Combined collector for direct flotation of diasporic bauxite and using method thereof

A combined collector and bauxite technology, applied in flotation, solid separation, etc., can solve the problems of weak collection capacity, low dispersion and dissolution performance, large foam volume, etc., and achieve the goal of improving selectivity and promoting dissolution ability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0013] A combined collector for the positive flotation of diaspore type bauxite is characterized in that: the main components are saponification products of vegetable oleic acid, naphthenic acid and lauryl ether phosphate; vegetable oleic acid, The dosage ratio of naphthenic acid and the saponification product of lauryl ether phosphate is 1:1:0.5.

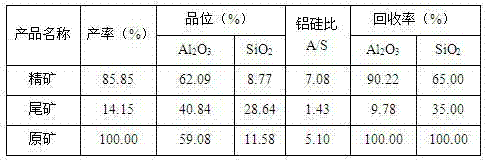

[0014] For the bauxite in the Xiaoguan mining area in Henan, Al in the raw ore 2 o 3 The content is 59.08%, SiO 2 The content is 11.58%, and the raw ore aluminum-silicon ratio A / S is 5.10. The positive flotation process system is: the particle size of the bauxite grinding product is -0.074mm, accounting for 80-90%, the pH value of the flotation system is 10, and the combined collector of the present invention is used as the collector. The dosage of the inhibitor sodium hexametaphosphate is 70g / t. The test results are shown in Table 1.

[0015] Table 1 Example 1 test results

[0016]

[0017] The test results show that the c...

example 2

[0019] A combined collector for the positive flotation of diaspore type bauxite is characterized in that: the main components are saponification products of vegetable oleic acid, naphthenic acid and lauryl ether phosphate; vegetable oleic acid, The dosage ratio of naphthenic acid and the saponification product of lauryl ether phosphate is 1:1:0.5.

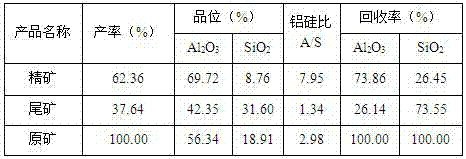

[0020] For the bauxite of a bauxite dressing plant in Henan, Al in the raw ore 2 o 3 The content is 56.34%, SiO 2 The content is 18.91%, and the aluminum-silicon ratio of raw ore is 2.98. The positive flotation process system is: the particle size of the bauxite grinding product is -0.074mm, accounting for 80-90%, the pH value of the flotation system is 9, and the combined collector of the present invention is used as the collector. is 800g / t, and the amount of inhibitor water glass is 60g / t. The test results are shown in Table 2.

[0021] Table 2 Example 2 test results

[0022]

[0023] The test results show that the combi...

example 3

[0025] A combined collector for the positive flotation of diaspore type bauxite is characterized in that: the main components are saponification products of vegetable oleic acid, naphthenic acid and lauryl ether phosphate; vegetable oleic acid, The dosage ratio of naphthenic acid and the saponification product of lauryl ether phosphate is 1:1:0.5.

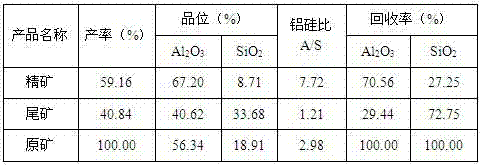

[0026] For the bauxite of a bauxite dressing plant in Henan, Al in the raw ore 2 o 3 The content is 56.34%, SiO 2 The content is 18.91%, and the aluminum-silicon ratio of raw ore is 2.98. The positive flotation process system is: the particle size of the bauxite grinding product is -0.074mm, accounting for 80-90%, the pH value of the flotation system is 11, and the combined collector of the present invention is used as the collector. is 1200g / t, and the dosage of inhibitor water glass is 80g / t. The test results are shown in Table 3.

[0027] Table 3 Example 3 test results

[0028]

[0029] The test results show that the com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com