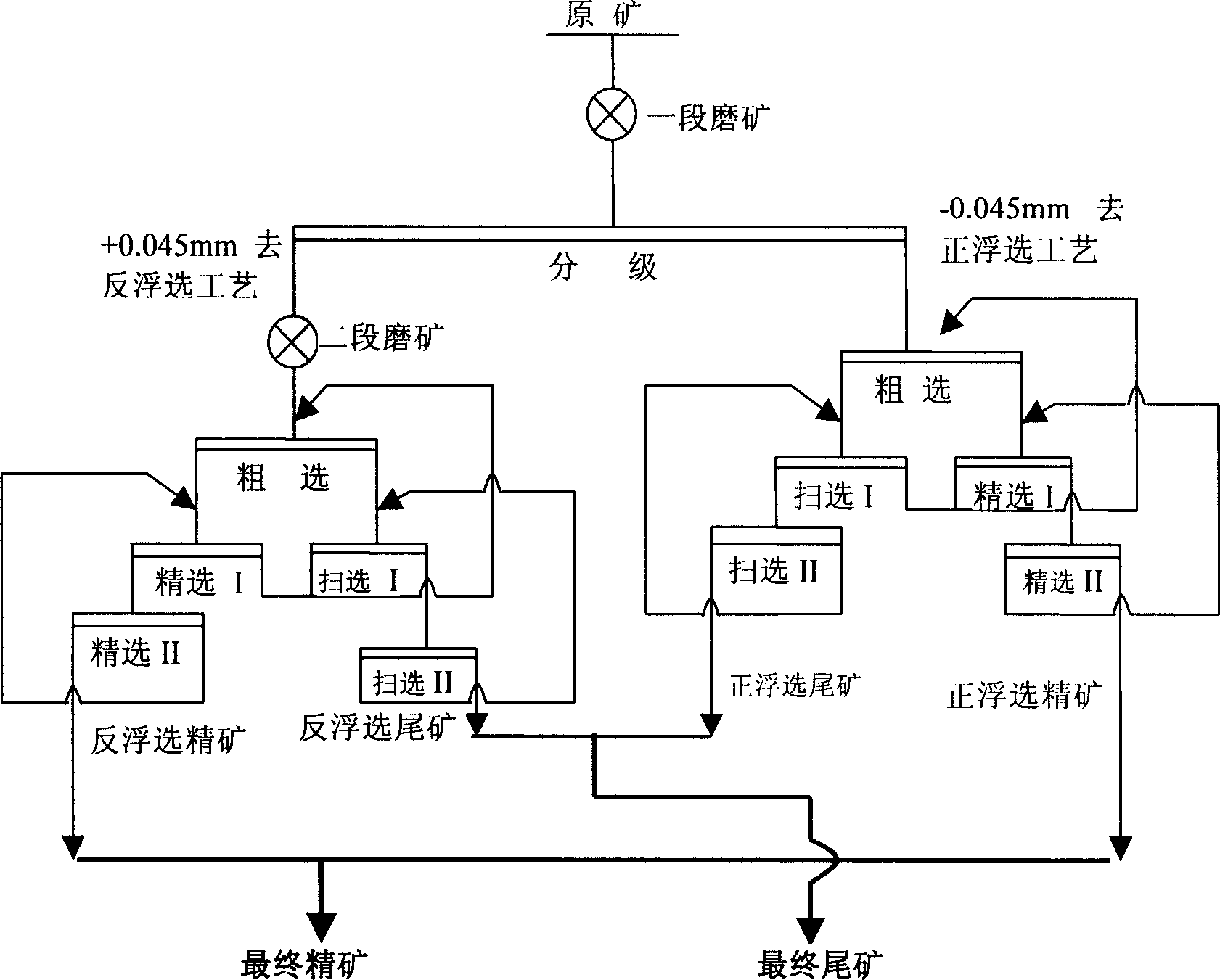

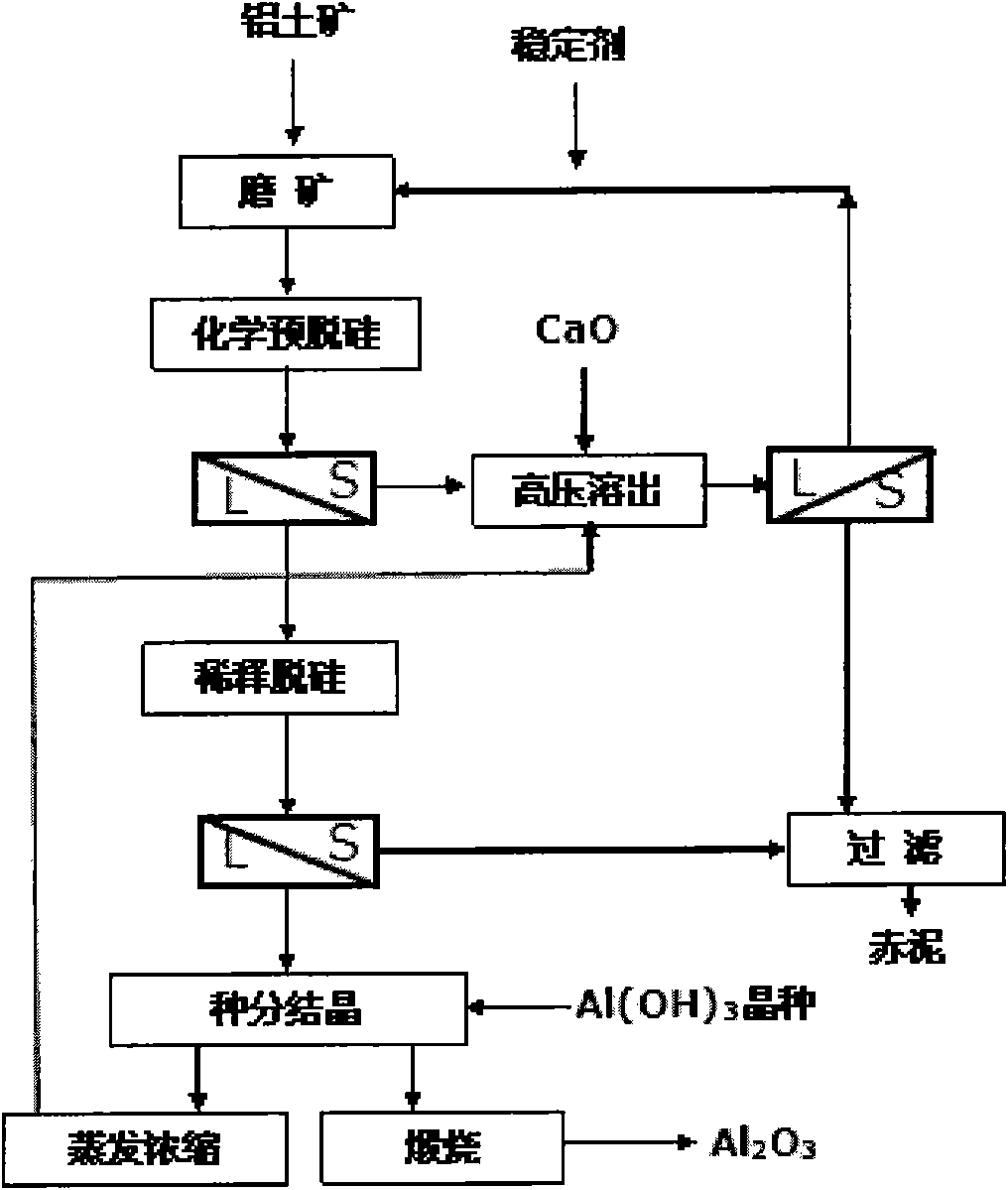

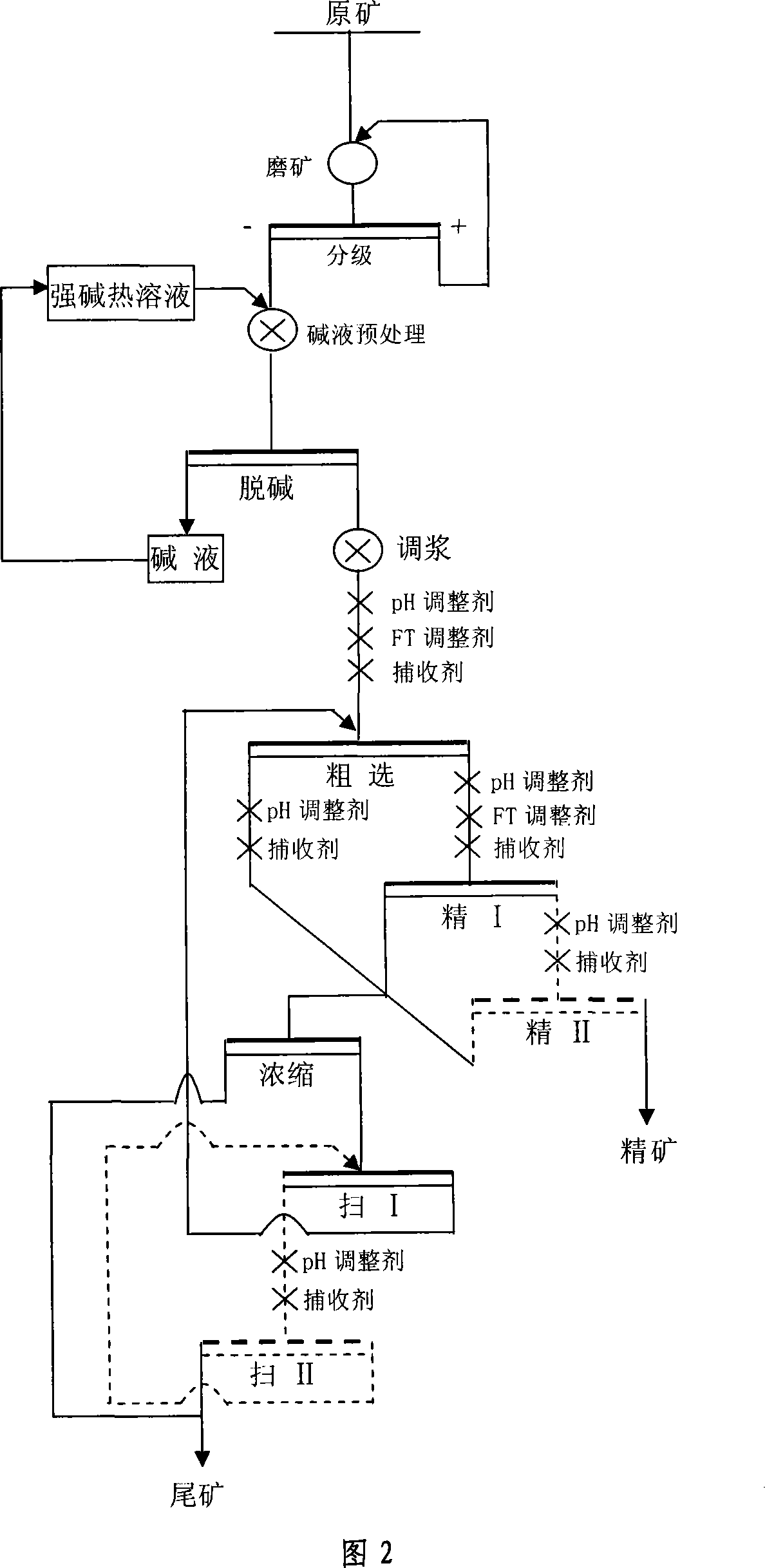

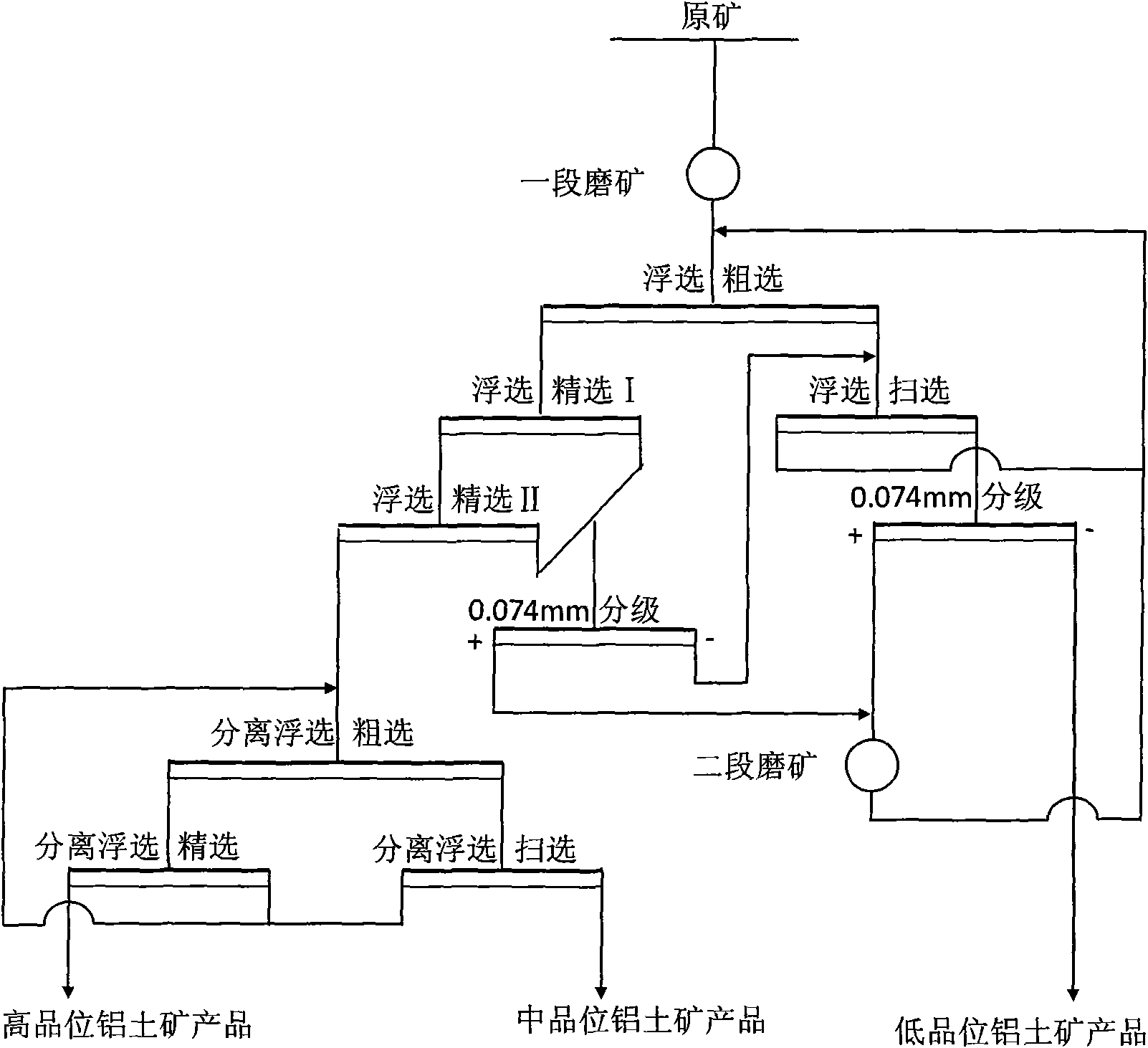

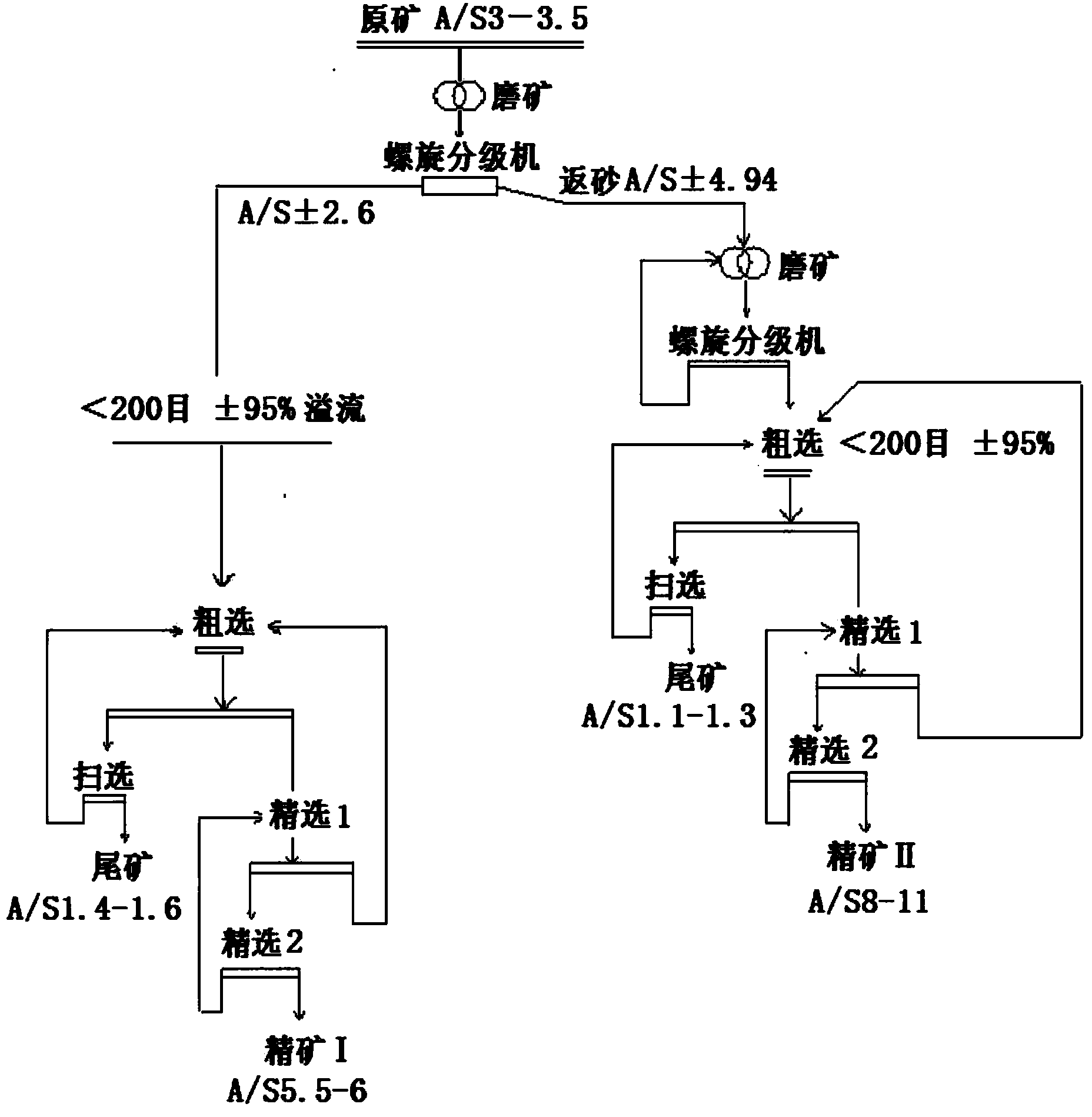

Parallel floatation process of desilionization for bauxite

InactiveCN1869258AEfficient separationIncrease production capacityFlotationProcess efficiency improvementEngineeringMaceral

The invention relates to a parallel floatation selecting method for bauxite desilication that adopts one section or two sections grinding technology to take classification to the bauxite pulp to gain raw and fine class product. The fine class product adopts positive floatation technology, and the raw class product adopts reverse floatation technology after taking or not taking second grinding. The positive floatation mine and the reverse floatation mine could be mixed to form final fine mine, and the positive floatation tail mine and the reverse floatation tail mine would be mixed to form final tail mine. The invention has great advantages and has wide application prospect.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

Stripping method for diasporite type bauxite

ActiveCN101054626ASolid waste managementProcess efficiency improvementResource utilizationPre treatment

A releasing method of monohydrate hard bauxite ore belongs to alumina production technical field, especially a pretreatment of pulp additive calcium ferrite and calcareousness and regeneration method of pretreated lye. The releasing process comprises: pretreating the bauxite by lye, calcium ferrite 2CaO.Fe2O3, calcareousness CaO, then performing centrifugal separation, releasing the separated solid under the common Bayer process releasing condition; adding calcareousness in the used pretreated lye, removing the alumina in solution, regenerating the pretreated lye. The method can economically treat monohydrate hard bauxite ore containing silicon by Bayer process, improves the resource utilization factor and provides a technical support to the aluminium industry.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

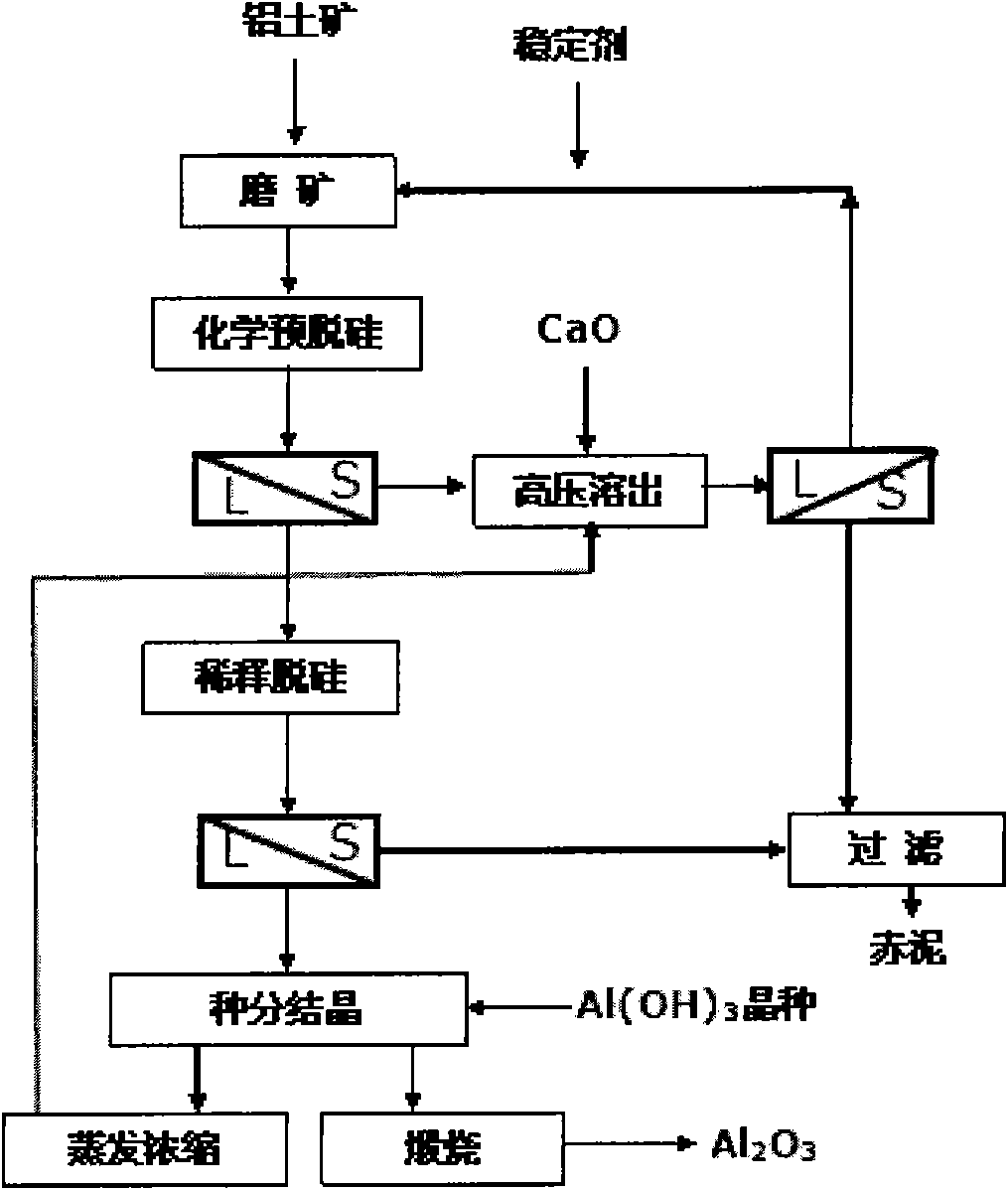

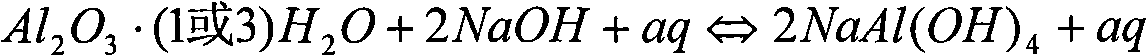

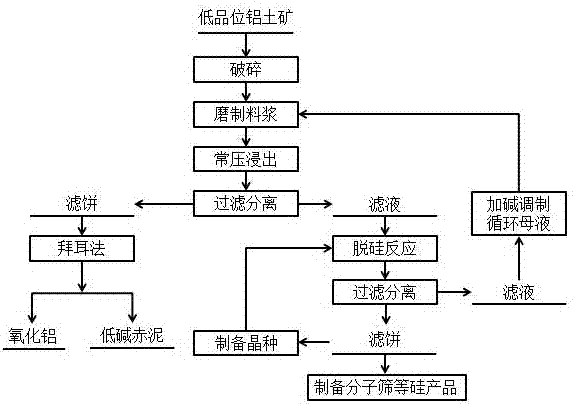

Method for modifying Bayer process, processing low-grade diaspore bauxite and producing alumina

The invention provides a method for modifying a Bayer process, processing low-grade diaspore bauxite and producing alumina. The method comprises steps that: (1) silicon is chemically pre-removed, wherein the low-grade bauxite is immersed into a sodium aluminate solution containing a stabilizing agent, such that a slurry containing dissolved silica is obtained; (2) obtained high-silicon sodium aluminate solution is processed through desilication, wherein desilication crystal seeds are added to the slurry processed through filtration, such that desilication is carried out; (3) the sodium aluminate solution is processed through seed precipitation, wherein aluminum hydroxide crystal seeds are added to the sodium aluminate solution processed through desilication, such that seed precipitation is carried out; (4) the obtained aluminum hydroxide product is baked, such that an alumina product is obtained; (5) a high-pressure dissolution process is carried out, wherein the obtained seed precipitation mother liquor is processed through evaporation and alkali supplementation, and is used in high-pressure dissolution of a concentrate obtained in the step (2); a stabilizing agent is added to the obtained sodium aluminate solution, the sodium aluminate solution is then used for processing the next batch of bauxite, and the steps (1) to (4) are repeated. The method provided by the invention is suitable to be used for processing low-grade diaspore bauxite. With the method, a silicon scaling problem in alumina industries can be effectively solved, energy consumption can be substantially improved, and the quality of the finished product alumina can be improved.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Bauxite surface preprocessing-reverse floatation desiliconizing method

A method of a pretreatment that is a desilication of bauxite surface by a reverse flotation relates to a method of the flotation towards diasporic bauxite, including the courses of grinding, a solid-liquid separation and the reverse flotation. The method is characterized in that before the desilication of the bauxite mineral by the reverse flotation, the surface of the mineral is pretreated by hot alkaline solution. The method of the intention can make a concentrate grade (an alumina-silica ratio) after the desilication by the reverse flotation improved 0.5 to 1 than the concentrate grade after the ordinary desilication by the reverse flotation and make a coefficient of recovery increase by 2 percent to 8 percent. The chemical entrainments of coarse particles are greatly reduced. A concentration adjustment of the flotation system of the present invention is convenient, and the balancing time is short, at the same time novel water can be used for further washing a red mud, which can reduce an alkalescence of the red mud and decrease the pollution influence on environment. The water after washing red mud is added into a grinding machine for the treatment of ore surface as the recycle utilization.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

Floatation method of desulfurizing and desiliconizing diaspore type bauxite

ActiveCN1562494AIncrease profitImprove the difference in surface hydrophilic/hydrophobic propertiesFlotationDiasporeEngineering

A floatation technology for desulfurizing and desiliconizing the diasporite-type bauxite features that the reverse floatation to desulfurize and the forward floatation for desiliconizing are sequentially performed to increase the utilization rate of bauxite and the recovery rate of Al2O3.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

Method for reverse-floatation mud-removing for bauxite

InactiveCN1947850AImprove sorting indexEasy to separateDifferential sedimentationFlotationSiphonSlurry

A reverse floatation method for removing mud from bauxite includes such steps as grinding crude bauxite, regulating concentration and pH value of ore slurry, stirring, adding catechol, stirring, adding phosphonated starch to flocculate the monohydrated duraluminite, layering, and removing suspended mud by siphon method.

Owner:XIAOYI TIANZHANG ALUMINUM

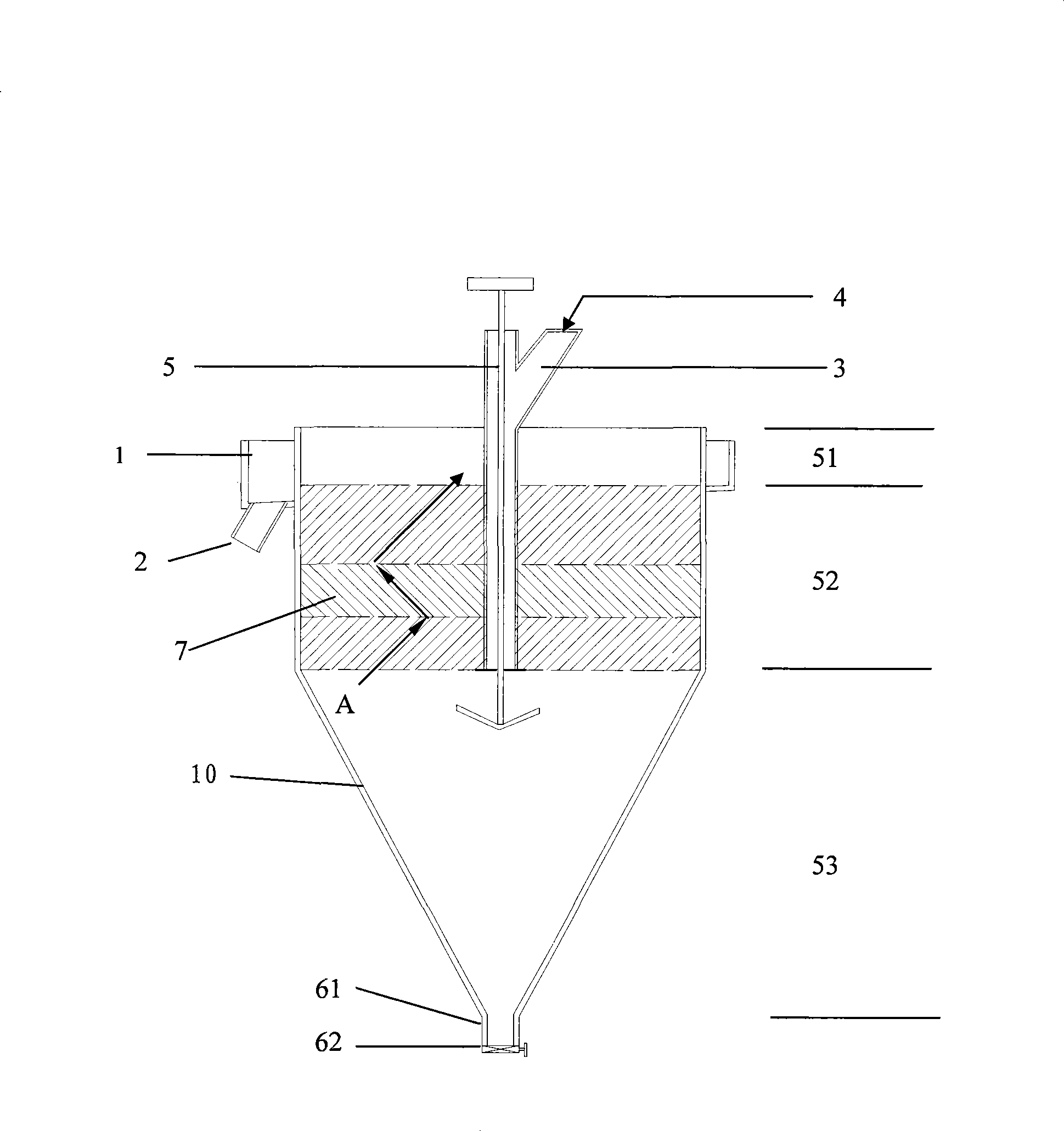

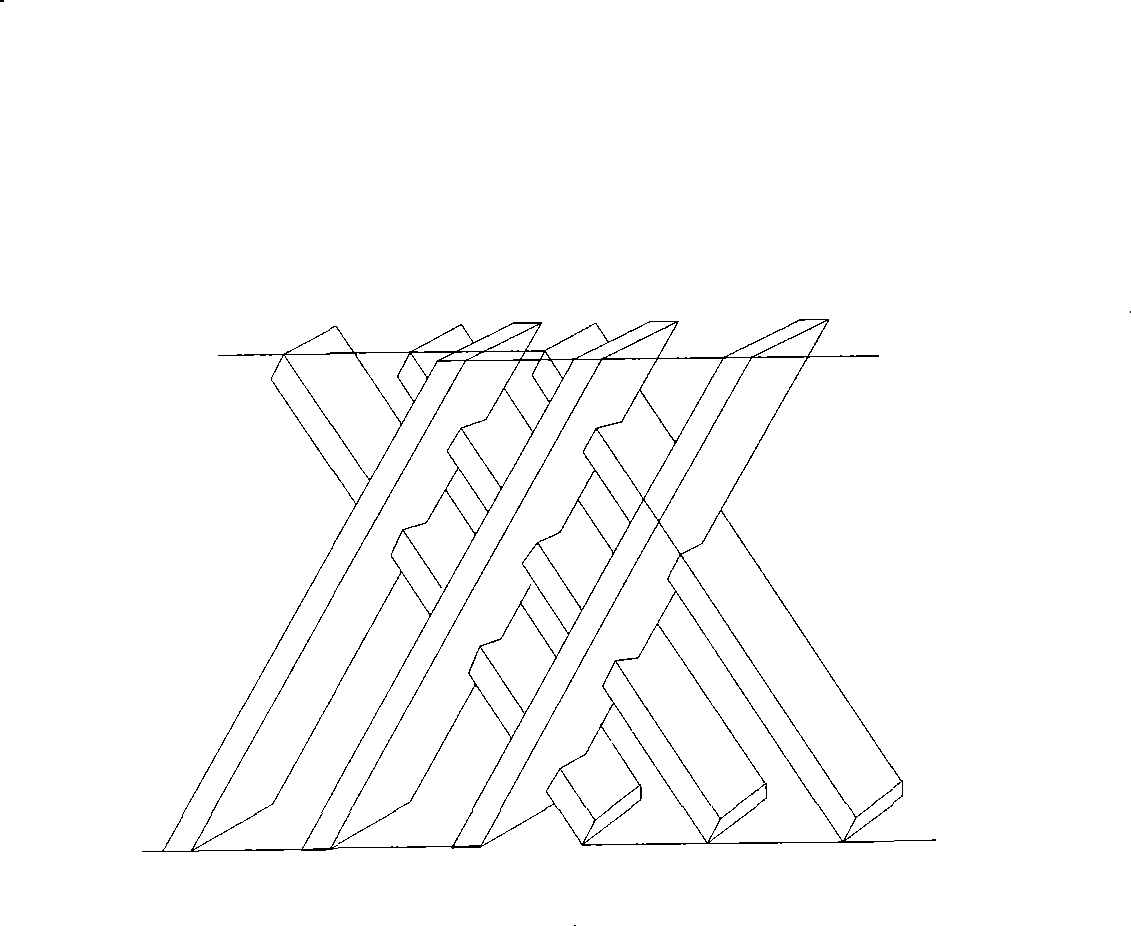

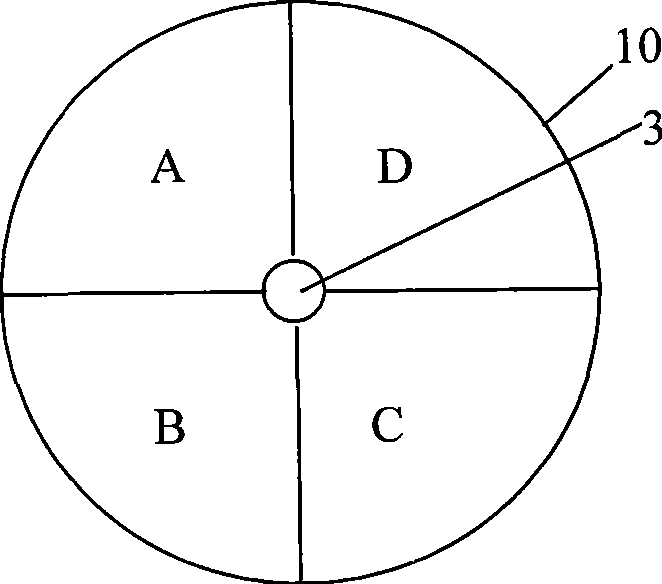

Hydraulic sorting device

InactiveCN101439313AReduce mechanical inclusionsImprove alumina recoveryWet separationEngineeringSilicate minerals

The invention discloses a hydraulic power sorting unit which comprises a container, a sand setting hole arranged at the bottom of the container, a central feeding tube arranged at a central shaft of the container, an ore pulp inlet opened at the upper part of the central feeding tube, and a turbulent current device installed in the central feeding tube; the interior of the container is divided into a static state settlement zone, a transition settlement zone and a turbulent fluctuation settlement zone; the transition settlement zone of the container is internally provided with a steady flow plate component which is formed by combining a plurality of 'Z'-shaped plates which are mutually fixed by grooves arranged on the 'Z'-shaped plates after rotating at 180 degrees. The hydraulic power sorting unit can improve the settlement separative efficiency between a diasporite and granule silicate minerals in the process of aluminum ore processing.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

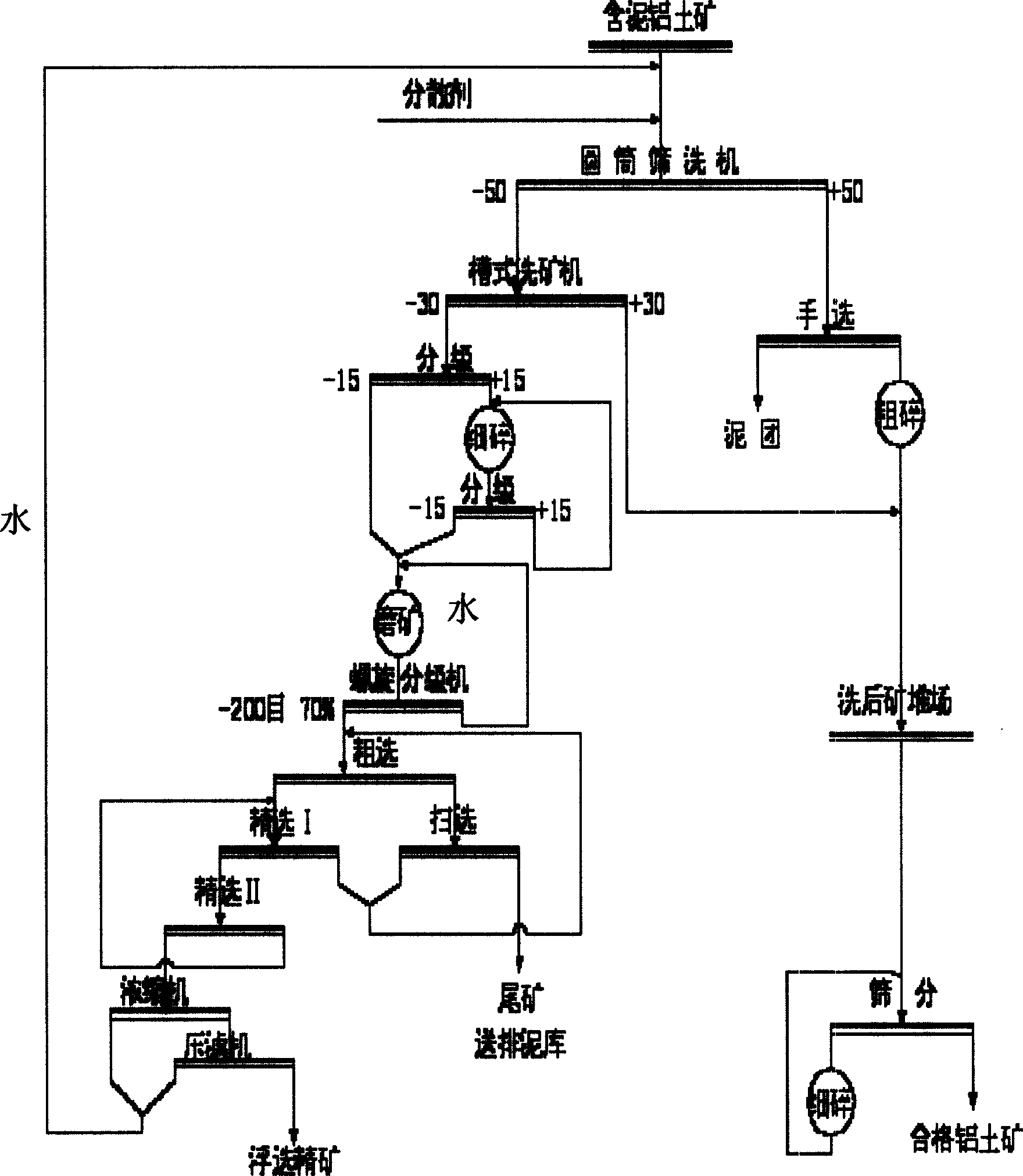

Method for mineral dressing and silicon removal of bauxite

InactiveCN101850297ASimple technical processGood technical and economic effectFlotationWet separationDiasporeLarge size

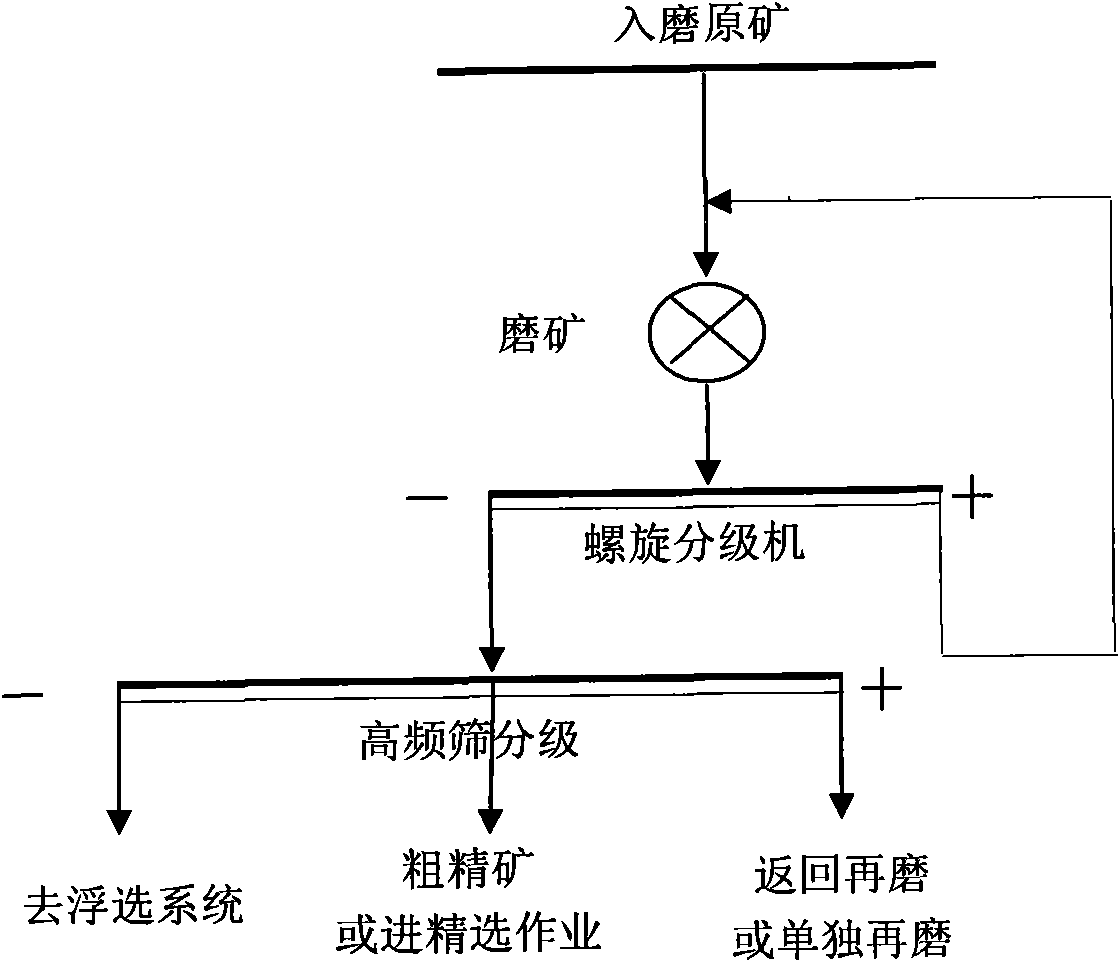

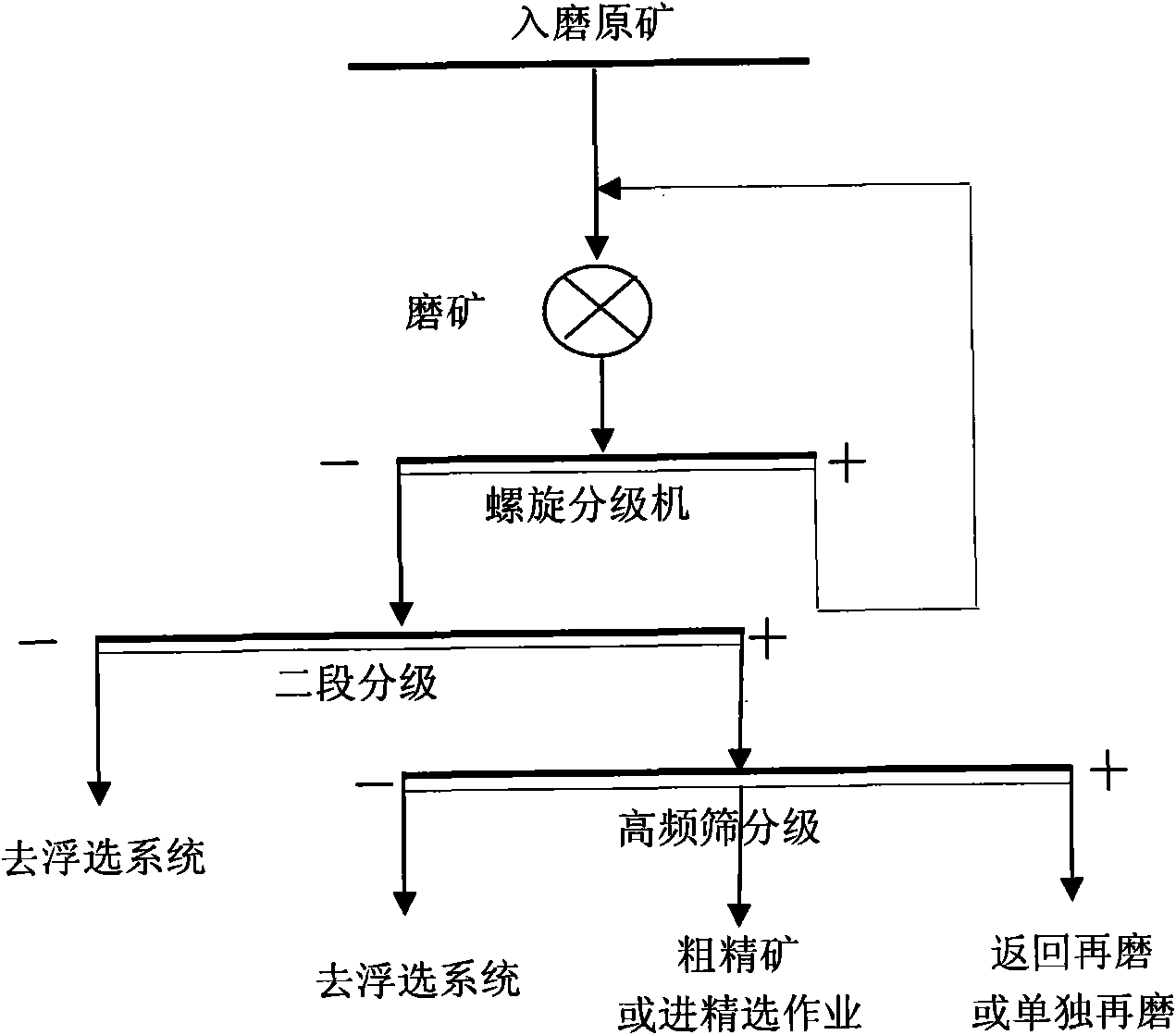

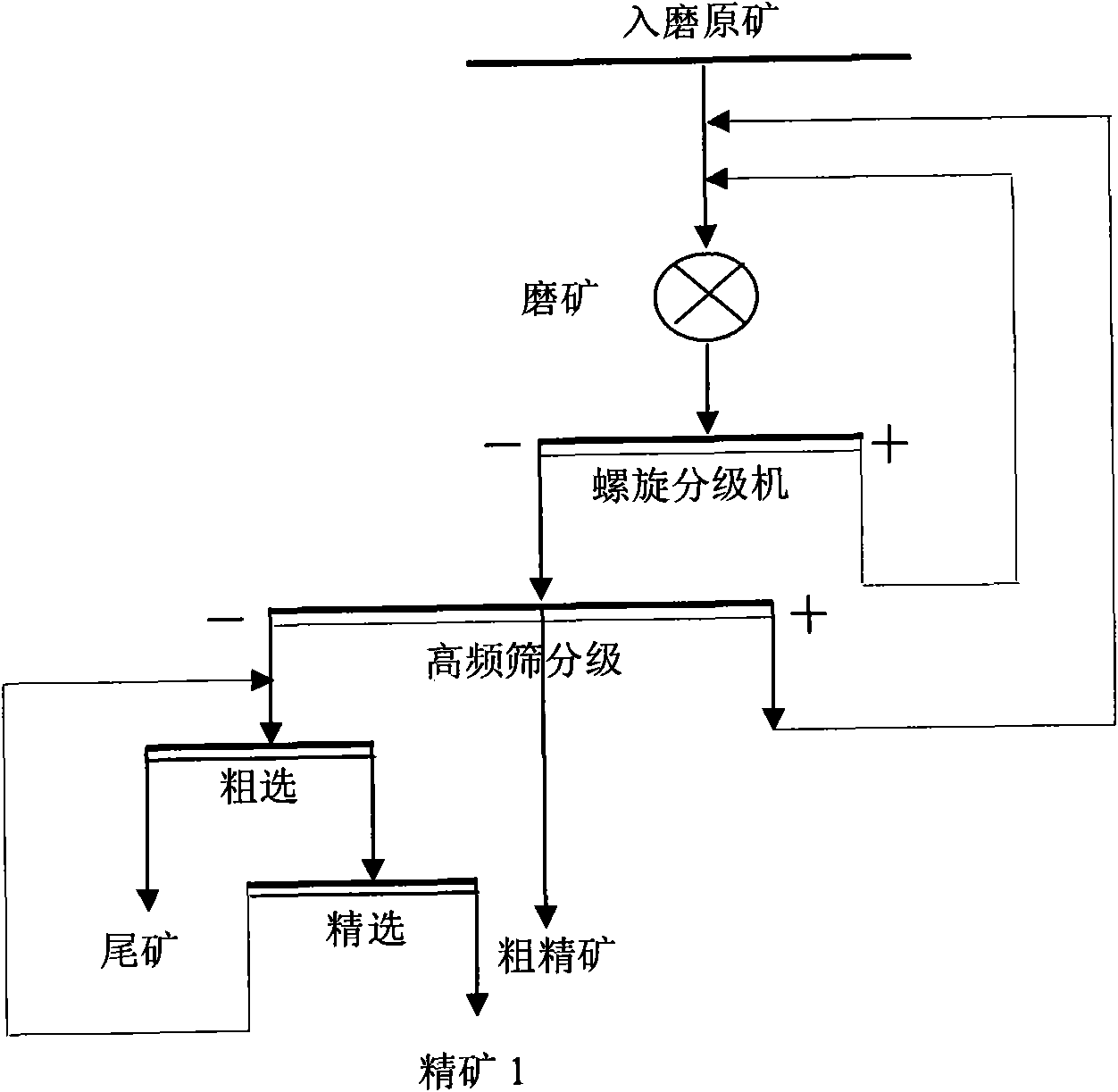

The invention provides a method for mineral dressing and silicon removal of bauxite, and particularly relates to a method for mineral dressing and silicon removal of diaspore type bauxite. The method comprises an ore-grinding grading process and a flotation silicon removal process, and is characterized in that: the product of ore grinding is graded for two or three times, wherein a double-layer high-frequency vibrating screen is used at the last time of grading; and among three products obtained by grading of the double-layer high-frequency vibrating screen, large-size grains are reground and re-dressed, medium-size grains are used as rough concentrates or enter the flotation system for concentration, and small-size grains enter the flotation system for flotation silicon removal. The method has the advantages of effectively solving the technical problem that the grinding machine is high in energy consumption and low in treating capacity, the problem that the grain size of the flotation materials is small and other problems, better performing flotation silicon removal of bauxite, obtaining bauxite concentrates with qualified grade, along with good process technique and economic indexes.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

Herbicide composition containing ametryn and terbutryn and preparation method thereof

The invention discloses a herbicide composition containing ametryn and terbutryn and a preparation method thereof. The herbicide composition takes ametryn and terbutryn as active ingredients. The invention also discloses the preparation method of the herbicide composition. The composition disclosed by the invention consists of two active components and has low toxicity; and when the herbicide composition is used, the dosage of the ametryn can be reduced, the growth safety of crops can be ensured, the active components stay in crops and soil for such a short time that toxin accumulation is avoided, the dosage of the ametryn is lower than the normal dosage and grass can be killed effectively. In addition, the herbicide composition has a wider herbicide spectrum than terbutryn alone, monocotyledonous grass such as cockspur grass, hairy finger, green bristlegrass (green foxtail) and eleusine indica can be better killed, and at the same time, the respective drawbacks of ametryn and terbutryn which are used alone are overcome.

Owner:SHANDONG WEIFANG RAINBOW CHEM

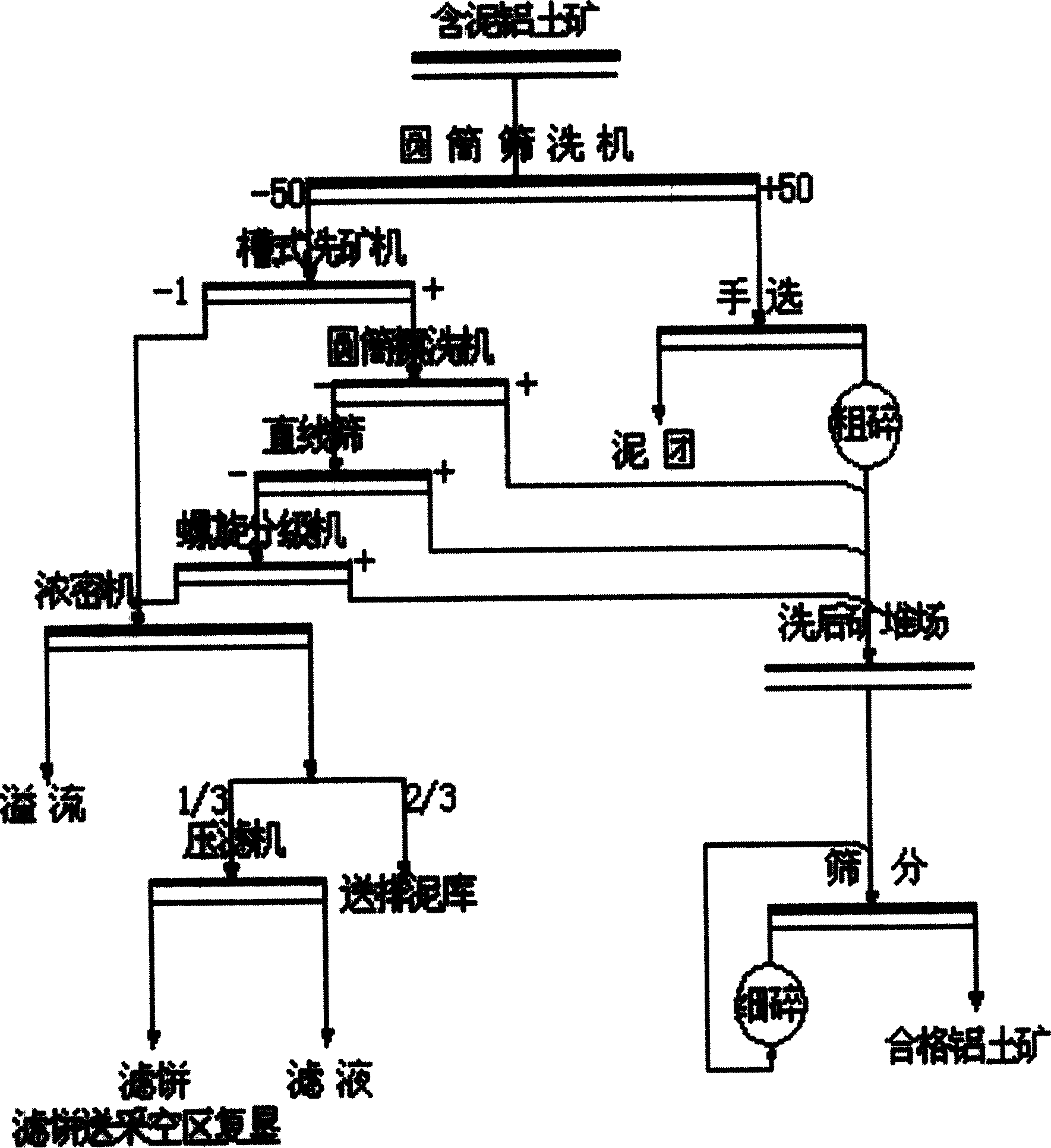

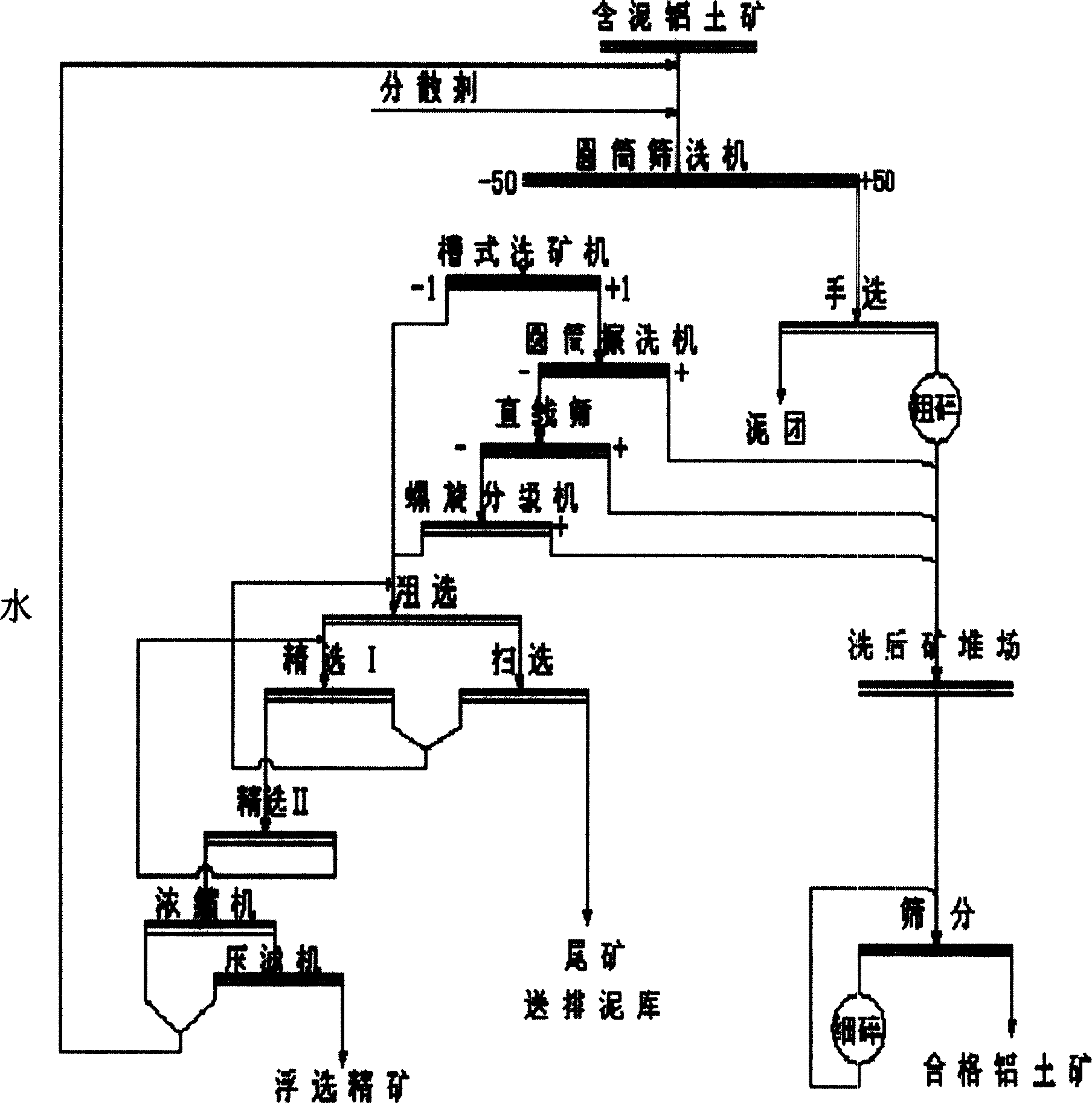

Washup-flotation process for stacked bauxite

The invention discloses a mill run technology of bauxite, especially relates to a ore wash-floatation technology of cumulate bauxite. For cumulate bauxite, changing the single ore wash technology into ore wash and appending dispersant, and floatation to the gangue. The invention can increase the quality of wash-concentrate and decrease the mud ratio of wash-concentrate; by floatation, a number of gibbsite, diasporite, bodhmite can be reclaimed, achieve the intention of using bauxite.

Owner:SHENYANG ALUMINIUM MAGNESIUM INSTITUTE

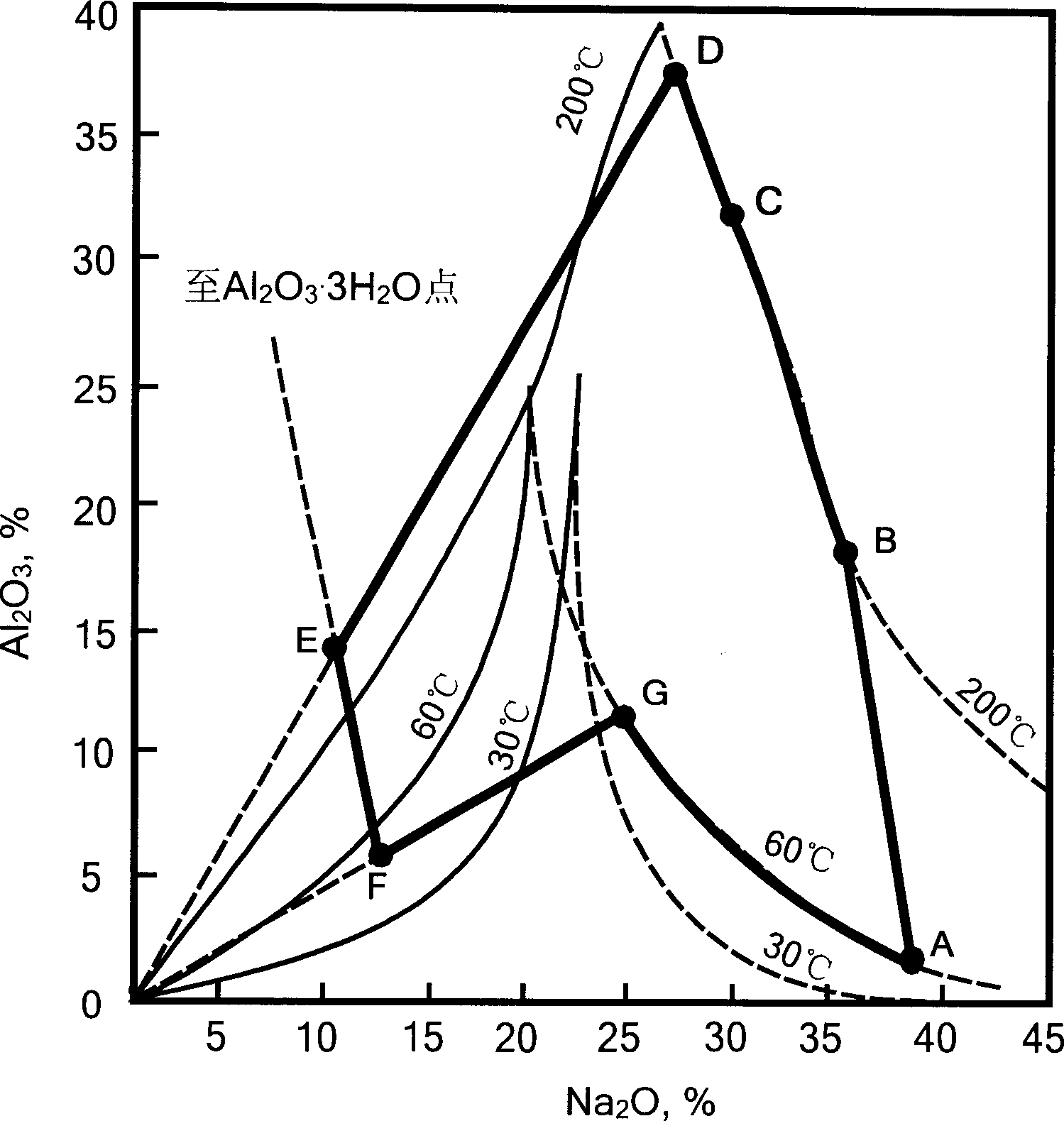

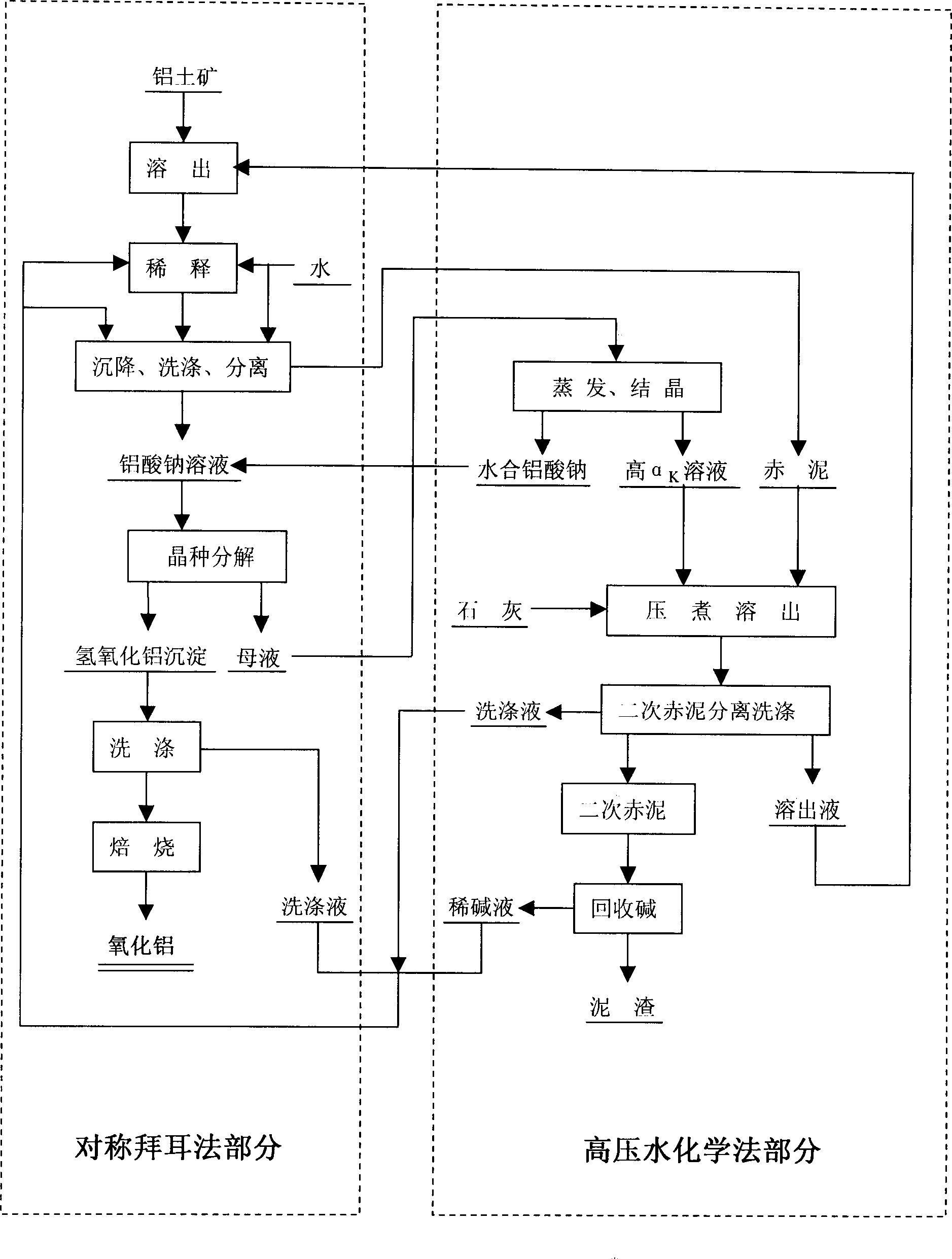

Method for extracting alumina from high silicon bauxite

InactiveCN1807251AEfficient decompositionReduce energy consumptionAluminium compoundsHybrid typeRed mud

The invention relates to a technique to produce alumina with bauxite by alkaline method, which comprises: combining the symmetrical Bayer process at 100-250Deg and high-pressure hydrochemical method at 200-300Deg to treat directly high-silicon bauxite to extract alumina and treat red mud to recover Al2O3 combined by SiO2 and send obtained solution to the symmetrical Bayer process, respectively; hydrolyzing the generated calcium sodium silicate hydrate to recover the combined alkali; adding lime in any system by 1-3 times mole ratio as the SiO2. This invention can decompose the bauxite effectively with low alkali quantity and energy consumption, and fits to treat the diaspore, boehmite and aluminum trihydrate or the mixture.

Owner:CENT SOUTH UNIV

Combined collector for direct flotation of diasporic bauxite and using method thereof

The invention discloses a combined collector for direct flotation of diasporic bauxite and a using method thereof. The combined collector mainly contains vegetable oil acid, naphthenic acid and a saponified product of dodecyl ether phosphate. The proportion of the vegetable oil acid to the naphthenic acid to the saponified product of the dodecyl ether phosphate is 1:1:0.5. The using method is that a bauxite grinding product with the alumina-silica ratio 3-5 and the particle size -0.074mm accounts for 80-90% when the direct flotation of the bauxite is performed, a potential of hydrogen (pH) value of a flotation system is controlled to be 9-11, the using amount of sodium silicate or sodium hexametaphosphate serving as an inhibitor is 60-80g / t, and the using amount of the combined collector serving as a collector is 800-1200g / t. The selectivity and collecting capacity on the diasporic bauxite during the direct flotation of the bauxite can be enhanced, the dispersing and dissolving capacity of the combined collector in ore pulp is enhanced, and the bauxite direct flotation effect is improved.

Owner:ZHENGZHOU MINERALS COMPOSITIVE UTILIZATION RES INST CHINESE GEOLOGICAL ACAD

Novel technology and device for Bayer process-based separation of iron in high-iron red mud

InactiveCN104368440ARealize dry storageEliminate potential safety hazardsProcess efficiency improvementMagnetic separationRed mudMagnetic separation

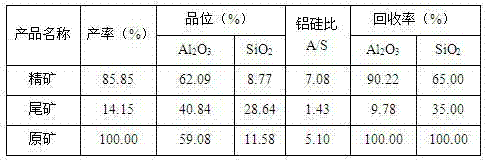

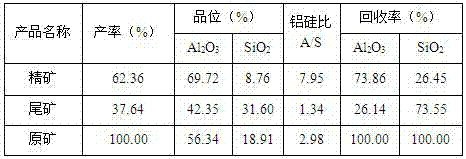

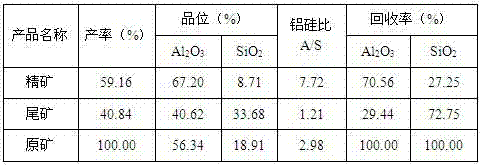

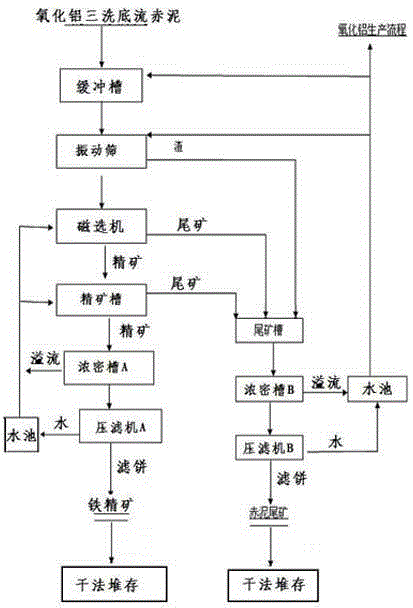

The invention discloses a novel technology for Bayer process-based separation of iron in high-iron red mud. The novel technology comprises the following steps of A, carrying out sedimentation on alumina production solid waste, washing bottom-flow red mud three times, carrying out roughing separation by a vibrating screen, adding water into the red mud so that red mud solid content satisfies magnetic separation requirements, and at least carrying out a magnetic separation process to separate concentrate and mine tailing, B, carrying out concentration on the concentrate, carrying out overflow separation to remove most water, and carrying out press filtration to obtain filter cake which is iron concentrate, and C, carrying out concentration on the mine tailing, carrying out overflow separation to remove most water, carrying out press filtration to obtain filter cake and carrying out dry-type stockpiling. The invention discloses a device for Bayer process-based separation of iron in high-iron red mud. The device comprises a buffer slot, the vibrating screen, a magnet separator, a concentrate tank, a mine tailing tank, a concentration machine and a filter press. The device matches the novel technology, has a high yield and a high total iron recovery rate and utilizes a mine tailing dry-type stockpiling process. The novel technology has a simple process, is mature in operation and realizes production easily.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

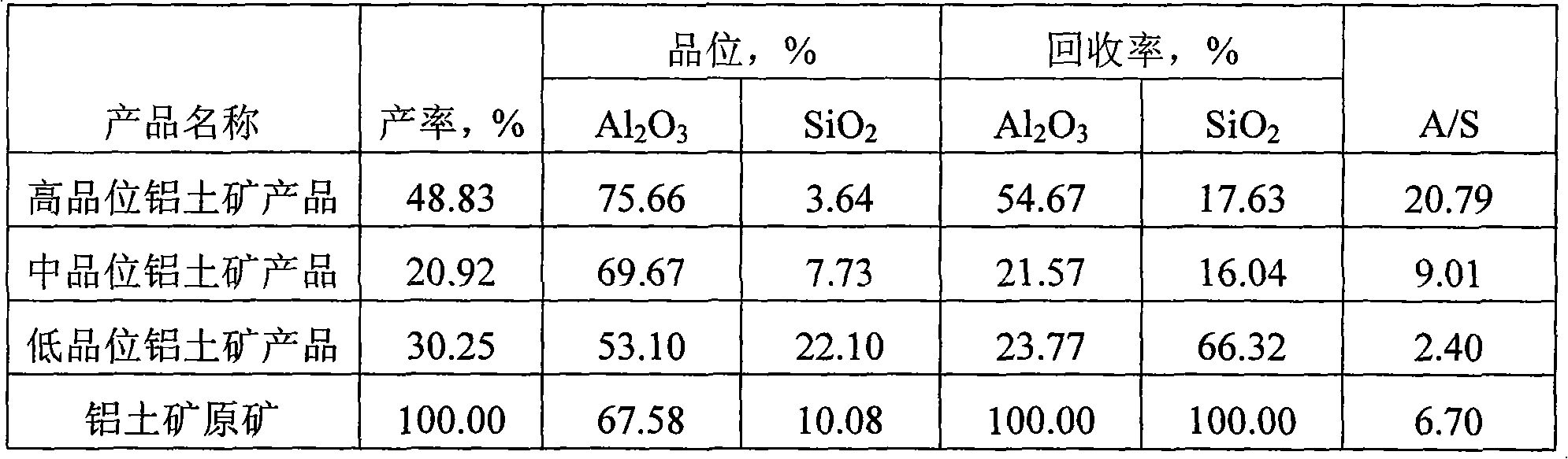

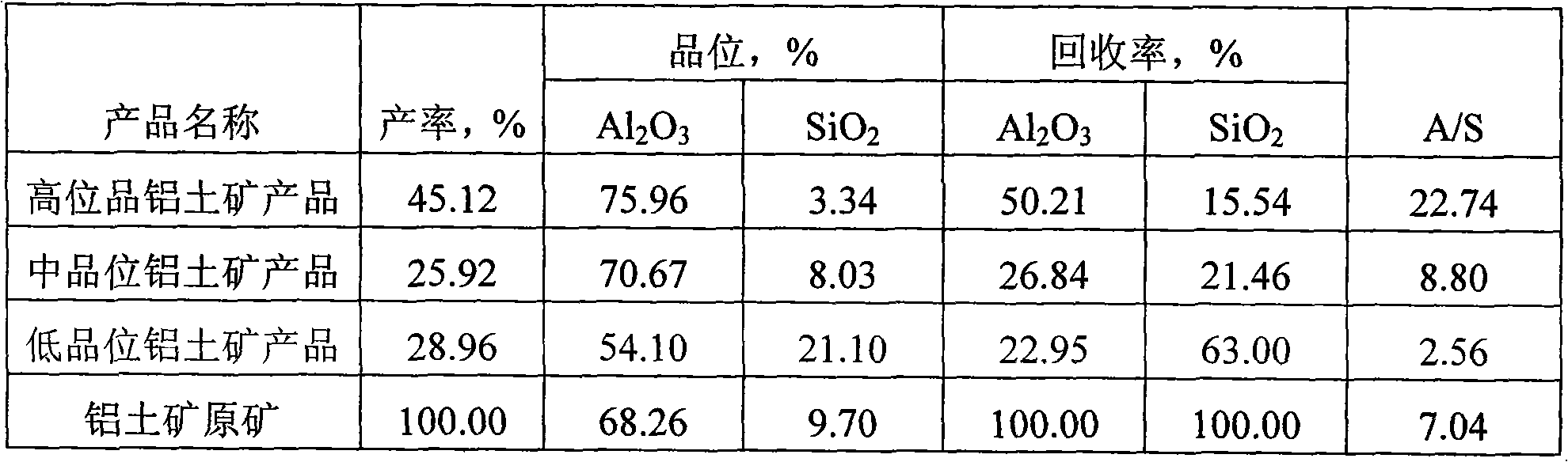

Beneficiating method of diaspore type bauxite

The invention relates to a beneficiating method of diaspore type bauxite, which is characterized by comprising the following steps: carrying out single-stage coarse grinding on raw bauxite, enabling ground bauxite products and a flotation reagent to act, and directly entering a rough concentration task; carrying out single scavenging on rough concentration base flow, grading scavenged base flow to obtain a low-grade bauxite product as a fine fraction product; carrying out twice blank selection on rough concentration foam, intensively grading the base flow, scavenging the fine fraction product, combining the scavenged foam and twice-grading coarse fraction regrinding products, and intensively carrying out floatation and rough concentration with the single-stage ground bauxite products; carrying out single rough concentration, single selection and single scavenging on the selected II foam, and then obtaining a high-grade bauxite product and a medium-grade bauxite product. The beneficiating method can obtain three kinds of products with different A / S, wherein a high aluminum product with the Al2O3 content being higher than 75 percent is used for calcining high aluminum clinkers, a medium aluminum product with the A / S being 8-12 is used for producing alumina by a Bayer process, and a low aluminum product with the A / S being about 2.55 is used for synthesizing mullite type refractory material, thereby realizing tailless production; the comprehensive utilization ratio of diaspore type bauxite approaches to 100 percent.

Owner:XIAOYI TIANZHANG ALUMINUM

Bauxite direct flotation collector

The invention relates to a bauxite direct flotation collector which is prepared by performing ultrasonic emulsification on an emulsifier, an oleic acid collector, an octyl hydroximic acid collector and kerosene. During the preparation, the mass ratio of the emulsifier, the oleic acid collector, the octyl hydroximic acid collector, kerosene and water is 1:(2-5):(10-15):(10-15):(64-77); the ultrasonic transmitting frequency is 25-30 kHz; and the ultrasonic emulsification period is 30-60 min. The bauxite direct flotation collector is suitable for diasporic bauxite of which the alumina-silica ratio is 3.3-3.4; the bauxite direct flotation collector has high stability, that is, the bauxite direct flotation collector can stably exist in the form of an emulsion for 60 min; basically, emulsion drops d50 are not changed after water is added, and the bauxite direct flotation collector can stably play a role within the ore pulp flotation period; the bauxite direct flotation collector is high in dispersive capacity and sufficiently acts with a mineral, so that flotation indices are obviously improved; and the foamability is high, and foam consists of small and uniform bubbles, so that the consumption of a foaming agent can be lowered and the reagent cost can be reduced.

Owner:CENT SOUTH UNIV

Method for producing aluminium oxide and by-product silicon by low-temperature alkali digestion of low-grade bauxite

InactiveCN107235501AAluminium silicatesAlkali-metal aluminates/aluminium-oxide/aluminium-hydroxide preparationSlagRed mud

The invention relates to a method for producing aluminium oxide and a by-product silicon by low-temperature alkali digestion of low-grade bauxite, and belongs to the technical field of aluminium oxide production. The method comprises the following steps: firstly, smashed low-grade diasporic bauxite and a circulating mother liquid are grinded to form a mineral slurry; secondly, a digestion reaction is performed enable kaolinite in the mineral to be dissolved, react and enter a solution, filtration residues are high-grade bauxite concentrate, and the high-grade bauxite concentrate is processed for produce aluminium oxide and low-alkali red mud by adopting a Bayer process; sodium aluminosilicate in a filtrate is subjected to desilication reaction, so that sodium-silicon residues, and a filtrate containing aluminium oxide, silicon oxide and sodium oxide are obtained; and finally, the filtrate is supplemented by sodium hydroxide, and the supplemented filtrate is used as the circulating mother liquid to return for preparation of the mineral slurry through grinding, and part of the sodium-silicon residues are used as a seed crystal to return to a desilication process, and the other part of the sodium-silicon residues are used to prepare silicon products such as molecular sieves. The method is a whole-procedure wet treatment process, aluminium and silicone are fully extracted from the bauxite for preparing the corresponding products, also alkali consumption in the red mud during the Bayer process is substantially reduced, the alkali content in the red mud is reduced, and recycle value of the red mud is improved.

Owner:NORTHEASTERN UNIV

Flotation gangue subsidence method of alumyte

The present invention relates to the deposition dewatering process of floated tail ore, and is especially the deposition dewatering process of floated tail ore of diaspore type alumyte. The present invention features that into the floated tail ore slurry, sulfuric acid or sulfate, aluminum sulfate, ferrous sulfate, zinc sulfate, copper sulfate, barium sulfate or alum in acidity after hydrolysis is first added to regulate pH value to 6.5-7.5; and polyacrylamide as organic flocculant in the amount of 0.001-0.01 % of the dry tail ore slurry weight is then added for flocculation and deposition. The present invention can raise the concentration of tail ore slurry from 6-11 % to over 25 %, reduce the overflow floated matter to below 1 g / L and make the overflow water capable of being reused.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

Alumina production process by using monohydrate bauxite lime Bayer process

InactiveCN1380253ARaise the reaction temperatureExtended reaction timeAlkaline-earth metal aluminates/aluminium-oxide/aluminium-hydroxide preparationAlkali-metal aluminates/aluminium-oxide/aluminium-hydroxide preparationCalcium silicateFoxtail

The production process of alumina by using monohydrate bauxite ore and adopting Bayer process is characterized by that when preparing ore pulp, the lime is added according to the demand for that the CaO content being in lime and TiO2 content being in bauxite are reacted to produce perovskite and the CaO in the lime and SiO2 being in bauxite are reacted to form hydrated calcium silicate, in which the molecular ratio of CaO added for balancing TiO2 is C / T=1-1.5 and the molecular ratio of CaO added for balancing SiO2 is C / S=1.5-3.0 and then the ore pulp is undergone the process of desilication pretreatment at 90-110 deg.c for 2-12 hr. and then undergone the conventional Bayer process. Its desilicated product mainly is hydrated calcium silicate.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

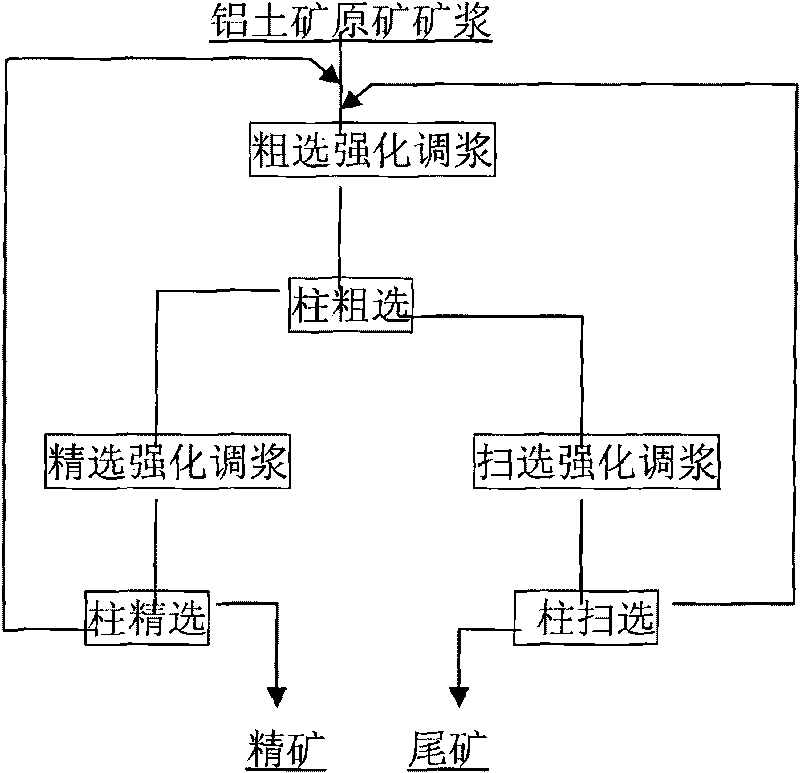

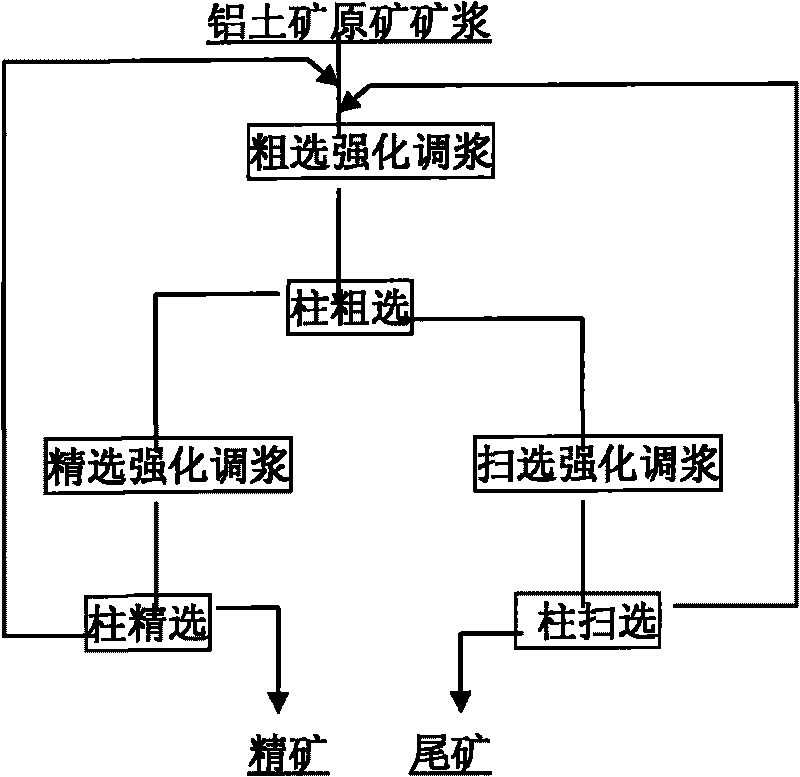

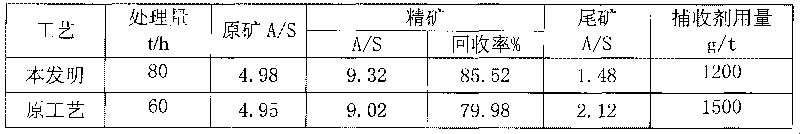

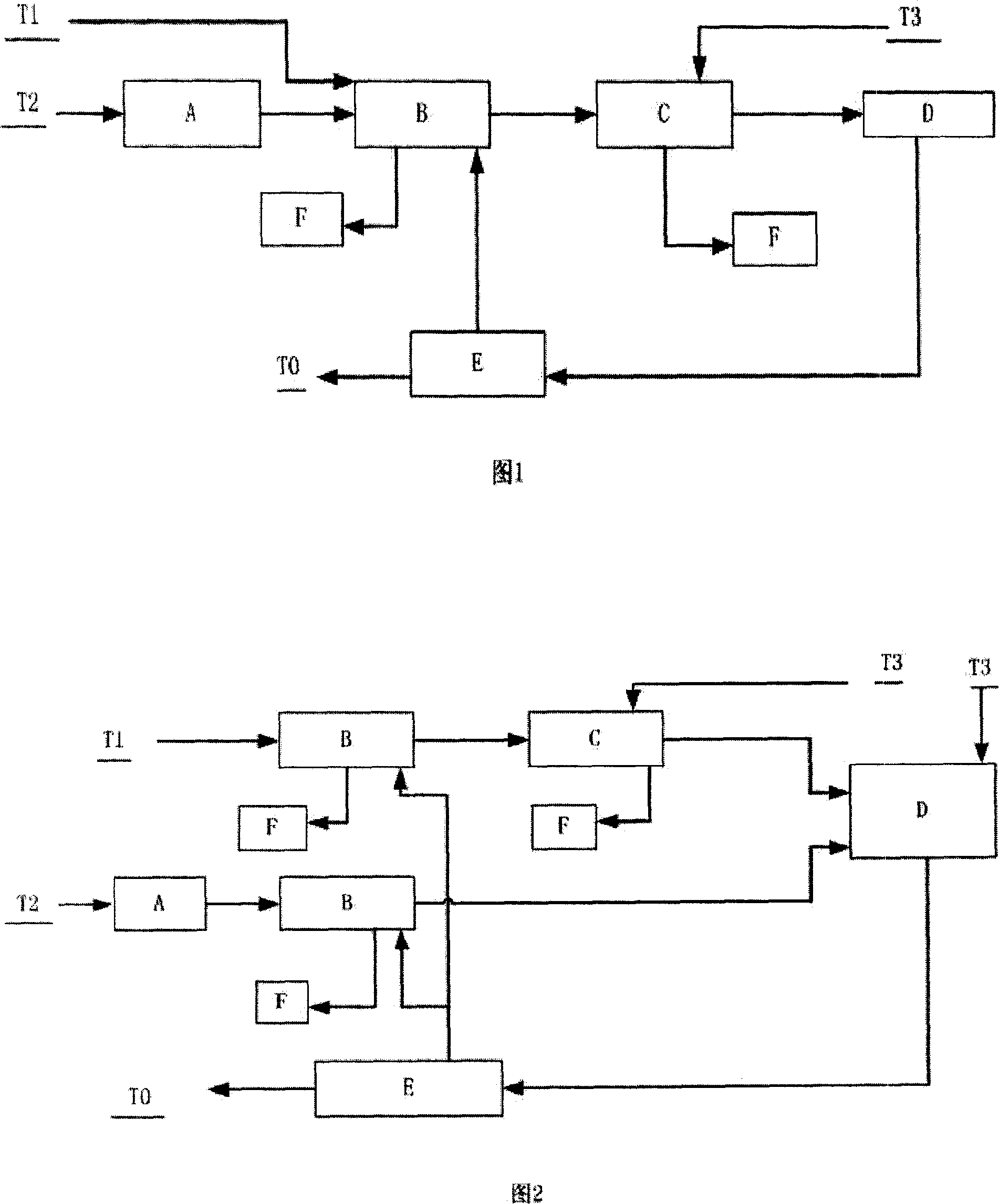

Bauxite column-type floatation method

The invention provides a bauxite column-type floatation method, and relates to bauxite ore-dressing and desilication, in particular to a low-grade diasporite bauxite ore-dressing and desilication method. The method is characterized in that a floatation process comprises the following steps: (1) adding flotation reagent for pulp regulation to bauxite raw ore pulp and adopting a flotation column for rough flotation; (2) adding the flotation reagent for pulp regulation again to flotation concentrate pulp overflowing from the flotation column for rough flotation, adopting the flotation column forconcentration and obtaining concentrate; (3) adding the flotation reagent for pulp regulation to tailings flowing at the bottom of the flotation column for rough flotation to perform column scavenging; and (4) returning the tailings obtained by adopting the flotation column for concentration in the step (2) and scavenging concentrate obtained in the step (3) to the process of adding the flotationreagent for pulp regulation to the bauxite raw ore pulp in the step (1). The method has the advantages of reasonable process, good industrial implementation effects, good flotation indexes and low reagent consumption.

Owner:中铝中州铝业有限公司

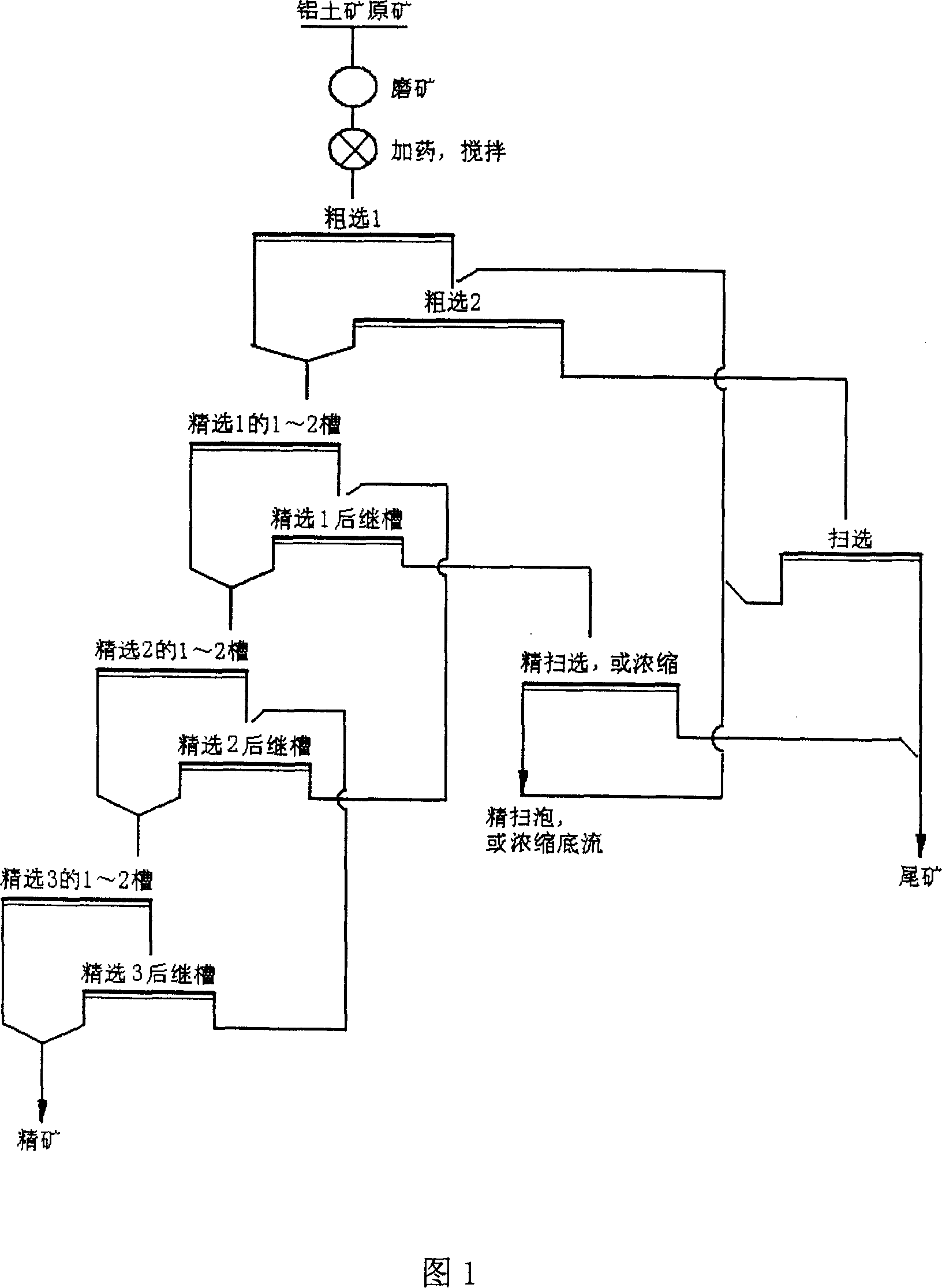

Gradient floatation method for bauxite

InactiveCN1958168ASolve difficult to float,Solve the phenomenon that the slot falls during the selection process after floatingFlotationSludgeFoxtail

Owner:CENT SOUTH UNIV

Flotation selection and desiliconization method for middle and low grade alumyte

ActiveCN1803300ATaking advantage of hydrophobicity differencesOvercoming high drug consumptionFlotationLower gradeLow graded

The invention discloses a flotation desiliconisation method of low-grade bauxite with ore grinding, agent paste mixing and floating courses, which is characterized by the following: mixing bauxite Baeyer stripping condensed water and ore dressing backwater as the floatation water according to stripping condensed water: fine ore backwater: tailing backwater=0.5-1.5: 4-6: 1.5-2.5; adding modifying agent, disperser and collector to float the low-grade bauxite of 4-6 A / S ratio, wherein the soda quantity scale of modifying agent is 1000-3000 g / ton; the hexametaphosphate quantity scale of disperser is 5-100 g / ton; the quantity scale of collector is 300-1000 g / ton. The invention improves the sorting property between hydraulic aluminum and silicon vein mineral, which reduces the agent consumption.

Owner:中铝中州铝业有限公司

Herbicide resistance mutant and application thereof

Owner:深圳洁田模式生物科技有限公司

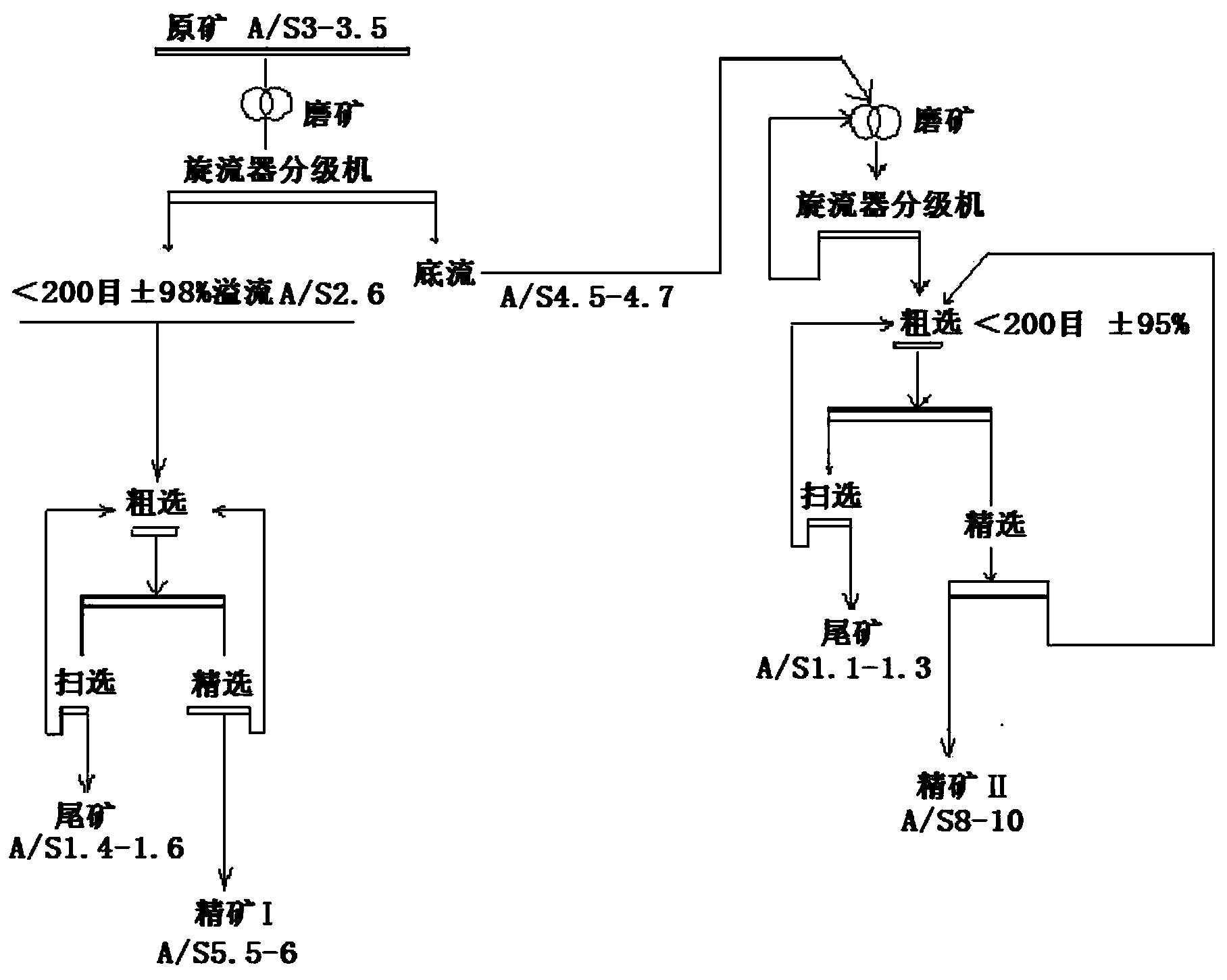

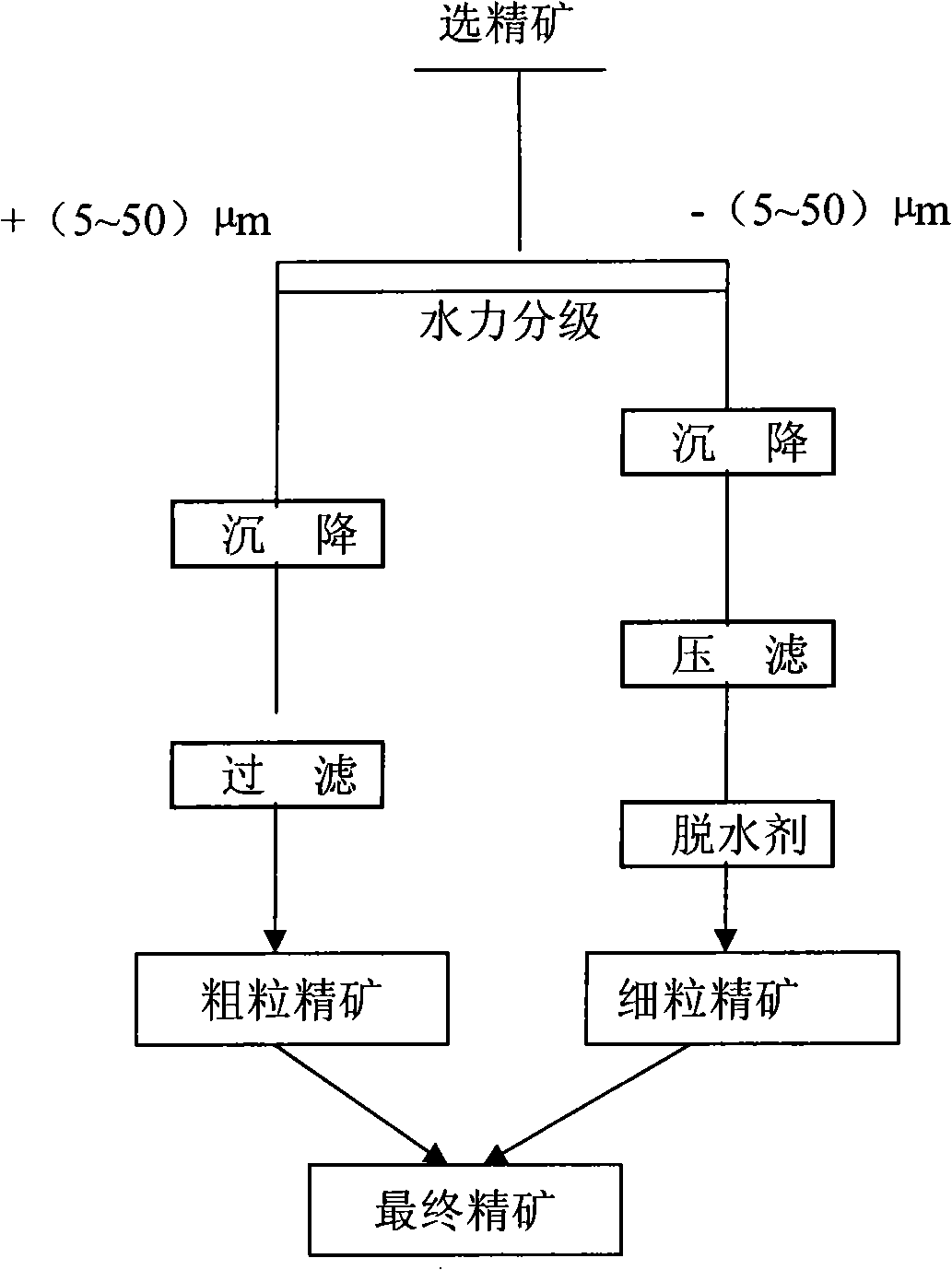

Low-quality raw bauxite ore open-grinding and dressing technology

InactiveCN103521363AHigh recovery rateLow costVortex flow apparatusMohs scale of mineral hardnessKaolinite

The invention provides a low-quality raw bauxite ore open-grinding and dressing technology. The technology comprises the following steps of roughing, scavenging and selecting so as to obtain concentrate with A / S of 5.6-6; feeding the bottom flow or return sand discharged by a classifying machine into another grinding machine for grinding and then classifying by another classifying machine, wherein the A / S of the bottom flow or return sand achieves the middle-quality bauxite standard, and the ore granularity is less than 60 meshes; roughing, scavenging and selecting overflow in which the ore with granularity less than 200 meshes accounts for + / -95% so as to obtain concentrate with A / S of 8-11. By fully utilizing the difference in Mohs hardness of diaspore and kaolinite, the technology improves A / S of bauxite concentrate to 8 above, can improve the production of alumina, and is high in Al2O3 recovery rate, energy-saving, low in cost and low in alkaline consumption; for ore dressing enterprises, the technology can increase the yield, save energy and reduce the cost, has favorable quality and price, and generates great benefit; the technology can also be used for producing in high-aluminum clay ore dressing enterprises; the technology can be used for dressing middle-grade bauxite, and the A / S of the concentrate can be stabilized at 11-12.

Owner:李耀吾

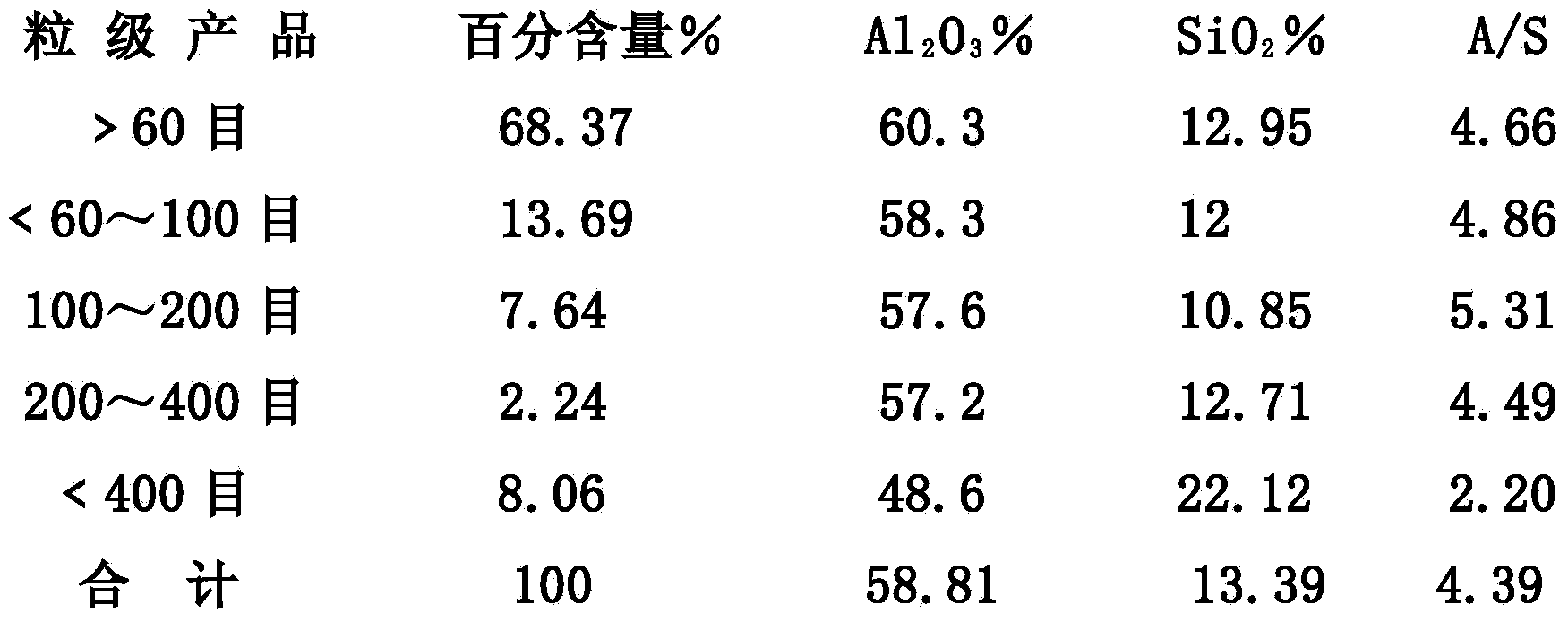

Dewatering process screening fine ore of alumyte

InactiveCN101254375AAccelerated settlementImprove filtering effectAluminium compoundsFiltration circuitsCycloneEngineering

The invention relates to a dewatering method for bauxite concentrate, and the method is used in the solid-liquid separation processes of a diasporite positive flotation concentrate product. The method comprises the operations such as classification, sedimentation, filtration, etc. The invention is characterized in that the diasporite positive flotation concentrate product is classified by adopting classifying equipment such as a hydraulic cyclone, etc., the classification size is 5 to 50 micrometer; after the classification the coarse concentrate and the fine-sized concentrate undergo the sedimentation and the filtration respectively, and are combined into the final concentrate. The method of the invention is simple and feasible, and can obviously improve the sedimentation and the filtration performances as well as the filter cake moisture of the bauxite concentrate, thereby greatly reducing the energy consumption and the mineral processing cost of the aluminum oxide production.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

Bauxite stripping process by Bayer process

The invention relates to a Bayer method digesting technology for bauxite that includes the following steps: taking preheating and heating for aluminum ore slurry after taking pre-desilication process and cycling alkaline liquor in the double pipe heat exchanger, heating to digesting temperature and taking heat insulation reaction for digesting in pot autoclave, and taking explosive boiling cooling to gain digesting ore slurry. The invention has the advantages of good digesting effect, light heat exchanger scar over, low constructing cost, low producing cost, etc.

Owner:SHENYANG ALUMINIUM MAGNESIUM INSTITUTE

Stripping process for high iron diaspore bauxite

The invention provides a method for dissolving out ferric diaspore type bauxite and relates to the method for dissolving out the bauxite in an alumina producing process. The method is characterized in that in the process, preprocessing alkali solution and lime CaO are used for preprocessing the ferric diaspore type bauxite; then solid-liquid separation is carried out, the separated solid is dissolved out under dissolving-out condition by normal Bayer process; the used preprocessing alkali solution is added with the lime to remove alumina in the solution, so as to realize the regeneration of the preprocessing alkali solution. In the method of the invention, only the lime is used as an additive, therefore the method has simple procedures and the ratio of aluminum and silicon (A / S) and the ratio of natrium and silicon (N / S) in the dissolved-out red mud are obviously reduced, which is applicable to processing the diaspore type bauxite with high content of ferric oxide (the content of the Fe2O3 is more than or equal to 8 percent).

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

Bauxite Milling method

The present invention relates to a grinding method of bauxite, belonging to a bauxite separation method. It is characterized by that the material-ball ratio in bauxite grinding machine is 1:0.8-1.2, in which the ball diameter of grinding ball includes large ball 110mm, medium ball 90mm and small ball 70mm, and matched ratio of number of large, medium and small balls is 1:1.5-2:0.9-1.4, the bauxite grinding concentration is 50%-20% and the grinding time is 10-30 min. Besides, said invention also provides its application range and field.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com