Gradient floatation method for bauxite

A bauxite and gradient technology, which is applied in the field of bauxite flotation with low aluminum-silicon ratio and gradient flotation of bauxite, can solve the problem of difficult flotation and affect the normal flotation recovery of bauxite flotation process Problems such as rate index, tank drop, etc., to achieve the effect of improving the flotation recovery index

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] A bauxite mine in Henan, the raw ore contains Al 2 o 3 55.10%, and the aluminum-silicon ratio (A / S) is 4.67.

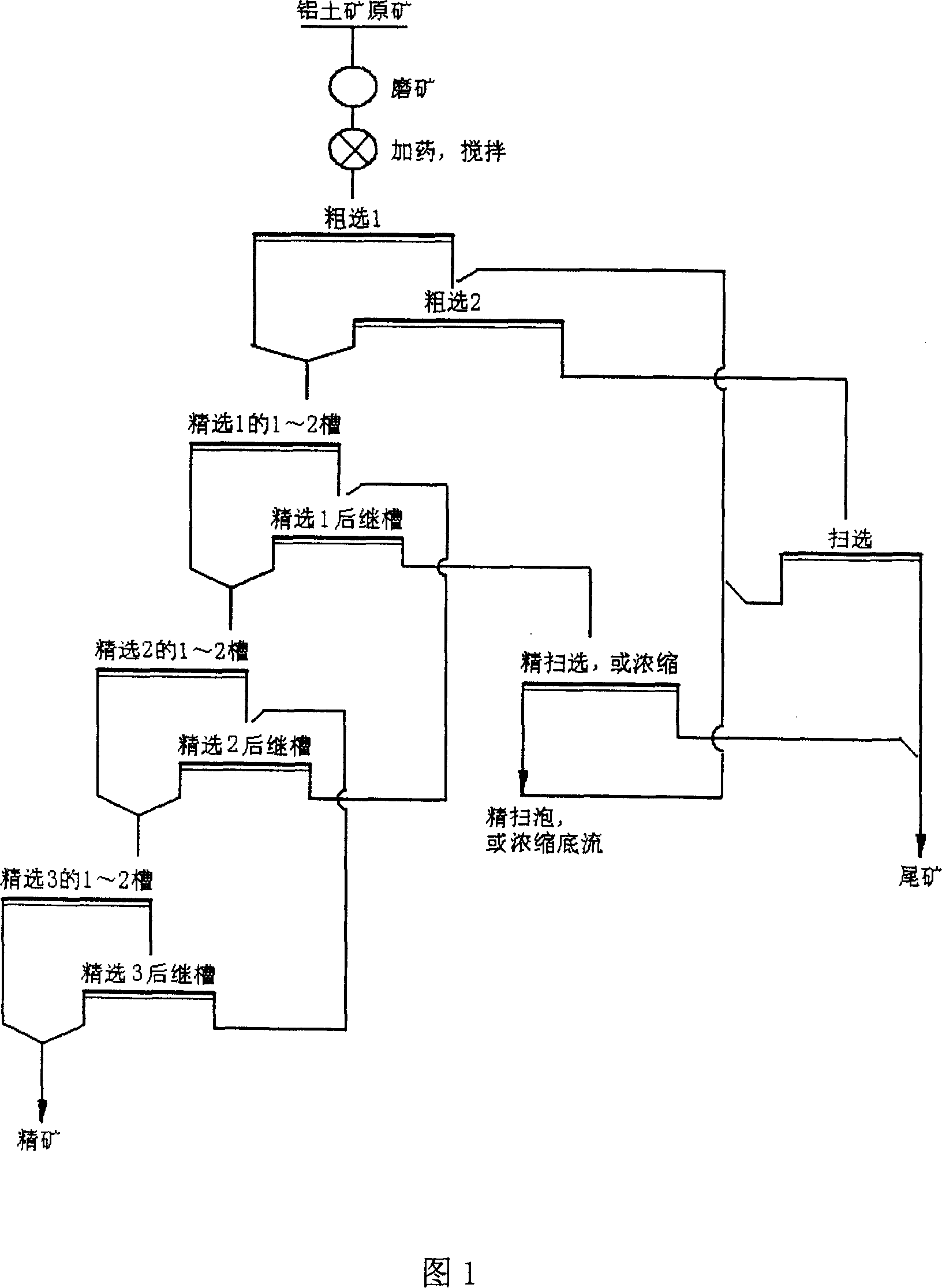

[0020] The process system is as follows: the particle size of the grinding product is -0.074mm, accounting for about 88% to 92%, the pH of the flotation system is adjusted to pH 8.5 to 9.0 by using sodium carbonate, and flotation is carried out by adding dispersion inhibitors and combined collectors. The flotation process is 2 roughing, 1 sweeping and 2 fine, and adopts the technical scheme of step-by-step flotation, and the pulp concentration of roughing 1 is controlled to be ≥35%. The closed-circuit test indicators are shown in Table 1.

[0021]

Embodiment 2

[0023] A bauxite mine in Henan, the raw ore contains Al 2 o 3 55.96%, and the aluminum-silicon ratio (A / S) is 4.72.

[0024] The process system is as follows: the particle size of the grinding product is -0.074nm, accounting for about 88% to 92%, the pH of the flotation system is adjusted to pH 8.5 to 9.0 by using sodium carbonate, and inorganic salt dispersion inhibitors and combined collectors are added. flotation.

[0025] In the 1t / d-scale continuous selection expansion test, the flotation process is 2 roughing, 1 sweeping and 3 fine, and adopts the technical scheme of step-by-step flotation, and the pulp concentration of roughing 1 is controlled to be ≥ 35%.

[0026] See Table 2 for the indicators of the re-election test.

[0027]

Embodiment 3

[0029] A certain bauxite, raw ore contains Al 2 o 3 61.71%, and the aluminum-silicon ratio (A / S) is 3.99.

[0030] The process system is as follows: the particle size of the grinding product is -0.074mm, accounting for about 88% to 92%, the pH of the flotation system is adjusted to pH 8.5 to 9.0 by using sodium carbonate, and flotation is carried out by adding dispersion inhibitors and combined collectors. The flotation process is 2 roughing, 1 sweeping and 3 fine, and adopts the technical scheme of step-by-step flotation, and the pulp concentration of roughing 1 is controlled to be ≥35%. The closed circuit test results are shown in Table 3.

[0031]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com